Spiral chute structure capable of using in combination and butt-joint

A spiral chute and docking technology, which is applied in the field of spiral chute, can solve the problem that the junction of the chute is not simple enough, and achieve the effect of convenient, concise and accurate connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

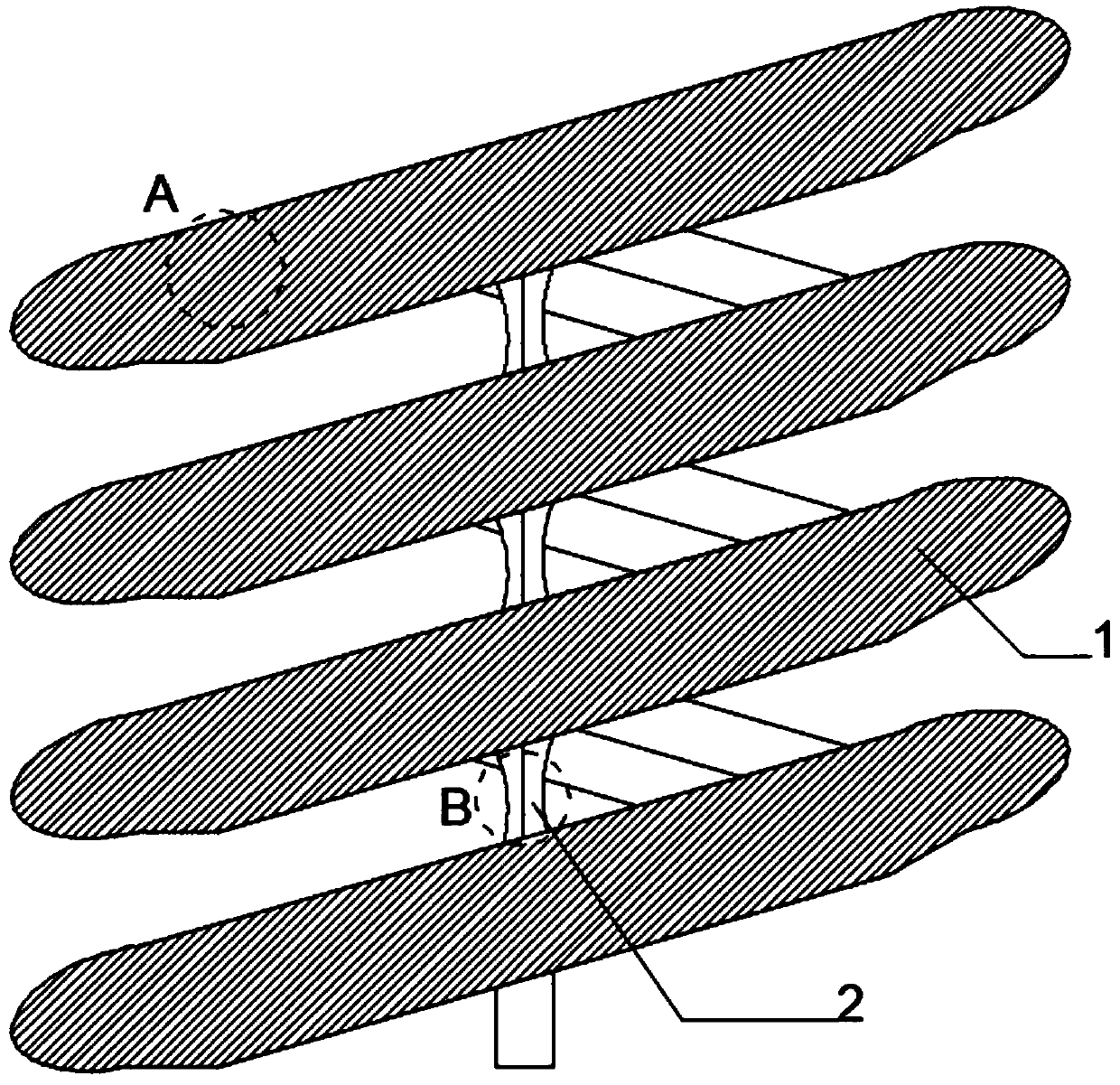

[0026] as attached figure 1 to attach Figure 5 Shown:

