Composite inspection system and method for transformer substation

A technology for inspection systems and substations, applied in the direction of control/regulation systems, non-electric variable control, and simultaneous control of multiple variables. The effect of increasing inspection capability and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

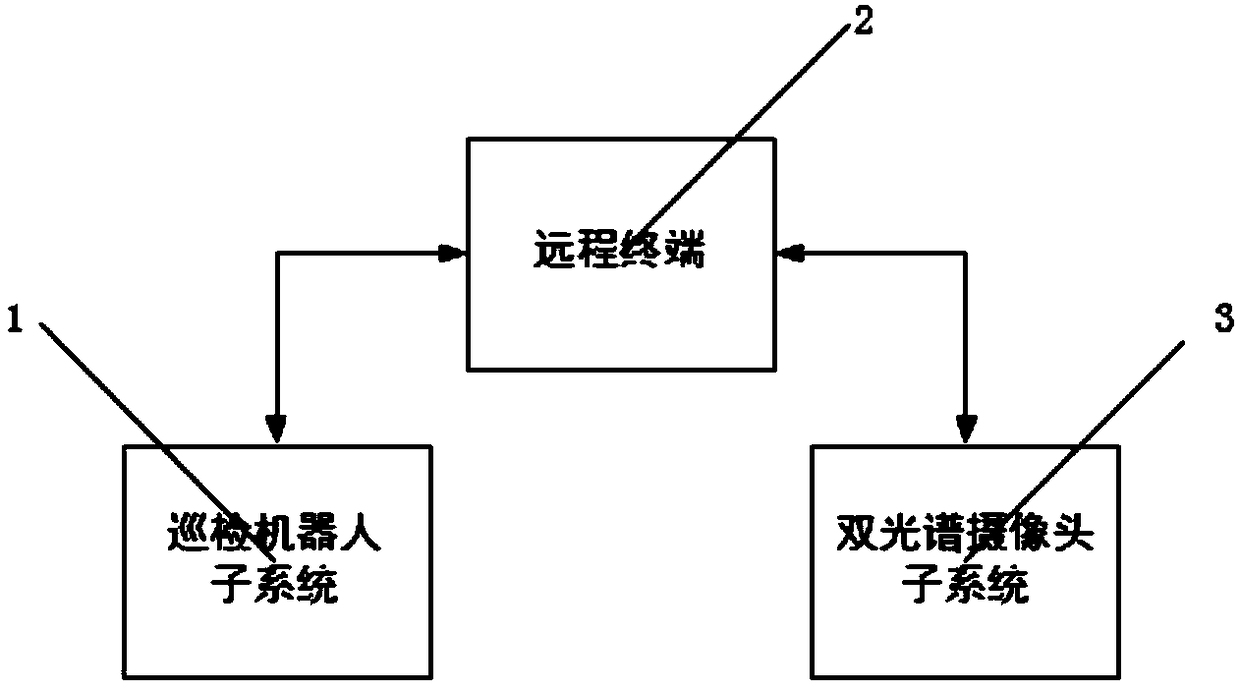

[0084] to combine figure 1 , the composite substation inspection system of the present invention includes an inspection robot subsystem 1, a dual-spectrum camera subsystem 3 and a remote terminal 2;

