Handle lock

A technology of horn lock and deadbolt, which is used in building locks, lock shells, door/window accessories, etc., can solve the problems of difficult assembly, many parts, easy failure of return springs, etc., and achieves simple structure, few parts, The effect of convenient assembly and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

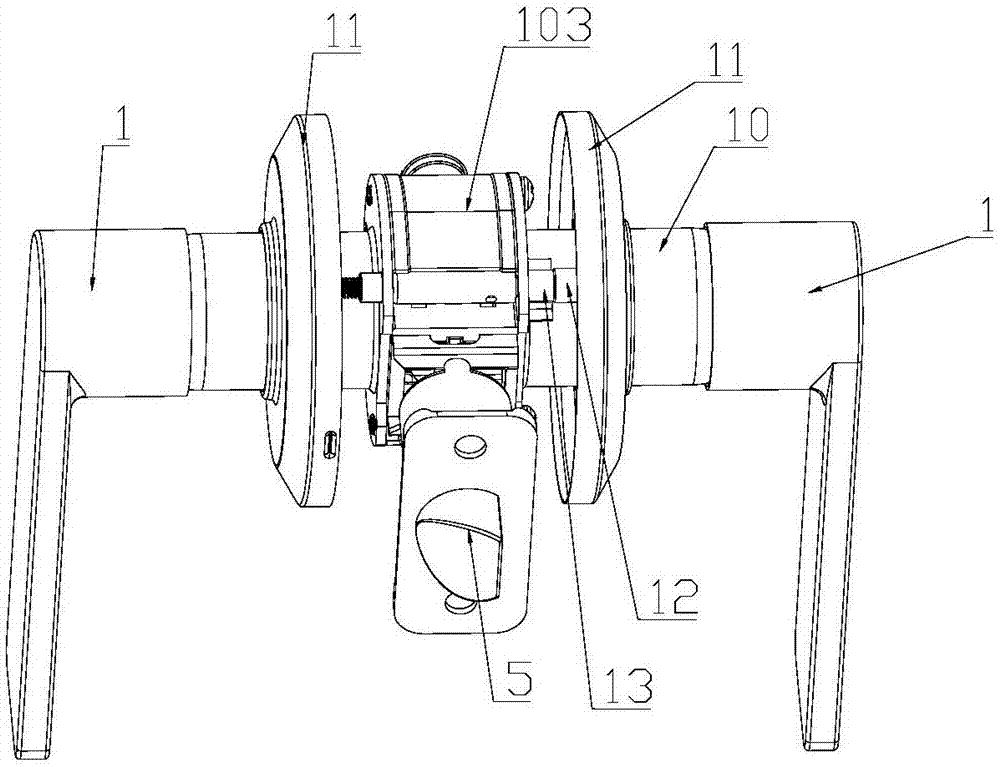

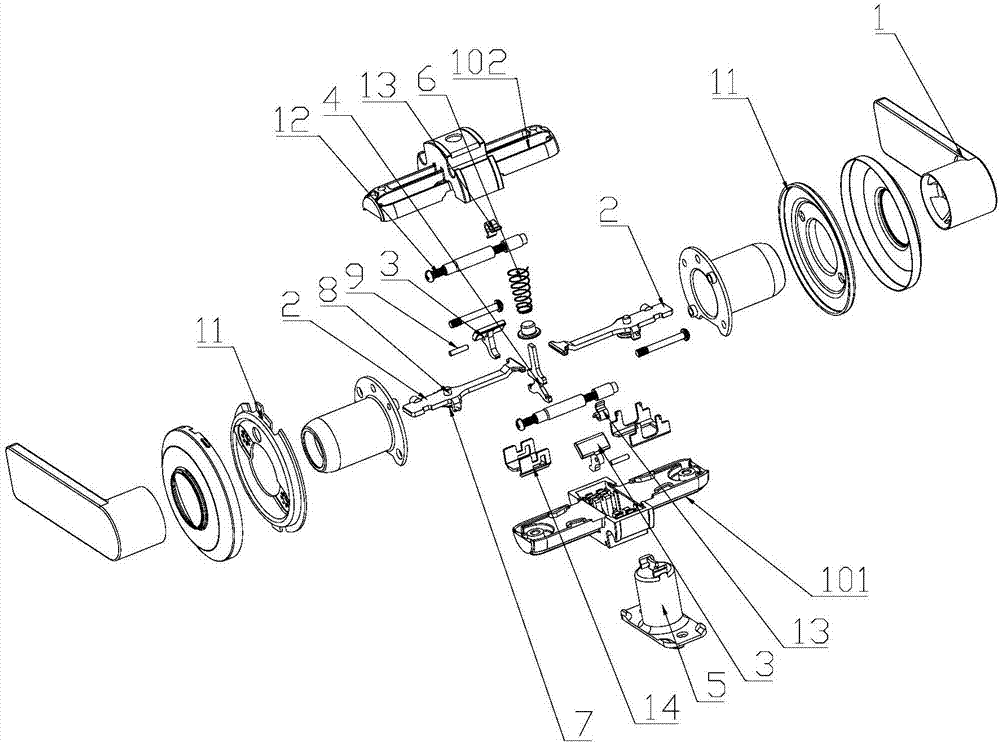

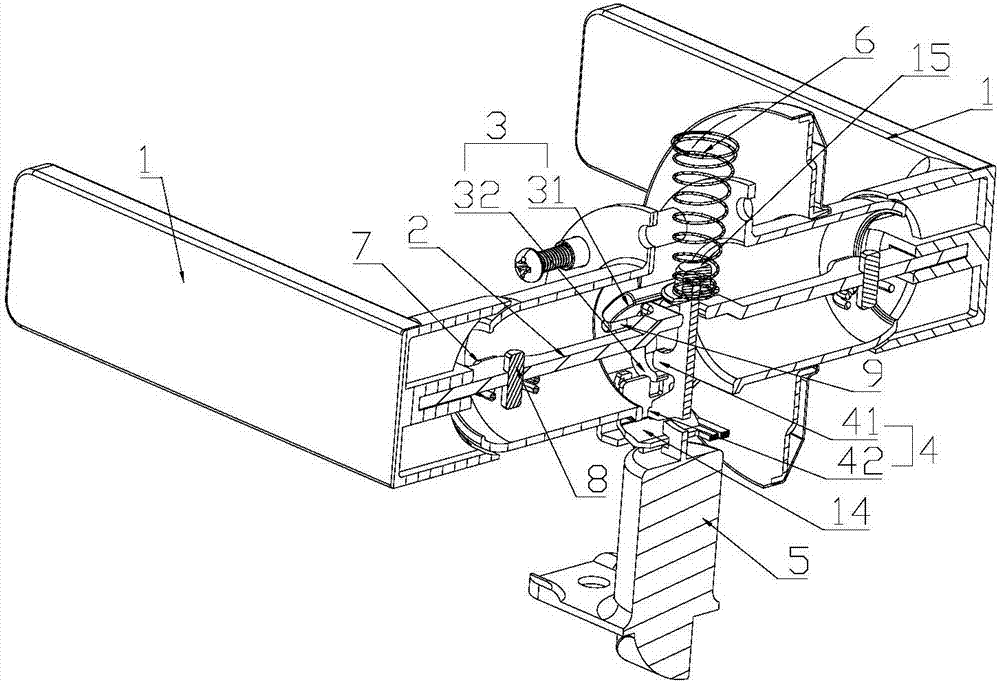

[0031] Such as Figure 1-Figure 9 As shown, the present invention provides a horn lock, comprising a handle 1, a driving lever 2, a reversing block 3, a slider 4, a dead bolt 5 and a reset device for resetting the dead bolt 5, a driving lever 2, a reversing block 3 And the slider 4 is located in the housing 10, the lever 2 and the reversing block 3 are hinged with the housing 10, the reversing block 3 includes a rotating part 31 and a touch part 32, and the rotating part 31 and the actuating part 32 are respectively located on the reversing block 3 on both sides of the hinge shaft, one end of the driving lever 2 is connected to the handle 1, and the other end is adjacent to the rotating part 31, one end of the slider 4 is connected to the deadbolt 5, and the other end is adjacent to the touching part 32, and the driving lever 2 The rotation triggers the rotating part 31 to rotate, thereby driving the rotating part 32 to push up the slider 4 . Turn the rotating part 31 of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com