Automatic mounting process for high-molecular sealing gasket

An automatic installation and sealing gasket technology, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve the problems that the gasket installation cannot be guaranteed, and the descending speed cannot be well controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

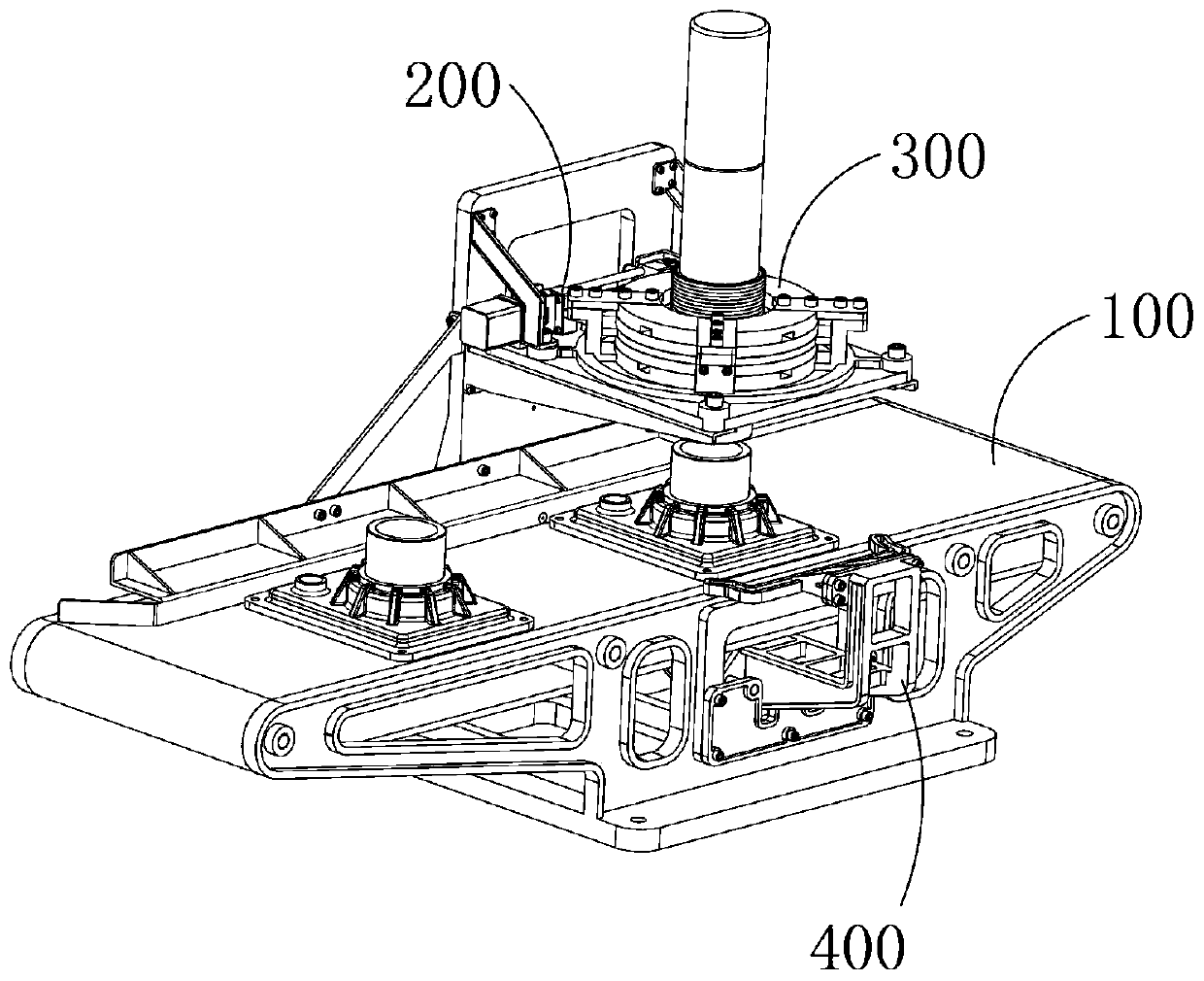

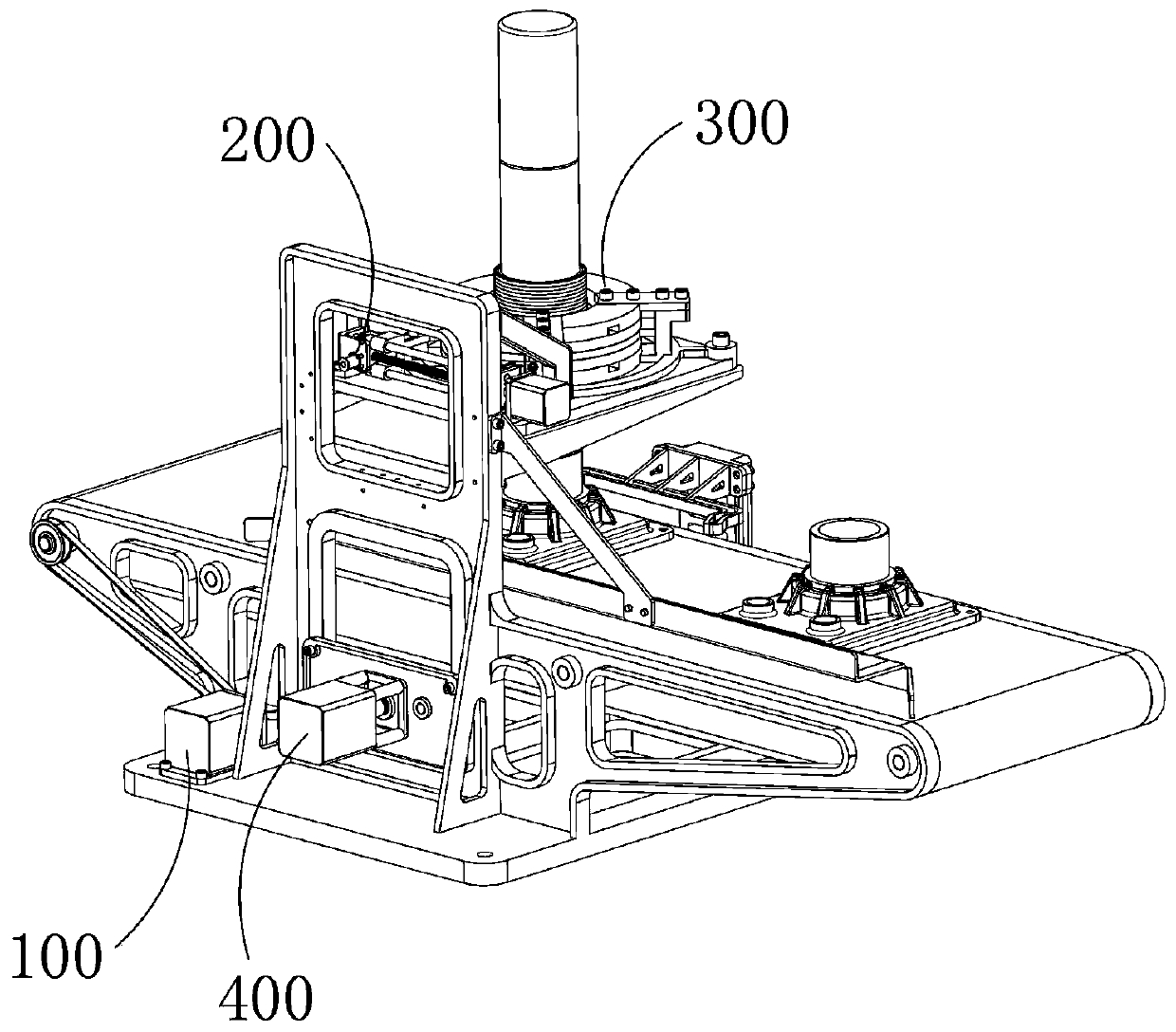

[0083] The automatic installation process of the polymer sealing gasket, the steps are:

