A new type of orchard operating platform leveling device

A work platform and leveling device technology, applied in agriculture, the chassis of agricultural machinery, agricultural machinery and machinery and other directions, can solve problems such as poor adaptability, overturning danger, and tilting of the platform's center of gravity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

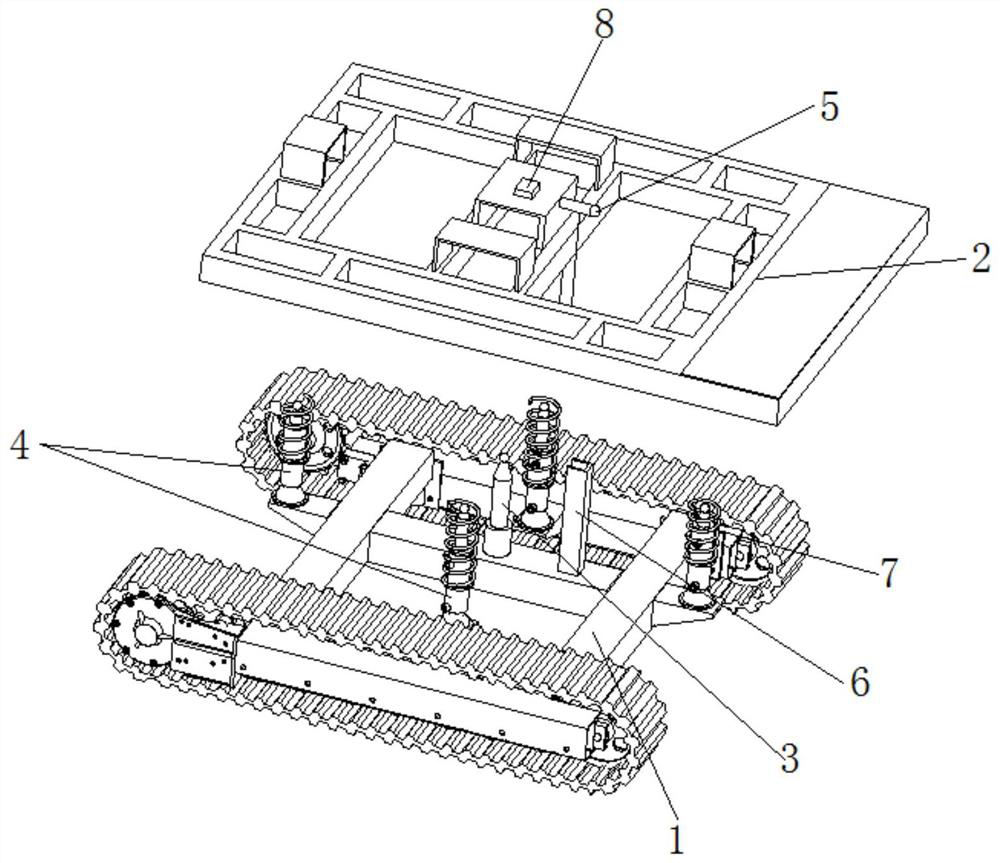

[0029] Such as figure 1 , 5 , 6 and 7, a novel orchard work platform leveling device includes a walking chassis 1. In this embodiment, the walking chassis 1 is set to a crawler-type walking chassis. Except for this embodiment, the walking chassis 1 can also be set as Wheeled walking chassis, a platform bracket 2 is arranged above the walking chassis 1, and the platform bracket 2 is connected with the walking chassis 1 through a support column 3 and four leveling oil cylinders 4.

[0030] Specifically, the support column 3 is arranged in the middle of the walking chassis 1, the lower end of the support column 3 is welded on the walking chassis 1, the upper end of the support column 3 is hinged on the platform bracket 2 through a ball joint, and the ball joint is welded to the support column 3. On the top, the ball seat is connected to the platform bracket 2 by bolts, and the four leveling cylinders 4 are respectively arranged on the front, back, left, and right sides of the su...

