A method for predicting equipment failure rate by combining Weibull distribution with ARMA is disclosed

A technology of Weibull distribution and equipment failure, applied in forecasting, data processing applications, design optimization/simulation, etc., can solve the problems of numerous influencing factors, difficulty in establishing equipment failure rate and prediction models of all influencing factors, and small number of statistical samples, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

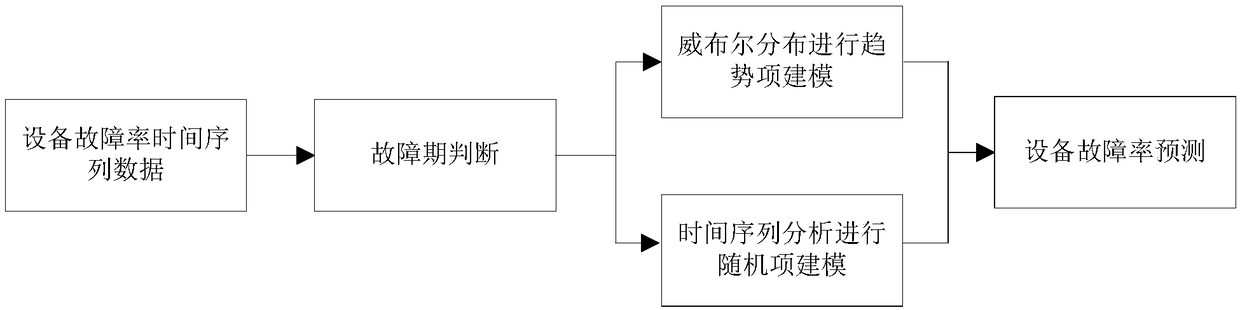

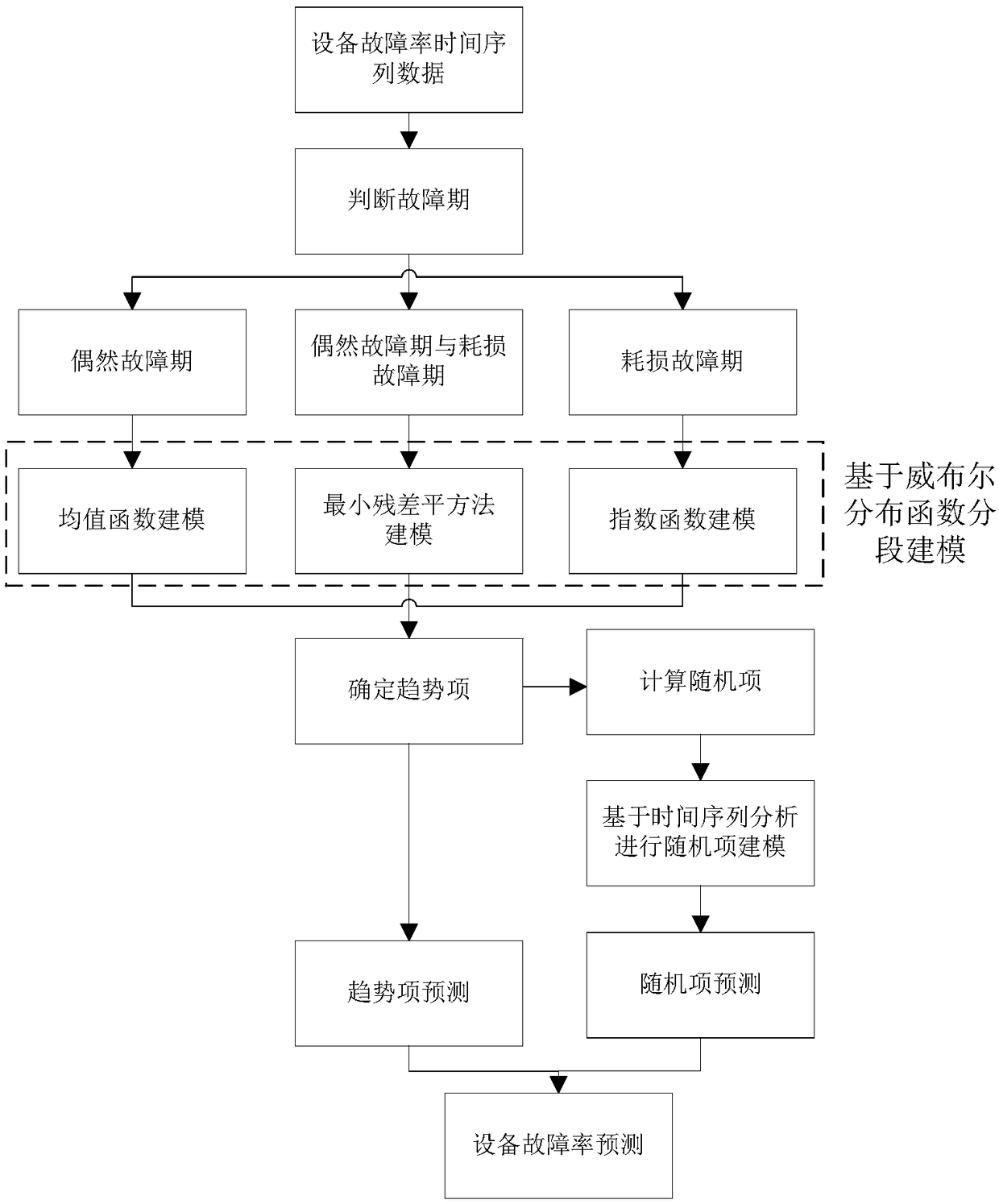

[0040] Such as figure 1 As shown, the present embodiment is realized through the following technical solutions, a method for predicting equipment failure rate using Weibull distribution combined with ARMA, comprising the following steps:

[0041] 1. Arrange the obtained equipment failure rate data in the order of time series to obtain the time series data of equipment failure rate. Its form is (t 1 ,λ 1 ), (t 2 ,λ 2 )···(t n ,λ n ), time t is the independent variable, failure rate λ i , i=1, 2, ... n is the dependent variable, and n is the number of data.

[0042] 2. According to the development trend of the equipment failure rate time series data, judge the equipment failure period, and based on the judgment results of the equipment failure period, select Weibull distribution functions at different stages to model the equipment failure rate da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com