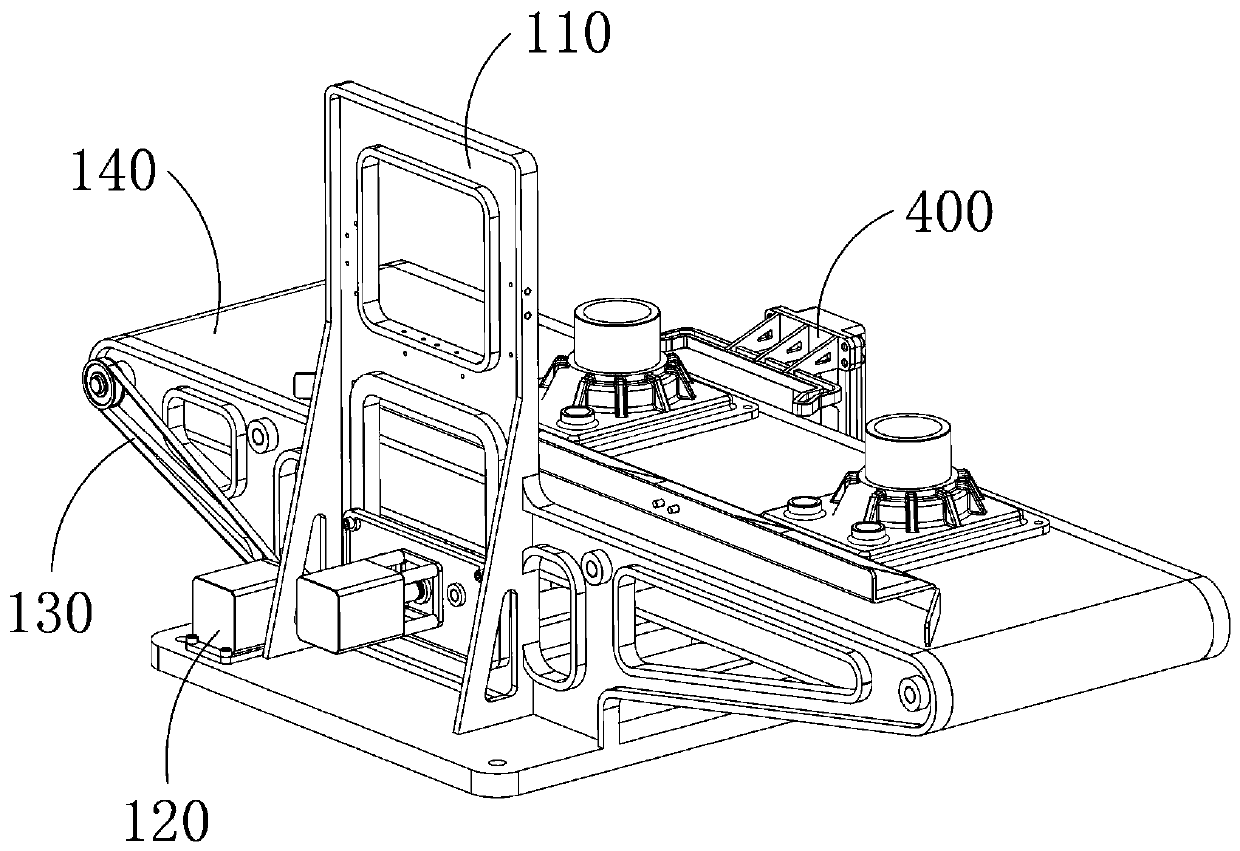

[0084] S1: the conveying device 100 operates and conveys the object to be installed with gaskets directly below the gasket installation device 300;

[0085] The conveying device 100 includes a mounting frame body 110 installed on the ground, a conveying mechanism 140 for conveying gasket objects to be installed, a conveying motor 120 for providing conveying power for the conveying mechanism 140, and a conveying motor 120 for receiving conveying power. And transmit it to the power transmission mechanism 130 of the conveying mechanism 140;

[0086] The conveying motor 120 runs and the conveying mechanism 140 conveys the object to be installed with the gasket to the right below the gasket installation device 300 through the power transmission mechanism 130;

[0087] S2: the driving device 200 runs and drives the washer installation device 300 to make the washer fall;

[0088] The gasket in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com