Multi-axis synchronous control unit

A control unit, multi-axis synchronization technology, applied in the direction of educational appliances, instruments, teaching models, etc., can solve the problem of single teaching function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

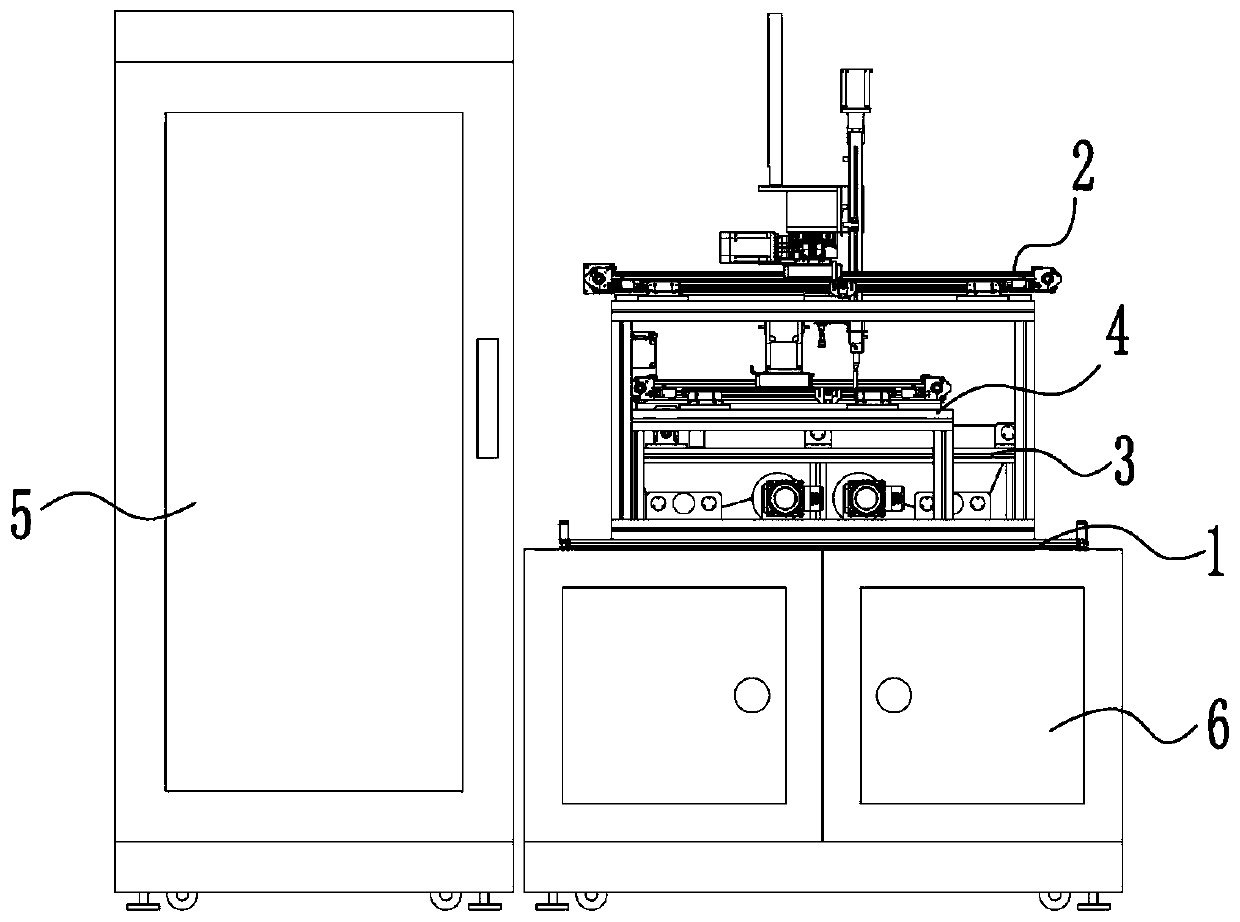

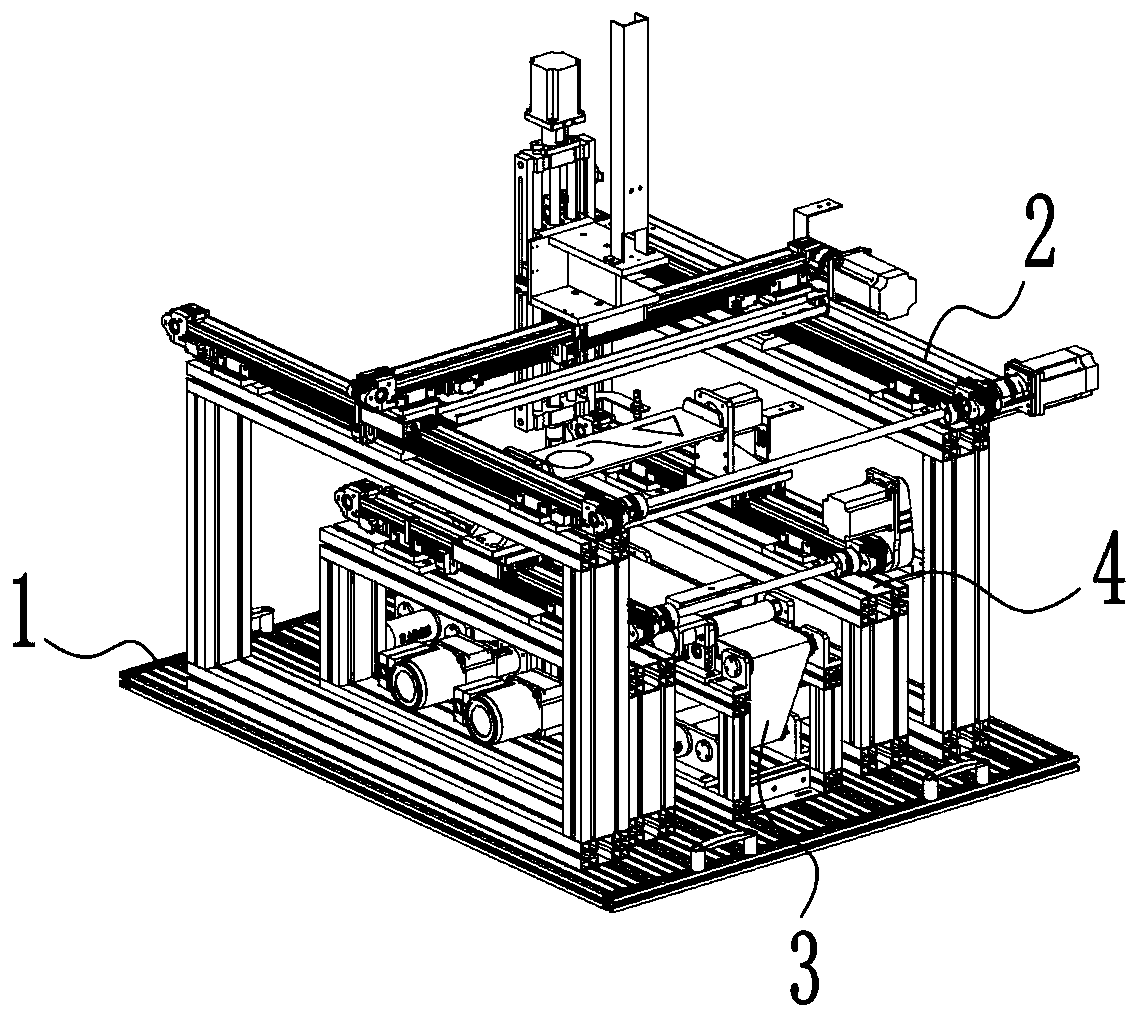

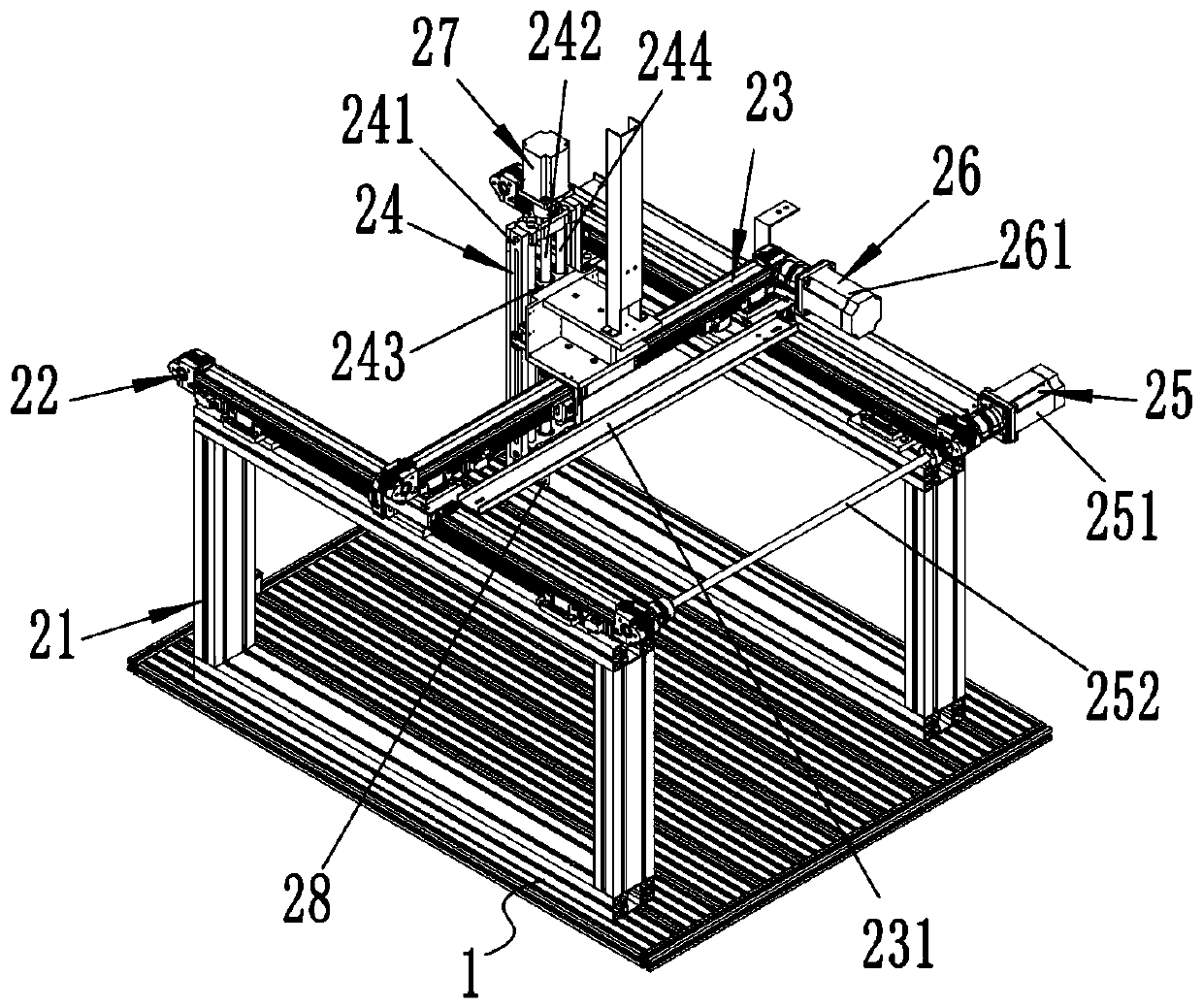

[0028] Refer below Figure 1 to Figure 7 The present invention is described further, as figure 1 A multi-axis synchronous control unit is shown, including base 1, motion control unit 2, tension control unit 3, electronic gear motion unit 4 and electrical control cabinet 5, motion control unit 2, tension control unit 3 and electronic gear motion unit 4 are all arranged on the base 1, the electronic gear movement unit 4 is located below the movement control unit 2, the tension control unit 3 is located between the two parallel supporting guide rails 41 of the electronic gear movement unit 4, and the electric control cabinet 5 is used to control The motion control unit 2, the tension control unit 3 and the electronic gear motion unit 4 work independen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com