An intelligent piezoelectric single droplet generator and method thereof

An intelligent piezoelectric and generator technology, applied in the field of atomization cultivation research, can solve the problems of thick droplets and small amount of atomization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

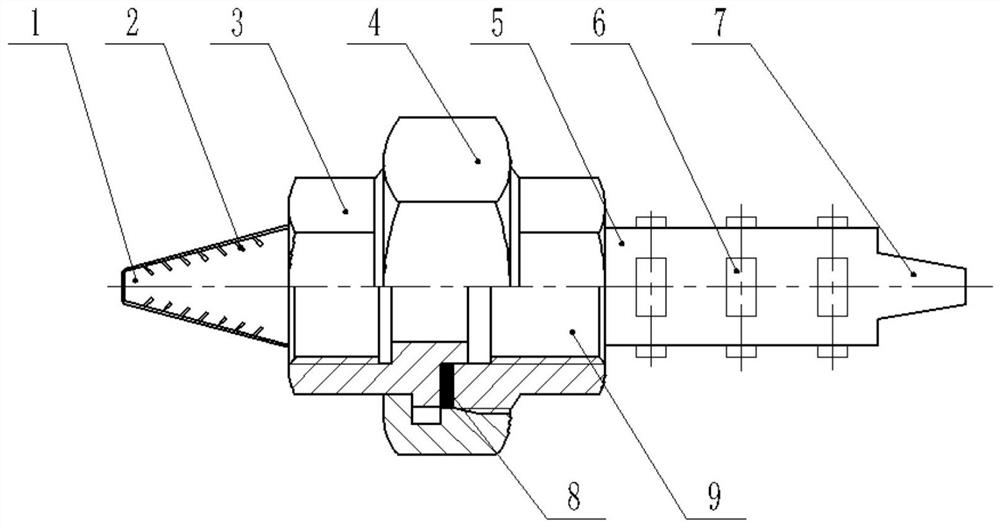

[0037] figure 1 Shown is an embodiment of the intelligent piezoelectric droplet generator of the present invention, including a one-way flow valve, a piezoelectric nozzle and a controller.

[0038] The one-way flow valve includes a valve body 1, the valve body 1 is gradually expanding, narrow on the left and wide on the right, with a water inlet on the left and a water outlet on the right.

[0039] The piezoelectric nozzle includes a cavity 5, a nozzle 7 and a piezoelectric ceramic 6; one end of the cavity 5 is detachably connected to the wide end of the valve body 1, and the other end of the cavity 5 is provided with the nozzle 7; The cavity 5 is provided with N groups of piezoelectric ceramics 6 , each group is provided with M pairs of piezoelectric ceramics 6 , M is greater than or equal to 2, and M pairs of piezoelectric ceramics 6 are evenly distributed along the circumference of the cavity 5 .

[0040] The controllers are respectively connected to the drivers of the pie...

Embodiment 2

[0050] A control method for the intelligent piezoelectric droplet generator described in embodiment 1, comprising the following steps:

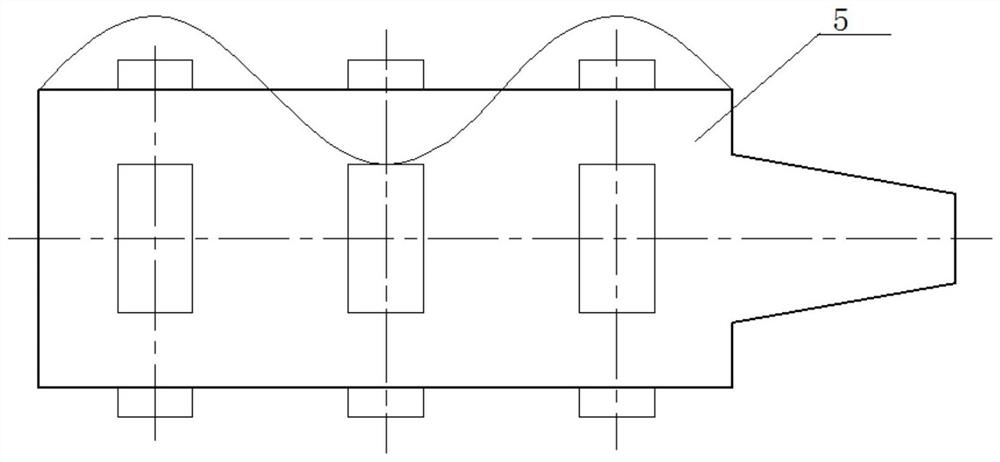

[0051] Such as figure 2 As shown, the controller controls the vibration of multiple piezoelectric ceramics 6 to form a sinusoidal curve on the cavity 5 to control the flow of liquid to form a single droplet;

[0052] The controller controls the amplitude of a plurality of piezoelectric ceramics 6, cosine waves are generated by the piezoelectric ceramics 6, and multiple peaks and troughs cause the internal pressure of the cavity 5 to change, and the vacuum degree caused by the piezoelectric vibration at the nozzle 7 is adjusted to control The size of the resulting droplet volume.

[0053] The controller controls the duty cycle of the plurality of piezoelectric ceramics 6 to change the vibration speed of the piezoelectric ceramics 6, thereby changing the velocity of the liquid droplets extruded by the piezoelectric nozzle.

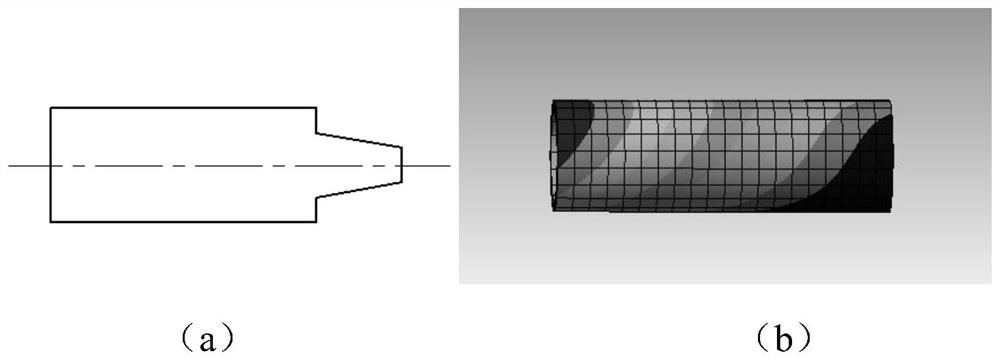

[0054] Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com