Suspension friction transport trolley guide device

A technology of guiding device and trolley, which is used in conveyors, mechanical conveyors, transportation and packaging, etc., to achieve the effect of reducing the amplitude of left and right swings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

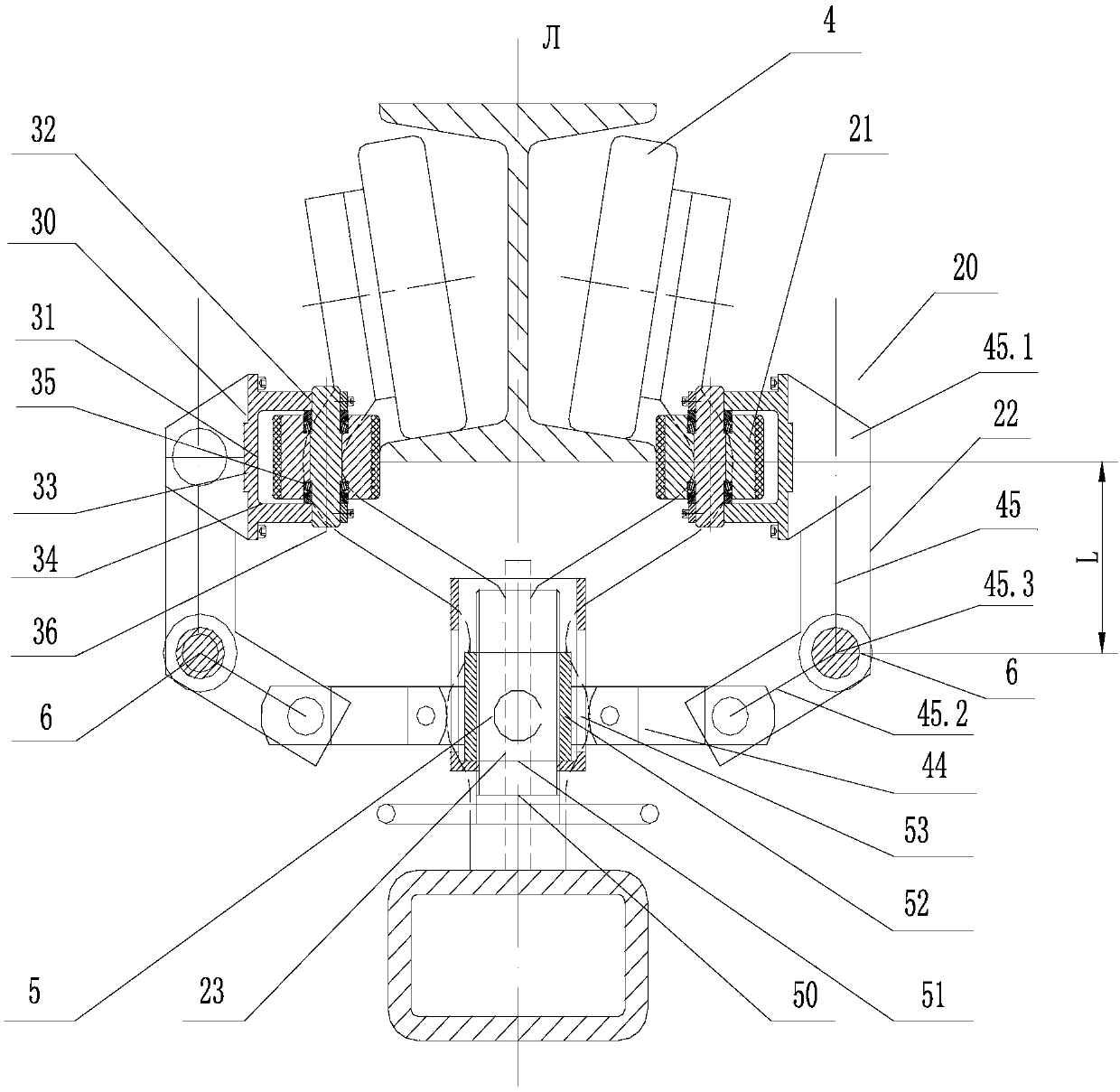

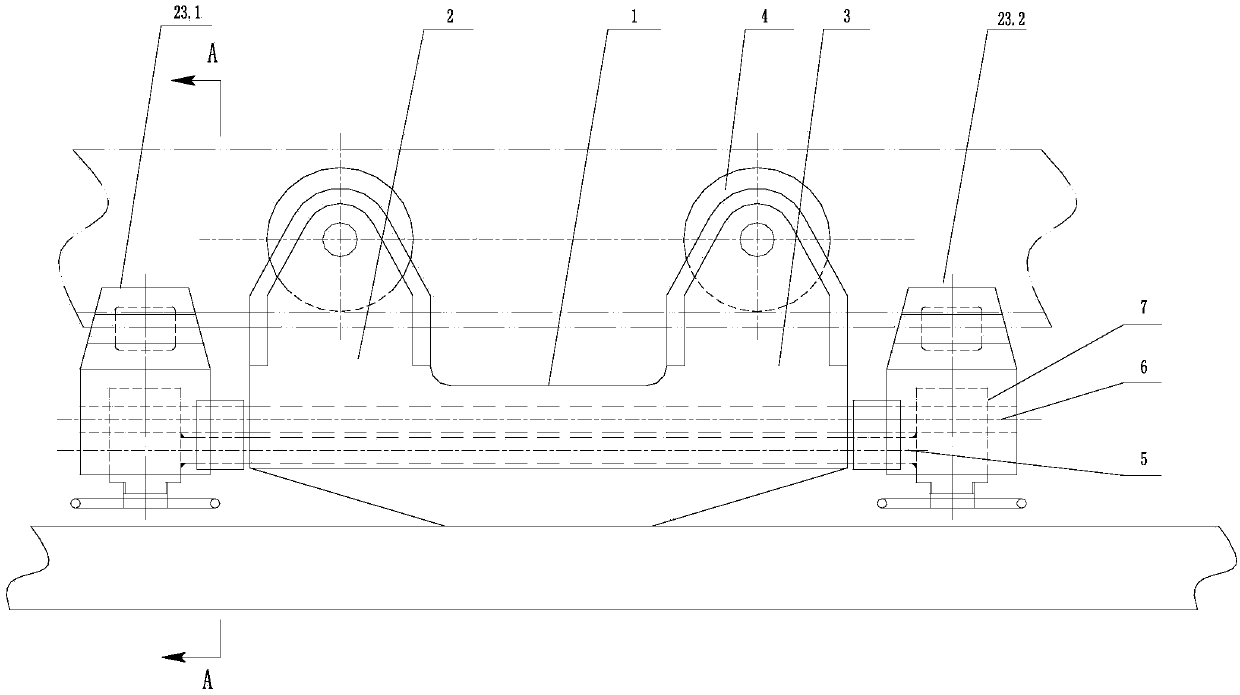

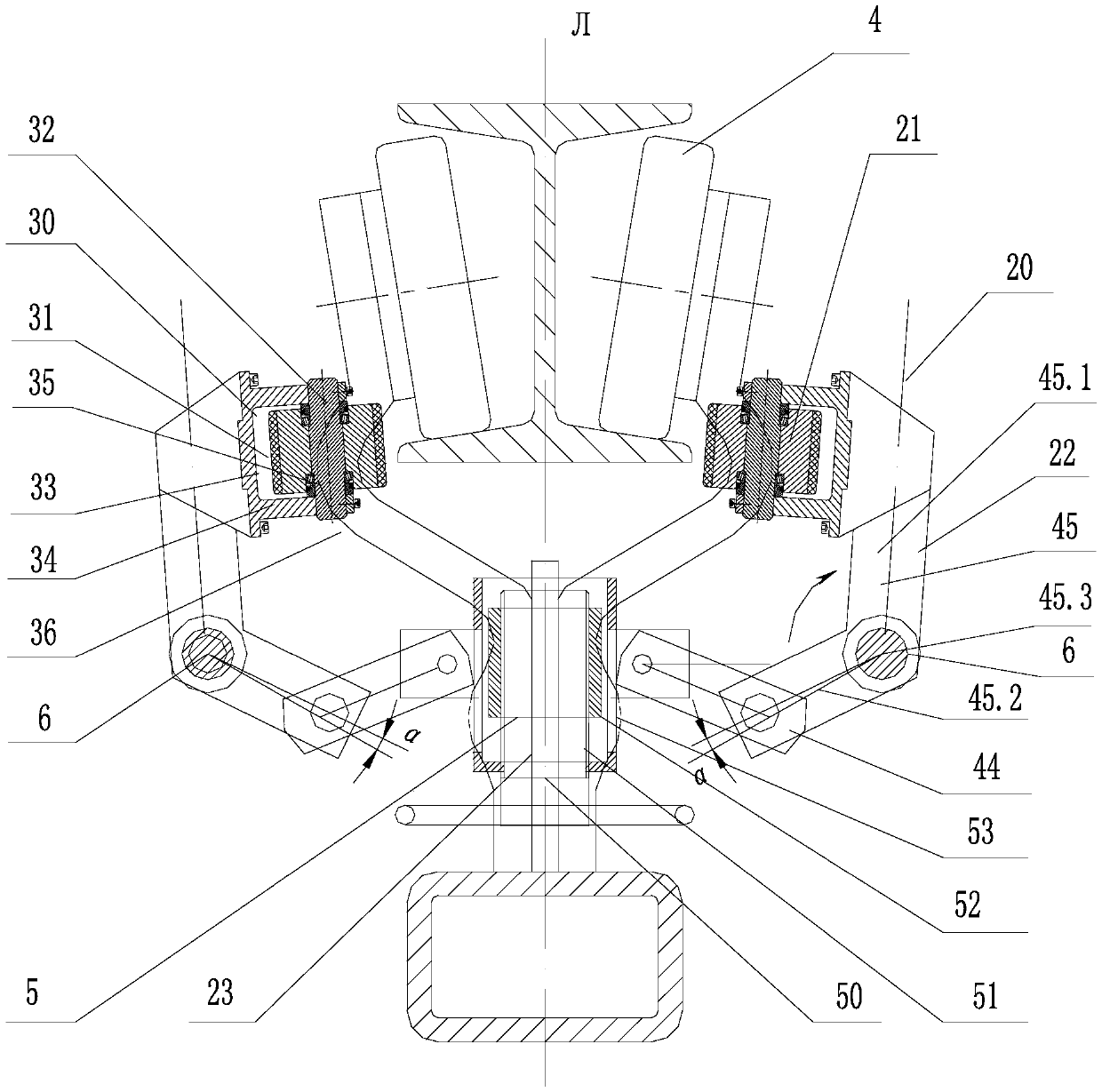

[0047] As shown in the figure, a guiding device for a trolley transported by a suspension friction conveyor includes a trolley body 1, a front wheel frame 2 and a rear wheel frame 3, and the front wheel frame 2 and the rear wheel frame 3 are integrally connected to the trolley body 1 The cross-section of the trolley body 1 is a Y-shaped structure arranged symmetrically with the mid-plane datum