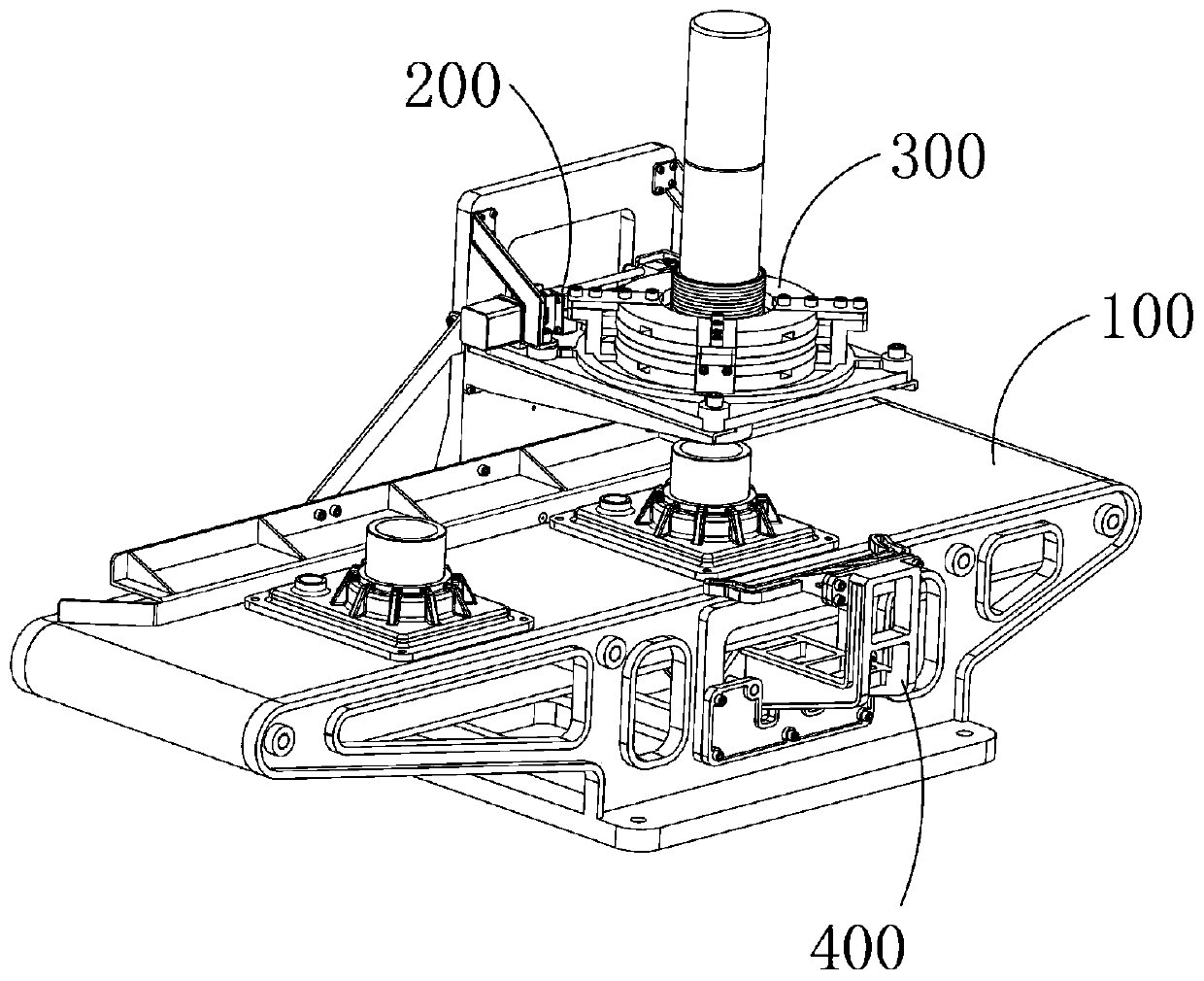

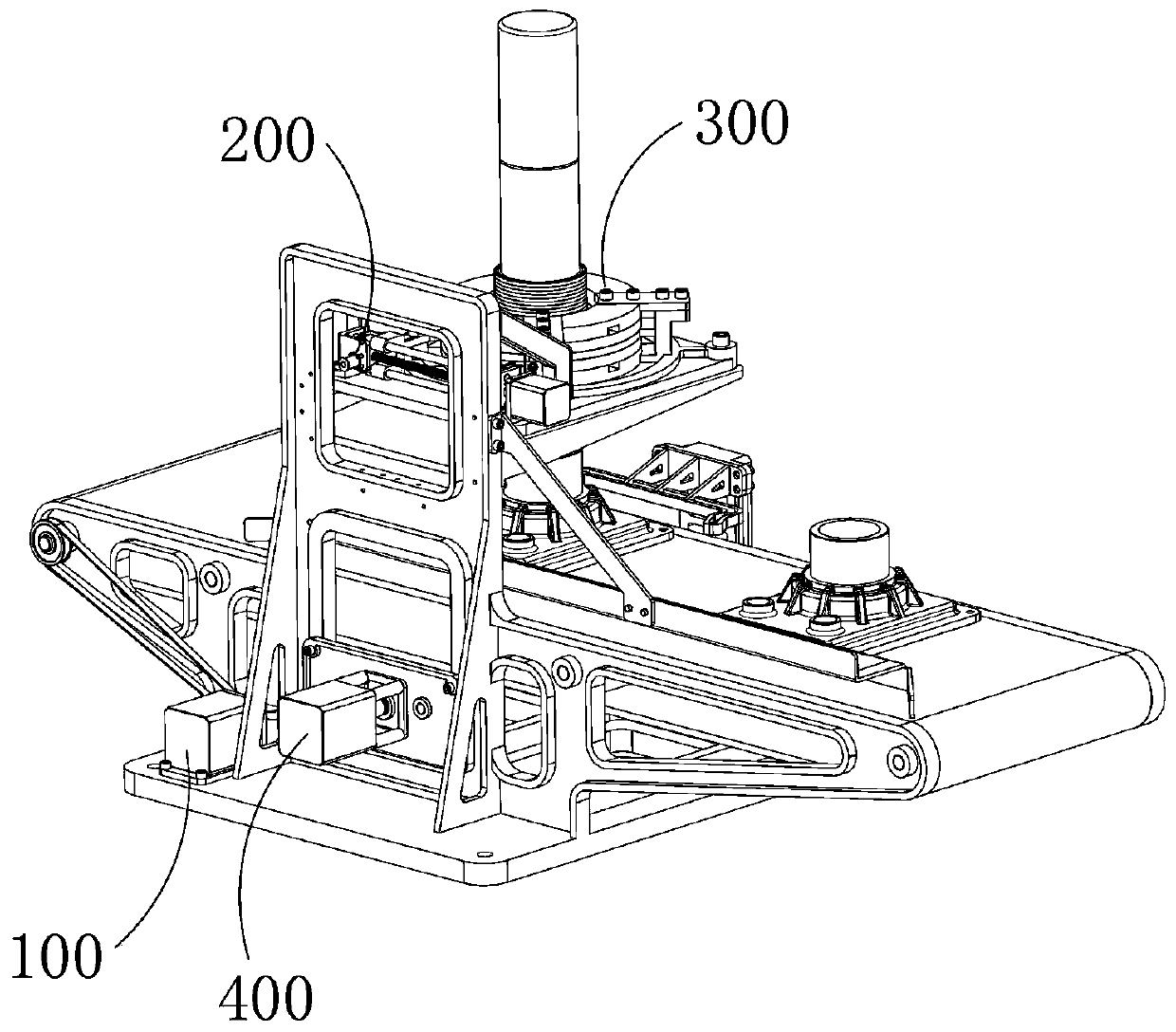

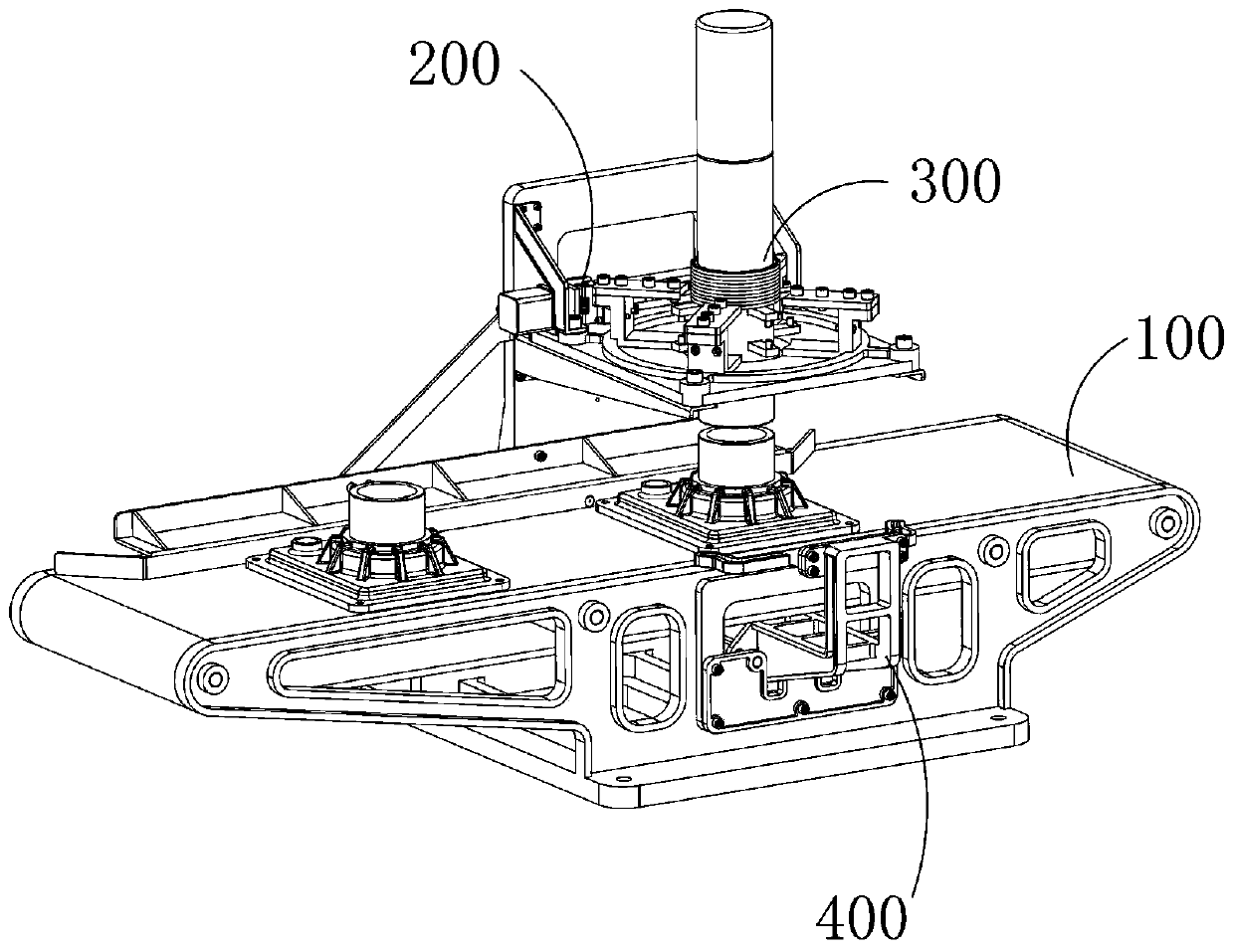

Automatic mounting machine for high-molecular sealing gasket

A technology for automatic installation and sealing of gaskets. It is used in metal processing, metal processing equipment, manufacturing tools, etc., and can solve the problems of not being able to control the descending speed well and not guaranteeing the installation of gaskets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The advantage of using the gasket installation device to automatically install the gasket in the present invention is that the gasket installation device uses the installation power provided by the drive device as the power source and installs the gasket on the outside of the gasket object to be installed, and the entire gasket installation process is fully automatic without manual operation At the same time, the gasket installation device adopts the method of falling layer by layer to make the gasket drop, which greatly reduces the deviation error caused by the influence of external factors during the dropping process of the gasket. The entire installation process is more stable and smooth. In addition, the setting of the positioning device enables the object to be smoothly transported to the right below the gasket installation device, so that the gasket can be lowered and placed outside the object smoothly.

[0081] The automatic installation machine for polymer sealin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com