Embodiment 2

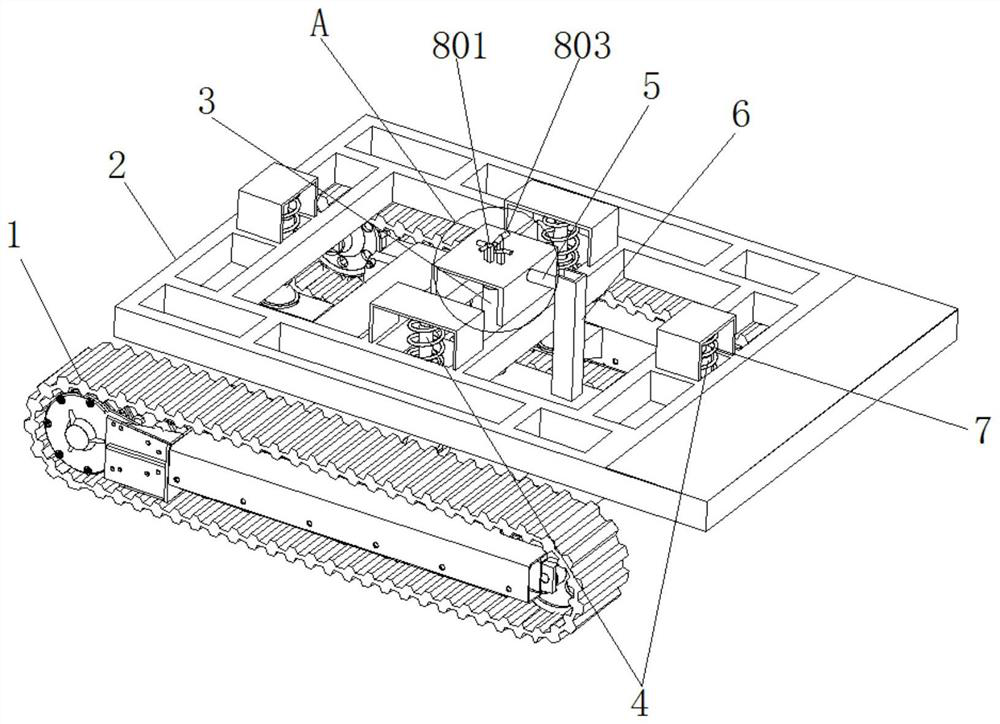

[0037] Such as Figures 2 to 7 As shown, a new orchard operation platform leveling device includes a walking chassis 1, the walking chassis 1 is set as a crawler-type walking chassis, a platform bracket 2 is arranged above the walking chassis 1, and the platform bracket 2 and the walking chassis 1 pass through a Support column 3 is connected with four leveling oil cylinders 4, and scissor lift frame 9 is installed on platform bracket 2, and work platform 10 is installed on the upper end of scissor lift frame 9, orchard staff can stand on work platform 10 to Orchard management work such as flower thinning, pruning, and picking of fruit trees. In this embodiment, the specific connection and installation methods of the components are the same as those in the embodiment, and will not be repeated here.

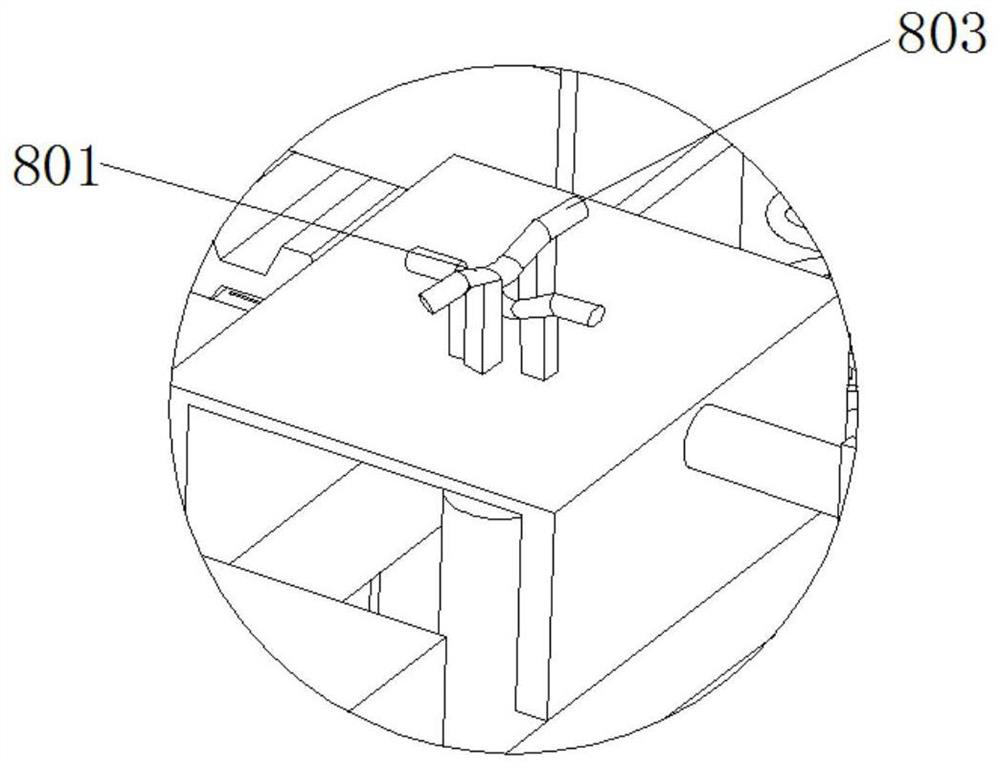

[0038]The difference is that in this embodiment, the leveling sensor 8 is set as a double-slide sensor, and the double-slide sensor includes two leveling tracks 801, and the two l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com