Dual-output reducer

A dual-output reducer and bearing seat technology, applied in mechanical equipment, transmission parts, belts/chains/gears, etc., can solve the problems of complicated operation and unfavorable operation, and achieve the effect of simple and convenient oil injection and easy operation of oil injection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

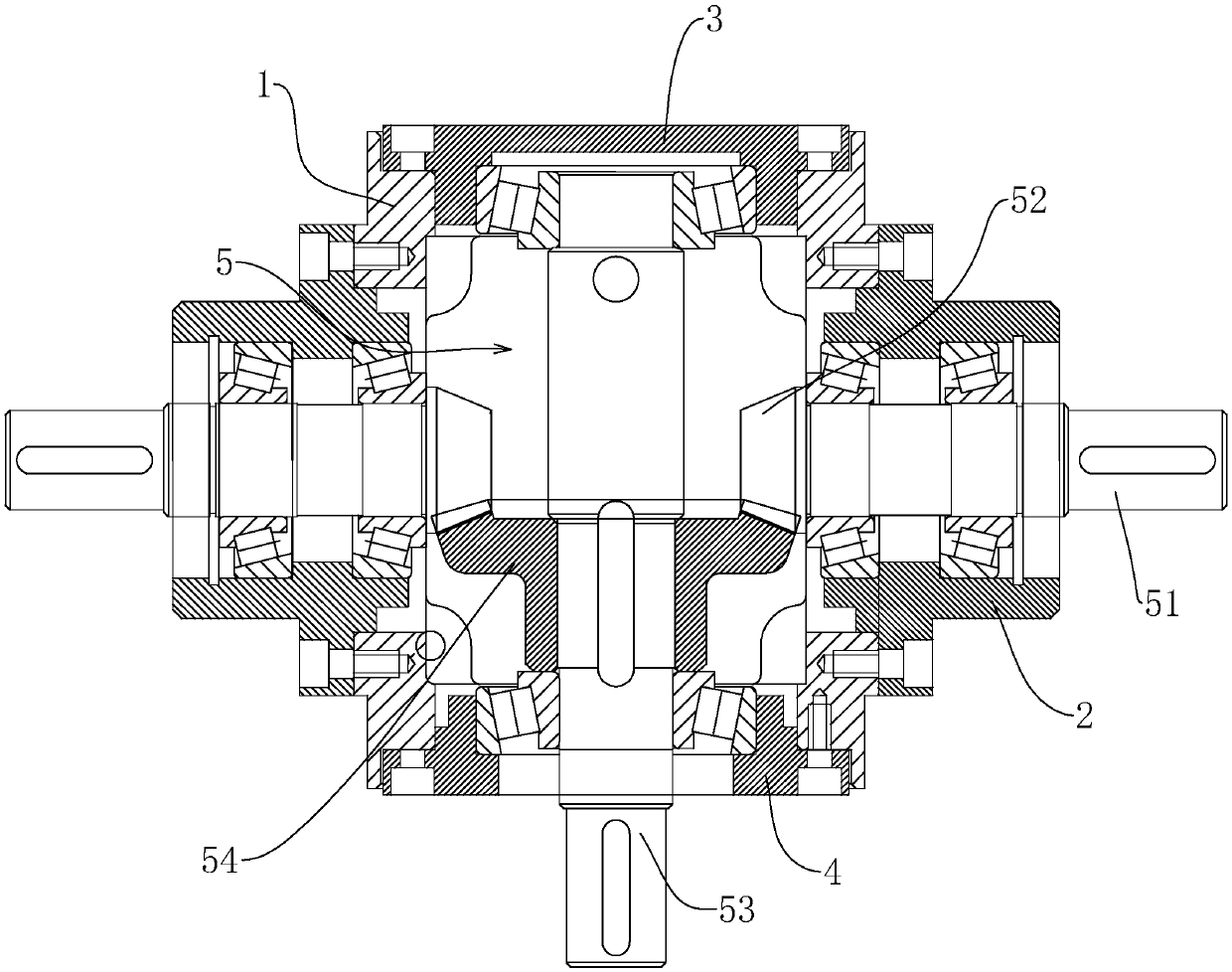

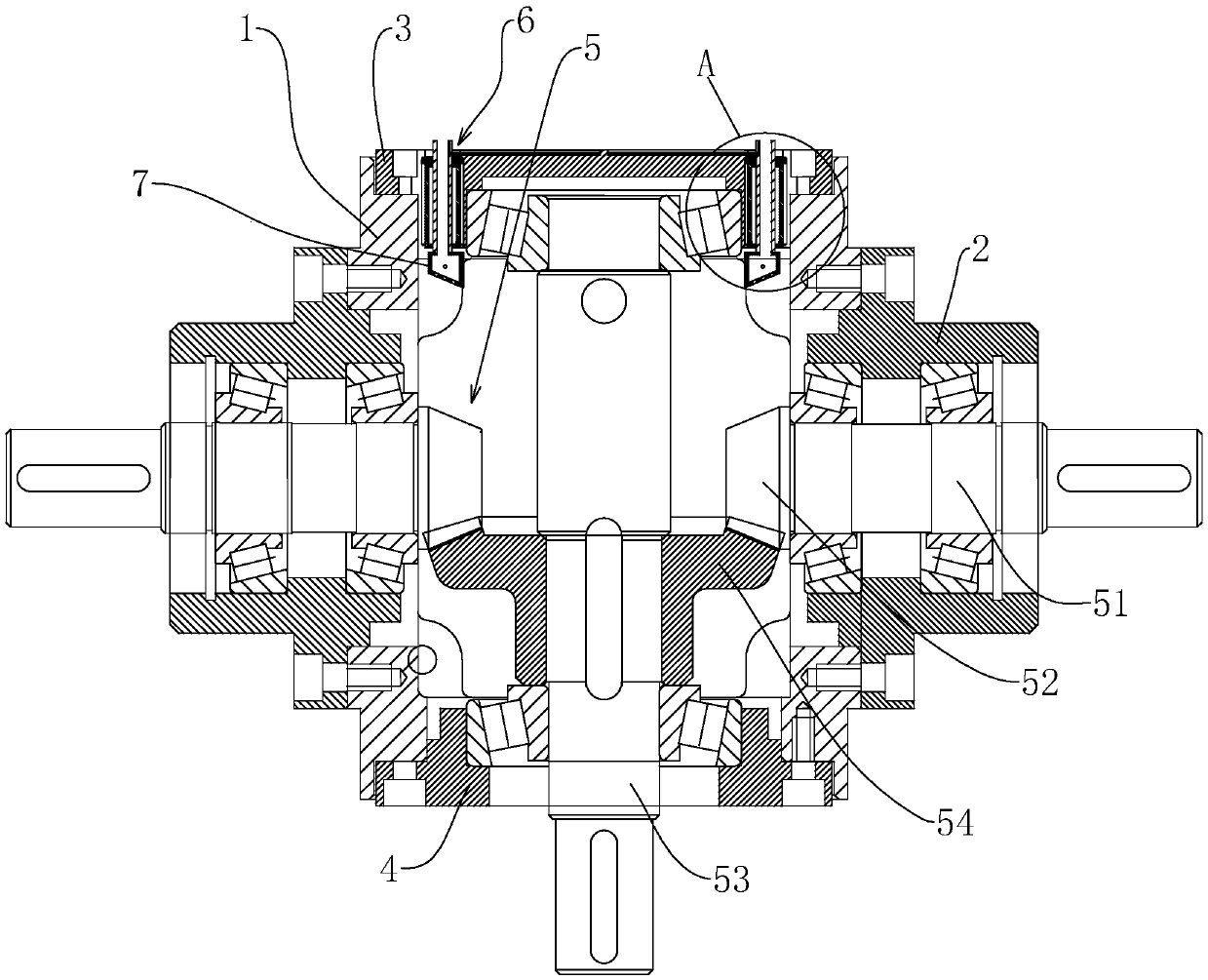

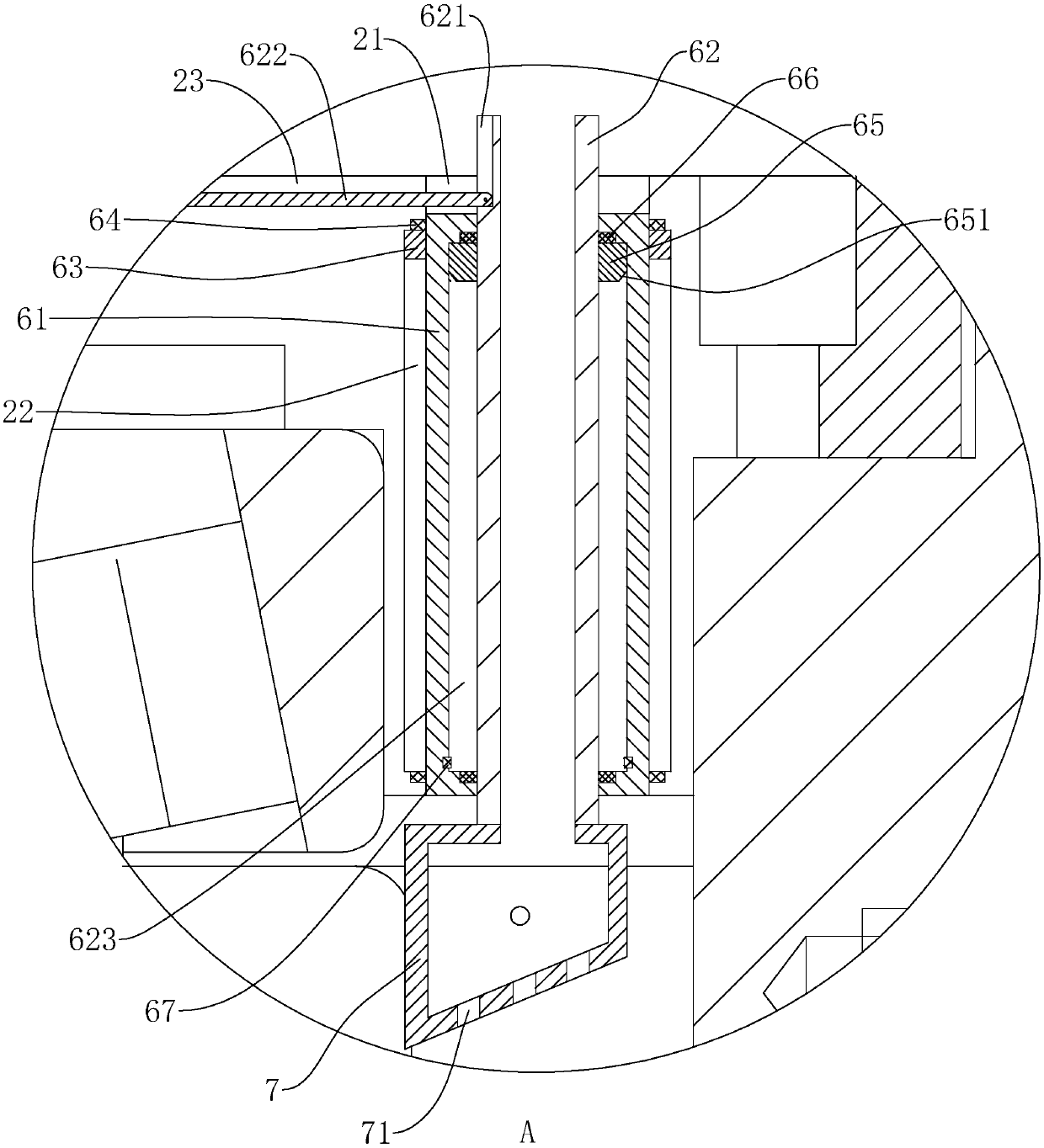

[0039] This embodiment discloses a double output speed reducer, such as figure 2 , image 3 As shown, it includes a shell, the first bearing seat is fixed by bolts on the left and right sides of the shell, and the second bearing seat and the third bearing seat are fixed by bolts on the upper and lower sides of the shell. The housing is provided with a transmission assembly, the transmission assembly includes two transmission shafts connected to the first bearing seat through bearings, the transmission bevel gear is fixed on the opposite side of the two transmission shafts, and the second bearing seat and the third bearing seat are connected by bearings. The driving shaft is fixed with a driving bevel gear meshed with two driving bevel gears. Two telescopic tubes which are symmetrical about the center of the driving shaft and which can inject oil to the transmission bevel gear are arranged on the second bearing seat, and an oil injection block is connected to the telescopic t...

Embodiment 2

[0047] Such as Figure 4 , Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that two center-symmetrical moving assemblies about the drive shaft are arranged on the second bearing seat, the oil injection block is connected with the moving assembly, and the shells on both sides of the second bearing seat A moving hole is opened on the top, and the end of the moving hole close to the housing is inclined to the transmission bevel gear, and a moving assembly is connected in the moving hole. The moving assembly includes a connecting pipe located in the moving hole. A moving block is fixed on the side wall of the connecting pipe. The moving block is slidably connected with a moving groove on the inner wall of the moving hole. The lower end is fixed with an oil injection block.

[0048] Such as Figure 4 , Figure 5 As shown, a first card slot and a second card slot are provided on the outside of the connecting pipe, the first card slot is closer to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com