Garment treatment control system and garment treatment equipment

A clothing processing and control system technology, which is applied to the control device of washing machines, household clothes dryers, textiles and papermaking, etc., can solve the problems of concealed loss, harmful clothing performance, and lack of equipment, so as to achieve a reasonable logical structure and appropriate judgment results actual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

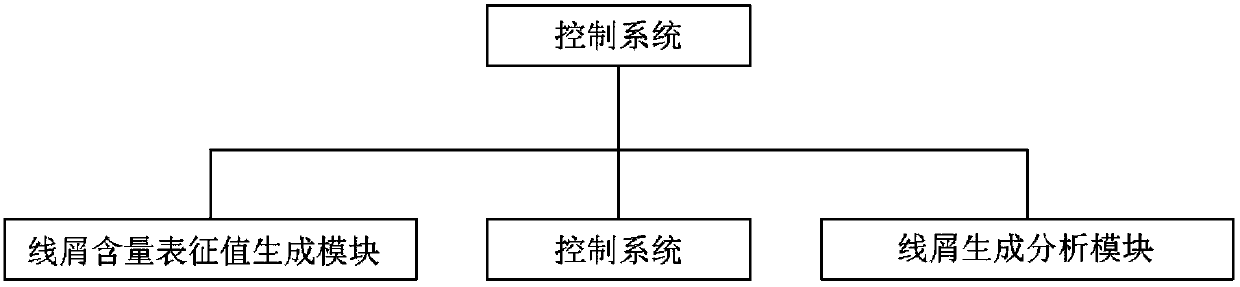

Embodiment 1

[0069] The difference between the laundry treatment control system in this embodiment and the above embodiments is that: the storage module includes a process data storage unit and a setting data storage unit; the lint content representative value generation module stores the acquired and generated data into into the process data storage unit; the data in the setting data storage unit can be manually set. Reasonably set the logical structure of the storage unit so that the data acquired and generated by the device is stored separately, and the threshold and preset values are set separately, so that users can properly adjust the threshold and preset values according to actual usage conditions, and then It enables users to exert their subjective initiative to a greater extent.

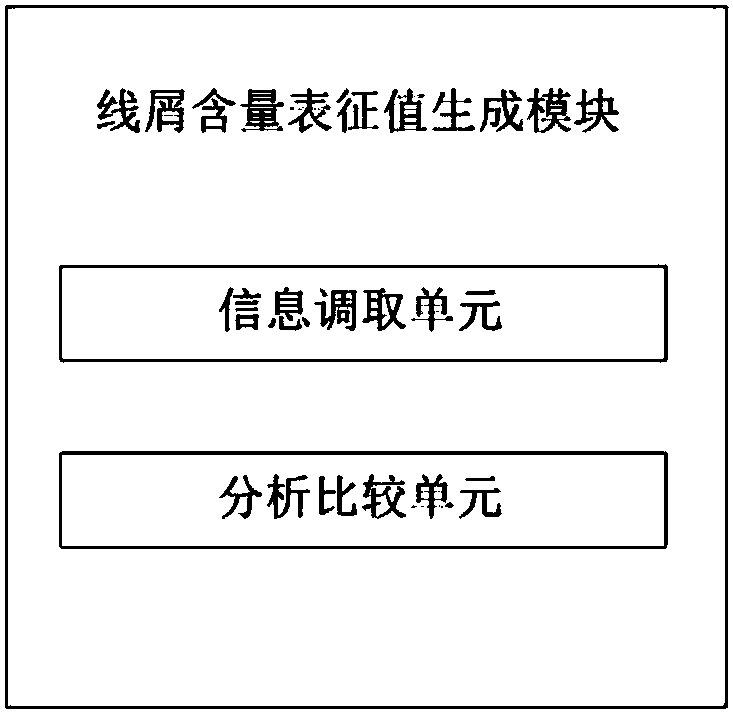

[0070] Further, as figure 2 As shown, the lint generation analysis module in this embodiment includes an information retrieval unit and an analysis and judgment unit; the information retrieval unit...

Embodiment 2

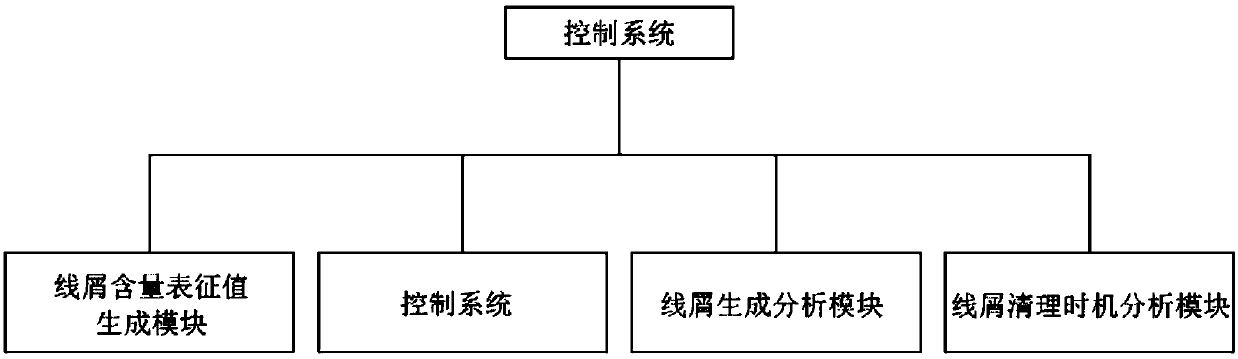

[0072] Such as image 3 As shown, the difference between the clothes processing control system described in this embodiment and the above embodiments is that: the clothes processing control system in this embodiment also includes a lint cleaning timing analysis module; the lint cleaning timing analysis module calls the The amount of lint obtained by the lint content characterization value generating module and the corresponding threshold and setting value in the storage module; and comparing the amount of lint with the corresponding threshold and setting, and then draw the corresponding The judgment result; the lint cleaning opportunity analysis module presents the judgment result to the user;

[0073] Preferably, the lint cleaning timing analysis module executes a lint cleaning timing analysis operation after each laundry treatment procedure.

[0074] The lint cleaning timing analysis module presets the lint content level; the lint cleaning timing analysis module obtains the...

Embodiment 3

[0086] The difference between the clothes processing control system described in this embodiment and the above-mentioned embodiments is that: the clothes processing control system in this embodiment also includes a lint collection abnormal analysis module; the lint collection abnormal analysis module calls the lint collection The amount of lint obtained by the content characterization value generation module is calculated to obtain the rate of change of the amount of lint; and the rate of change of the amount of lint is compared with the corresponding threshold and set value in the storage module , and then obtain a corresponding judgment result; the rate of change of the amount of thread waste includes the rate of change of the amount of thread waste over time. The abnormality analysis module of wire debris collection detects the rate of change of the amount of wire debris in real time. When the rate of change of the amount of thread debris exceeds the corresponding threshold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com