Spraying robot door opener

A technology for spraying robots and door openers, which is applied in the directions of manipulators, spray booths, spray devices, etc., can solve the problems of slow production rhythm and waste of resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is attached Figure 1-10 The features and principles of the present invention are described in detail, and the examples given are only used to explain the present invention, not to limit the protection scope of the present invention.

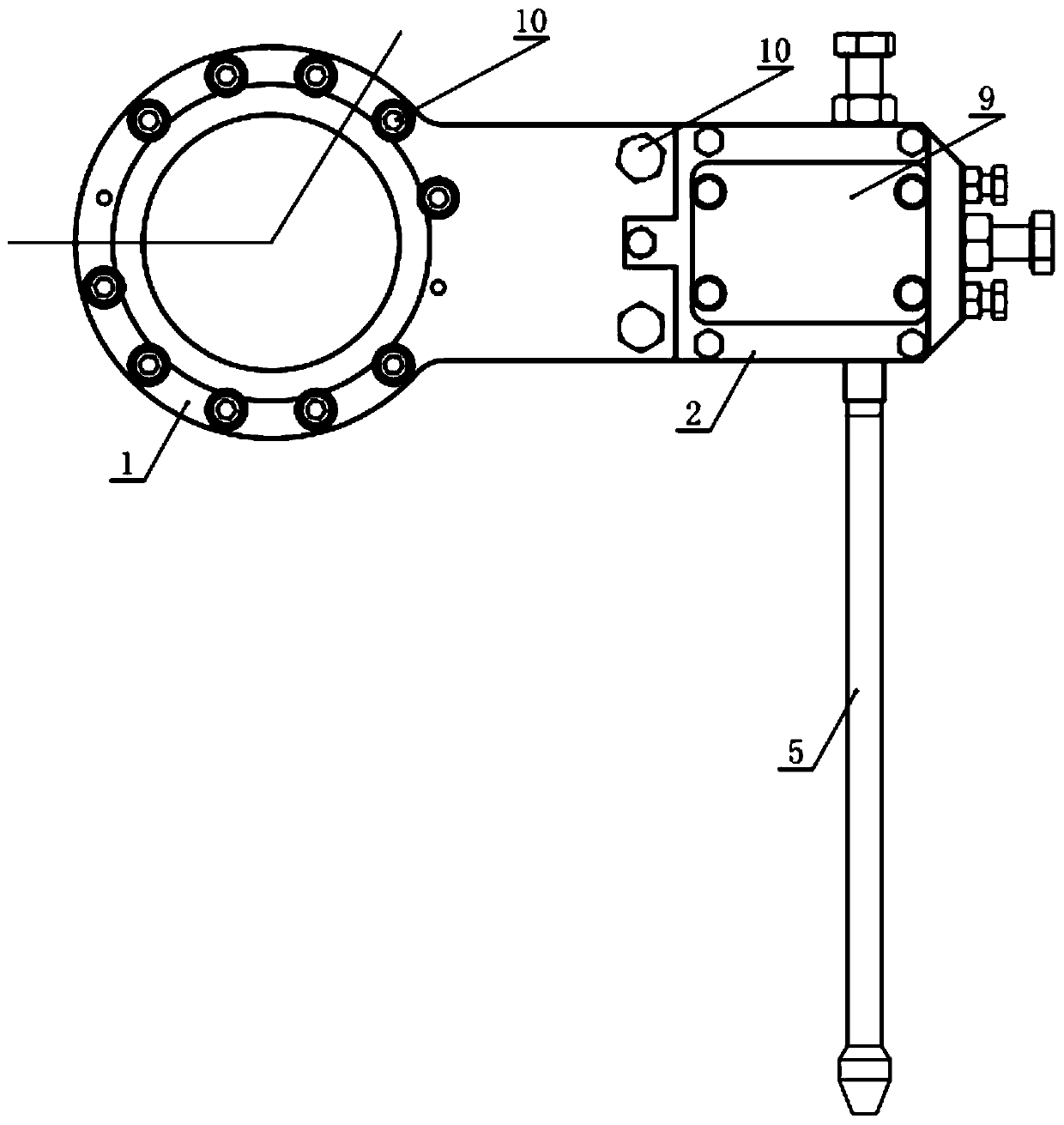

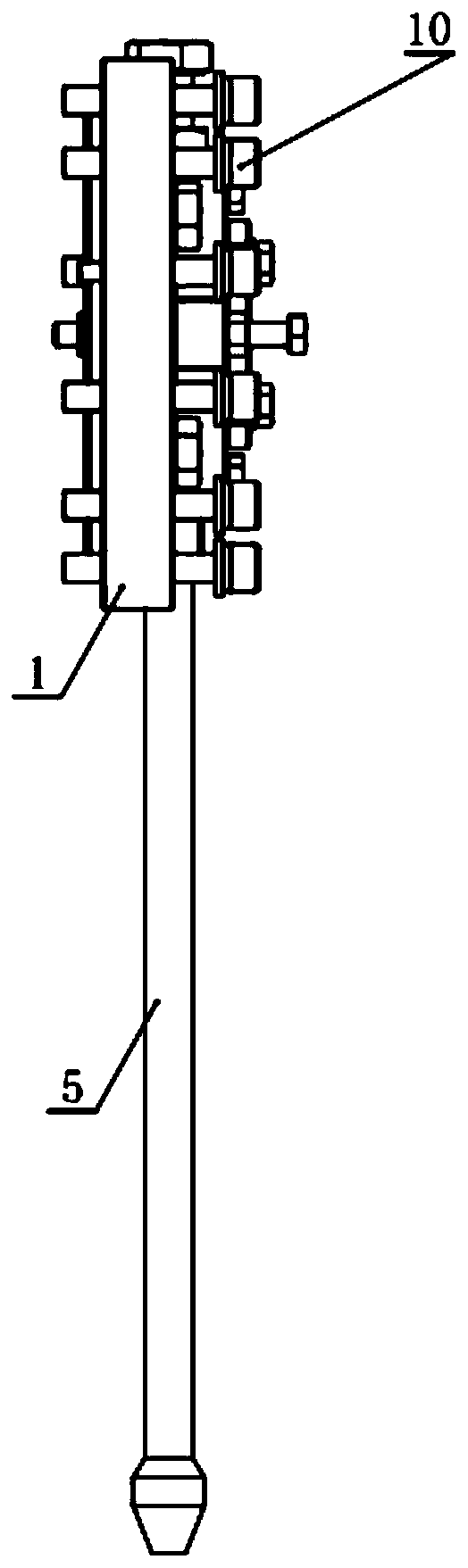

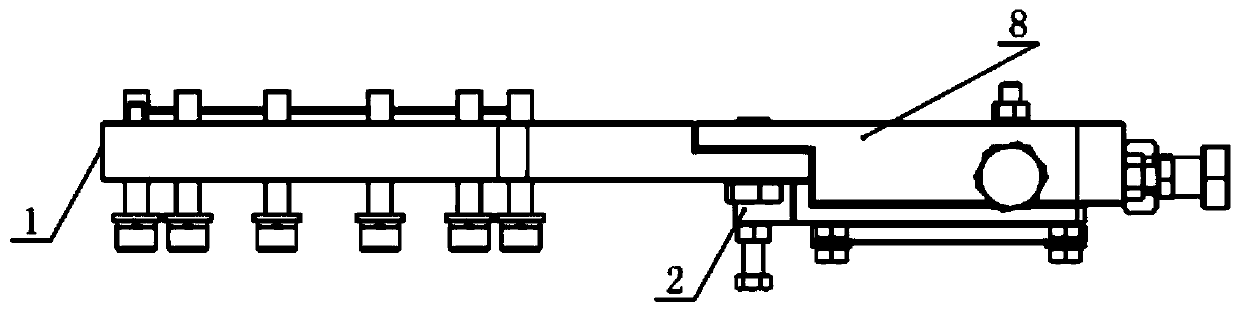

[0026] Such as Figure 1-4 As shown, this kind of spraying robot door opener includes a flange plate 1 connected to the upper flange of the spraying robot, and the flange plate 1 is connected to the connecting plate 8 and the cover plate 2 through bolts 10 .

[0027] The flange plays the role of fixing on the robot. The flange can be integrated, but many parts need to be disassembled during disassembly. Such as figure 1 As shown, the flange can be spliced from two parts, and figure 1 The two halves are cut along the dot-dash line, which is convenient for installation on the robot flange.

[0028] Such as Figure 5 As shown, an installation space 81 is formed between the connecting plate and the cover plate, the rotati...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap