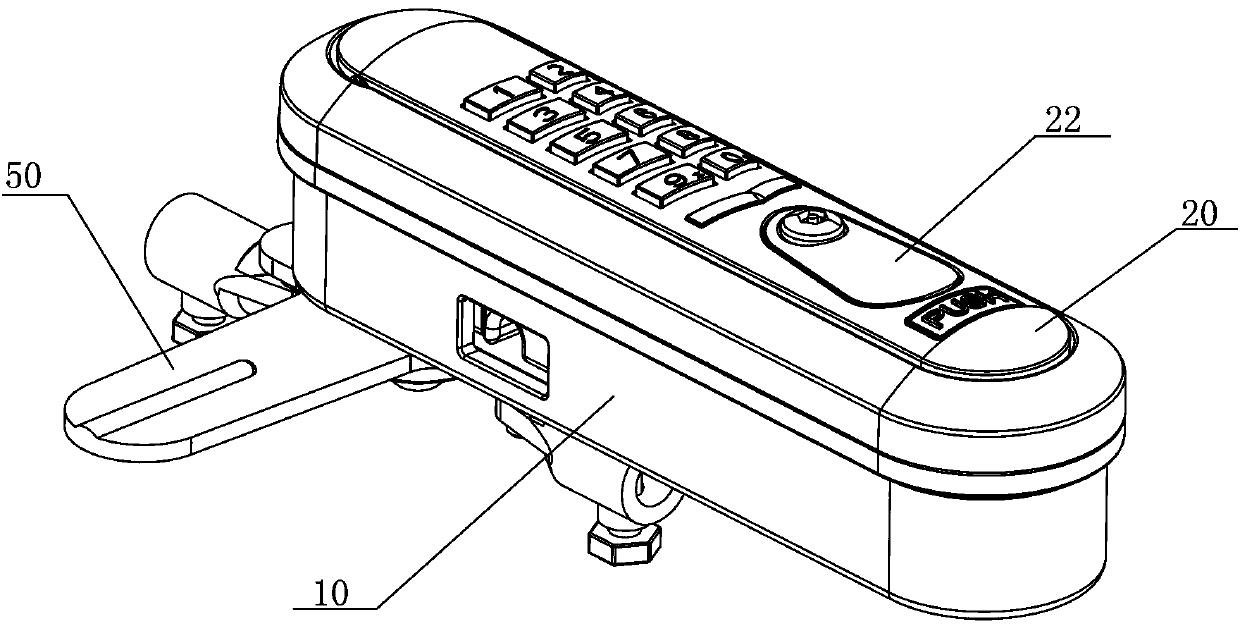

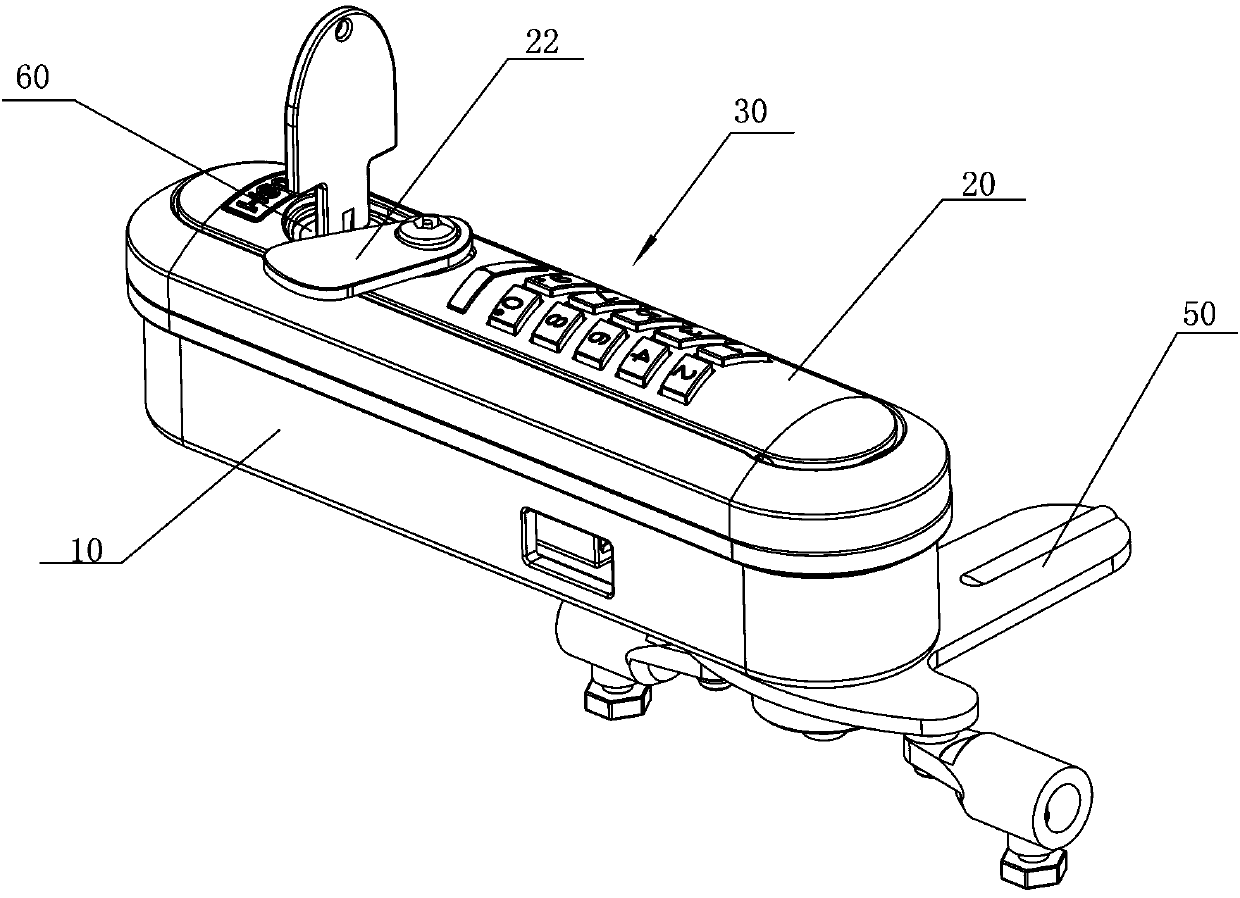

Equipment cabinet lock for preventing vibration retraction

A cabinet and mechanical lock cylinder technology, applied in the field of cabinet door locks, can solve problems such as unsecured safety, and achieve the effect of ensuring safety and ensuring normal work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

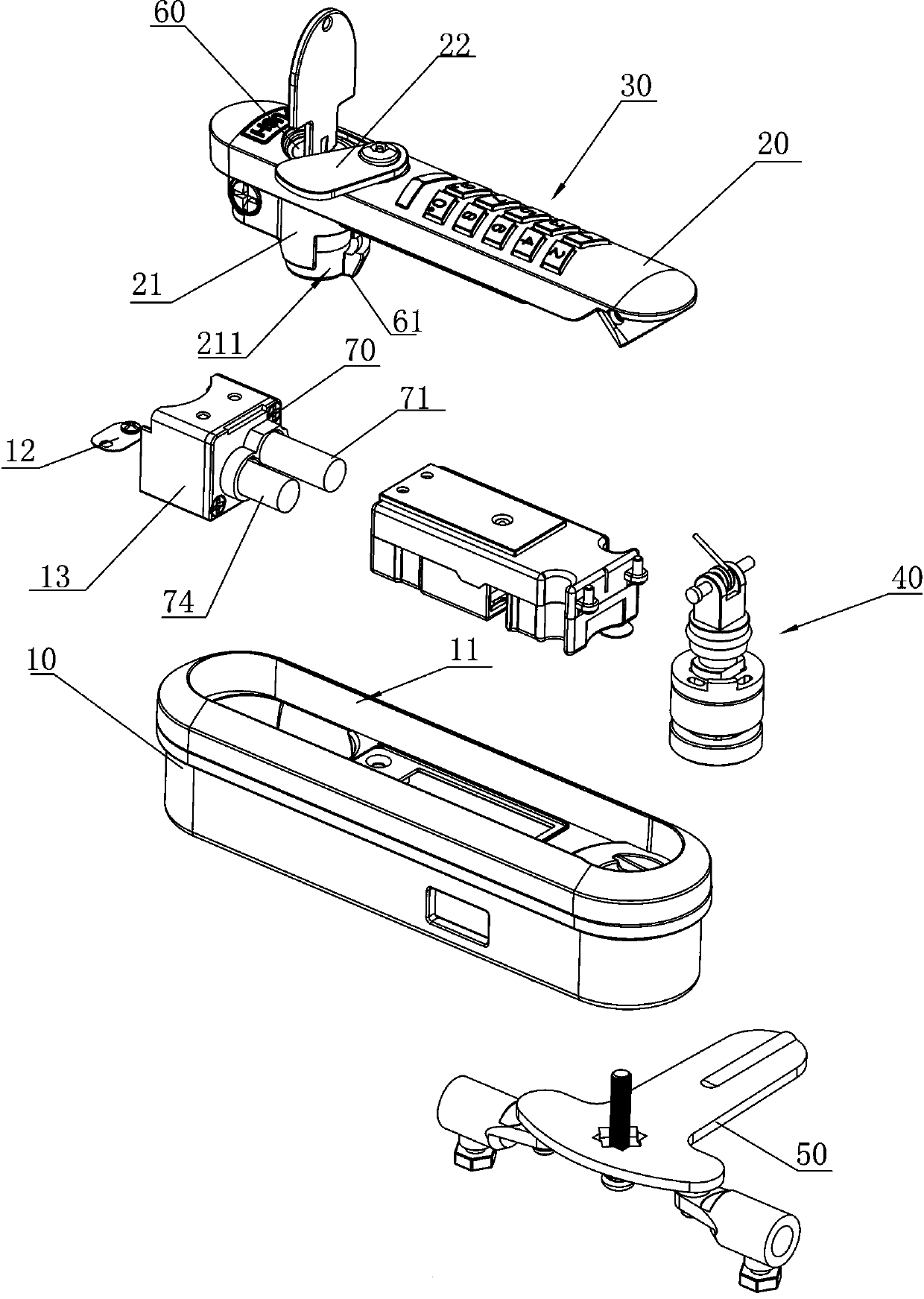

[0039] The back side of the handle 20 is provided with a housing 21, and the housing 21 is also provided with an opening 211 for the mechanical locking hook 612 to protrude, so that when the mechanical lock is unlocked, the entire mechanical locking hook 612 can only be locked within the area of the opening 211. Turn inside. As a preferred implementation manner, the mechanical lock cylinder 60 can drive the mechanical lock hook 612 to rotate 40 degrees in the opening 211 .

[0040] Such as Figure 4 and Figure 19 As shown, the electromagnetic assembly 70 also includes an anti-key lock pin 73 for preventing the lock cylinder dial 61 from being separated from the lock pin 72 when the mechanical lock cylinder 60 drives the lock cylinder dial 61 to rotate, and is used to control the anti-key lock. Anti-key electromagnet 74 of pin, fixed seat 13 is provided with the second hole for anti-key lock pin 73 to insert, after whole cabinet locks power-on work, under normal communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com