Ship engine

A marine engine and cylinder technology, which is applied to machines/engines, mechanical equipment, etc., can solve the problems of complex crankshaft structure, easy-to-break marine engine thermal efficiency, manufacturing difficulties, etc., to improve thermal efficiency, reduce effective rotation radius, and reduce vibration. and friction and other losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

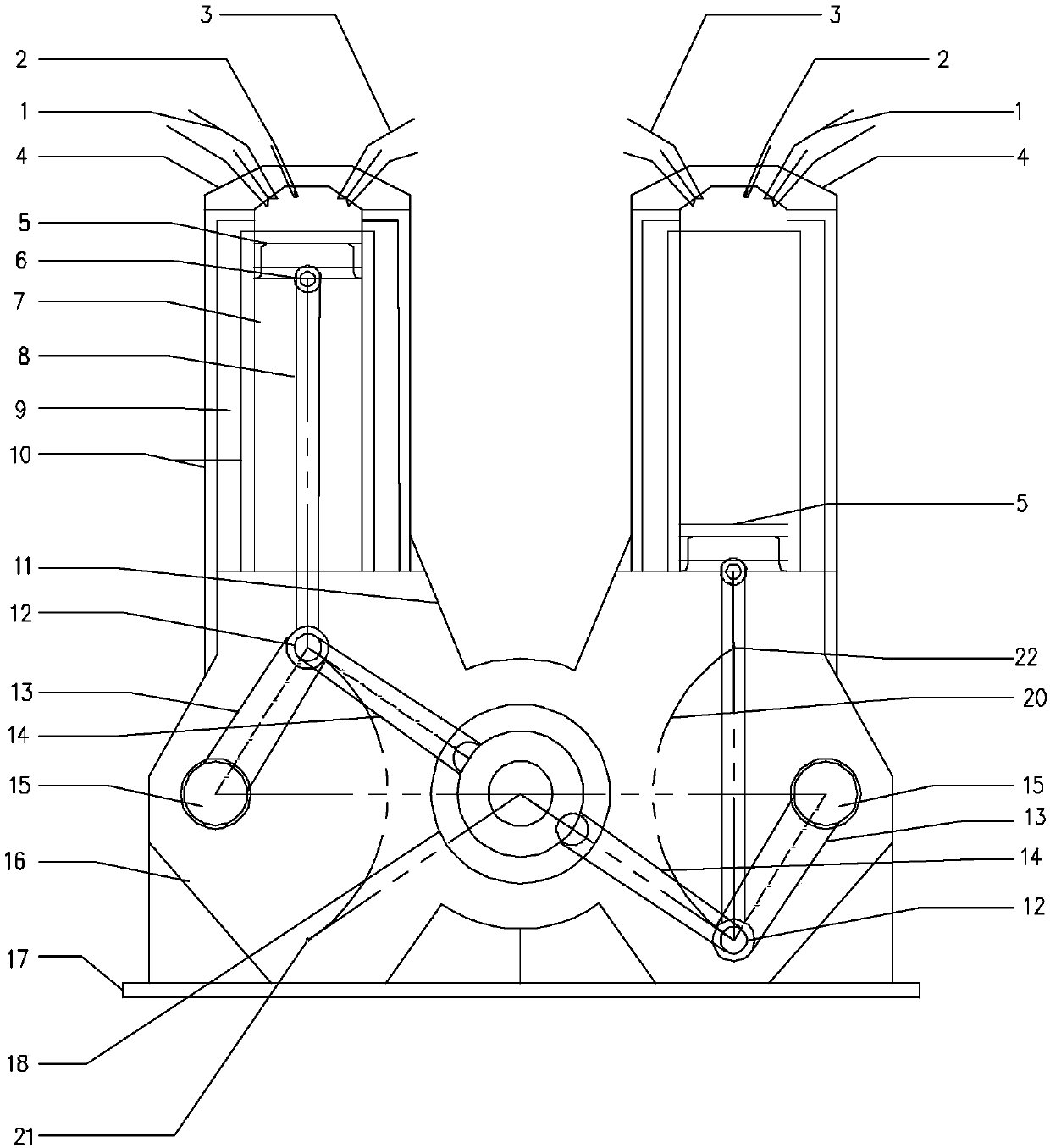

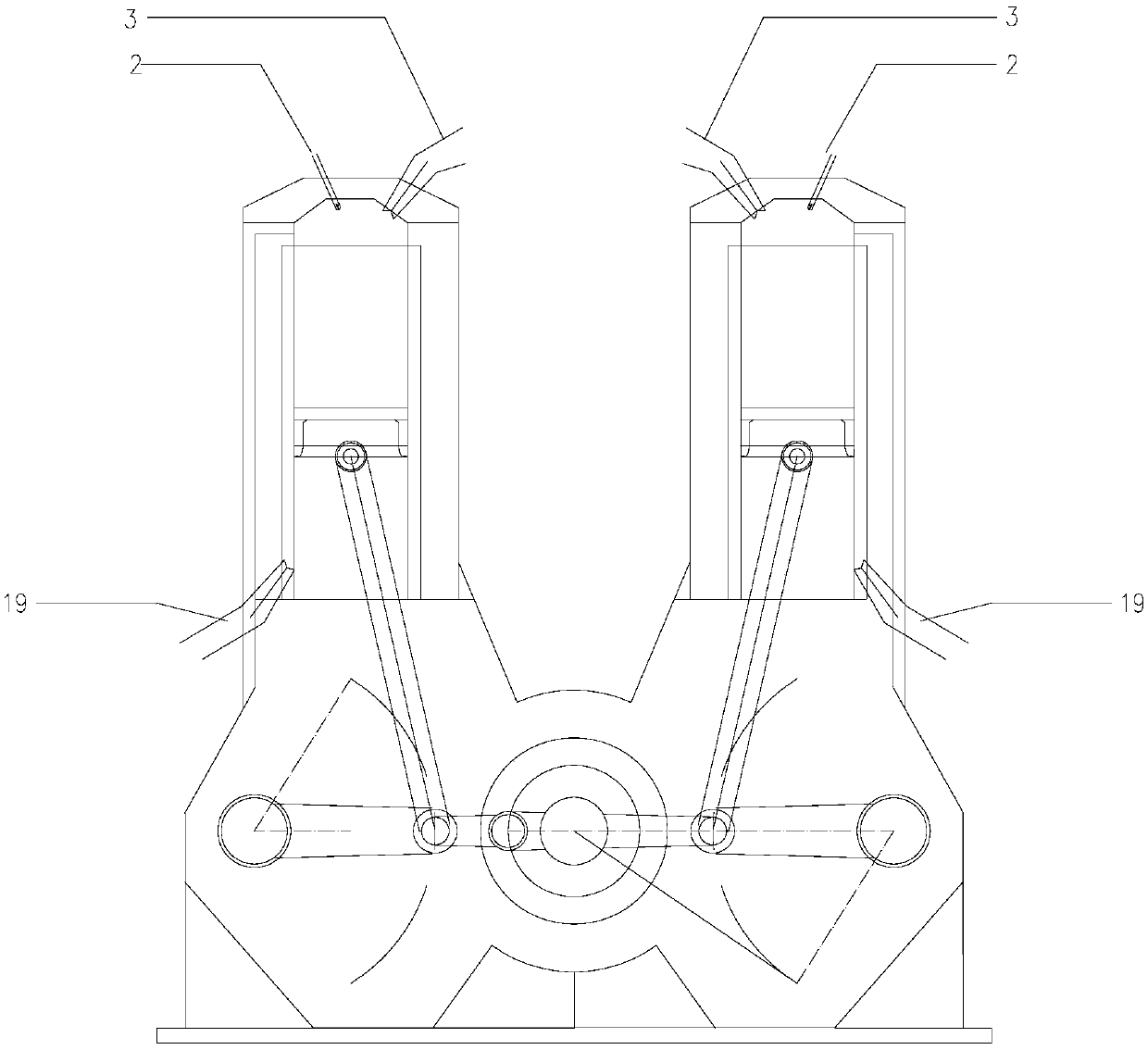

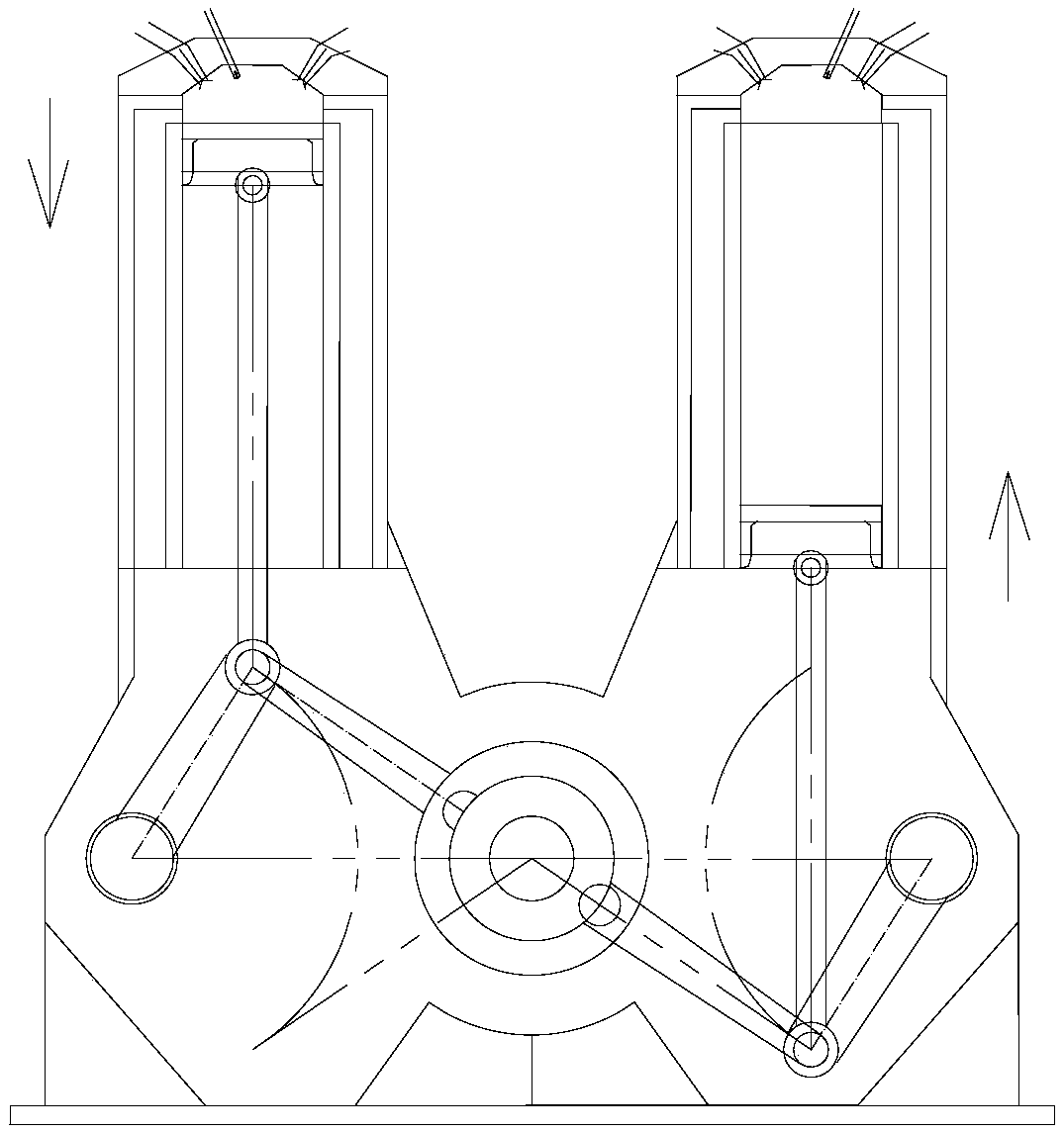

