SMD reel in-place condition monitoring device

A state monitoring device and reeling technology, which is applied in the direction of optical device exploration, etc., can solve problems such as wrong pick and place of SMD reels, errors in SMT production, and no SMD reel monitoring system, so as to avoid errors in sending materials and avoid The effect of wrong pick and place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

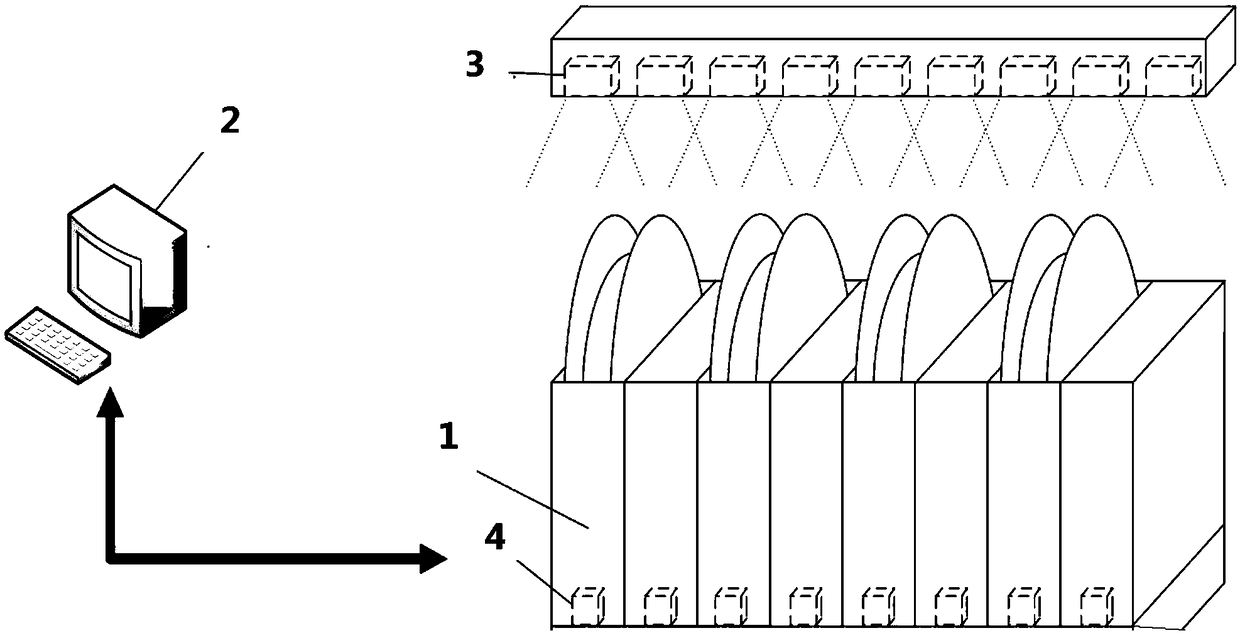

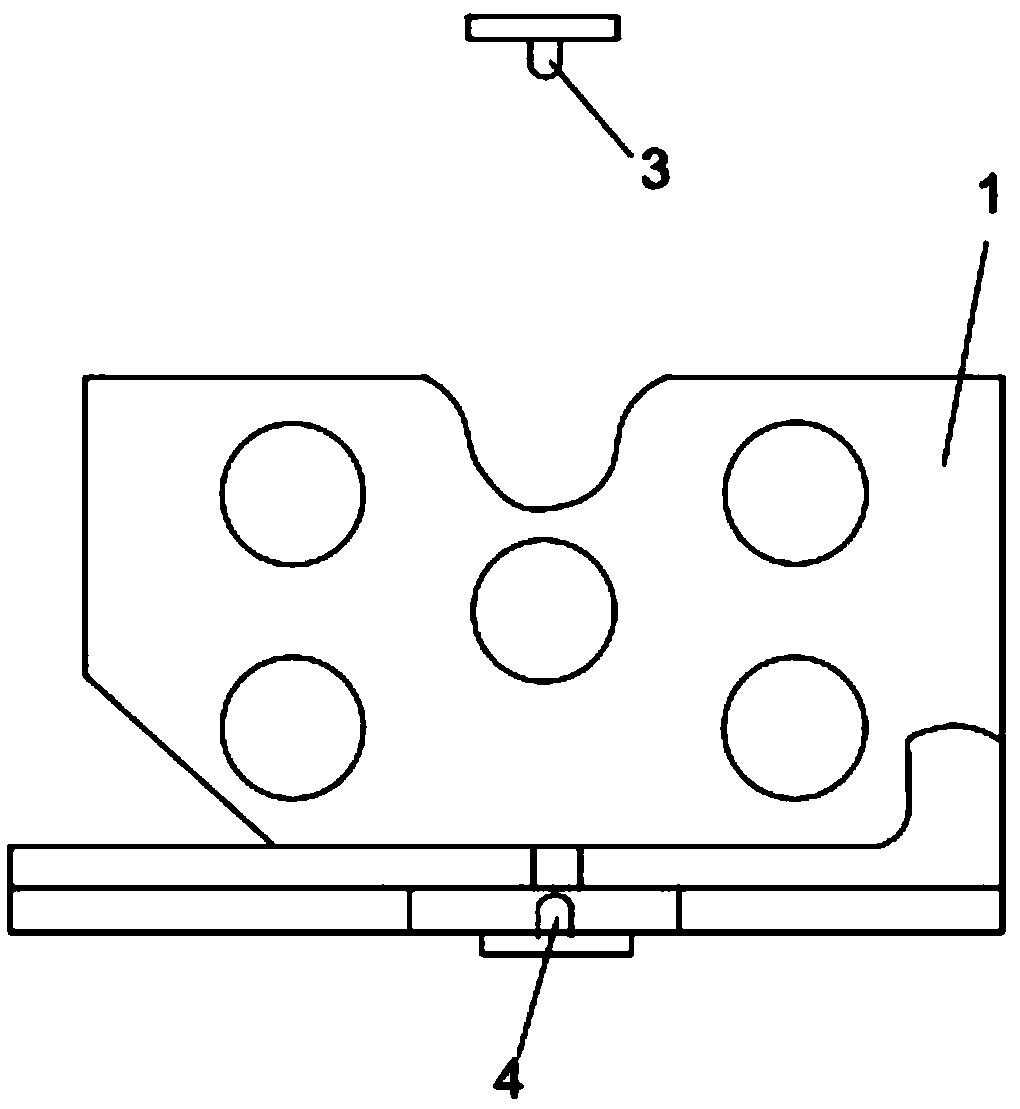

[0015] Such as figure 1 As shown, a kind of SMD reel in-position status monitoring device of the present invention comprises a material box 1, a detection sensor and an intelligent controller 2, the detection sensor is electrically connected to the intelligent controller 2, and the detection sensor includes an infrared emitting tube 3 and an infrared receiving tube 4. The infrared emitting tube 3 is provided directly above the material box 1, and the infrared receiving tube 4 is installed at the bottom of the material box 1 relative to the infrared emitting tube 3, and the infrared receiving tube 4 receives the infrared signal sent by the infrared emitting tube 3. Such as figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com