Automatic sucking closing mechanism for automobile door lock

A pull-in mechanism, a technology for car door locks, applied in vehicle locks, lock applications, special locking actions, etc., can solve problems such as inconvenience in comfort, high production costs, and high requirements for coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

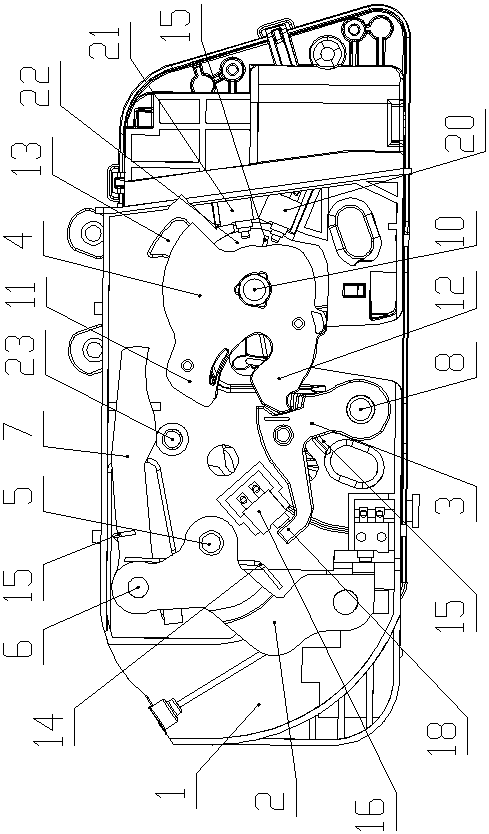

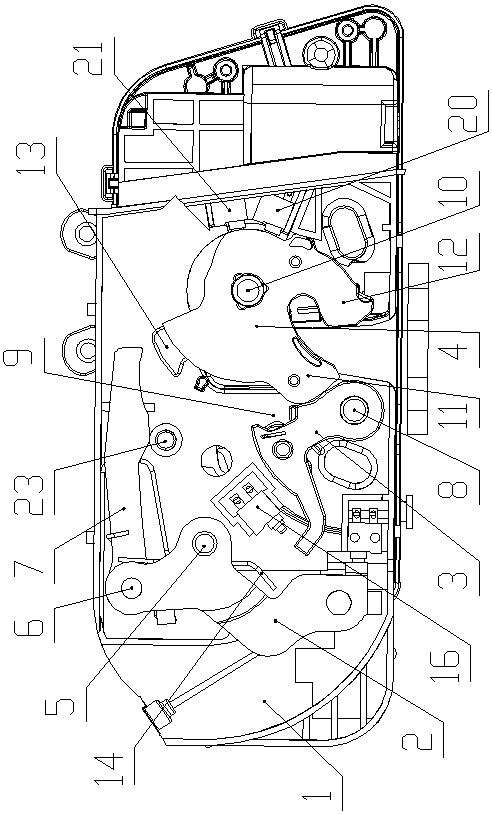

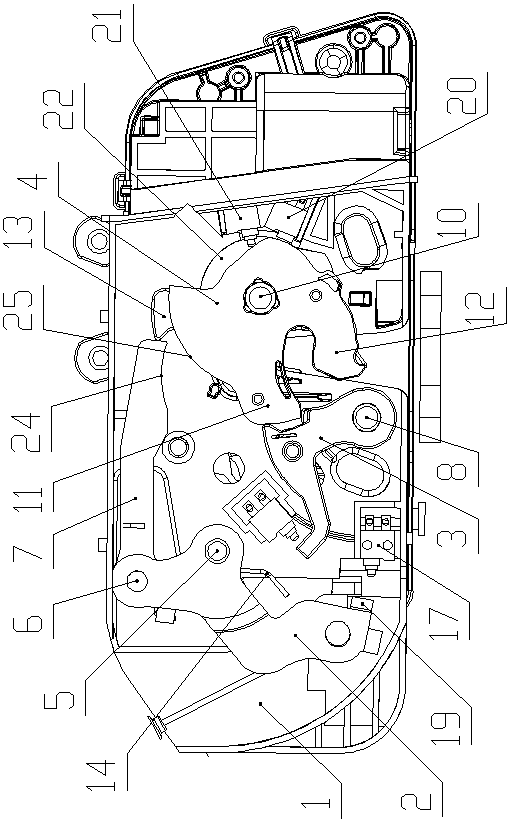

[0020] Such as Figure 1-4 As shown, an automatic suction mechanism for automobile door locks of the present invention includes a housing 1, a drag arm 2, a stop pawl 3 and a clamp 4 are arranged in the case 1, and the stop pawl 3 is located at the drag Between the moving arm 2 and the clamping plate 4, the middle part of the dragging arm 2 is rotatably connected in the housing 1 through the connecting shaft 5, the upper part of the dragging arm 2 is rotatably connected with the drag conversion arm 7 through the hinge shaft 6, and the lower part of the stop pawl 3 It is connected in the housing 1 through the rotation of the intermediate shaft 8. The stop pawl 3 is provided with a slot 9 facing the side of the clamping plate 4. The clamping plate 4 is connected in the housing 1 through the rotating shaft 10. The sides of the clamping plate 4 are fixedly connected at intervals. There are a first clamping head 11 and a second clamping head 12, the side of the clamping plate 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com