A kind of intelligent nano powder degausser and degaussing method

A nano-powder, degaussing technology, applied in the direction of magnetic objects, inductance/transformer/magnet manufacturing, circuits, etc., can solve the problem that the size of the degaussing magnetic field is not easy to control, destroy the shape of the degaussing object itself, etc., to achieve low cost, convenient control, low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

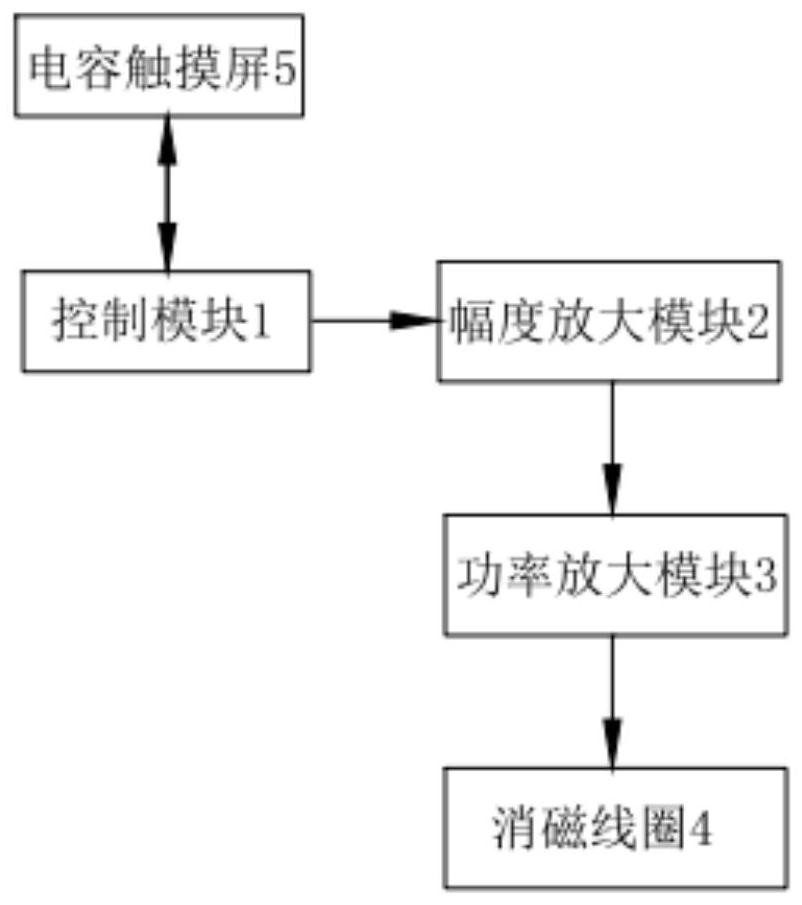

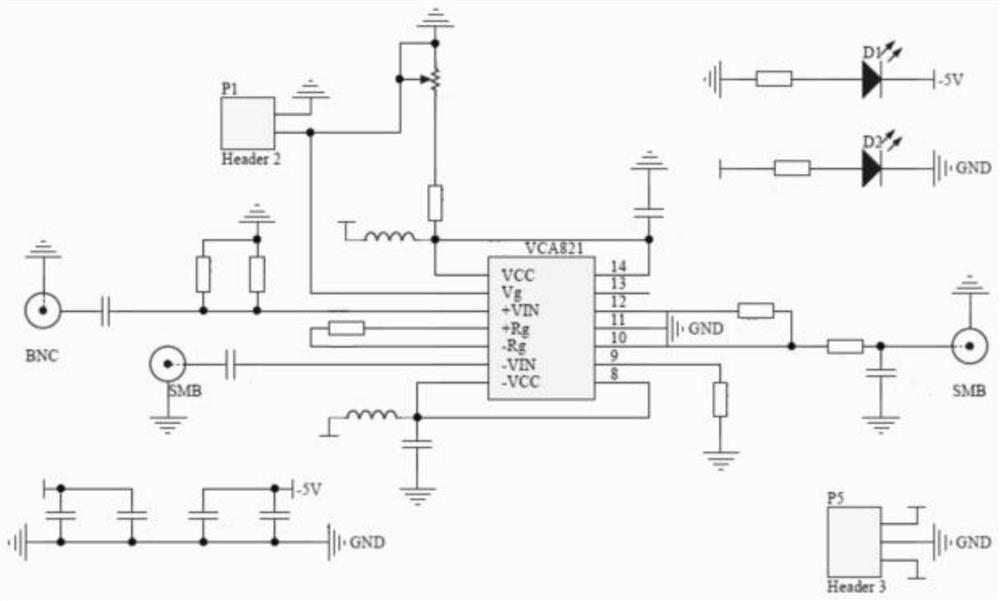

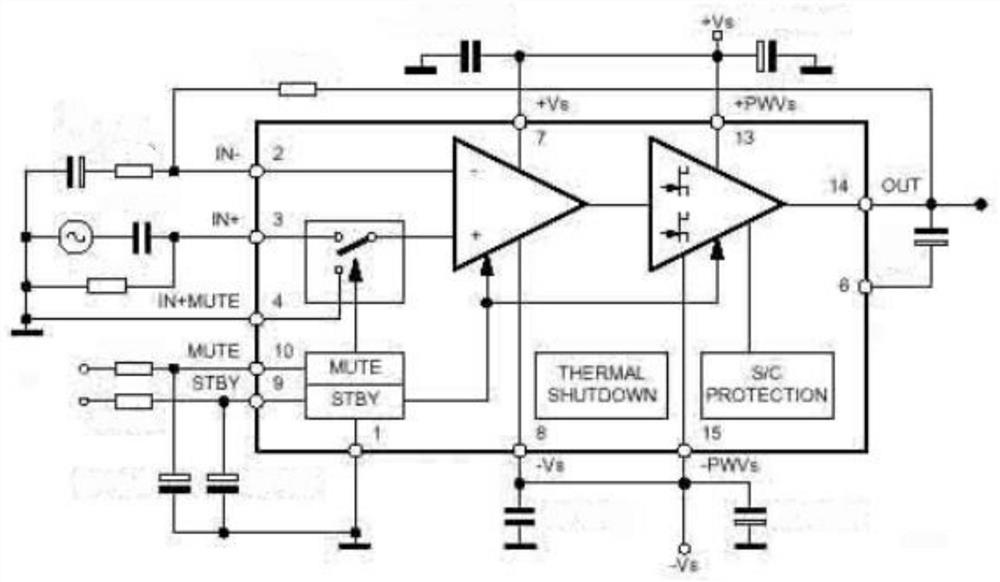

[0031] like figure 1 As shown, a kind of intelligent nano-powder degausser described in the present invention includes a control module 1, an amplitude amplification module 2, a power amplification module 3 and a degaussing coil 4; the signal output end of the control module 1 is connected to the amplitude amplification module 2 The signal input end of the amplitude amplification module 2 is connected to the signal input end of the power amplification module 3, and the power amplification module 3 is electrically connected to the degaussing coil 4.

[0032] The working principle of the present invention is as follows: the control module 1 generates a sine wave signal according to the control command, and the amplitude is amplified by the amplitude amplifying module 2 to reach a voltage amplitude sufficient to drive the power amplifying module 3 and then input it into the power amplifying module 3 . The power amplification module 3 amplifies the power of the signal, and then se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com