Line deviation preventing structure for steel bar straightening equipment

A technology of anti-running wire and wire-pressing structure, which is applied in the field of steel bar straightening equipment, can solve the problems of steel bar and driven wheel slipping, inaccurate entry, wire running, etc., and achieve the effect of avoiding deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

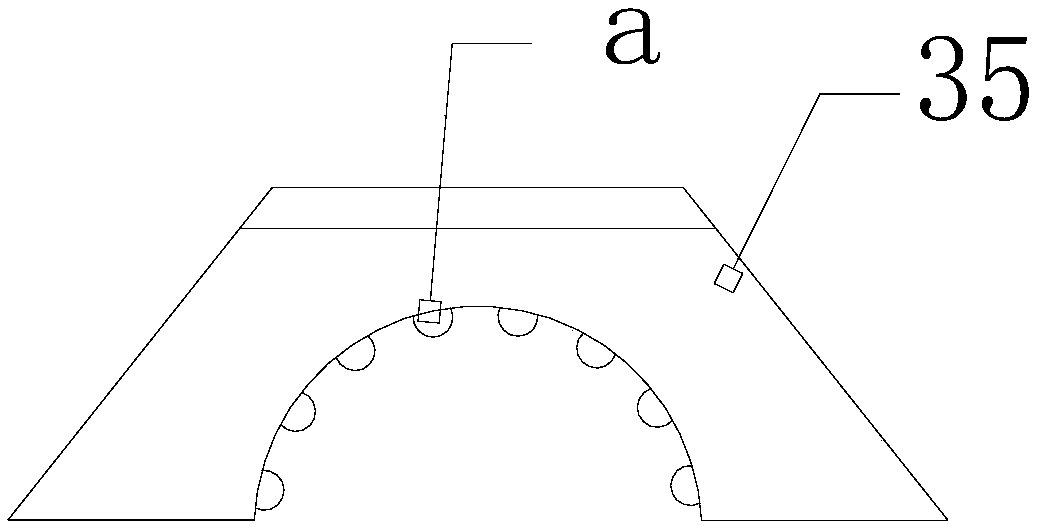

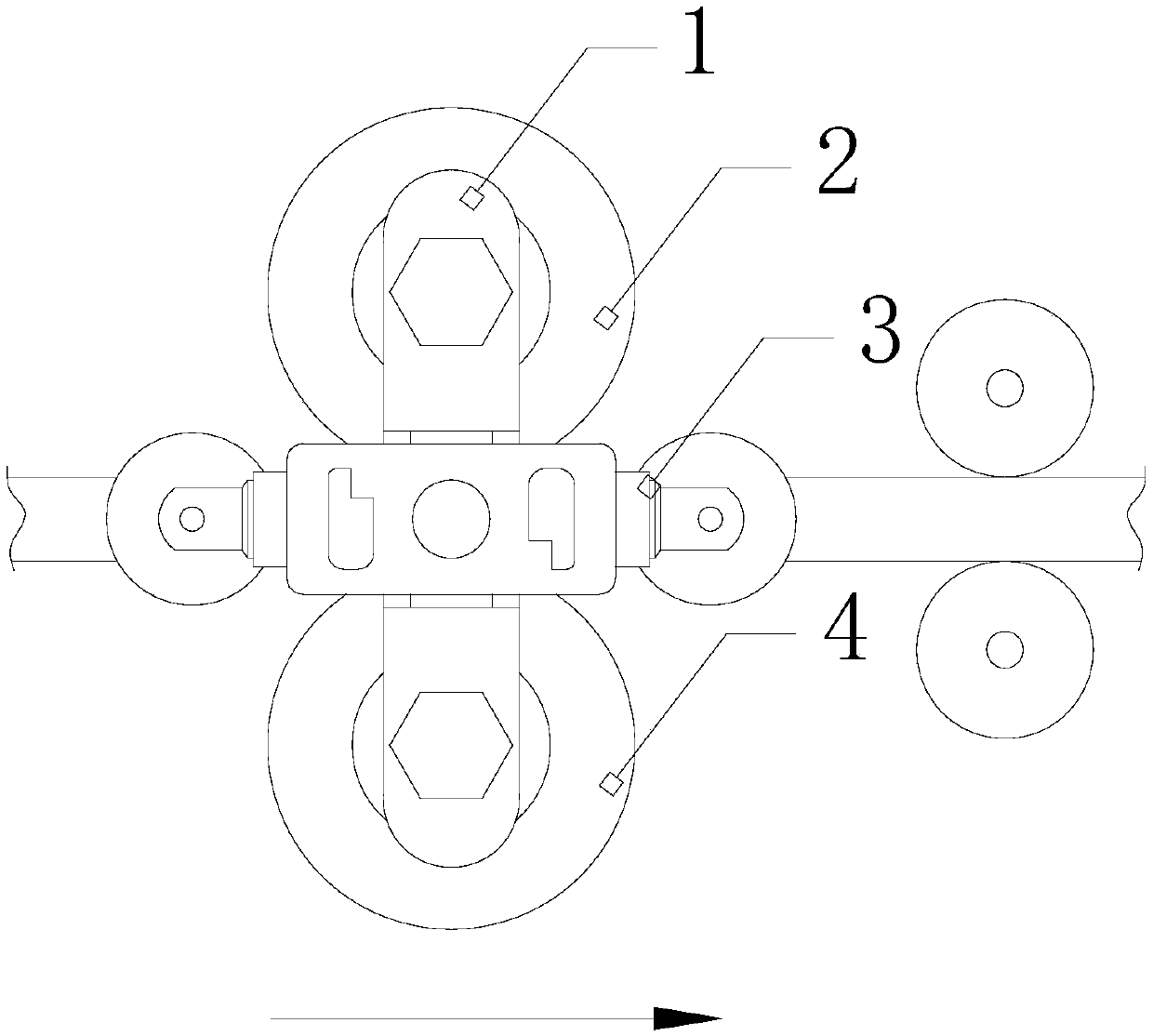

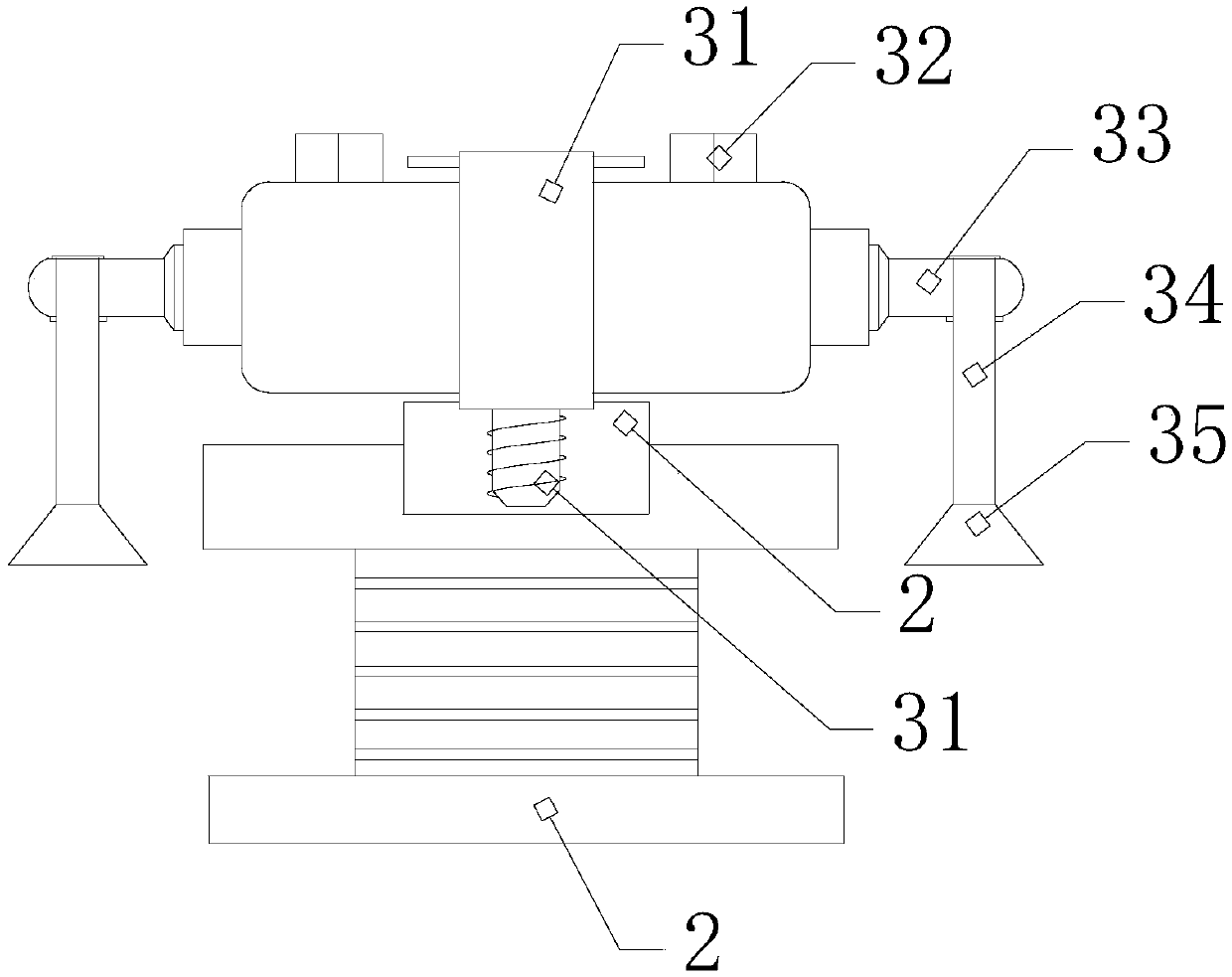

[0023] see Figure 1-Figure 7 , the present invention provides an anti-running line structure for steel bar straightening equipment, which structure includes a beam 1, a first driven wheel 2, a crimping structure 3, a second driven wheel 4, and the first driven wheel 2 and the second driven wheel The driving wheels 4 are on the same axis, and a beam 1 is arranged between the first driven wheel 2 and the second driven wheel 4, and the two ends of the beam 1 pass through the center of the first driven wheel 2 and the second driven wheel 4 through columns. Fixed on the straightening equipment, the crimping structure 3 is arranged in the middle of the beam 1, the crimping structure 3 and the beam 1 are perpendicular to each other, and the crimping structure 3 and the beam 1 are connected by threads.

[0024] The crimping structure 3 is provided with a threaded fixed rod 31, a support block 32, a movable lever 33, a hanging rod 34, and a matching block 35. The horizontal ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com