Fuel system and control method for regulating internal pressure

A fuel system and internal pressure technology, applied in fuel injection control, electrical control, charging system, etc., can solve the problems of carbon canister not being desorbed, fuel tank weight, environmental pollution, etc. The effect of reducing and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

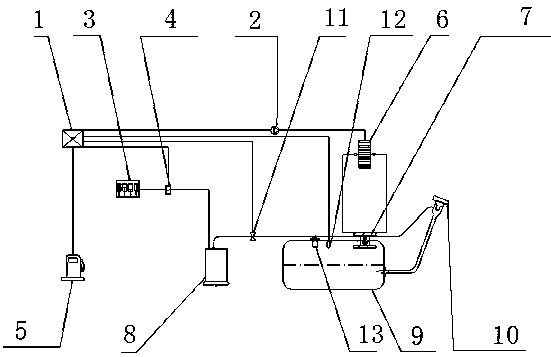

[0018] Embodiment 1: see figure 1 , a fuel system that regulates internal pressure, the fuel system includes ECU1, engine 3, battery 6, carbon pump 8, lock cover 10 and fuel tank assembly 9, the ECU1 is connected to battery 6, engine 3 and carbon pump 8 through a line, The carbon pump 8 is connected to the fuel tank assembly 9 through a pipeline, and the lock cover 10 is connected to the fuel tank assembly 9 through a pipeline. The fuel system also includes a semiconductor refrigerator / heater 7, and the semiconductor refrigerator / heater 7 is set On the fuel tank assembly 9, it is connected to the battery 6 through a line, and connected to the carbon pump 8 through a pipeline; the fuel system also includes an isolation valve 11, and the isolation valve 11 is arranged between the carbon tank 8 and the fuel tank assembly 9 On the pipeline between; the fuel tank assembly is provided with a pressure sensor 12; the fuel tank assembly is provided with an exhaust valve 13. The fuel s...

Embodiment 2

[0019] Example 2: see figure 1 , As an improvement of the present invention, the semiconductor refrigerator / heater 7 is composed of two ceramic sheets with N-type and P-type semiconductor materials in the middle, wherein the semiconductor material is bismuth telluride. The semiconductor refrigerator / heater can both cool and heat, and the working operation uses direct current, and the car battery generates direct current. By changing the polarity of the direct current, it is determined to realize cooling or heating on the same cooler; A monolithic refrigerator consists of two ceramic sheets with N-type and P-type semiconductor materials in the middle. The semiconductor element is composed of multiple monolithic refrigerators connected in series in the circuit. When the current passes through the N stage through the P stage, its working end absorbs heat to achieve the cooling effect; when the current passes through the P stage through the N stage, its working end releases heat t...

Embodiment 3

[0020] Embodiment 3: see figure 1 , as an improvement of the present invention, the temperature range of the semiconductor refrigerator / heater 7 is -40~80 degrees, and its volume is 300mm*300mm*300mm. The highest temperature of the semiconductor refrigerator / heater can reach +80 degrees, and the lowest temperature can reach -40 degrees, which fully meets the desorption and adsorption performance of the carbon tank; its volume is 300mm*300mm*300mm, so that it covers the carbon tank area and achieves a relatively high temperature. Good cooling / heating effect. The thermal inertia of the semiconductor refrigerator is very small, and the cooling and heating time is very fast. In the case of good heat dissipation at the hot end and no load at the cold end, the refrigerator can reach the maximum temperature difference within one minute after being powered on, which can reach about 40 degrees. . In addition, the semiconductor refrigerator / heater is small in size, light in weight, do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com