Spring mechanical seal compensation ring assembly and machining process thereof

A technology of mechanical seals and compensating rings, applied in the direction of engine seals, mechanical equipment, engine components, etc., can solve the problems of insufficient sealing effect, insufficient fit, wear, etc., and achieve convenient disassembly and installation, simple and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

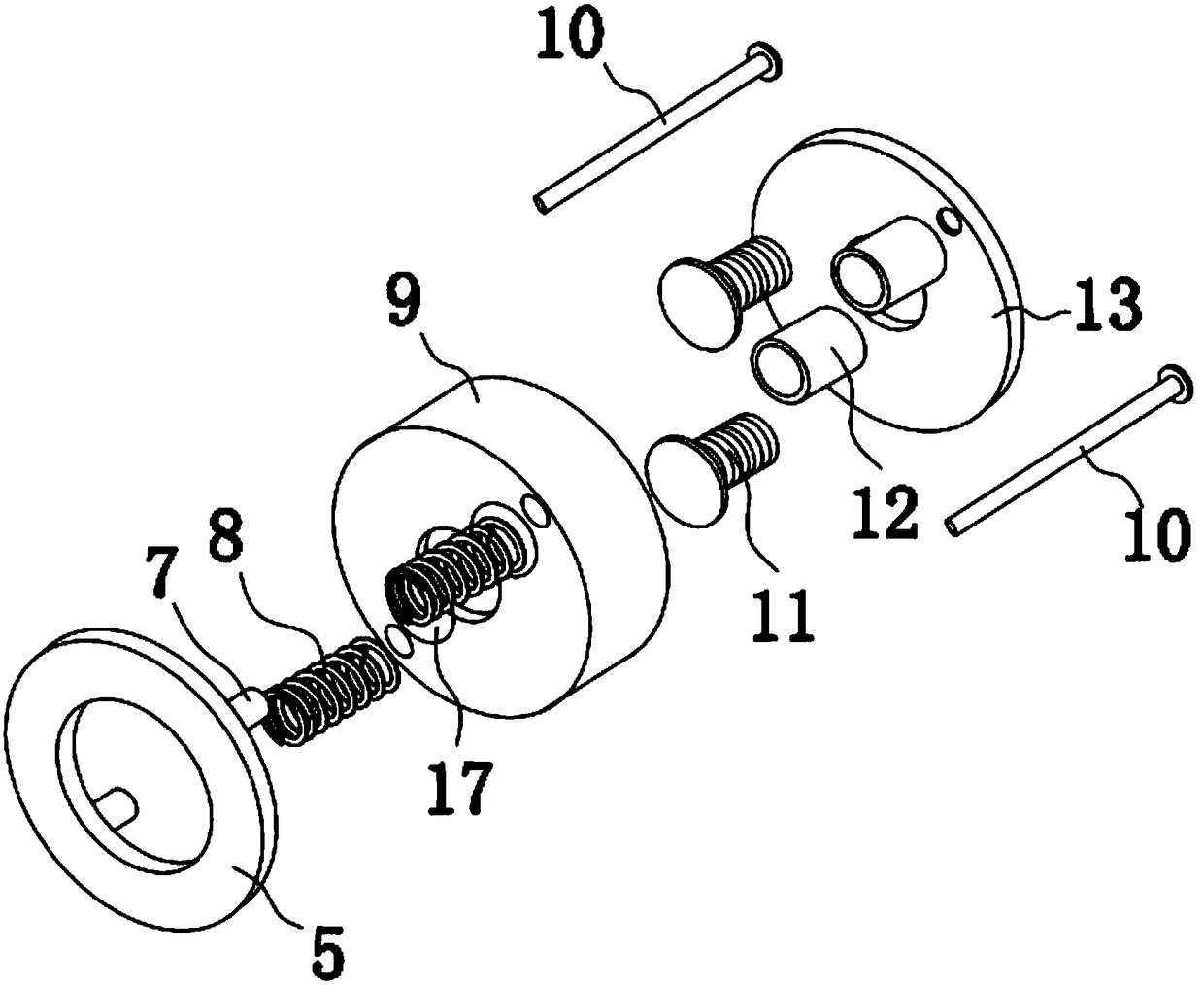

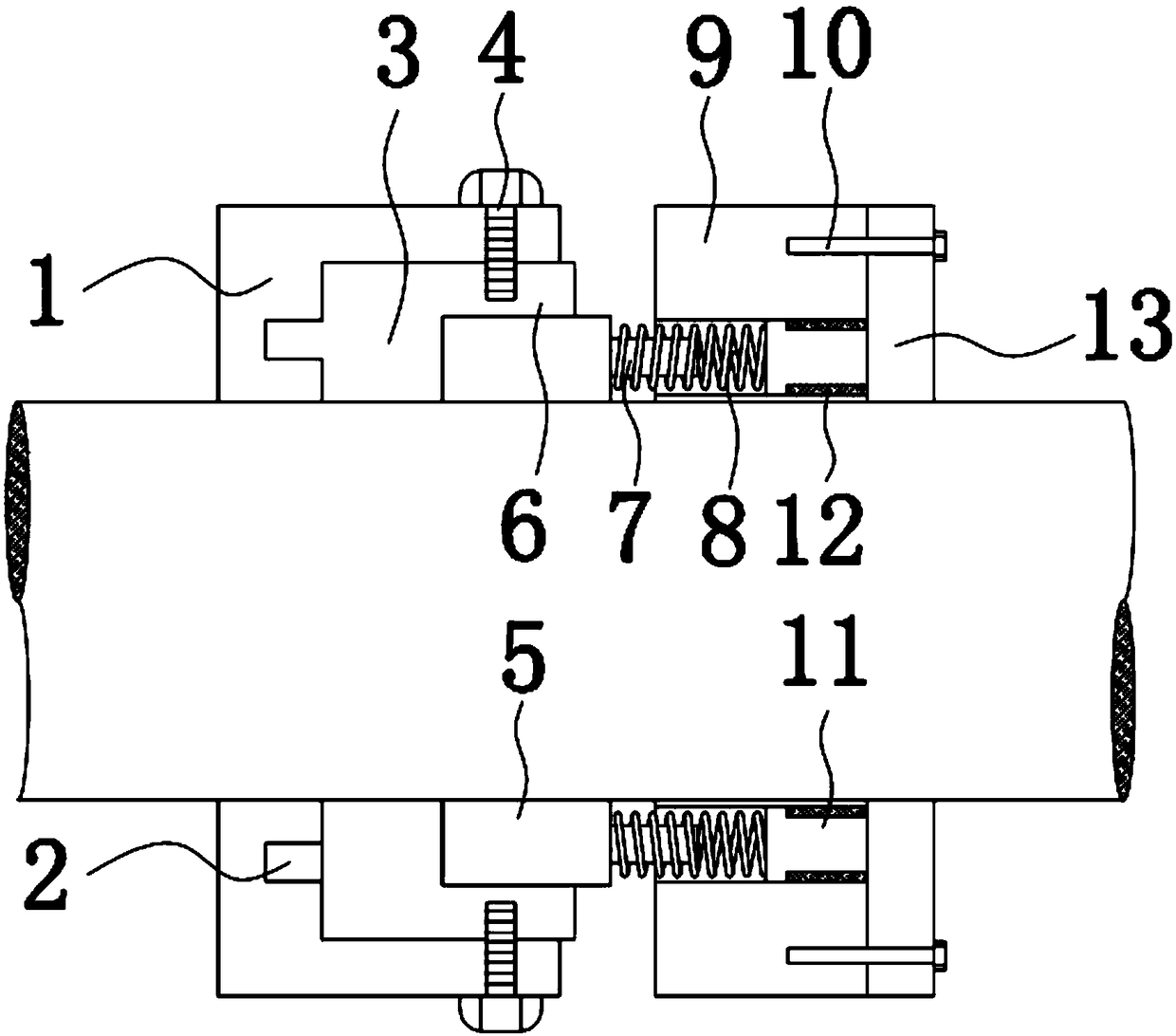

[0022] The present invention provides such Figure 1-4 A spring mechanical seal compensating ring assembly, including a moving ring 5, a static ring 3 and a spring mounting seat 9, the static ring 3 is fixedly installed in the static ring seat 1, and the inside of the spring mounting seat 9 is provided with a The cavity 17 of the spring 8, the upper and lower parts of the right end of the moving ring 5 are provided with a positioning pin 7, the positioning pin 7 is inserted to the left side of the cavity 17, the spring 8 is sleeved on the positioning pin 7, the spring The right end of the mounting seat 9 is fixed with a sealing seat 13 by a bolt 10, and the upper and lower parts of the left side of the sealing seat 13 are provided with a tube tube 12, and a T-shaped column 11 is screwed inside the tube tube 12, and the tube tube 12 is inserted into the to the right of cavity 17.

