Scrap lathe blade recycling method

A blade and blade body technology, which is applied in the field of scrap car blade recycling, can solve the problems of high tool cost and low blade utilization rate, and achieve the effect of saving tool cost, good cutting effect and improving blade efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

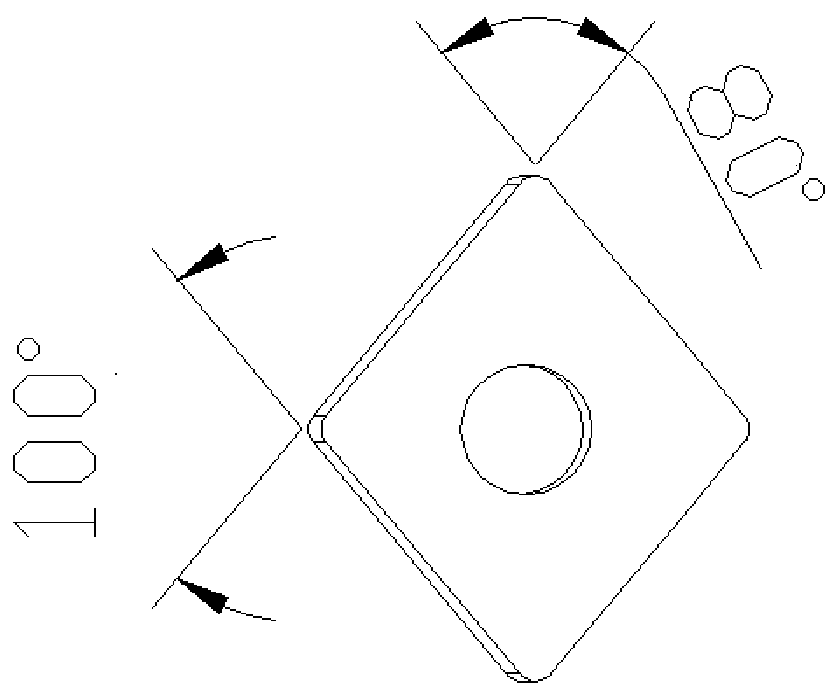

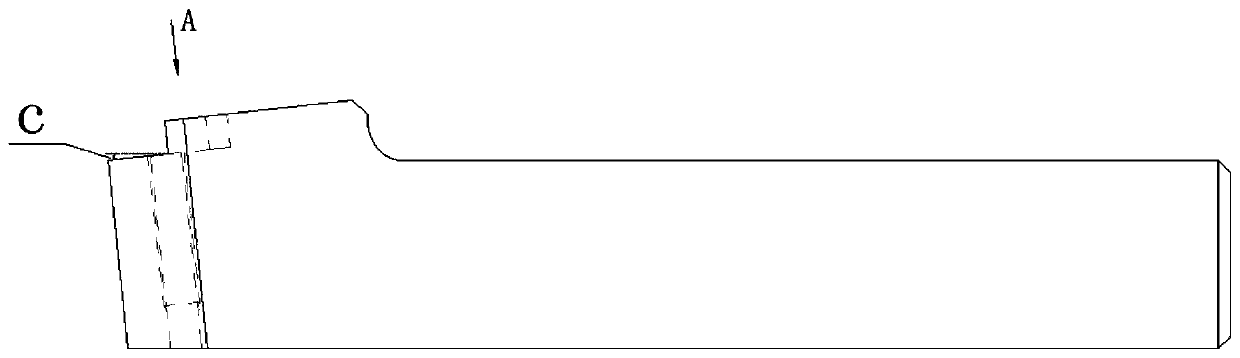

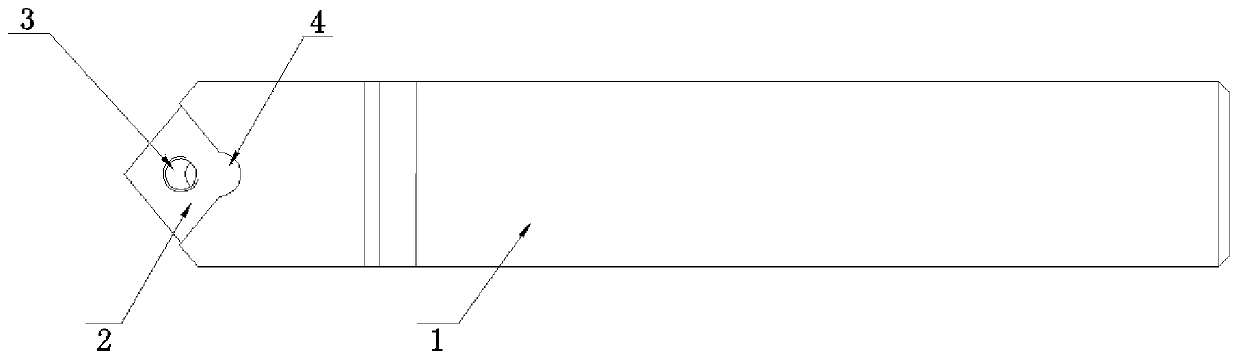

[0016] Specific Embodiment 1: In this embodiment, the scrapped car blade recycling method is carried out according to the following steps: process the cutter body 1 with the blade mounting groove 2 at an angle of 100°, and direct one of the 80° diamond-shaped turning blades at an angle of 100° toward the blade The root of the installation groove 2 is installed on the cutter body 1, and finally the set screw 5 is passed through the through hole of the 80° rhombic turning blade and screwed into the threaded hole 3 at the bottom of the blade installation groove 2;

[0017] Described blade mounting groove 2 is arranged on cutter body 1 front end upper surface, and the bottom of blade mounting groove 2 is a rhombus plane, and the included angle between rhombus plane and cutter body 1 upper surface is 5 °, and the bottom of blade mounting groove 2 is provided with Threaded hole 3, the groove wall of blade mounting groove 2 is V-shaped, and the opening end of groove wall is towards th...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment differs from Embodiment 1 in that: the rear end of the cutter body 1 is a regular quadrangular prism. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Embodiment 3: This embodiment differs from Embodiment 2 in that: the size of the regular quadrangular prism section at the rear end of the cutter body 1 is 25mm×25mm. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com