Low-HC-permeability fixing support frame for pressure sensor of fuel tank

A technology of pressure sensor and fixed bracket, which is applied in the direction of power plant, layout combined with internal combustion engine fuel supply, substructure, etc., can solve the problems of difficult fuel system, large HC steam emission, and difficulty in meeting the national VI low evaporative emission, etc. Achieve the effect of satisfying welding and assembly performance and reducing infiltration emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

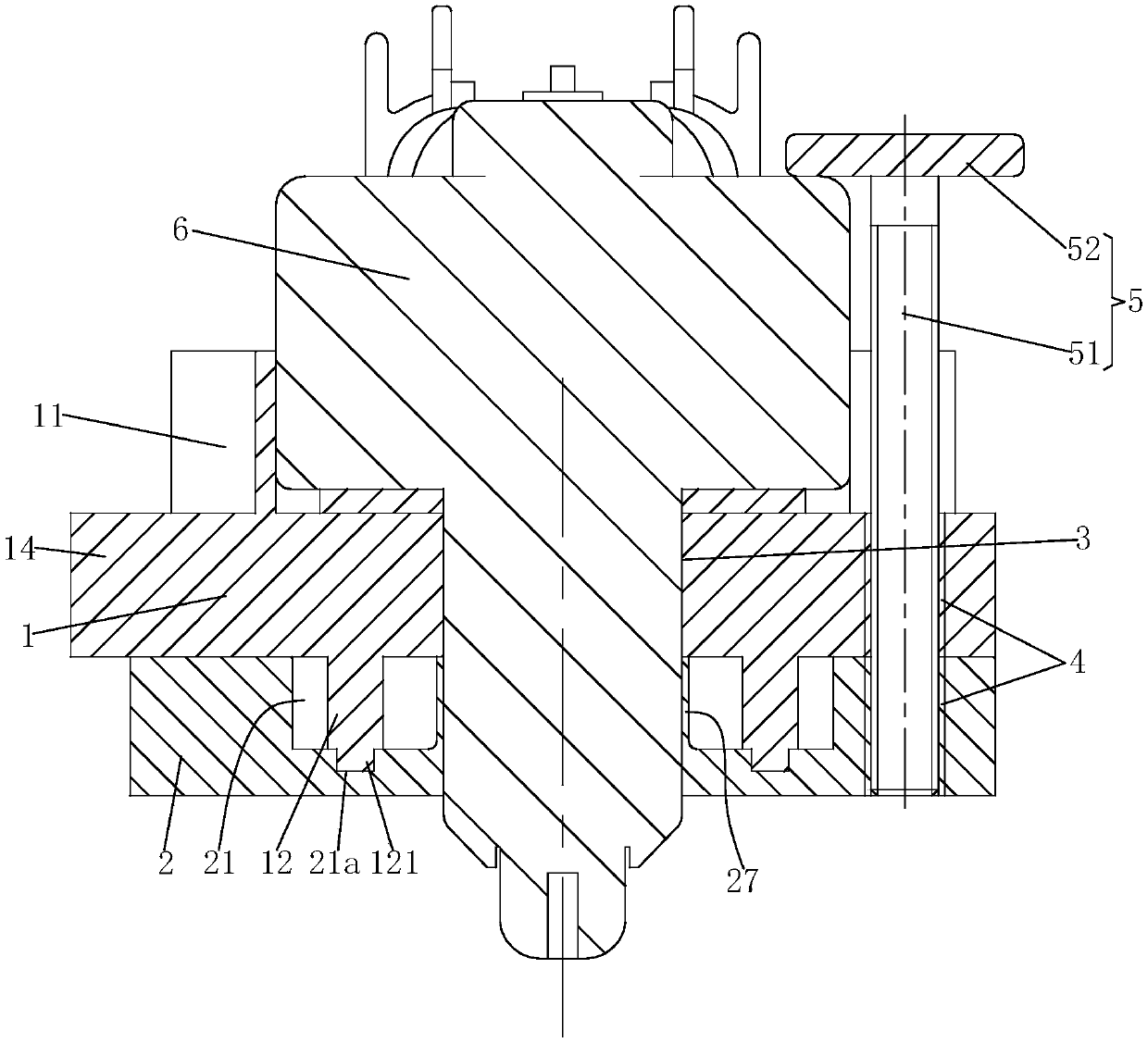

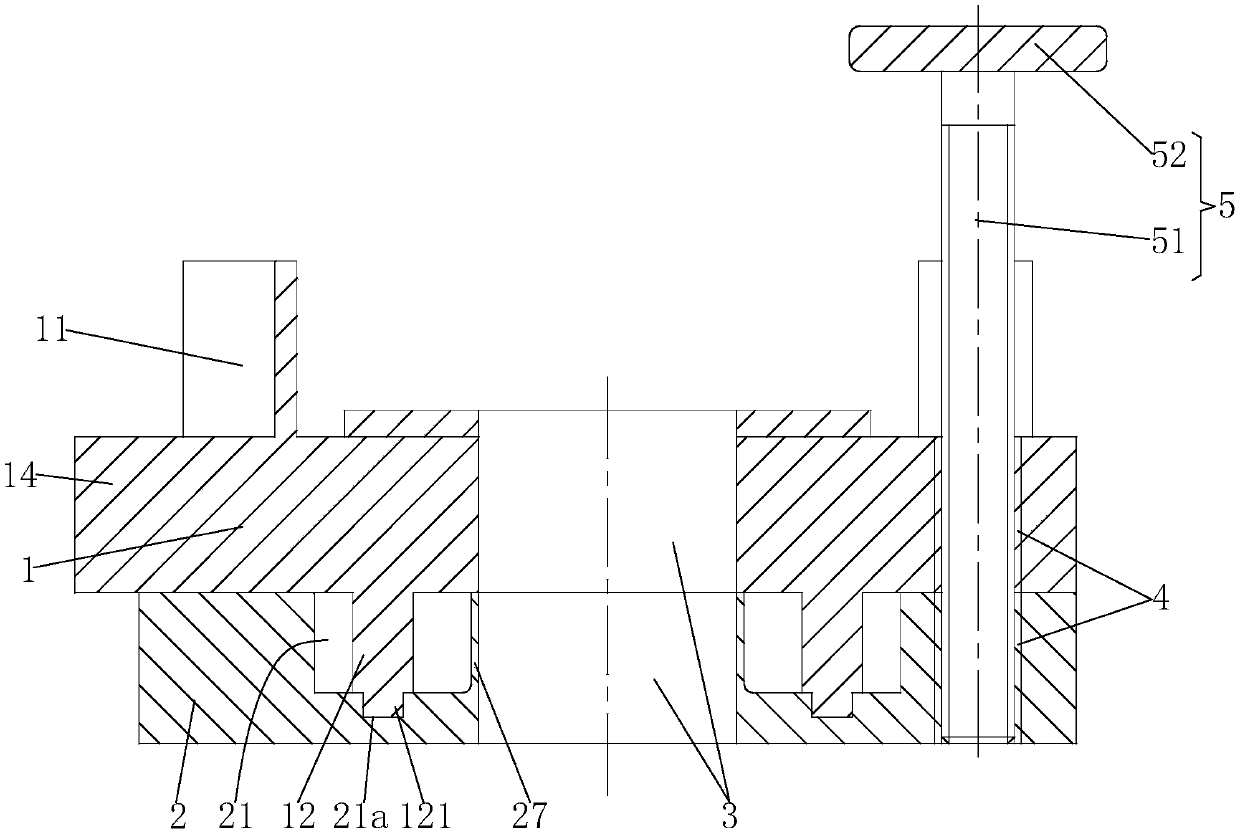

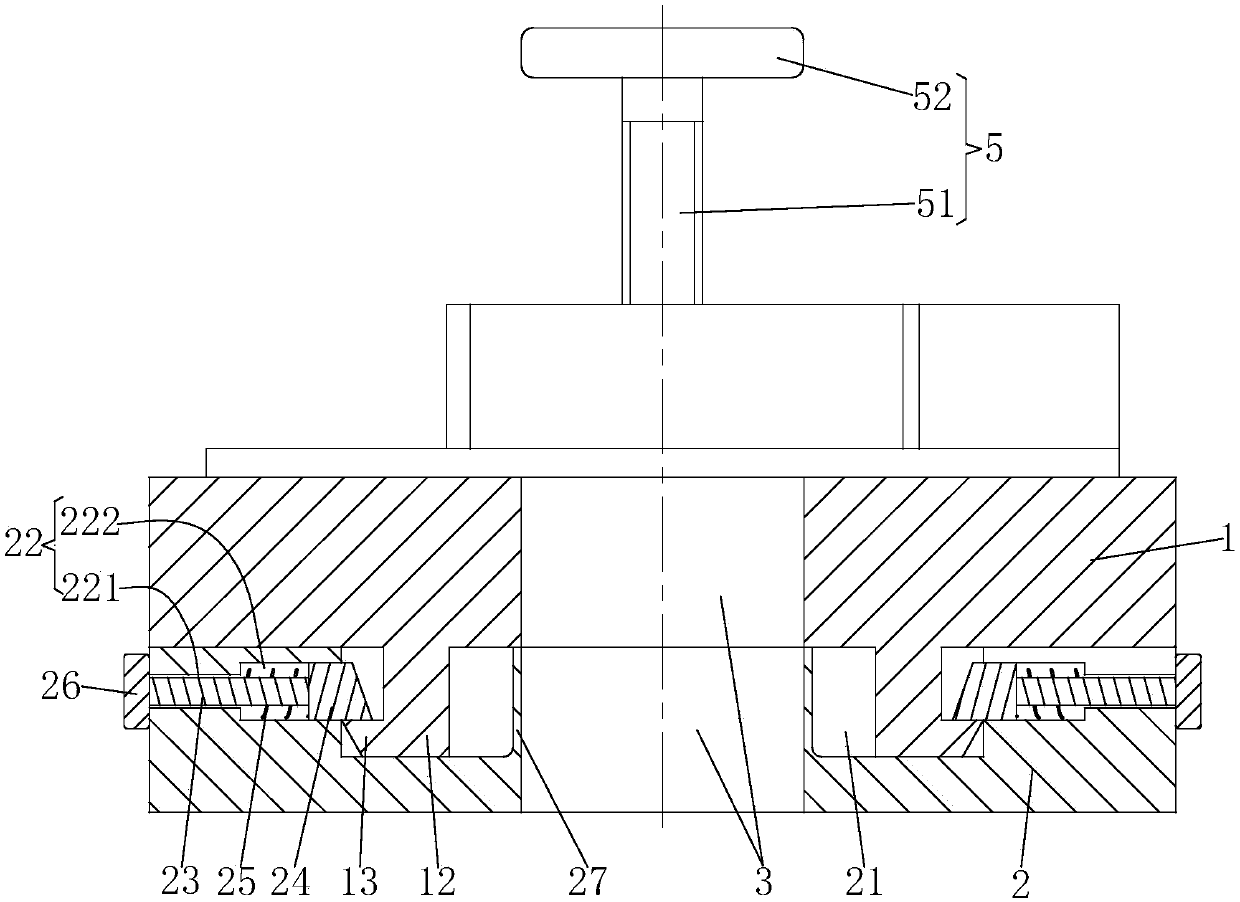

[0026] Such as Figure 1 to Figure 6 As shown, a fuel tank pressure sensor low HC penetration fixing bracket includes an upper fixing bracket 1 and a lower fixing bracket 2 that can engage with each other, and the upper fixing bracket 1 and the lower fixing bracket 2 are two matching cylinders body shape, the upper fixing bracket 1 and the middle of the lower fixing bracket 2 are provided with an assembly hole 3 correspondingly, and the two assembly holes 3 are concentrically arranged, and the assembly hole 3 and the sealing ring of the fuel tank pressure sensor 6 can be closely matched, Wherein, the upper left side of the upper fixed bracket 1 is provided with a limiting part 11, and the lower bottom surface is concentricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com