Л, and the mid-plane datum Л is the cross-section of the straight wall centerline of the Y-shaped structure; the lower beam of the I-beam extends into the Y-shaped structure In the opening of the front wheel frame 2, the two sides of the rear wheel frame 3 are respectively rotatably provided with a pair of road wheels 4, and the distance between the axis of the road wheels of the front wheel frame 2 and the rear wheel frame 3 is the distance between the front and rear of the road wheels L0; the trolley body 1 The left and right sides are axially symmetrical and can be opened and closed wi...

Embodiment 2

[0057] On the basis of Embodiment 1, a lower beam guiding and pressing mechanism 60 is added, and the specific structure is as follows:

[0058] The front and rear ends of the triangular frame structure 10 are respectively provided with the lower beam guiding and pressing mechanism 60, and the lower beam guiding and pressing mechanism 60 includes a bottom guide wheel 64, between the rotating shaft of the bottom guide wheel 64 and the second main shaft 6 Pivotally connect the left arm 61 and the right arm 62, pivotally connect the middle arm 63 between the rotating shaft of the bottom guide wheel 64 and the first main shaft 5, the first main shaft 5 is provided with a chute 66, and the middle arm 63 The rotating shaft is slidingly arranged in the chute 66; it also includes a hook 67, one end of the hook 67 is rotatably fixed on the first main shaft 5, and the hook 67 is engaged with the rotating shaft of the middle arm 63 to lock it in the chute position in .

[0059] The trol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com