Stem Assemblies, Plug Assemblies and Valves

一种阀塞组件、阀杆的技术,应用在具有阀杆组件的控制阀领域,能够解决先导头出现故障等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

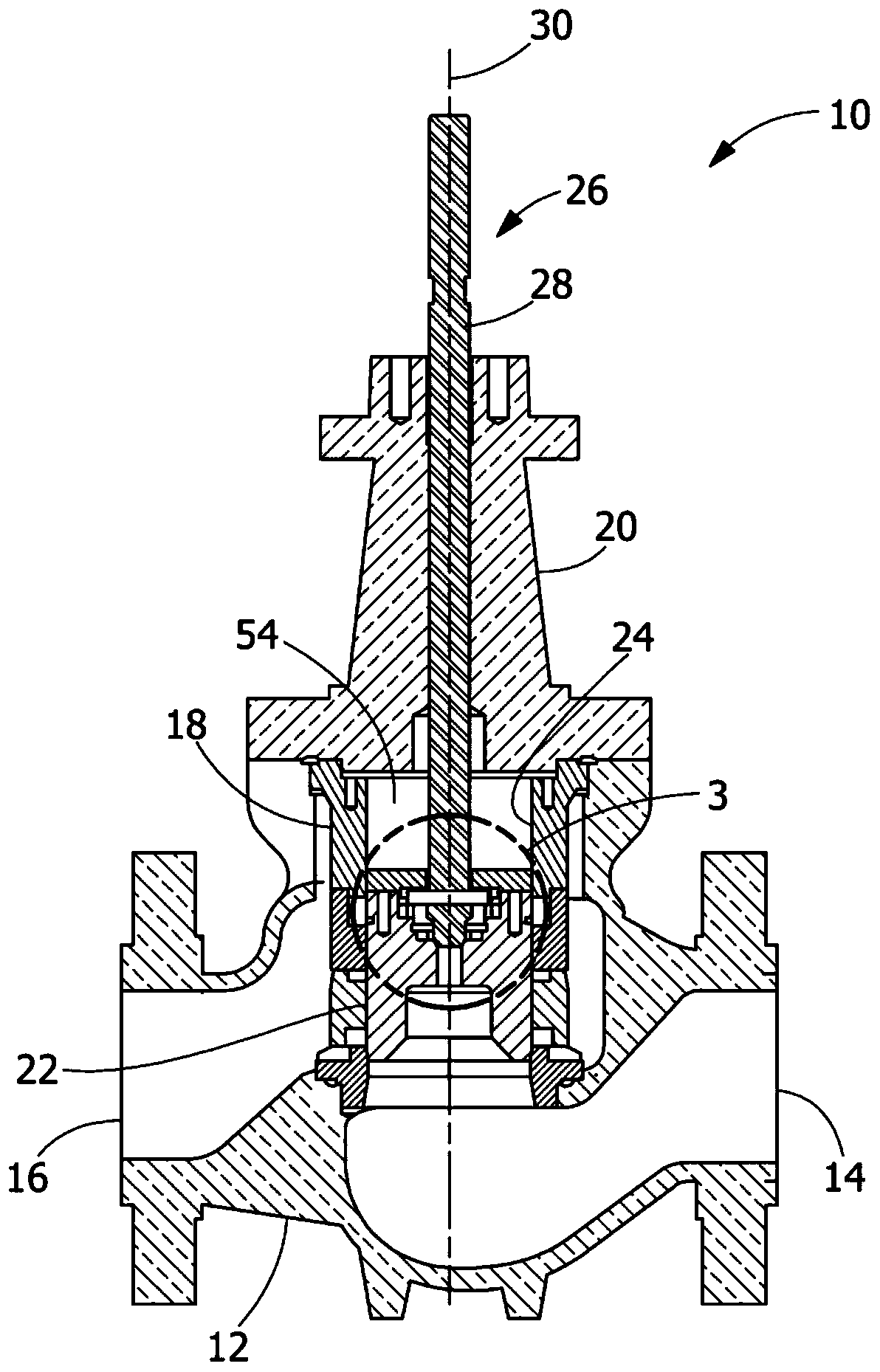

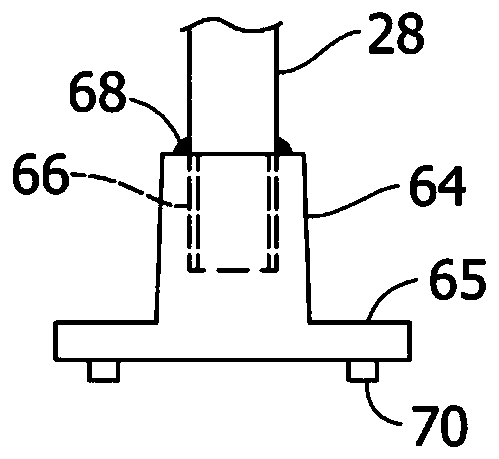

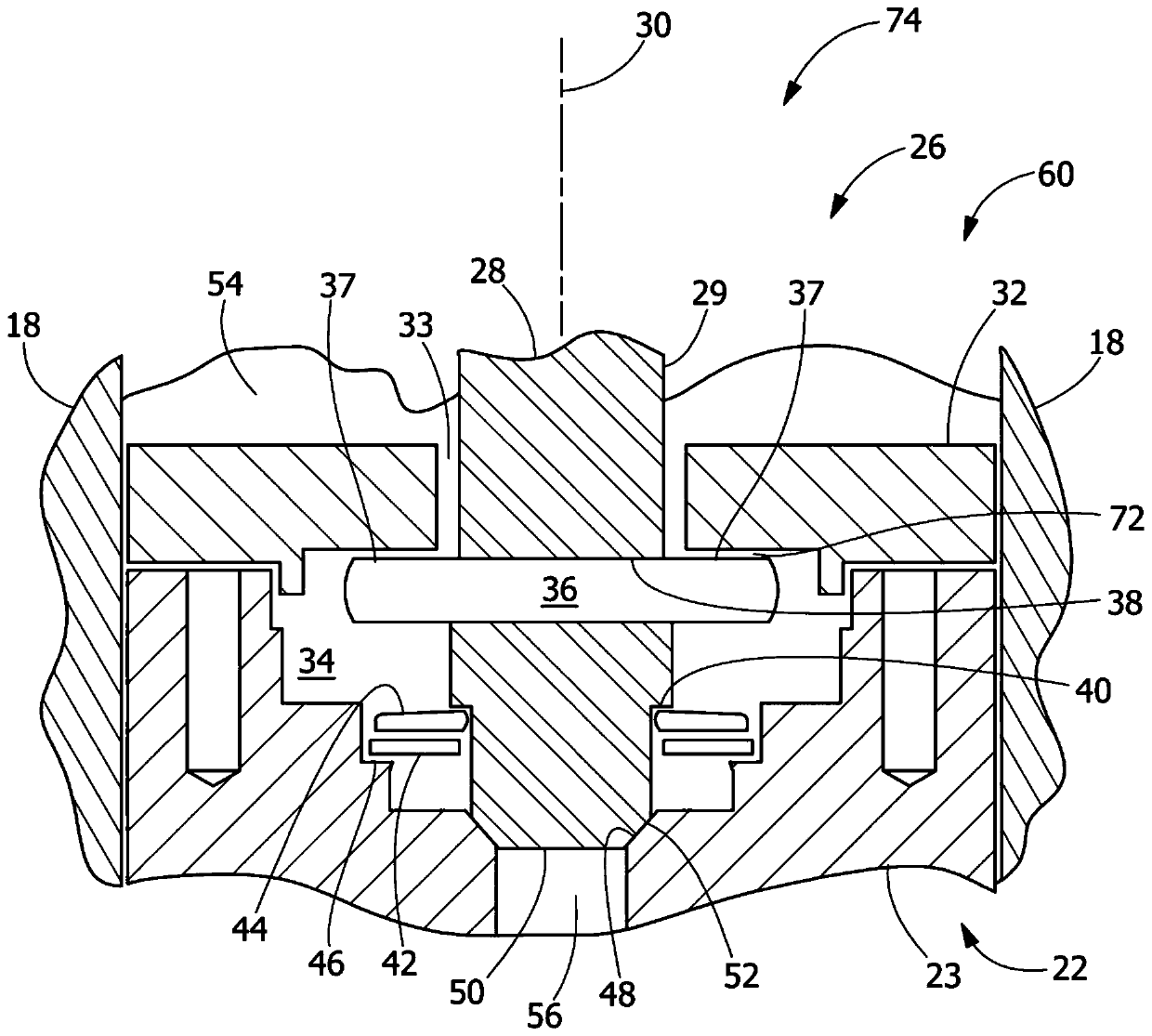

[0053] figure 1 , image 3 and Figure 4 Valve 10 is shown having a body 12 including an inlet 14 and an outlet 16 . A valve closure or plug 22 is slidably movable along an inner surface 24 of a cage 18 secured within body 12 and bonnet 20 for regulating fluid flow between inlet 14 and outlet 16 . Such as image 3 shown, which is taken from figure 1 In an enlarged view of area 3 , the valve plug 22 includes a body 23 and a cap 32 . A pilot area or compartment 34 is formed inside the valve plug 22 between the junction of the body 23 and the cap 32 . The stem assembly 26 includes a shaft 28 having an axis or longitudinal axis 30 that extends to an end 50 . The valve plug assembly 74 includes a valve stem assembly coupled to the valve plug. In one embodiment, the cross-section of the end is less than or equal to the cross-section of the shaft (eg, as measured perpendicular to the longitudinal axis). In one embodiment, at least one of the shaft and the shaft end is circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com