Process for assembling sealing gasket by adopting layer-by-layer falling mode

A sealing gasket, layer-by-layer technology, applied in the field of parts installation, can solve the problems of not being able to ensure that the gasket is installed in the corresponding station, and can not control the falling speed well, so as to achieve a smooth and smooth dropping process, a smooth and smooth placement process, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

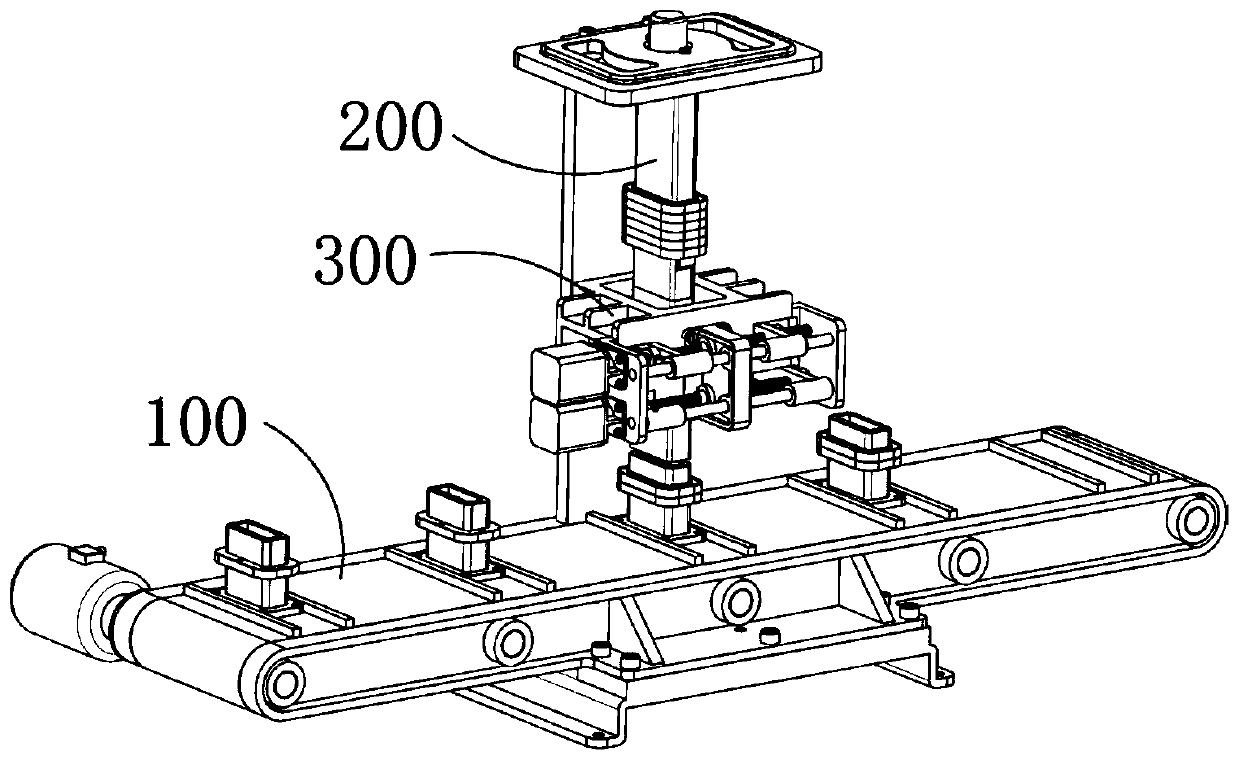

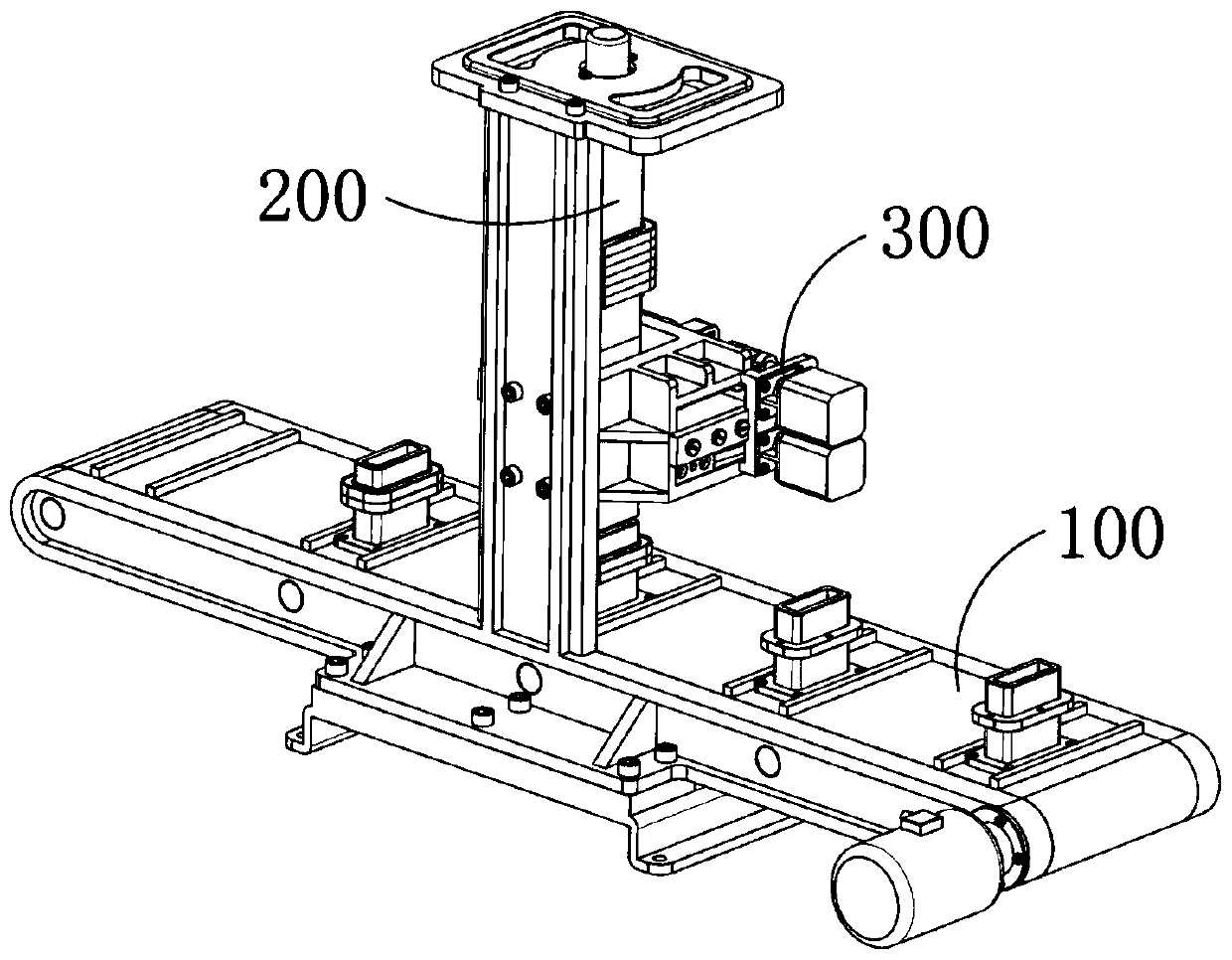