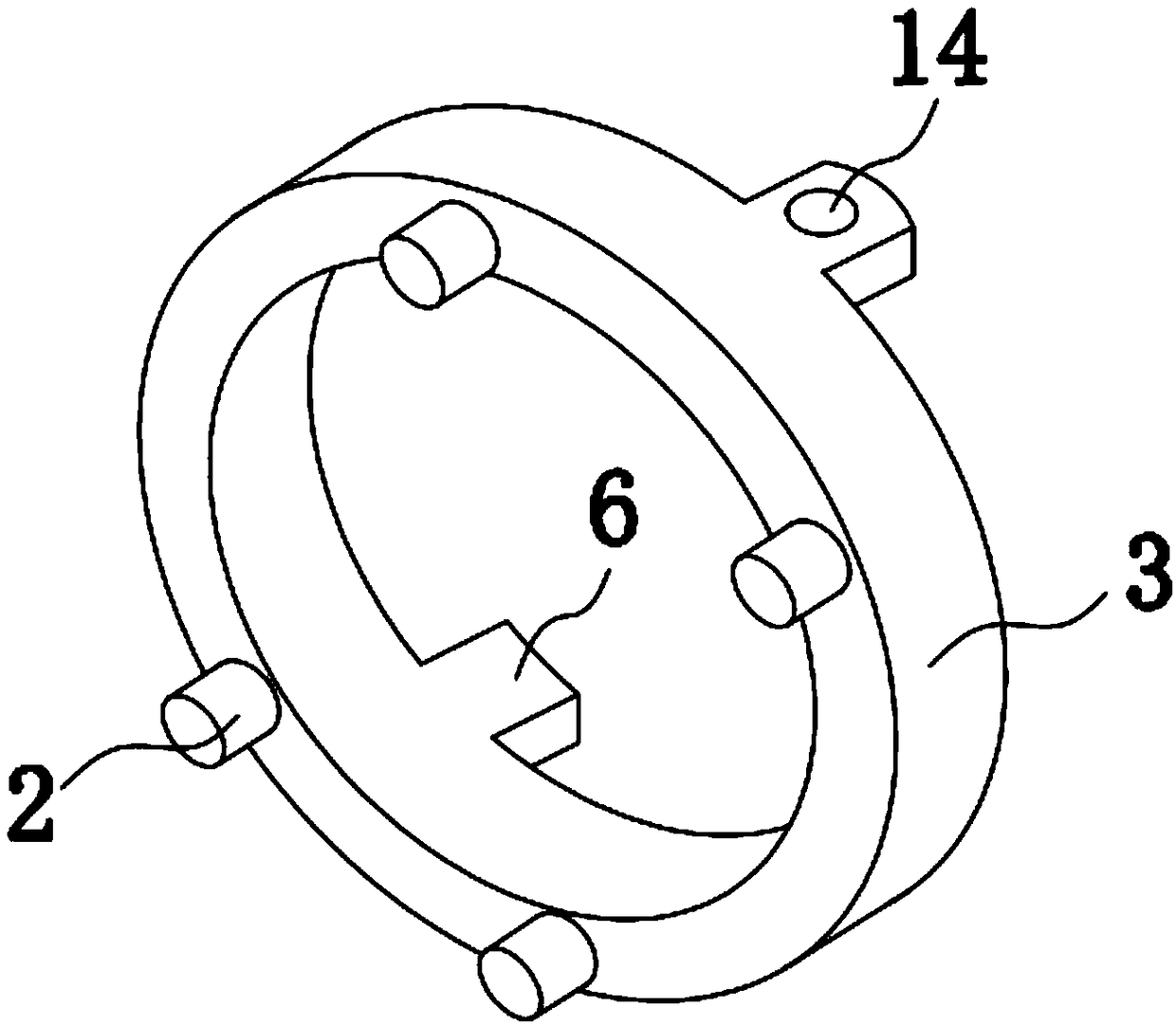

[0023] Specifically, the upper and lower surfaces of the right end of the static ring 3 are prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com