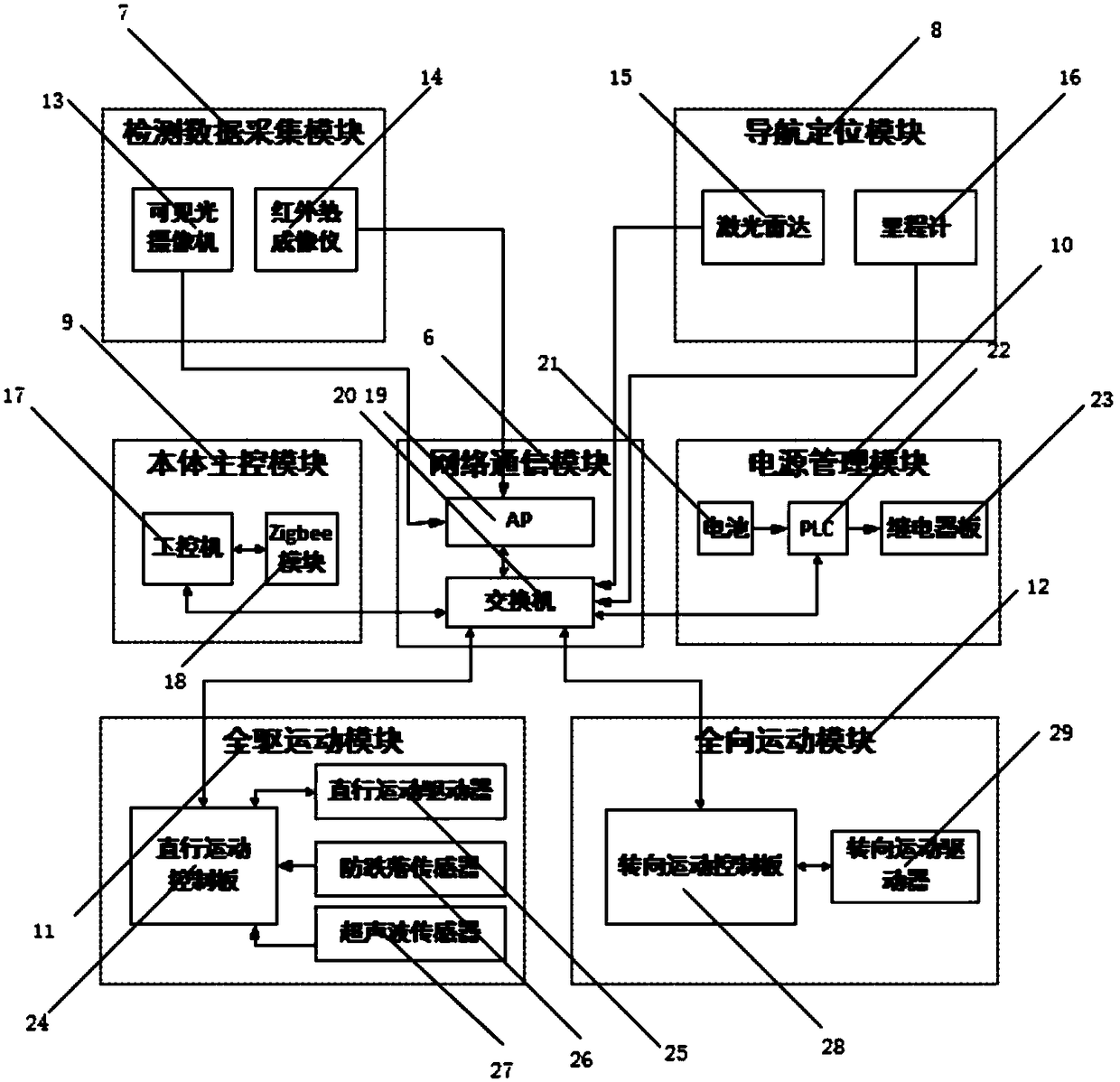

[0085] The inspection robot subsystem 1 includes a network communication module 6, a body main control module 9, a power management module 10, a detection data acquisition module 7, a navigation positioning module 8, an all-drive motion module 11 and an omnidirectional motion module 12;

