A suspension friction conveyor transport trolley guide device

A guiding device and conveyor technology, applied in the direction of conveyor, mechanical conveyor, transportation and packaging, etc., to achieve the effect of reducing the amplitude of left and right swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

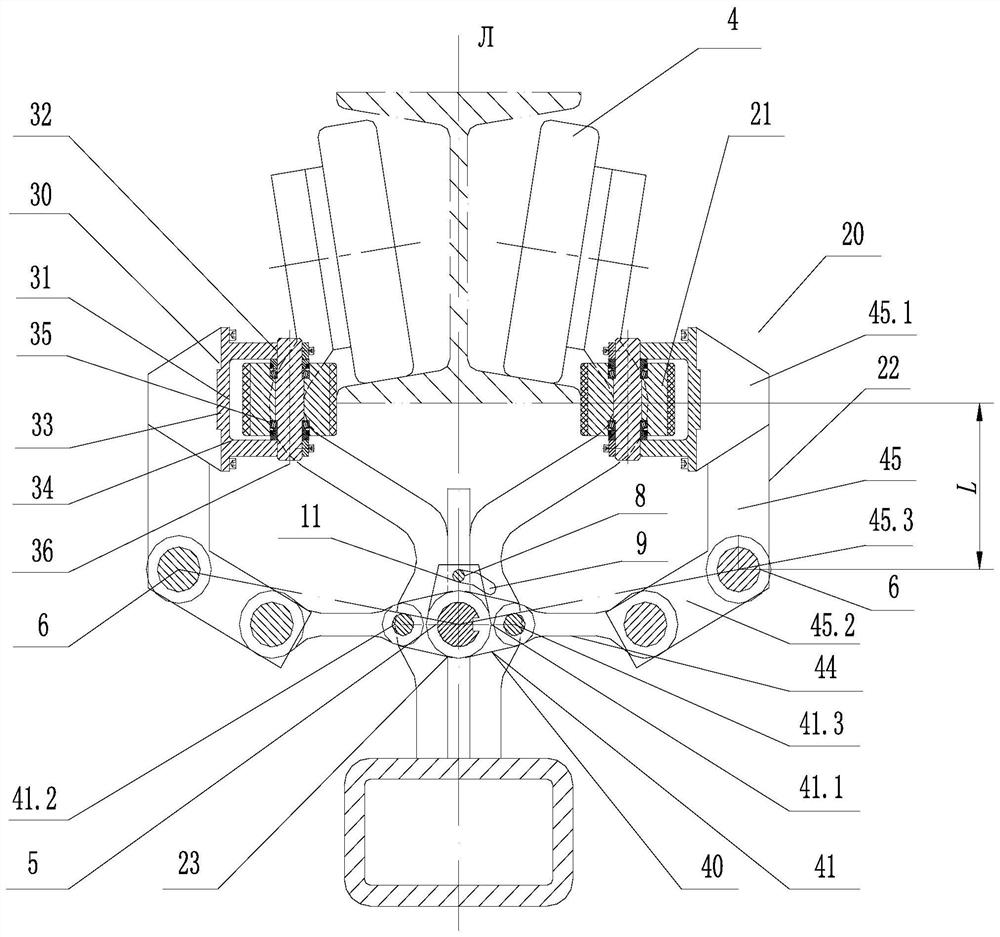

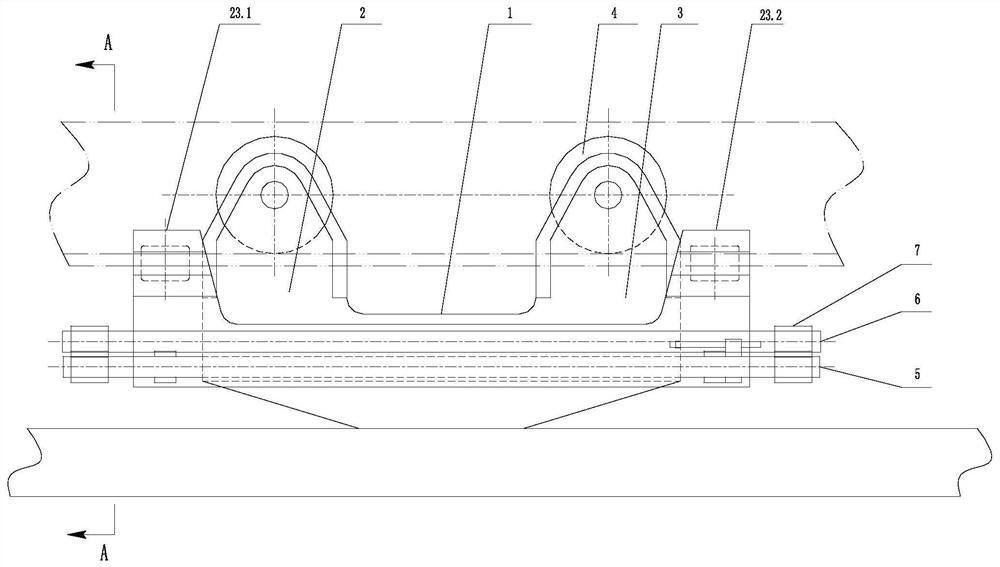

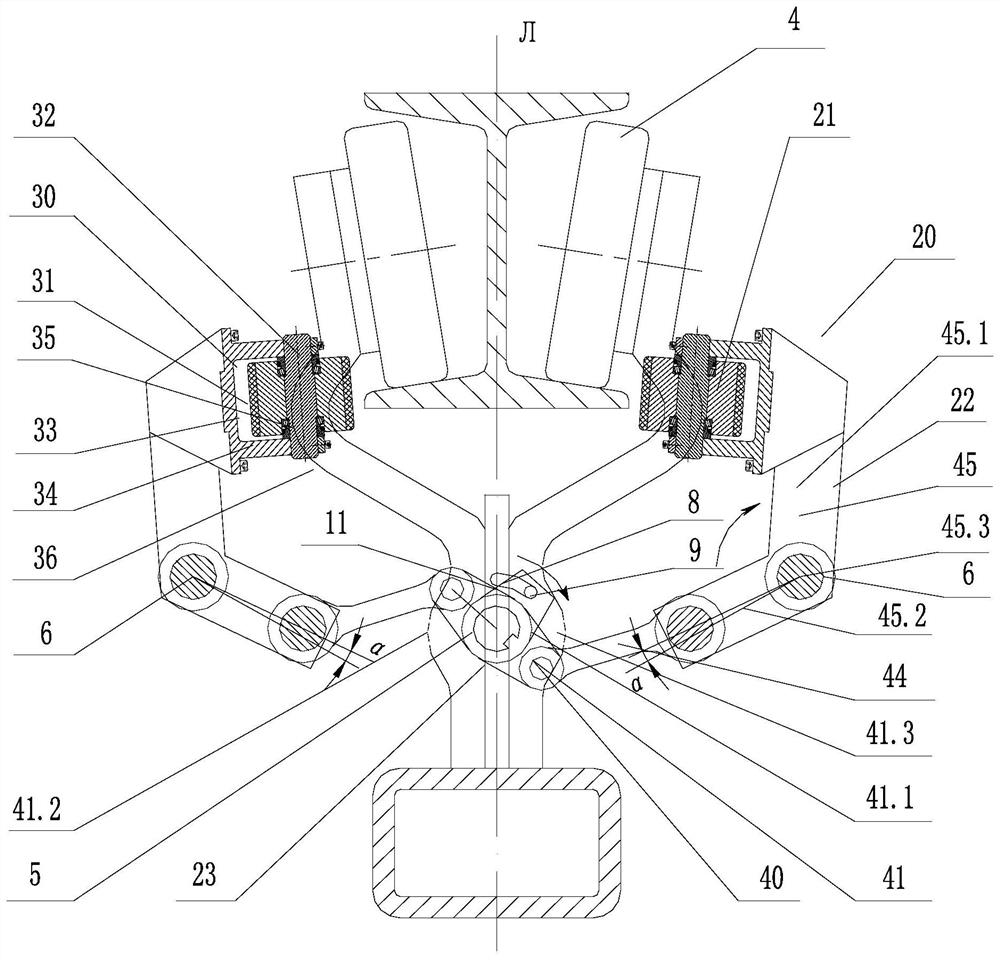

[0041] As shown in the figure, a guiding device for a trolley transported by a suspension friction conveyor includes a trolley body 1, a front wheel frame 2 and a rear wheel frame 3, and the front wheel frame 2 and the rear wheel frame 3 are integrally connected to the trolley body 1 The cross-section of the trolley body 1 is a Y-shaped structure arranged symmetrically with the mid-plane datum Л, and the mid-plane datum Л is the cross-section of the straight wall centerline of the Y-shaped structure; the lower beam of the I-beam extends into the Y-shaped structure In the opening of the front wheel frame 2 and the rear wheel frame 3, a pair of road wheels 4 are rotatably arranged on both sides respectively, and the distance between the axis of the road wheels of the front wheel frame 2 and the rear wheel frame 3 is the front and rear distance L of the road wheels. 0The left and right sides of the trolley body 1 are axisymmetrically and openably provided with a guide wheel mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com