Flue easy to install

A flue and pipe technology, applied in the field of flue that is easy to install, can solve the problems of wasting raw materials, occupying residential space, increasing the weight of the flue, etc., and achieves the effect of preventing backflow of flue gas and smooth discharge of flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

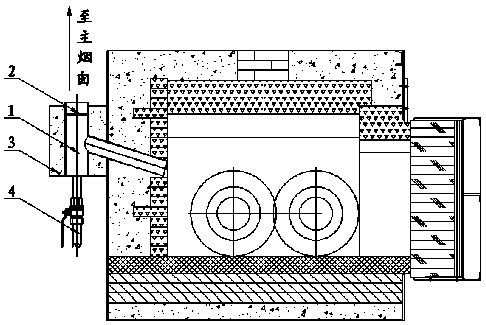

[0009] An easy-to-install flue, which is composed of a T-shaped stainless steel barrel 1, a manual butterfly valve 2, an insulating castable 3, and a cold air inlet pipe 4. It is characterized in that one end of the T-shaped pipe rises into the furnace, and the other two sections are respectively Connect the cold air pipe and the main chimney, and adjust the manual butterfly valve 2 to the best angle to obtain the best furnace pressure effect. One end of the T-shaped pipe is fed with cold air, the flow rate is increased to reduce the temperature of the pipe, and the heat-insulating castable is wrapped outside the pipe to further reduce the temperature rise of the outer wall. The length of the flue pipe is two-thirds of the sum of the floor height and the floor thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com