Fatigue test modeling method for cryogenic sensitive components of rail vehicles

A fatigue test and rail vehicle technology, applied in the field of fatigue test modeling of low temperature sensitive components of rail vehicles, to achieve the effect of wide application and reasonable assumption conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] The invention provides a fatigue test modeling method for low-temperature sensitive components of a rail vehicle, which can be applied to the fatigue test of low-temperature sensitive components of a rail vehicle. According to the periodicity and slowness of natural temperature changes in different test areas, this method uses the internal correlation of various temperature data to determine the number of fatigue tests that need to be carried out in different test temperature ranges, and to determine the low temperature sensitive components of rail vehicles. The low temperature life that the test area should have.

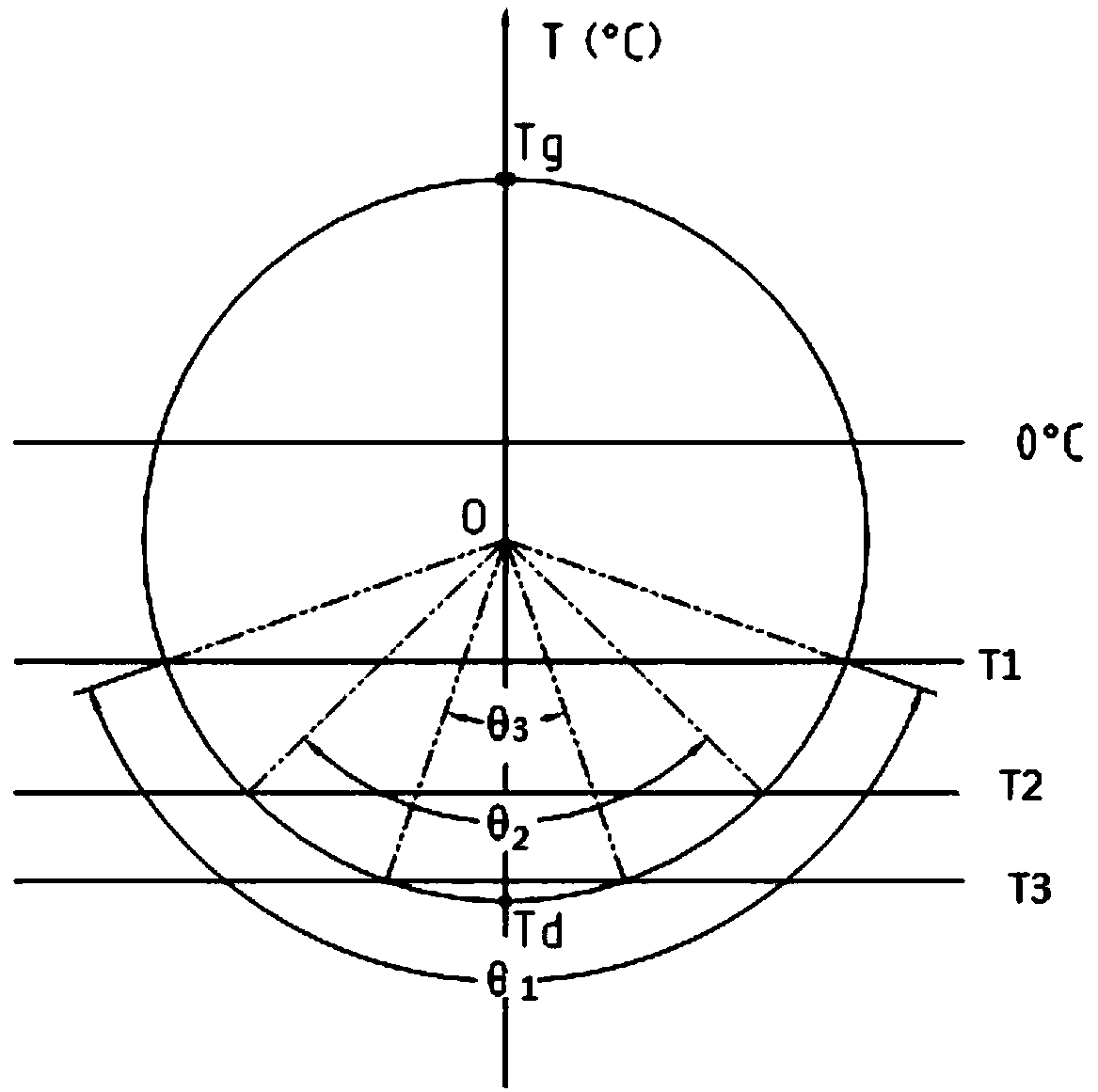

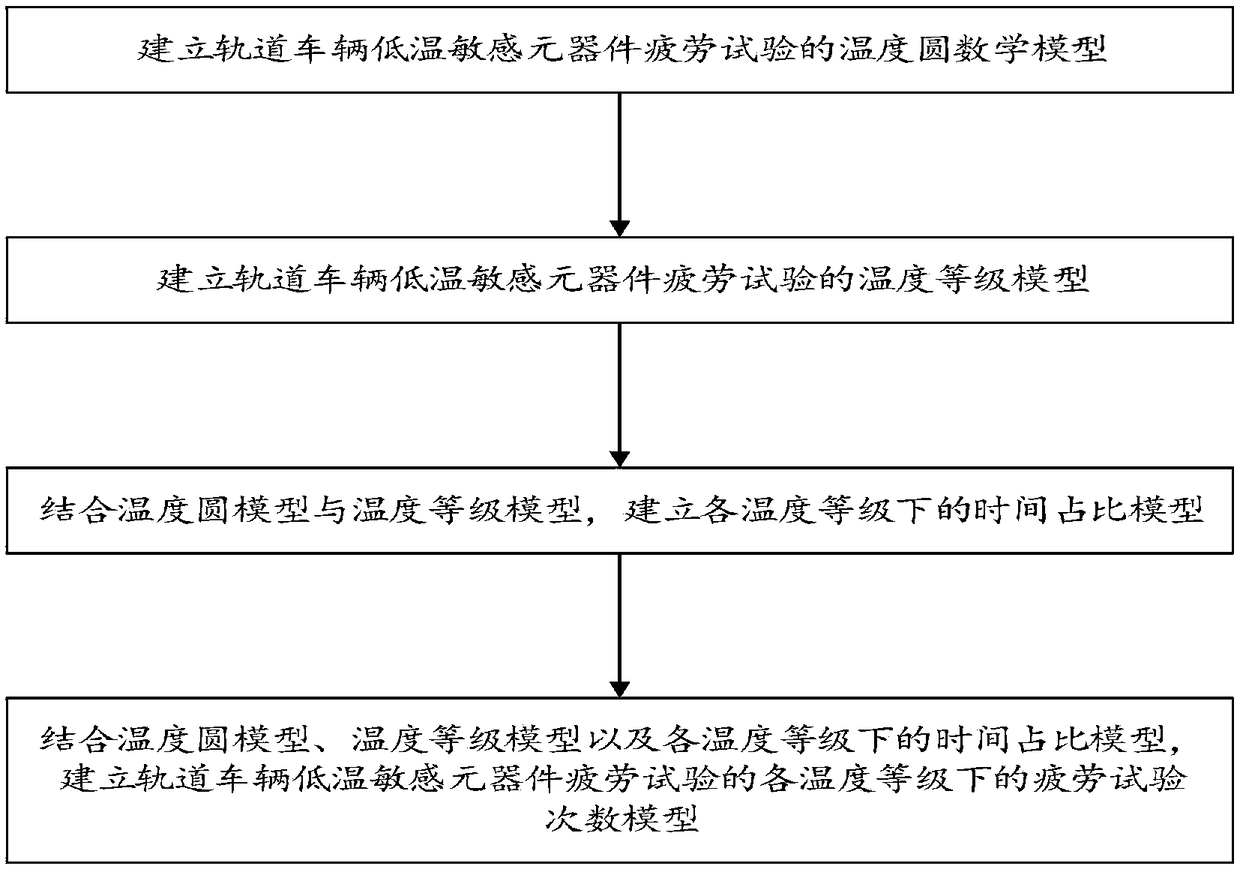

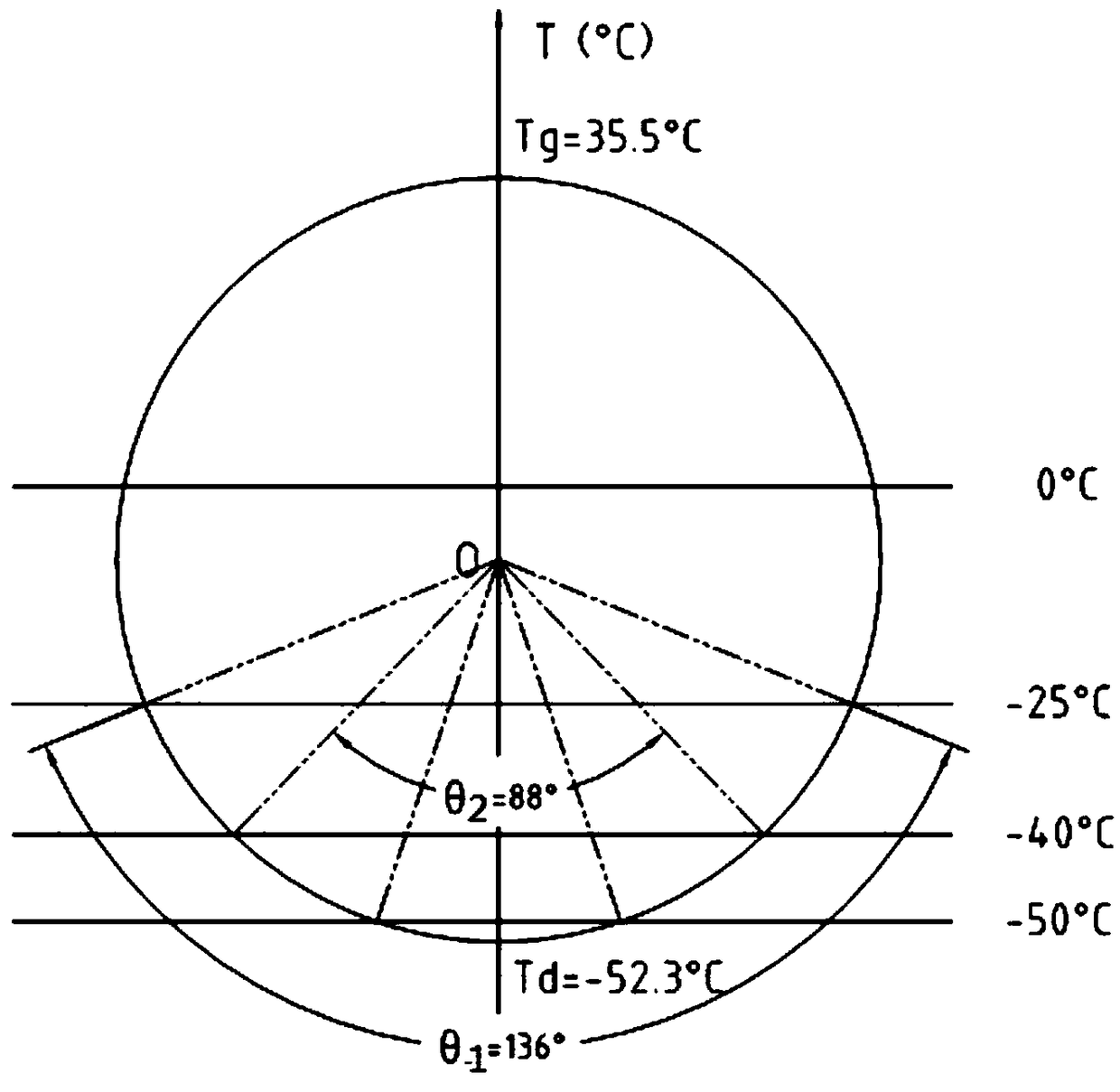

[0038] combine figure 1 , figure 2 As shown, a fatigue test modeling method for rail vehicle low temperature sensitive components includes the following steps:

[0039] (1) Establish the mathematical model of the temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com