Net release machine with rotating tray

A rotating material tray with self-contained technology, applied in the field of net release machine, can solve the problems that the clamping device cannot get the material, the whole net release machine cannot work normally, etc., and achieve the effect of accurate positioning of the material.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with specific embodiment:

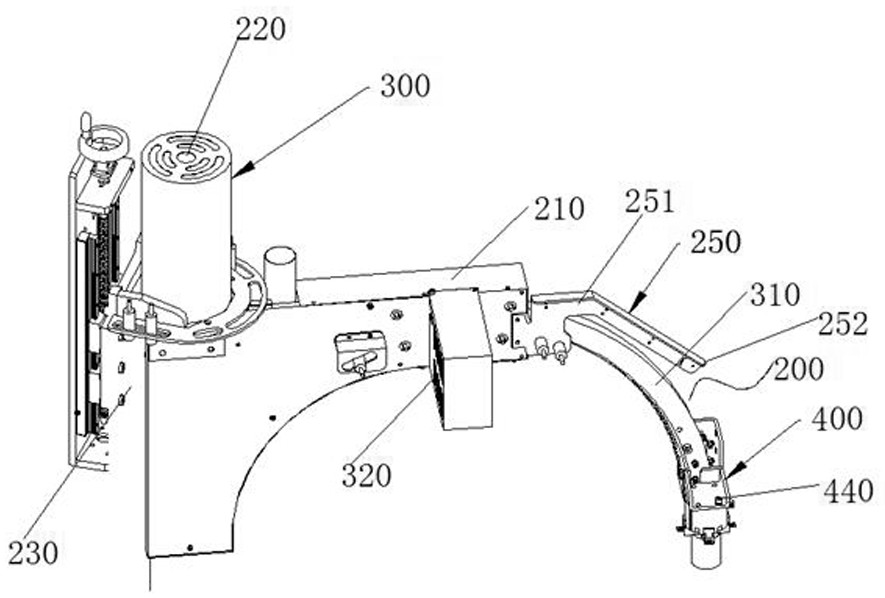

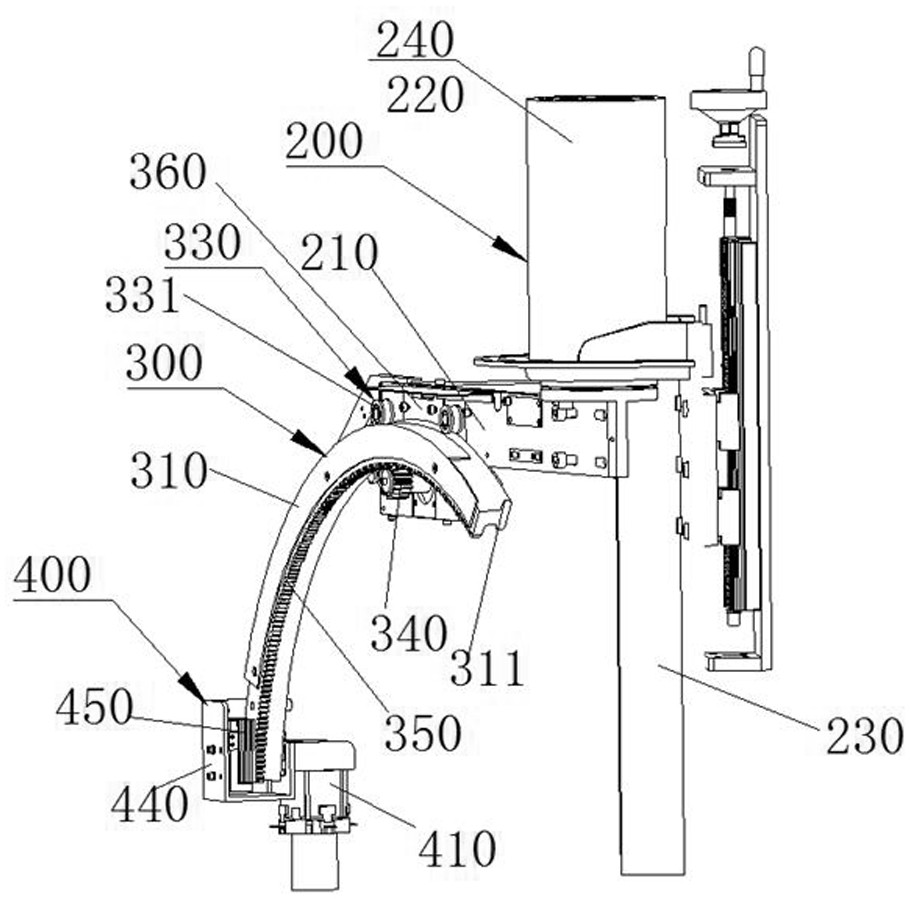

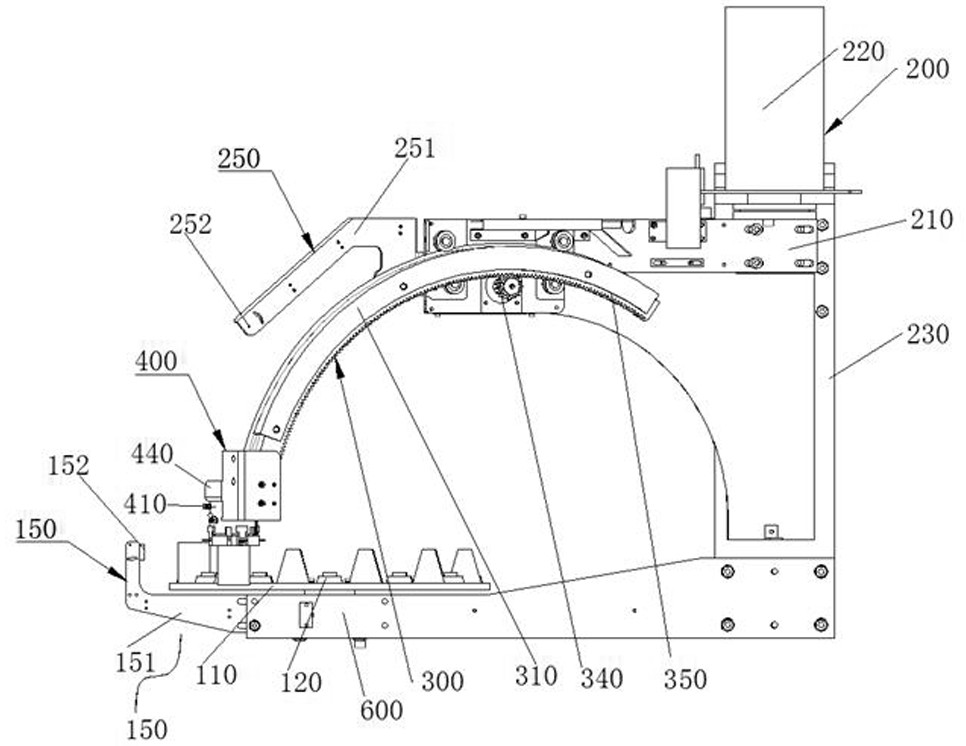

[0027] Such as Figure 1 to Figure 5 As shown, a net unwinding machine with a rotating tray includes an up and down swing device 300 and a left and right swing device 200 , a rotary feeding device 100 , a material detection device 150 and a clamping device 400 .

[0028] The left and right swing device 200 includes a swing frame 210 , the vertical swing device 300 is fixedly arranged on the swing frame 210 , and the clamping device 400 is fixedly connected to the output end of the vertical swing device 300 .

[0029] Such as image 3 combine Figure 5 As shown, the rotary feeding device 100 includes a swinging material device 160 and a driving device 130. The swinging material device 160 includes a rotating material tray 110 and a material positioning block 120. The upper end surface of the rotating material tray 110 is distributed with a plurality of material positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com