Anti-running line structure for steel bar straightening equipment

A technology of anti-running wire and wire-pressing structure, which is applied in the field of steel bar straightening equipment, can solve the problems of inability to accurately enter and insert small driven wheels, wire running, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

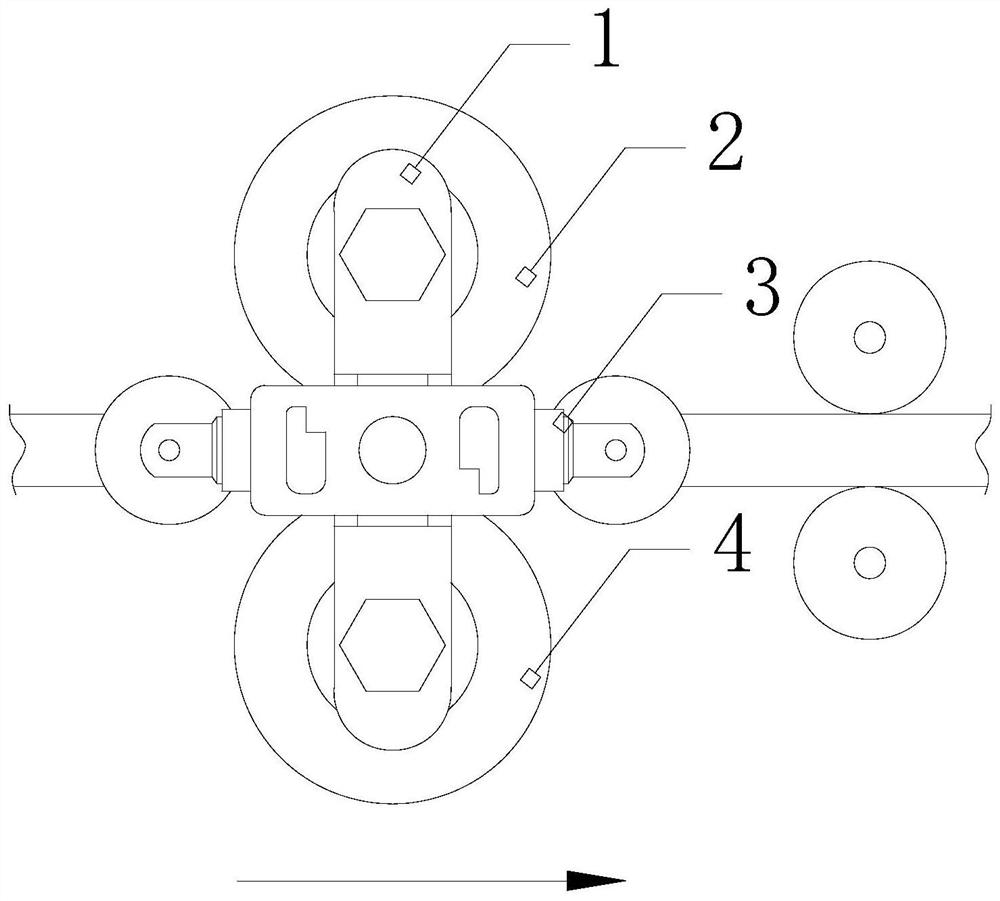

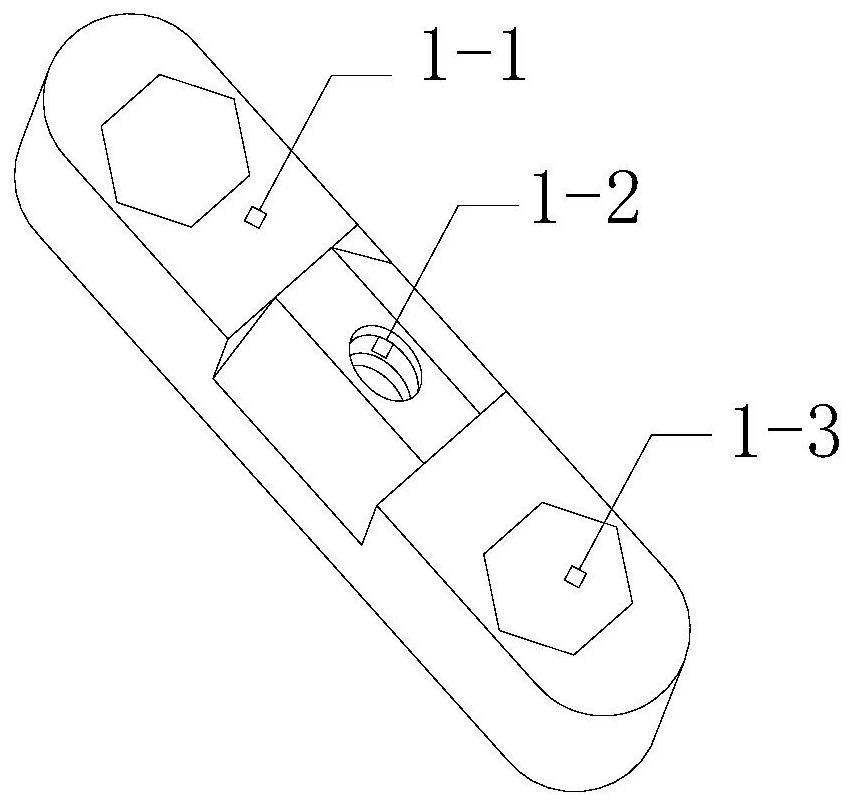

[0025] see Figure 1-Figure 7 , the present invention provides an anti-running line structure for steel bar straightening equipment, which structure includes a beam 1, a first driven wheel 2, a crimping structure 3, a second driven wheel 4, and the first driven wheel 2 and the second driven wheel The axis of the vertical