A test loading device for a cable-stayed bridge spanning cables and its assembly method

A technology of loading device and loading beam, which is applied in the direction of measuring device, application of repeated force/pulsation force to test material strength, instrument, etc., can solve the problem of lack of headroom, etc., and achieve the effect of ensuring lateral stability and facilitating intuitive observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

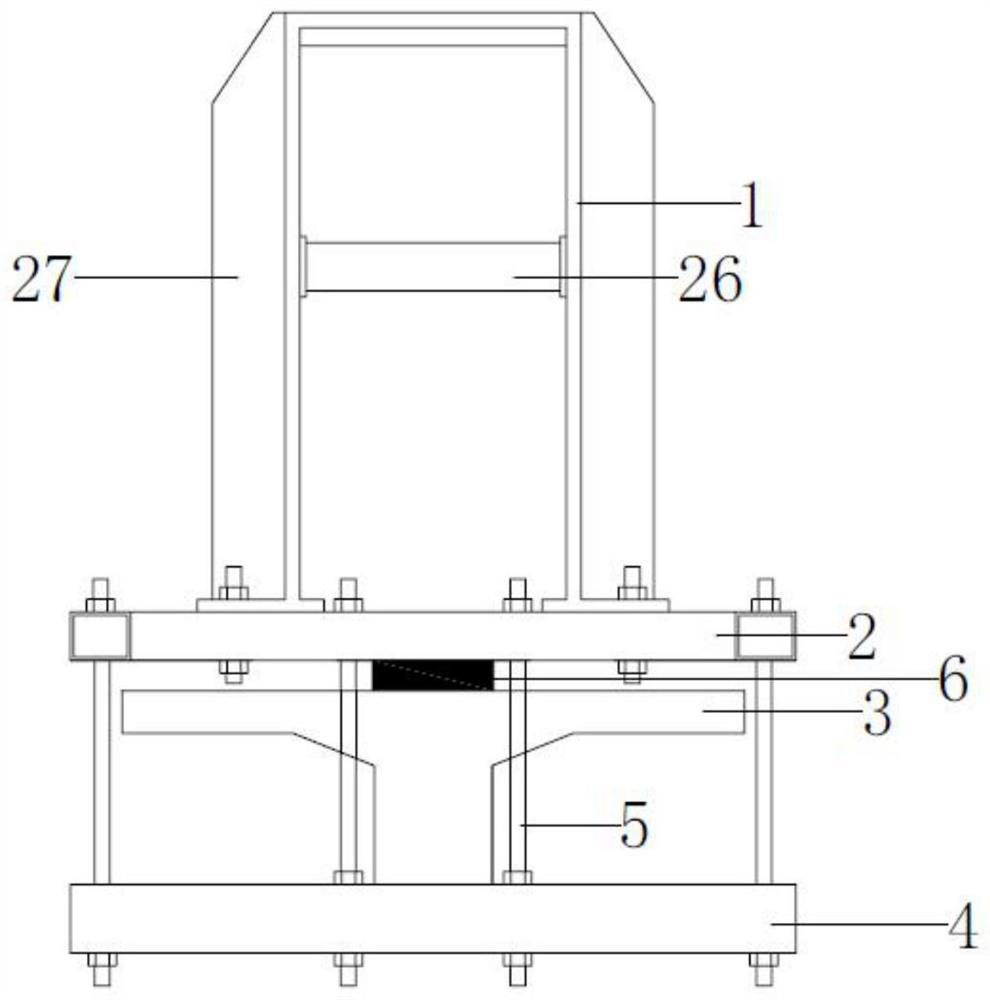

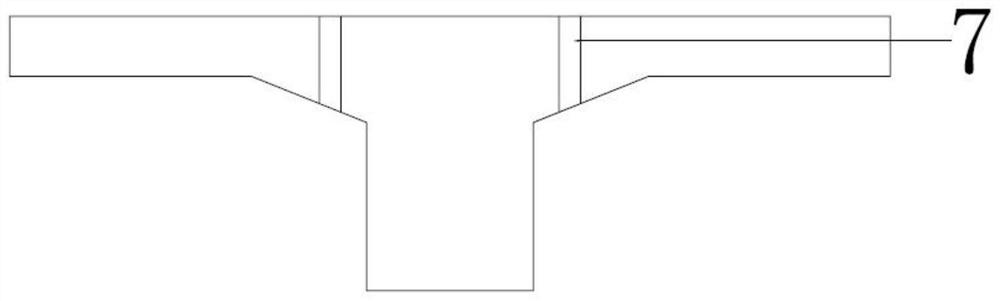

[0038] combine Figure 1-7 , this embodiment proposes a test loading device for a cable-stayed bridge, including a force transmission frame 1, a loading beam 2, a steel beam 4, a main beam 3 and a support 6; the force transmission frame 1 is connected to the loading beam 2 and located Above the beam 2 , the loading beam 2 is connected to the steel beam 4 , the main beam 3 is located below the loading beam 2 and set on the steel beam 4 , and the support 6 is clamped between the main beam 3 and the loading beam 2 .

