Sealing gasket suspension type precise distribution automated production line

A sealing gasket and suspension technology, which is applied in the field of parts installation, can solve the problems of not being able to control the descending speed well, and cannot ensure that the gasket is installed in the corresponding station, so as to achieve a smooth and smooth dropping process and a smooth and smooth placement process. The effect of reducing deviation error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The present invention has the advantage of using the automatic feeding device and the hierarchical traction device to install the ring parts to the outside of the object. The placement process of the ring parts is fully automated without manual operation, which increases production efficiency and reduces costs. The whole placement process adopts a layer-by-layer drop method, which makes the dropping process of the ring parts more stable and smooth, greatly reduces the deviation error between the ring parts and the object during the placement process, and enables the ring parts to fall accurately. Outside the object, in addition, the automatic feeding device only releases one set of ring parts at a time, making the placement process more stable and smooth.

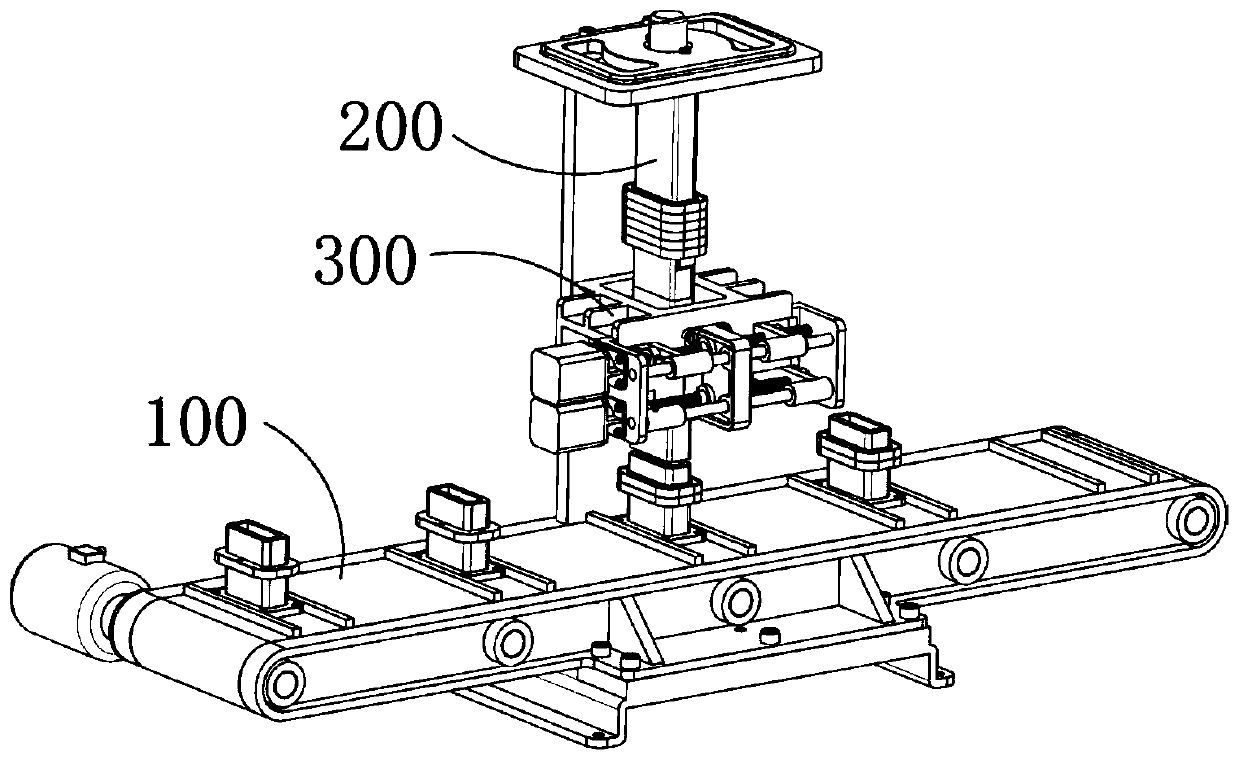

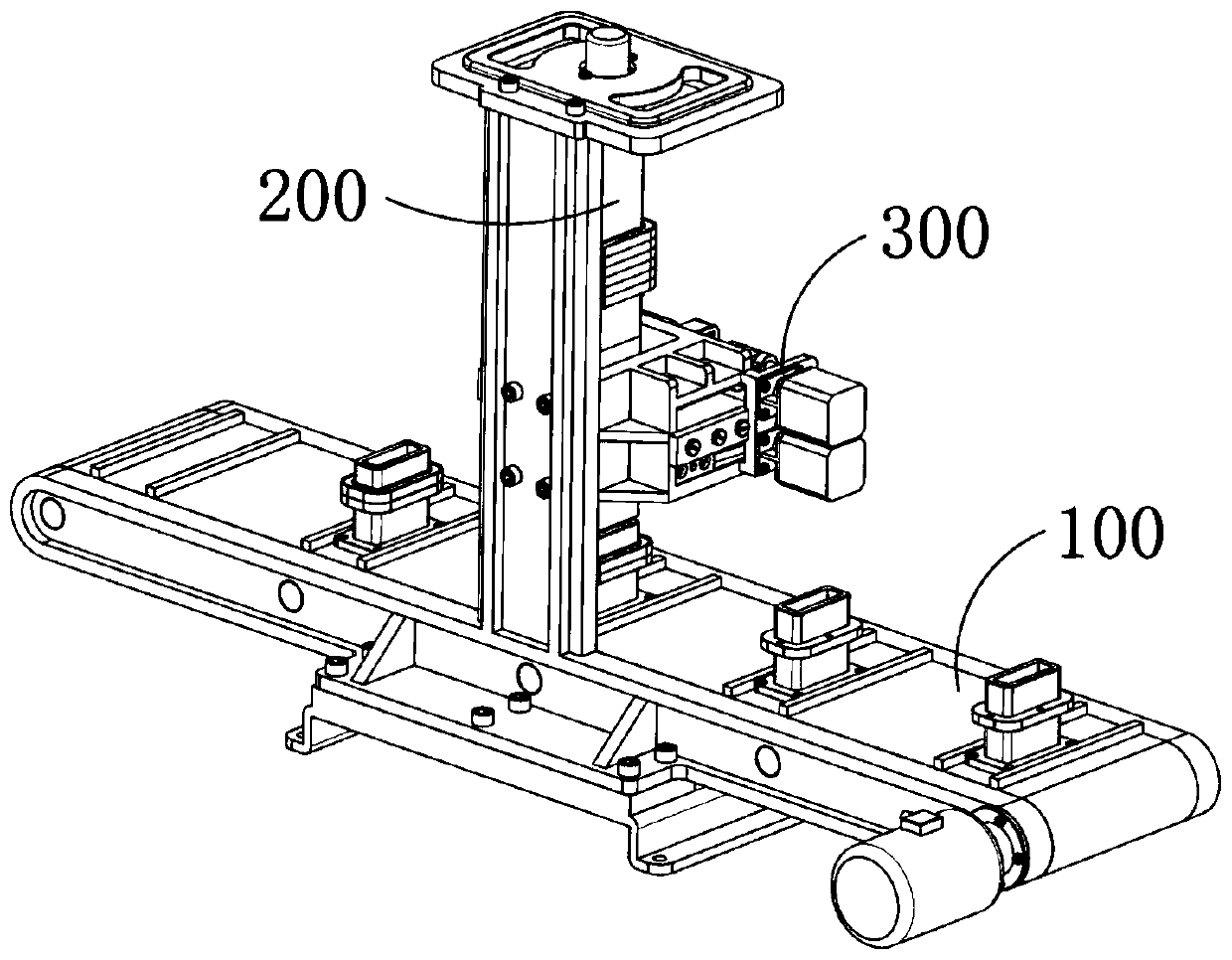

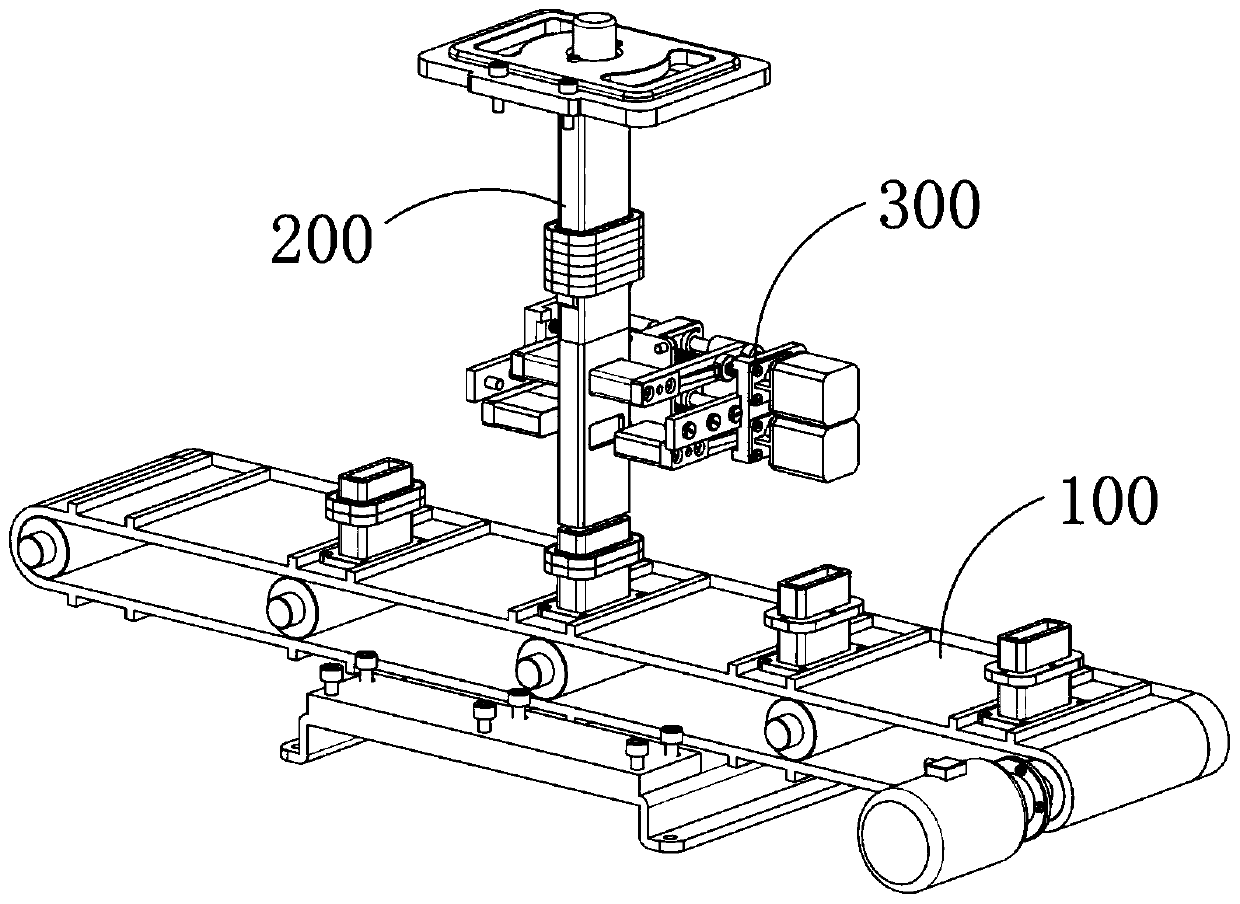

[0057] The automatic assembly line for the suspension type precision distribution of sealing gaskets, including the installation frame body, the transportation device 100, the automatic feeding device 200, and the lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com