Automatic assembly process of elastic sealing ring

An elastic sealing and assembly process technology, applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as low efficiency, increased assembly cost, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

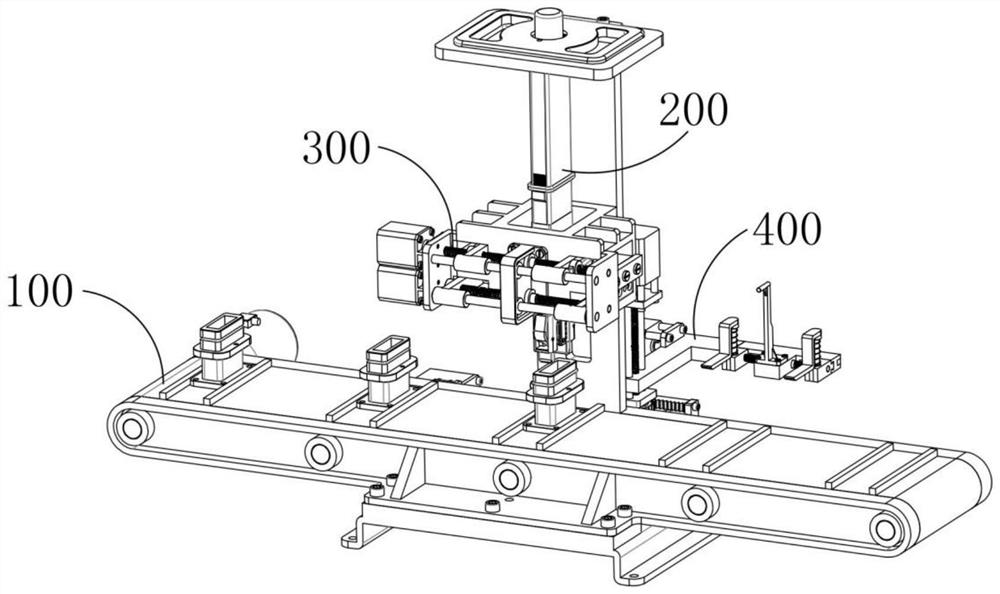

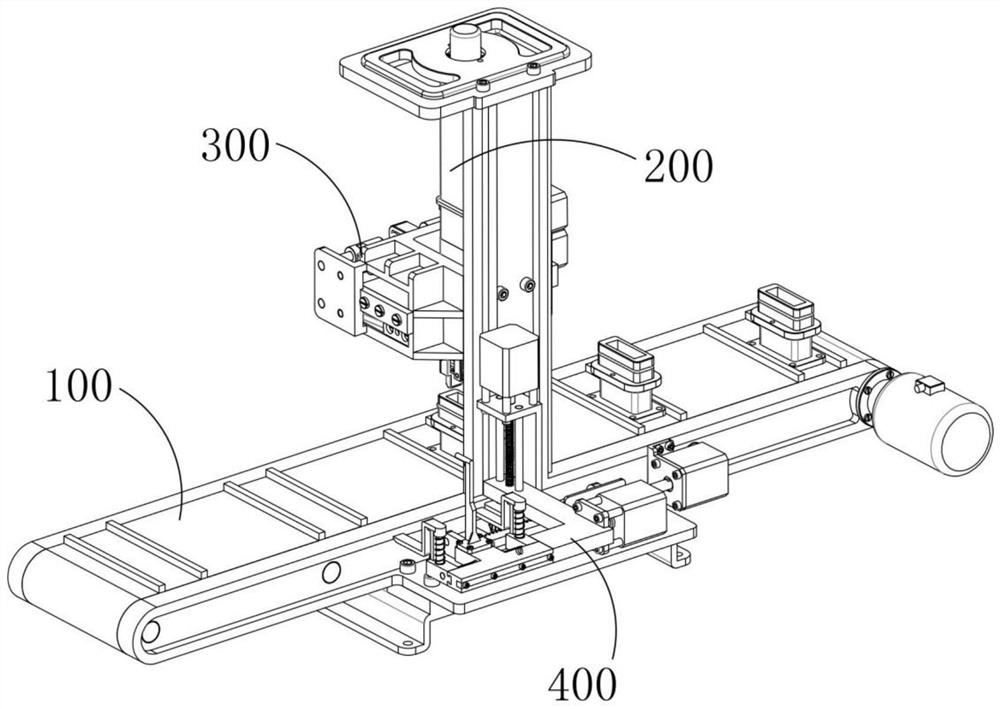

[0104] The automatic assembly process of the elastic sealing ring, the steps are:

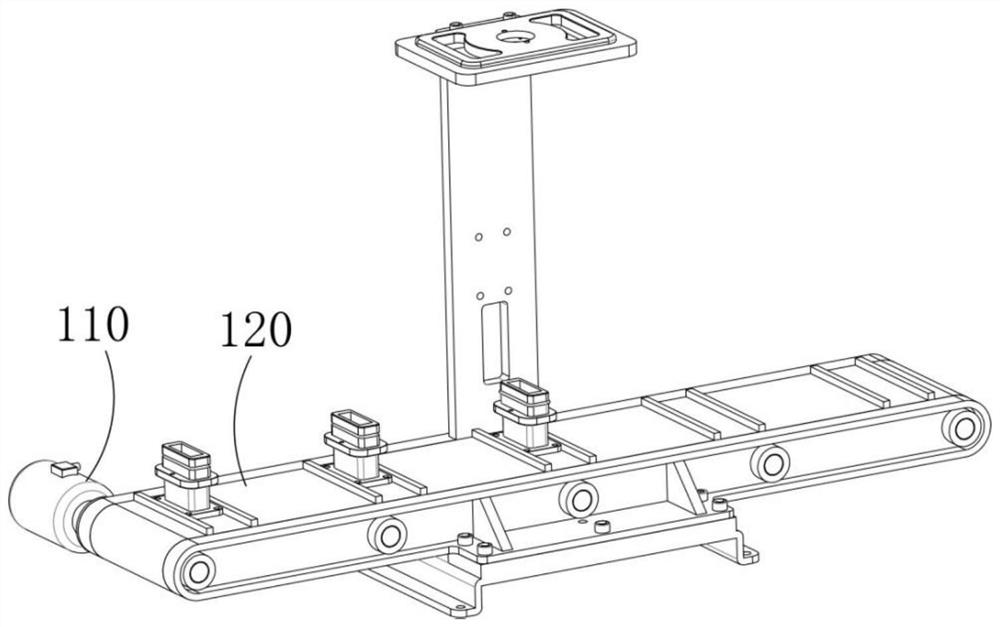

[0105] S1: The conveying device 100 installed on the mounting frame runs and conveys the object to the right below the releasing device 200 / layer-by-layer guiding device 300;

[0106] S2: the release device 200 releases the sealing ring in a single-group release manner;

[0107] The release device 200 includes a guide post 210, a power mechanism 220, and a single-set release mechanism 230. The sealing ring is sleeved outside the guide post 210. The single-set release mechanism 230 is used to automatically release the seal ring set outside the guide post 210 and Only one group is released each time, and the power mechanism 220 is used to provide power for the operation of the single group release mechanism 230;

[0108] The single-group release mechanism 230 is arranged in the guide column 210, and the single-group release mechanism 230 includes a limiting rod 232 and a supporting rod 233, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com