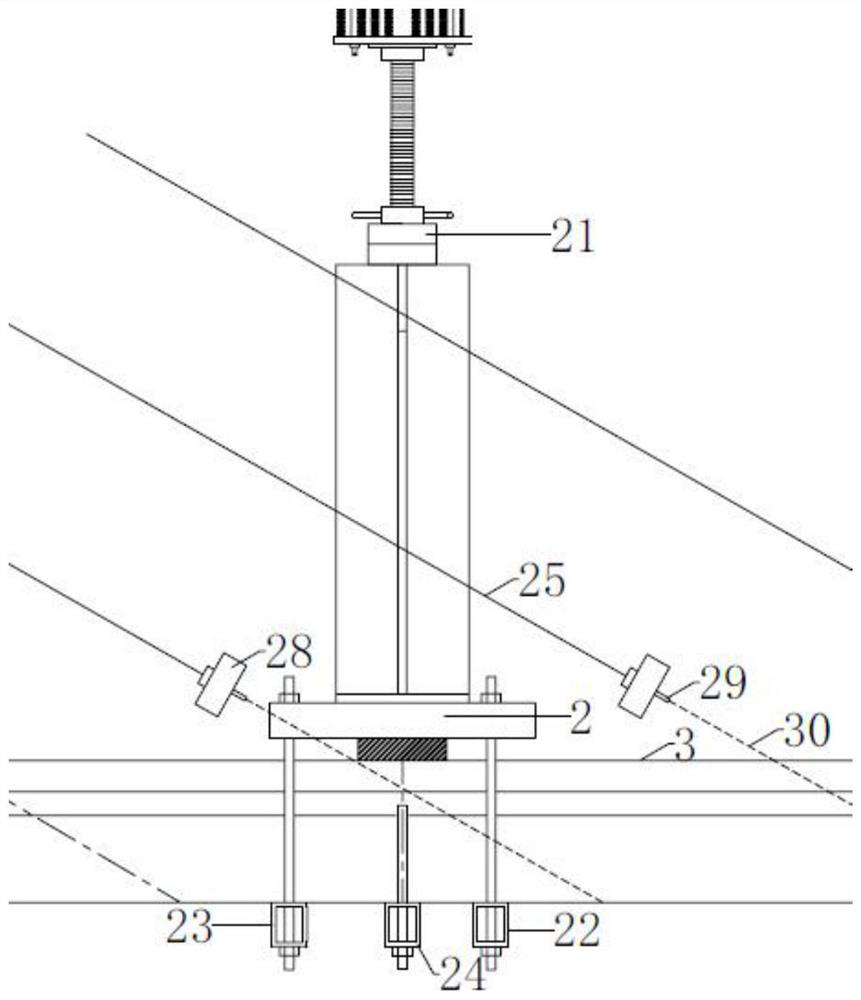

[0039] It should be noted that one end of the cable stay cable 25 in the test loading device of the span cable-stayed bridge in this embodiment is fixedly connected by the anchor plate 28 and the anchorage 29, and one end of the embedded anchor rod 30 is connected with the anchor plate 28, The other end is anchored on the main beam, the stay cables 25 are located in the middle of the main beam 3, the force transmission frame is a hollow structure, and the force tran...

Embodiment 2

[0058] combine Figure 8 , The difference between the test loading device of the span cable-stayed bridge of this embodiment and the above-mentioned embodiment is that: the upper end of the top plate is provided with a reinforcing plate 31, and the actuator, the reinforcing plate 31 and the top plate 8 are anchored and connected together. This structure can enhance the overall stability and make the connection with the actuator more stable.

[0059] A first frame 32 is provided around the reinforcing plate 31, and a first beam 33 and a first longitudinal beam 34 are provided at the bottom of the reinforcing plate 31, and the first transverse beam 33 and the first longitudinal beam 34 are perpendicular to each other. . The first beam and the first longitudinal beam reinforce the strength of the reinforcing plate.

[0060] Further, in this embodiment, the surrounding of the loading beam 2 is provided with a second frame 35, and the bottom of the loading beam 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com