Heating method of electronic cigarette component and electronic cigarette component

A heating element and heating method technology, applied in the field of electronic cigarettes, can solve the problems of difficulty, high brittleness, and limited substrate size, and achieve the effects of reducing distance, reducing temperature difference, and lasting and mellow roasted aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

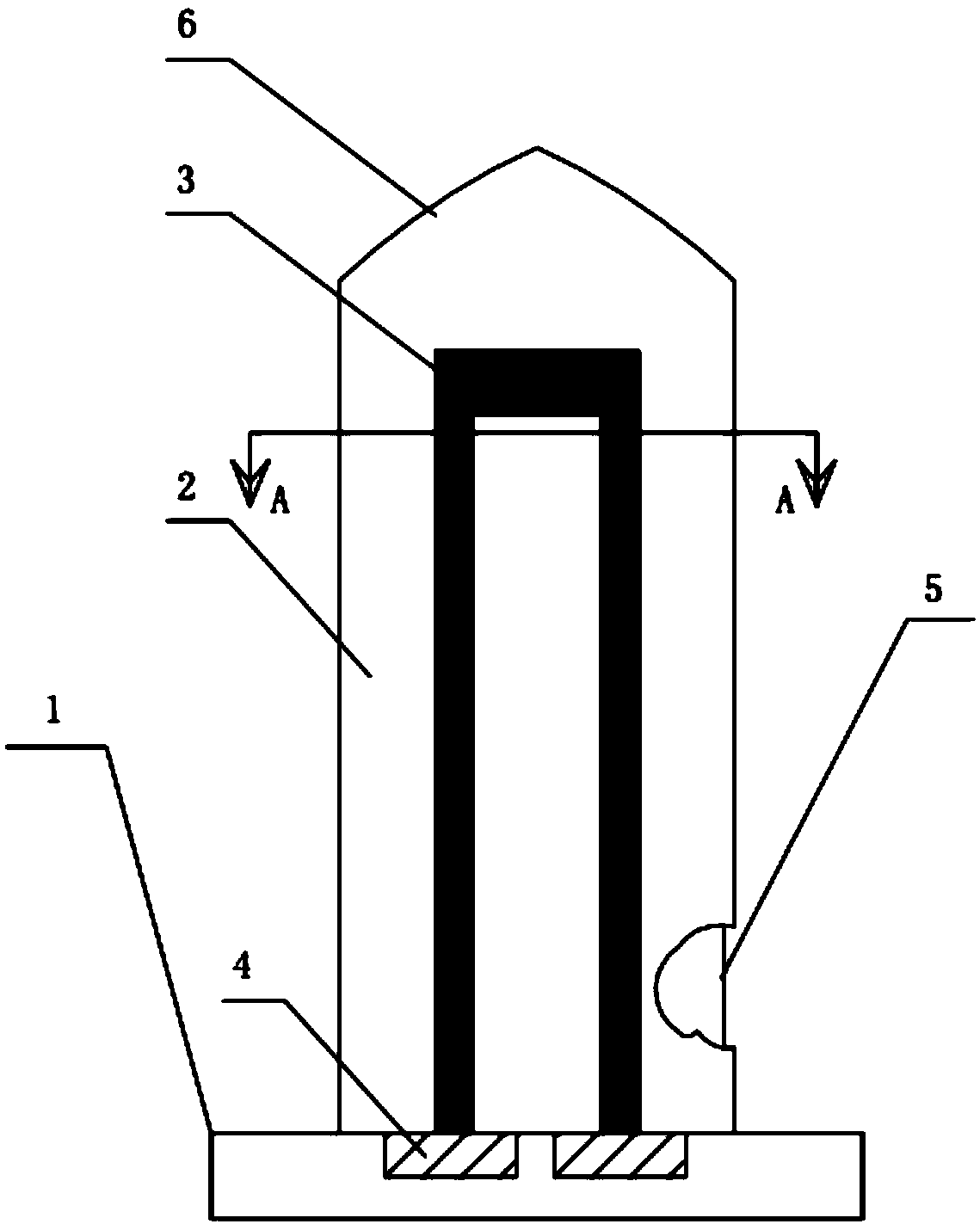

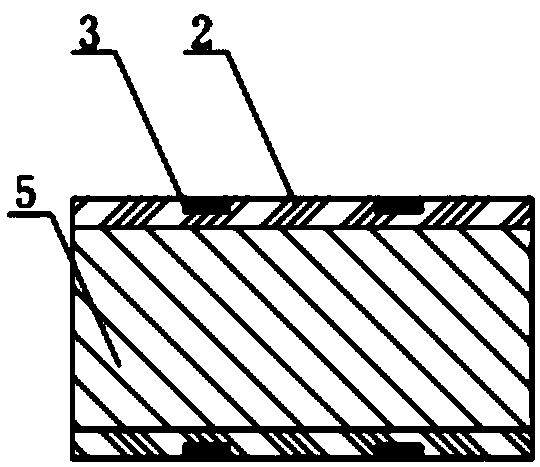

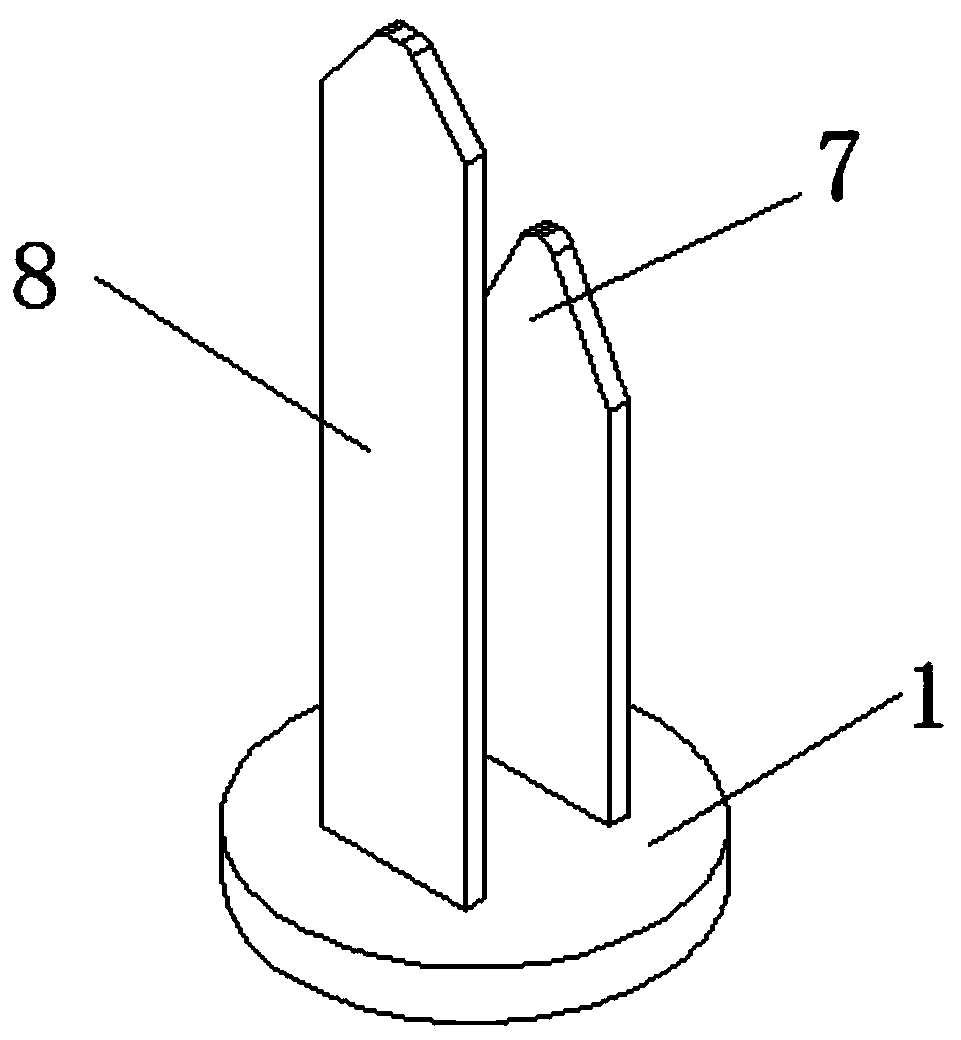

[0029] Example 2 and Example 3 such as image 3 and Figure 4 As shown, there are two heating elements in embodiment 2 such as image 3 Shown label 7 and shown in label 8 (the first heating body 7 and the second heating body 8), it is exactly a kind of heating sheet, is consistent with the heating body 6 in the embodiment 1, just according to the required shape. Variety. Such as Figure 4 Shown is the structural diagram of embodiment 3, this embodiment has adopted three heating elements 9, 10, 11 (the third heating element 9, the fourth heating element 10 and the fifth heating element 11), in the actual process according to the needs There can be multiple heating elements, which can be inserted into the cigarette to disperse the heating and make the heating more uniform. Compared with the existing technical solutions, the structure and process involved in this embodiment can greatly improve the performance of the electronic cigarette. The heating sheet belongs to the core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com