Setting method of starting position of suction band in cigarette weight control system of cigarette making machine

A technology of weight control and starting position, which is applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve the problems of not taking into account, the output value of the final starting position deviates from the ideal starting position, and the GPR model cannot be effectively reflected, so as to reduce the number of unqualified cigarettes. Support and improve the effect of efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

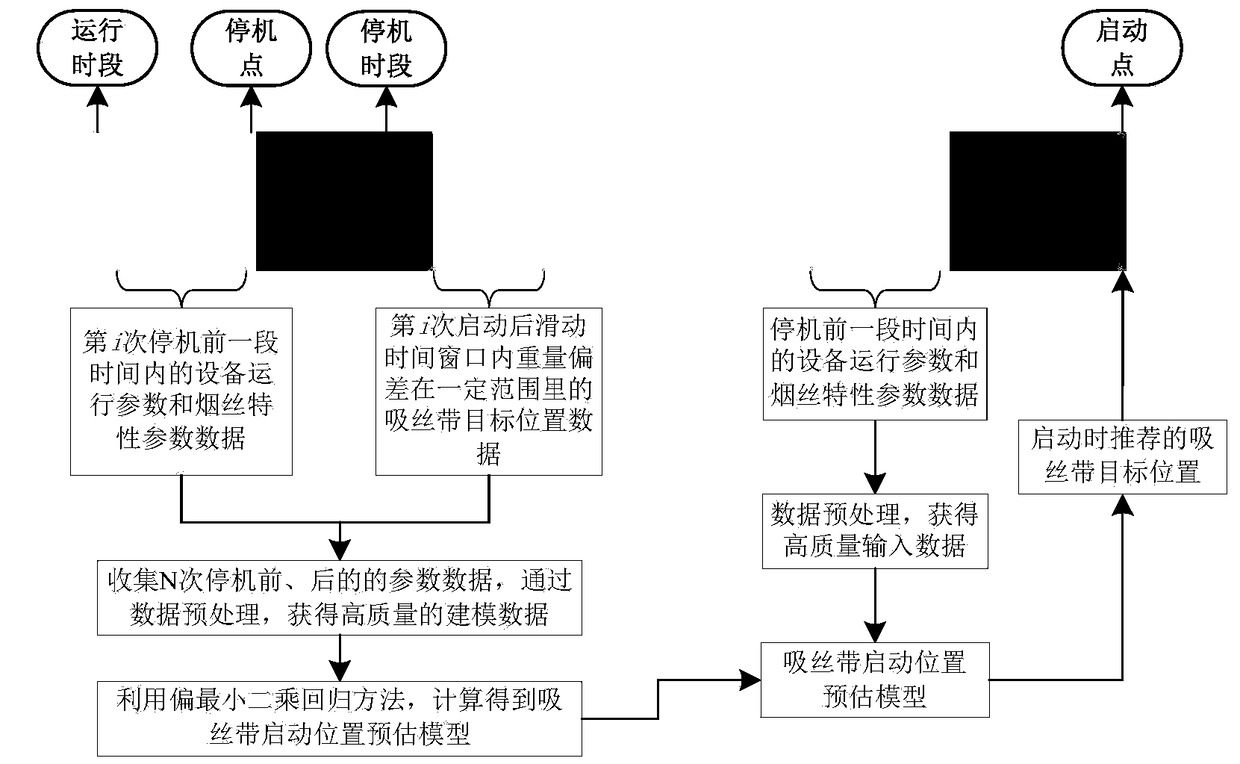

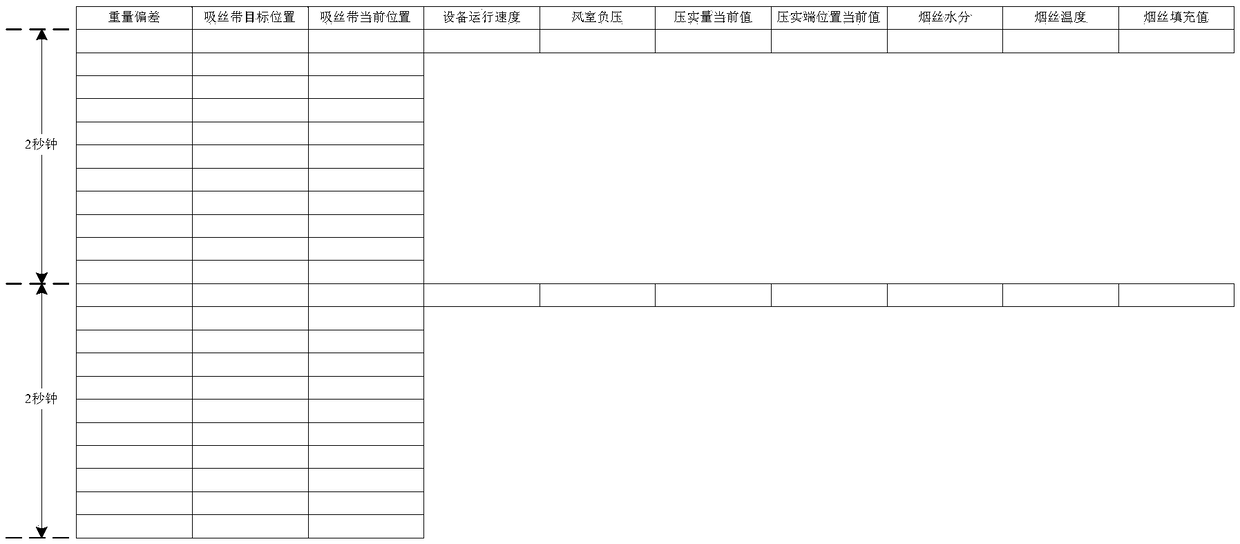

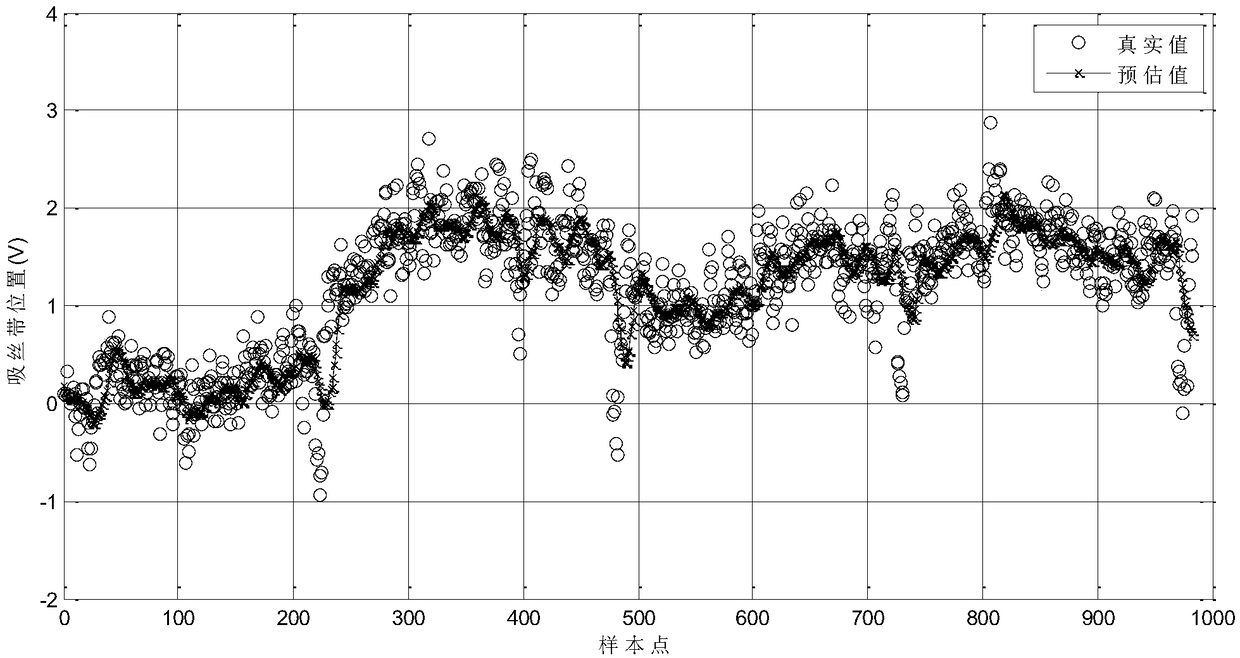

[0036] In order to better understand the technical solutions of the present invention, the implementation manners of the present invention will be further described below in conjunction with the accompanying drawings. This implementation is an intelligent optimization setting method for the starting position of the suction ribbon of the ZJ112 high-speed cigarette machine cigarette weight control system (SRM) of Changde Tobacco Machinery Co., Ltd. The cigarette weight control system of ZJ112 cigarette machine is mainly composed of cigarette weight detector (microwave scanner B800V), tobacco temperature sensor (R800V), cigarette weight control system execution device (tobacco rod leveler TRM), and cigarette weight control It is composed of monitoring device (A800V), human-computer interaction touch screen (MLP), etc. The cigarette weight control system of the cigarette machine evaluates the detected value of the cigarette weight from the microwave scanner and the target value of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com