direction of the driving wheel 4 coincides, a beam 1 is arranged between the first driven wheel 2 and the second driven wheel 4, and the two are symmetrically arranged with respect to the beam 1, and the two ends of the beam 1 pass through the first driven wheel through a column 2 and the second driven wheel 4 are centered and then fixed on the straightening equipment. A crimping structure 3 is provided in the middle of the beam 1. The crimping structure 3 and the beam 1 are perpendicular to each other. The crimping structure 3 and the beam 1 with threaded connection.

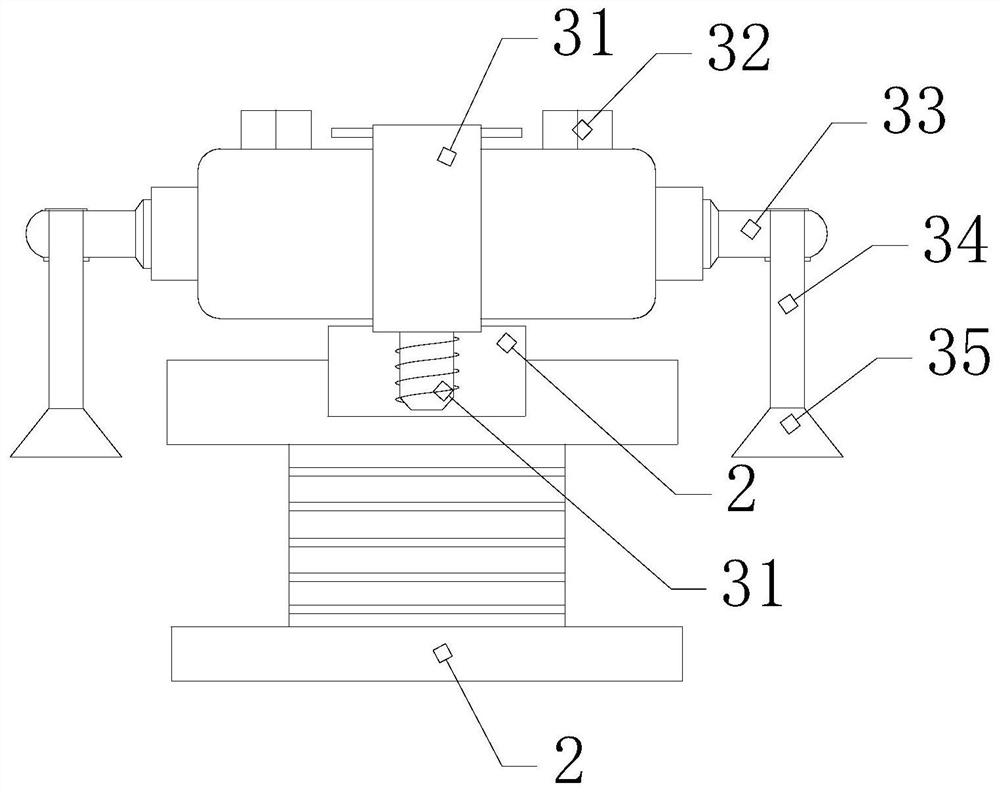

[0026] The crimping structure 3 is provided with a threaded fixed rod 31, a support block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com