China VI metal fuel tank

A fuel tank and metal technology, which is applied to the layout, power plant, vehicle parts, etc. combined with the fuel supply of the internal combustion engine, can solve the problems of uneven tightening pressure, poor sealing effect of the fuel tank, and uneven extrusion deformation of the sealing ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

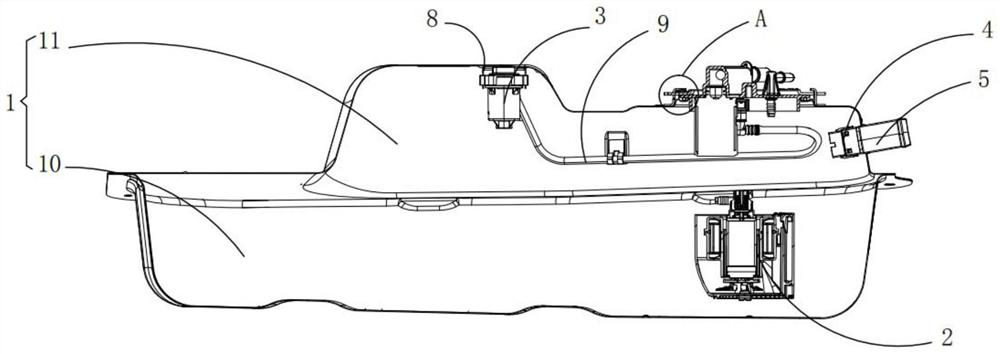

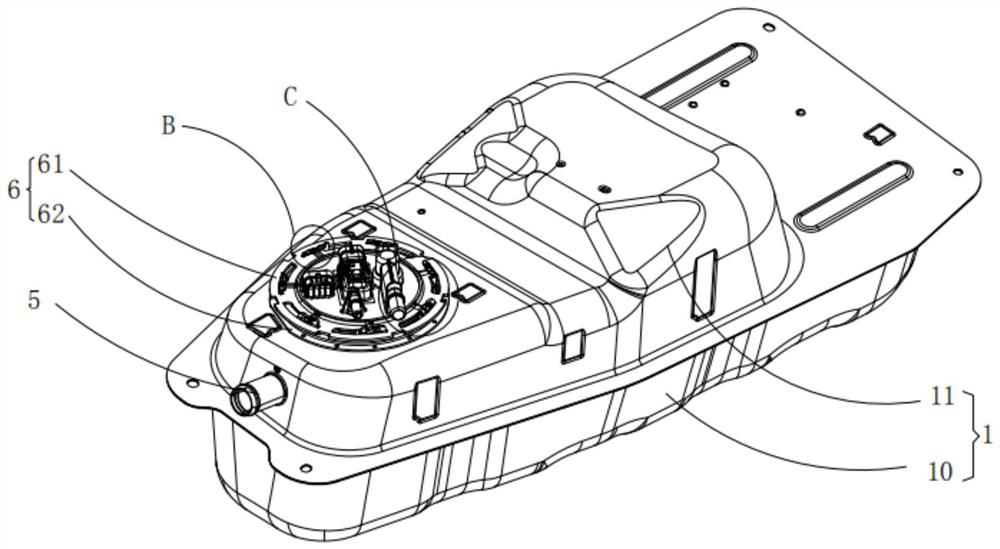

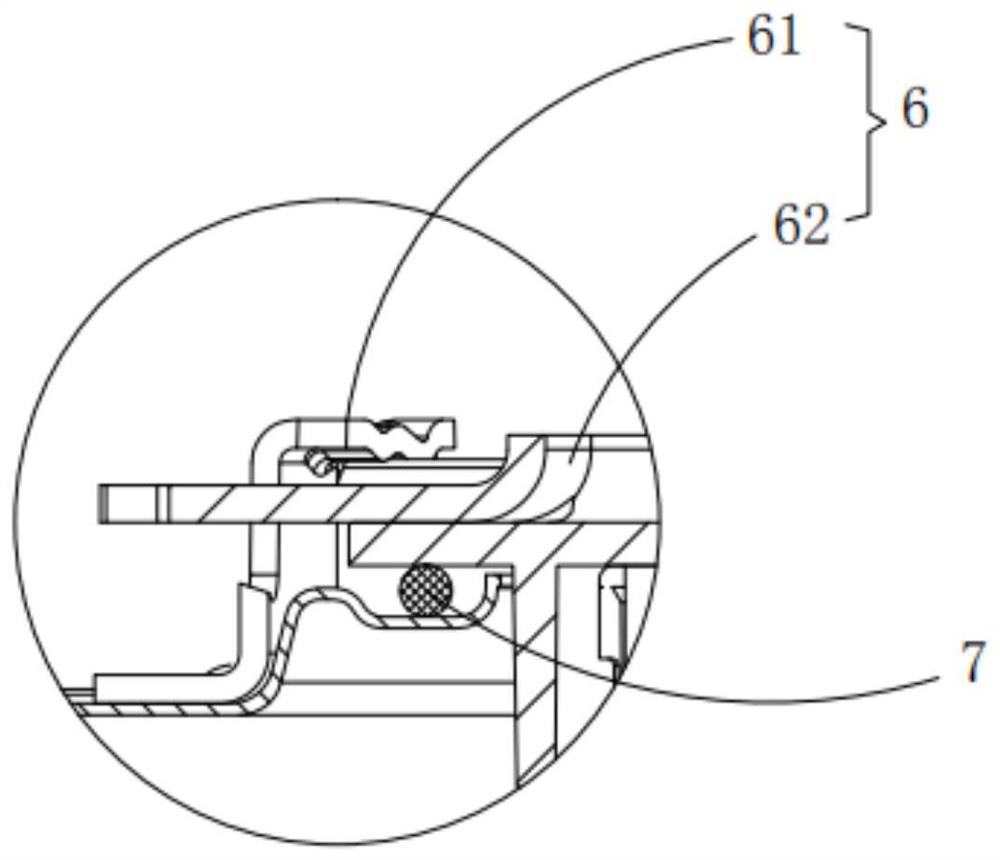

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] Such as Figure 1-5 As shown, the national six metal fuel tanks are disclosed in the specific embodiments of the present invention,

[0029] Including: National VI fuel tank body, made of metal, with a lower box body 10, an upper box body 11 with a sealing cover closed at the opening of the lower box body 10; the lower box body 10 and the upper box body 11 are used to store fuel accommodating chamber;

[0030] The gravity valve 3 is built in the inner top of the upper box body 11, and is connected with the upper box body 11 through the mounting bracket 8; the gas inlet end of the gravity valve 3 is fixedly connected with the ventilation pipe 9 through welding;

[0031] The oil pump assembly is located in the containing chamber; the oil pump 2 on the bottom wall of the lower box 10 is resist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com