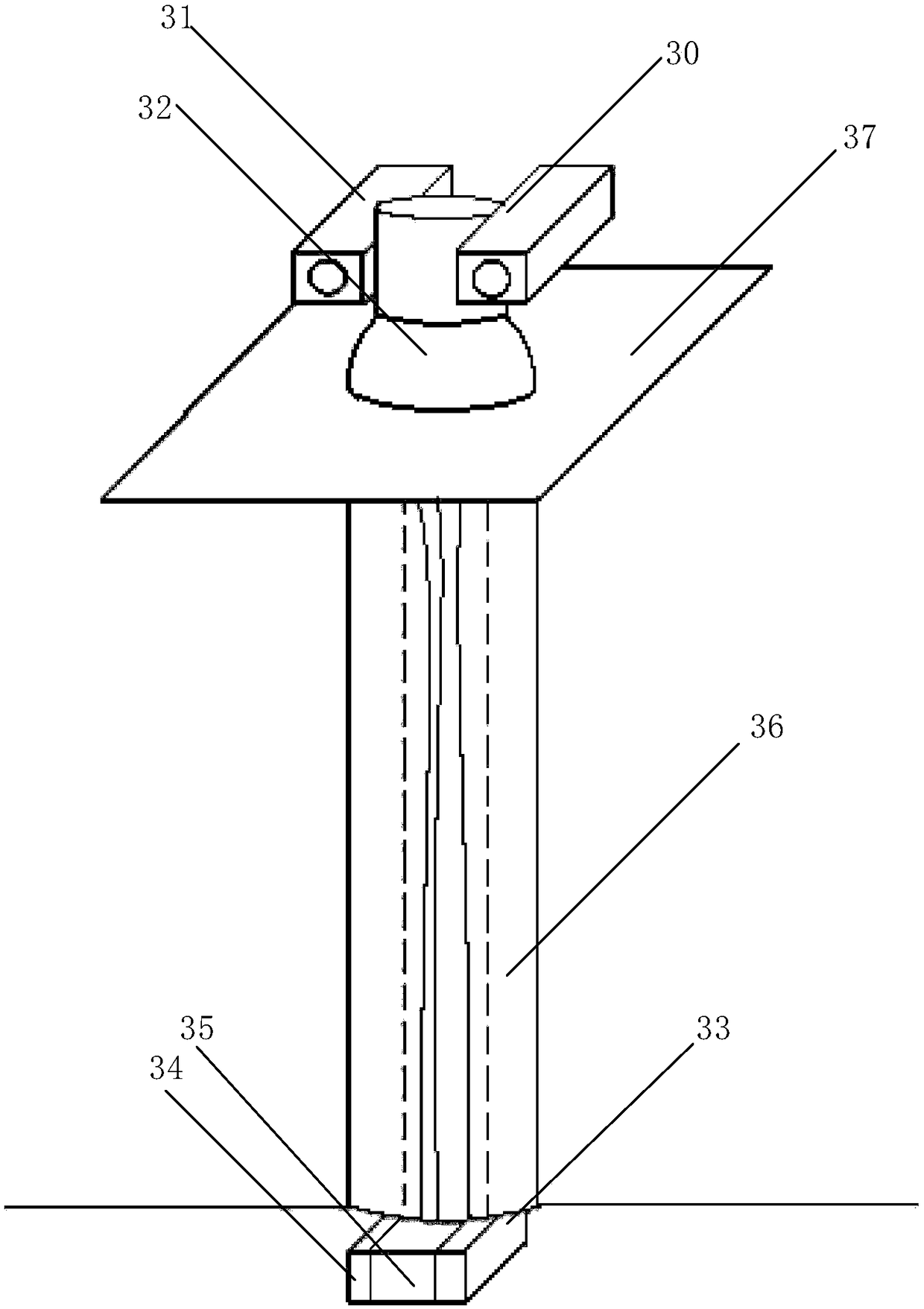

[0086] The dual-spectrum camera subsystem 3 is used for fixed-point inspections in special cases, including a video acquisition module, a cloud platform 32, a communication module 33, a local storage module 34, a power supply module 35 and a support device 36, wherein the video acquisition module includes a high-definition Camera 30 and infrared camera 31;

[0087] The remote terminal 2 is used to monitor the operation of the robot, including a computer, communication equipment, monitoring and ...

Embodiment 2

[0102] to combine figure 1 , the composite substation inspection system of the present invention includes an inspection robot subsystem 1, a dual-spectrum camera subsystem 3 and a remote terminal 2;

[0103] The inspection robot subsystem 1 includes a network communication module 6, a body main control module 9, a power management module 10, a detection data acquisition module 7, a navigation positioning module 8, an all-drive motion module 11 and an omnidirectional motion module 12;

[0104] The dual-spectrum camera subsystem 3 is used for fixed-point inspections in special cases, including a video acquisition module, a cloud platform 32, a communication module 33, a local storage module 34, a power supply module 35 and a support device 36, wherein the video acquisition module includes a high-definition Camera 30 and infrared camera 31;

[0105] The remote terminal 2 is used to monitor the operation of the robot, including a computer, communication equipment, monitoring and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com