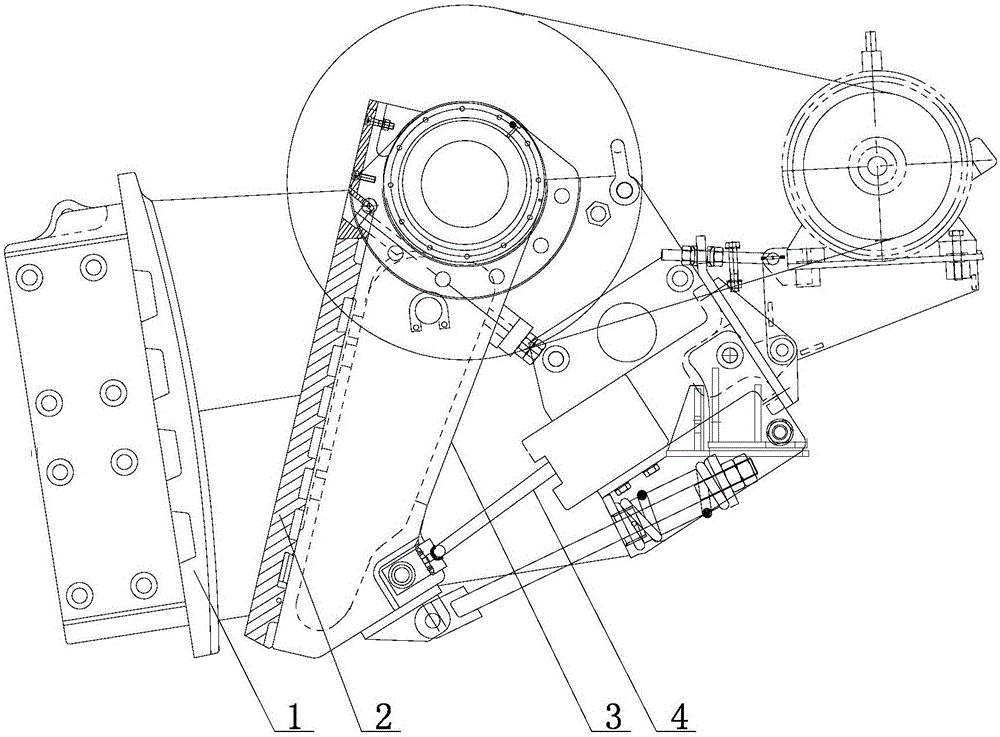

C-series European type jaw crusher

A jaw crusher, European-style technology, applied in the field of C series European-style jaw crushers, can solve the problems of unresolved, difficult to improve the crushing effect, material discharge, etc., to achieve increased output and reasonable reduction of left and right swings , to ensure the effect of the crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

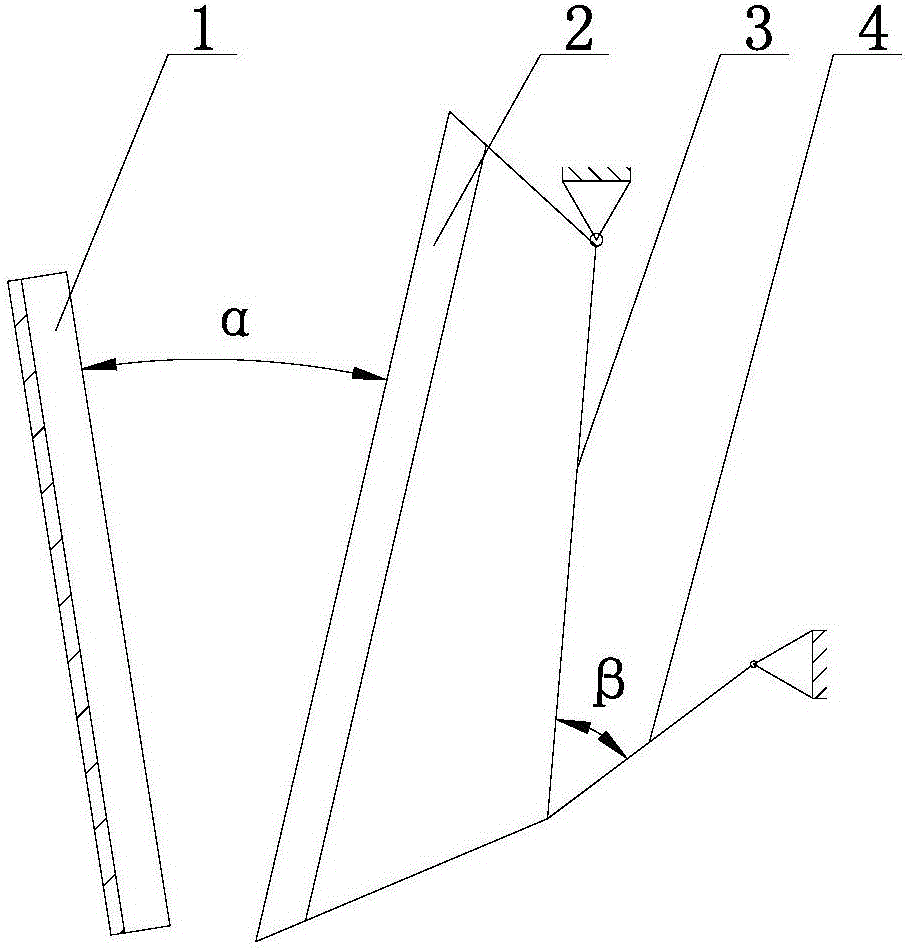

[0019] In Example 1, α = 20.8°, β = 49.7°, the motor speed can be as high as 310r / min, there is no discharge or blocking phenomenon, and the maximum output is 142T / h, compared with the traditional C series European jaw crusher of the same model , production increased by 22.4%.

Embodiment 2

[0020] In Example 2, α = 21.6°, β = 48.9°, the motor speed can be as high as 325r / min, there is no discharge or blocking phenomenon, and the highest output is 149T / h, compared with the traditional C series European jaw crusher of the same model , the output increased by 28.44%.

Embodiment 3

[0021] In Example 3, α = 22.1°, β = 48.4°, the motor speed can be as high as 340r / min, there is no discharge or blocking phenomenon, and the highest output is 158T / h, compared with the traditional C series European jaw crusher of the same model , the output increased by 36.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com