Flue gas treatment and exhausting device based on dynamic seal design

An exhaust device and flue gas treatment technology, which is applied in the directions of combination device, dispersed particle separation, chemical instruments and methods, etc. The effect of gas backflow, prolonging service life and avoiding flue gas backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

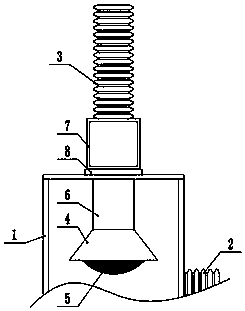

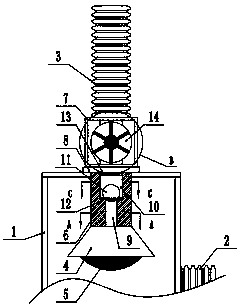

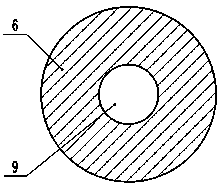

[0027] see Figure 1-6 , a flue gas treatment and exhaust device based on a dynamic sealing design, including a device body, the device body is provided with a treatment chamber 1, and the side of the treatment chamber 1 is provided with a flue gas inlet pipe 2, and the flue gas inlet pipe 2 is connected to the The inside of the processing chamber 1 communicates with each other, the inside of the processing chamber 1 is provided with a smoke guide hood 4, the bottom of the described smoke guide 4 is provided with a filter screen 5, and the effect of the screw between the filter screen 5 and the smoke guide 4 Fixedly connected, the top of the smoke hood 4 is provided with an anti-backflow mechanism 6, the anti-backflow mechanism 6 is welded to the smoke hood 4, the anti-backflow mechanism 6 is connected to the top of the processing chamber 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com