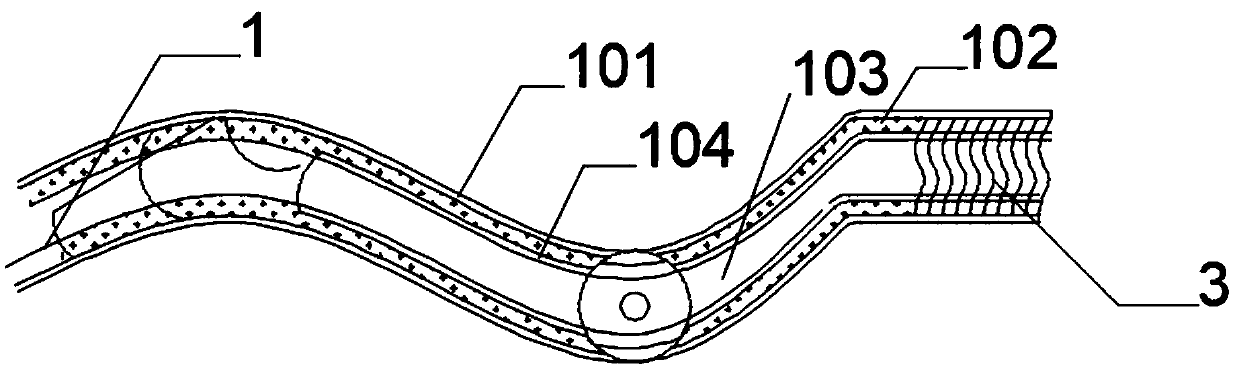

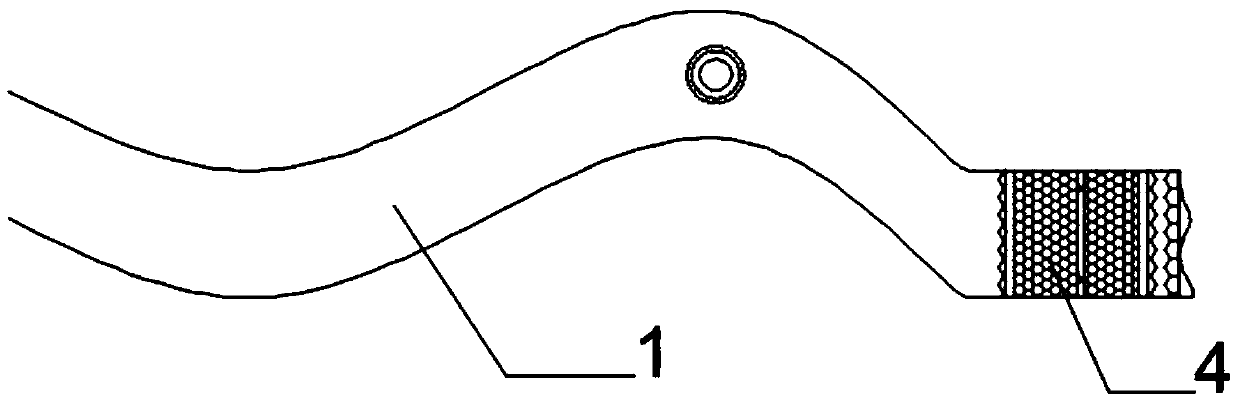

[0027] The present invention provides a spiral chute structure that can be combined and docked, including a chute body 1, a middle connecting rod 2, a curved feed port 3 and a docking chassis 4; the chute body 1 is a spiral structure, and the chute The middle section of each spiral section of the tank body 1 is open; the middle connecting rod 2 runs through the opening of the chute tank body 1, and the middle connecting rod 2 supports the entire chute tank body 1; the bottom surface of the chute tank body 1 is Double-layer structure, connected by slide rails and installed with a docking chassis 4; the opening of the chute body 1 is an S-shaped opening structure—a curved feed port 3.

[0028] Wherein, the internal surface of the chute body 1 is divided into three parts from the outside to the inside, the edge synaptic damping layer 101, the hexagonal honeycomb damping layer 102 and the center smooth layer 103; A magnet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com