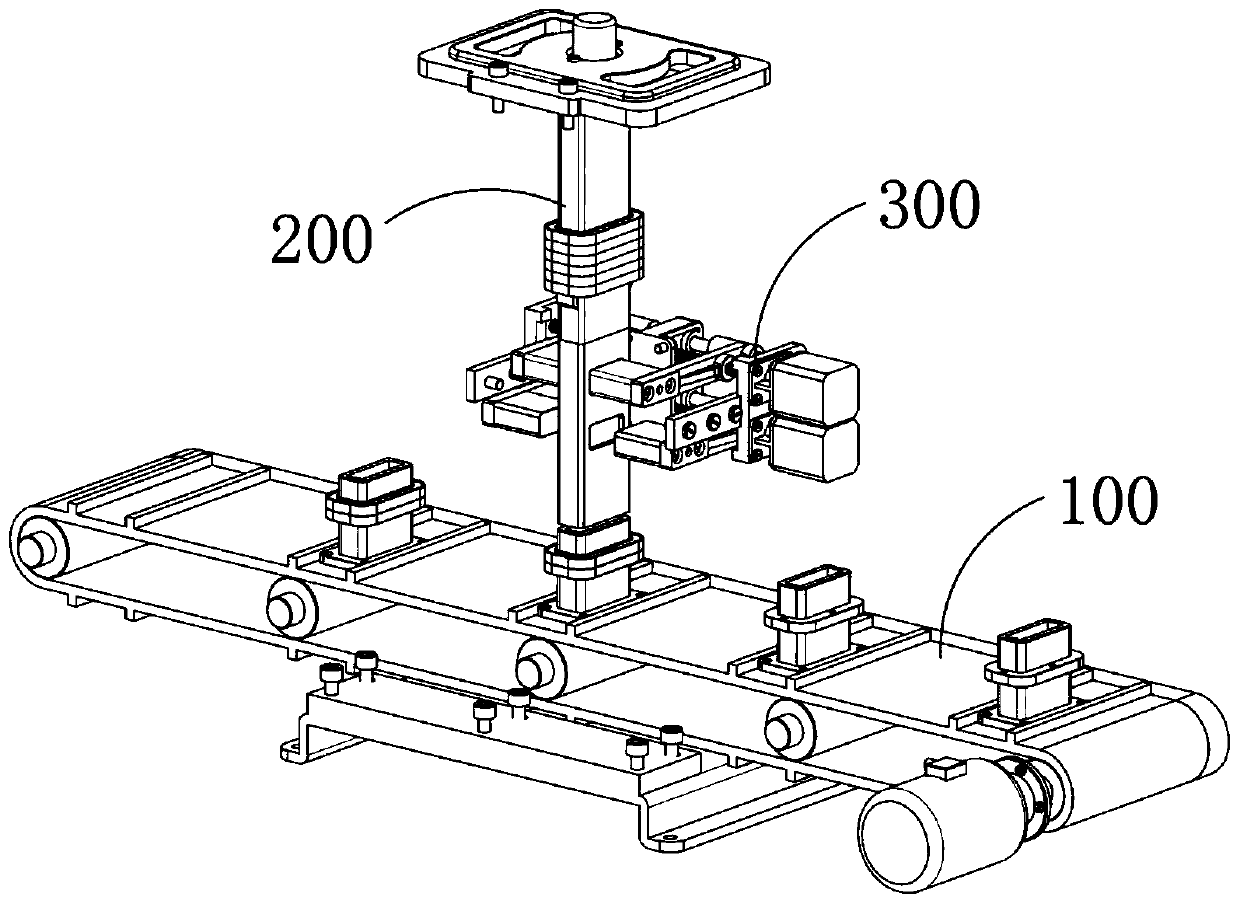

[0061] The process of assembling the sealing gasket by layer-by-layer dropping method is as follows:

[0062] S1: the transportation device 100 operates and transports the objects directly below the automatic feeding device 200;

[0063] S2: the automatic feeding device 200 runs and releases the coil parts;

[0064] The automatic feeding device 200 includes a driving mechanism 210 and a feeding mechanism 220. The feeding mechanism 220 includes a placement column 221 and a feeding member. The placement column 221 is fixedly installed on the mounting frame body and is located directly above the conveyor belt. 221 is provided with a placement chamber that runs through its height, and the placement chamber is composed of two parts, chamber 1 and chamber 2 located below chamber 1;

[0065] The feeding member is arranged in the placement chamber of the post 221, and the feeding member includes a trigger plate 222, a limit rod 223, and a support rod 224. The trigger plate 222 is com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com