[0070] Embodiment 1, the crank diameter of this marine engine can be 1260mm, the diameter of cylinder 7 can be 960mm, the length of piston rod 8 can be 3275mm, the length of crankshaft connecting rod 14 can be 1514mm, and the length of swing rod 13 can be 1439mm, thus The obtained piston stroke is 2600mm, the ratio of the stroke to the diameter of the crankshaft 18 is 2.064, and the aspect ratio of the cylinder 7 is 2.708.

Embodiment 2

[0071] Embodiment 2, the crank diameter of this marine engine can be 892mm, the diameter of cylinder 7 can be 880mm, the length of piston rod 8 can be 2318mm, the length of crankshaft connecting rod 14 can be 1119mm, and the length of swing rod 13 can be 1011mm, thus The obtained piston stroke is 1840 mm, the ratio of the stroke to the diameter of the crankshaft 18 is 2.063, and the aspect ratio of the cylinder 7 is 2.091.

Embodiment 3

[0072] Embodiment 3, the crank diameter of engine can be 703mm, the diameter of cylinder 7 can be 860mm, the length of piston rod 8 can be 2641mm, the length of crankshaft connecting rod 14 can be 1000mm, the length of pendulum 13 can be 1411mm, thus draws The piston stroke is 1840mm, the ratio of the stroke to the diameter of the crankshaft 18 is 2.617, and the aspect ratio of the cylinder 7 is 2.140.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com