Surface machining apparatus comprising a curved portion

A technology of bending parts and processing equipment, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve problems such as limiting the application range of grinding blocks, and the processing surface is not suitable for circular workpieces or grooves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

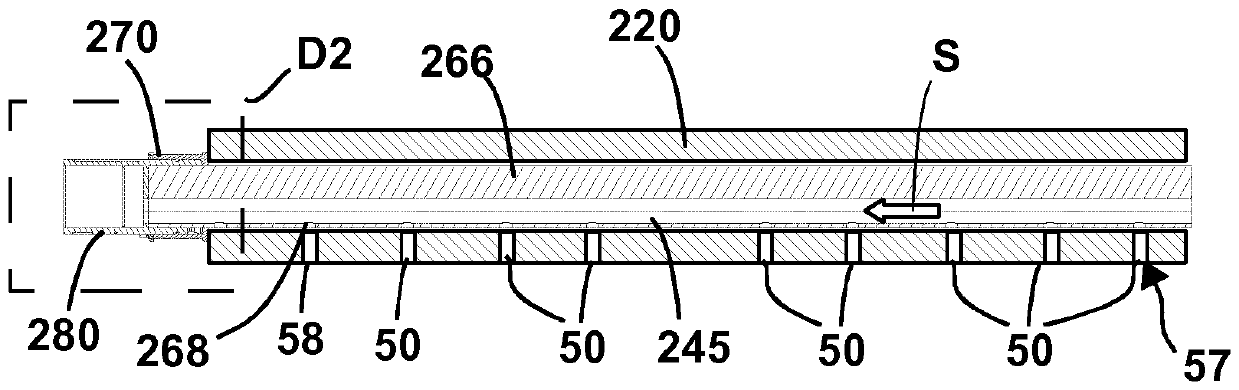

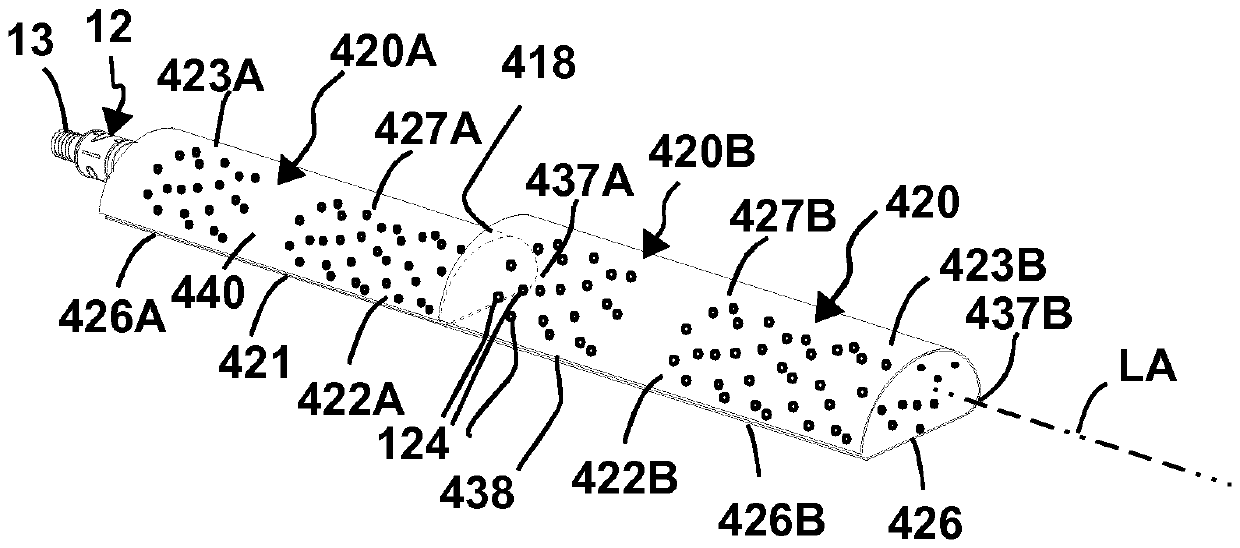

[0094] The processing apparatus 10 includes a processing body 20 at the outer periphery of which a plurality of processing surfaces 21 , 22 and 23 are provided. The schematically indicated workpiece W can be machined, for example ground and / or polished, on its workpiece surface O by means of the machining surfaces 21 - 23 . The working surfaces 21 - 23 extend on the outer circumference 24 of the per se cylindrical working body 20 . The processing body 20 has a longitudinal profile and extends along a longitudinal direction or a longitudinal axis L. As shown in FIG.

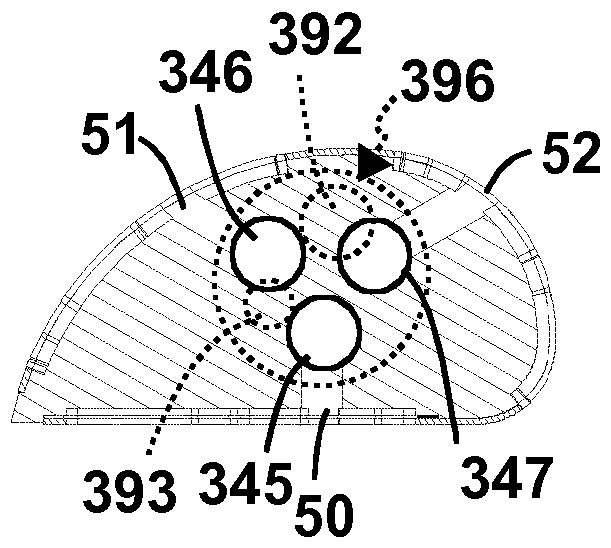

[0095] The machining surface 21 is provided as a flat surface 25 or flat surface with which a correspondingly flat workpiece surface O can be machined optimally. The working surface 21 or the planar surface 25 is arranged on a working surface part 28 , which is designed by means of the planar surface 25 as a planar surface part 26 .

[0096] In contrast, the working surfaces 22 and 23 are curved working surfaces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com