Patents

Literature

37results about How to "Adapt to thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

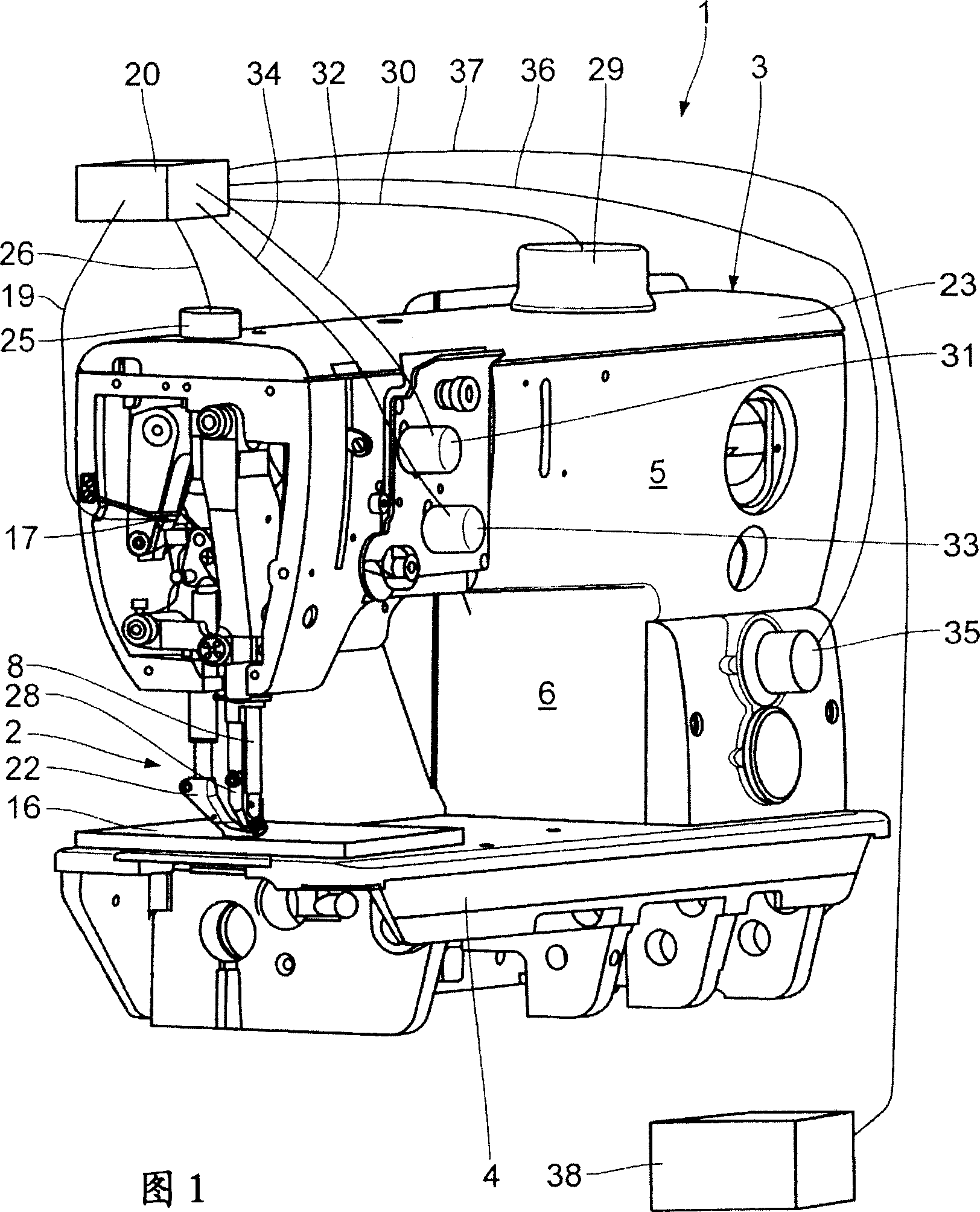

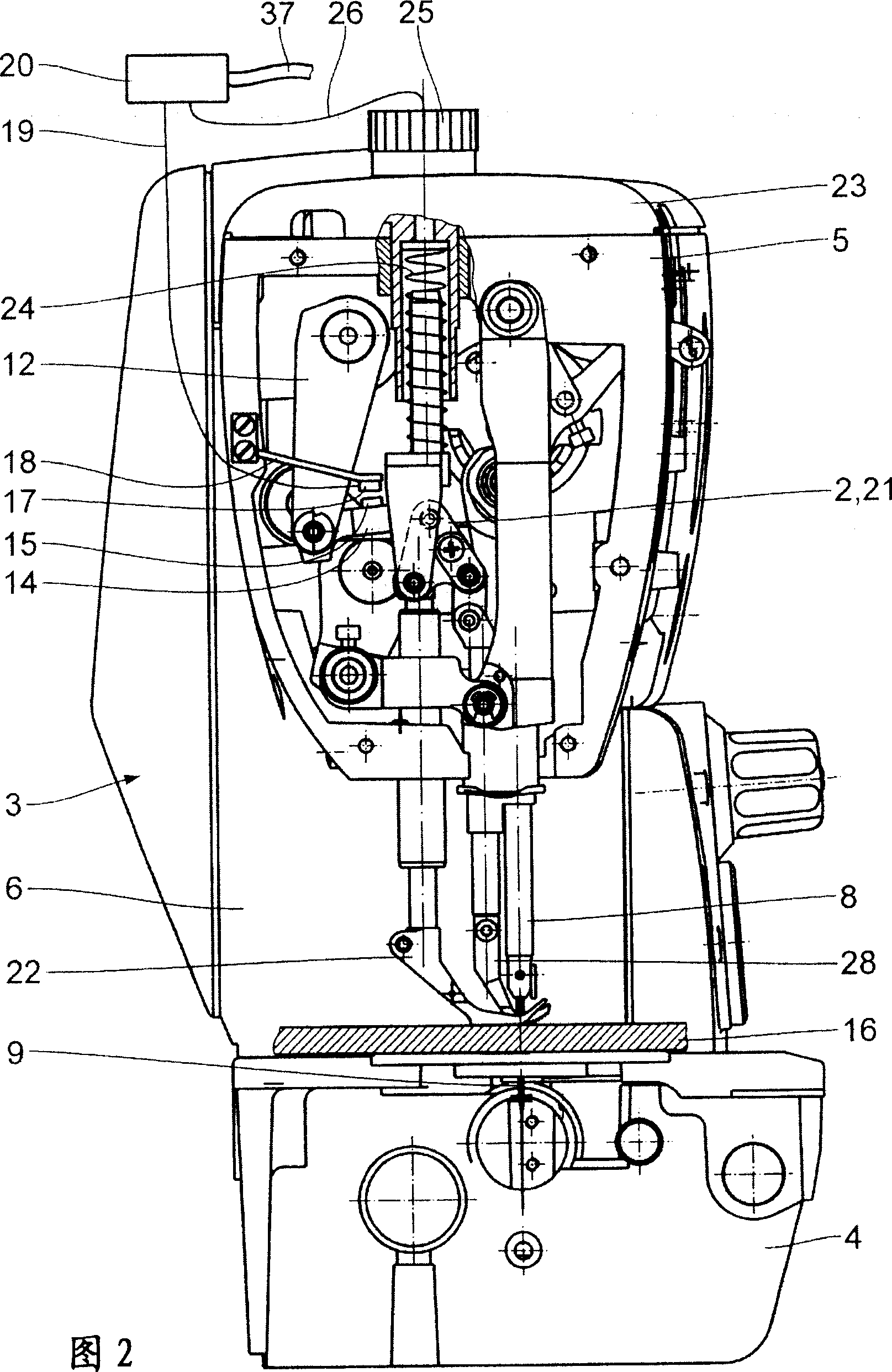

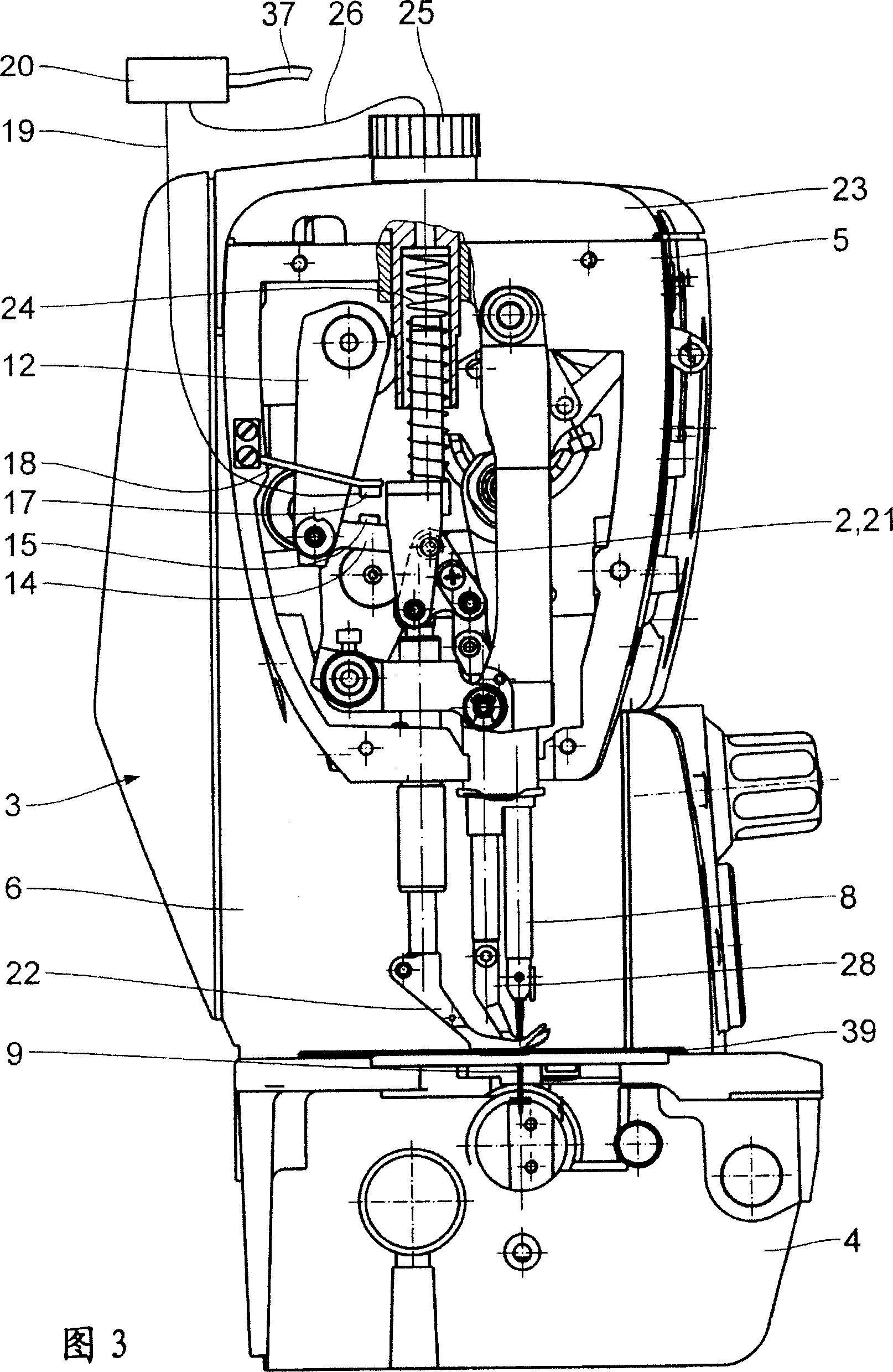

Sewing machine

InactiveCN1891887AReduce setup timeAvoid misadjustmentProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention provided a sewing machine, improved to automatically switch the sewing machine to the thickness of cloth. This sewing machine includes: a housing having a base plate; a top arm; and a strut for integrating the base plate with the top arm. A metallic presser presses a cloth piece near a stitch forming position. The metallic presser driven by a movable rod is capable of moving between the lift position for releasing the cloth piece and the pressing position for the cloth piece to be pressed. When the metallic presser moves between these positions, the distance of at least one movable rod part from a reference structure fixed to the housing stably changes. The position sensor detects the position of the metallic presser in the pressing position. A control system makes signal connection thereto. The system sets an adjustment variable for the sewing machine depending upon the output value of the position sensor. As a result, the obtained sewing machine automatically performs switching to the thickness of variable cloth piece.

Owner:DURKOPP ADLER AG

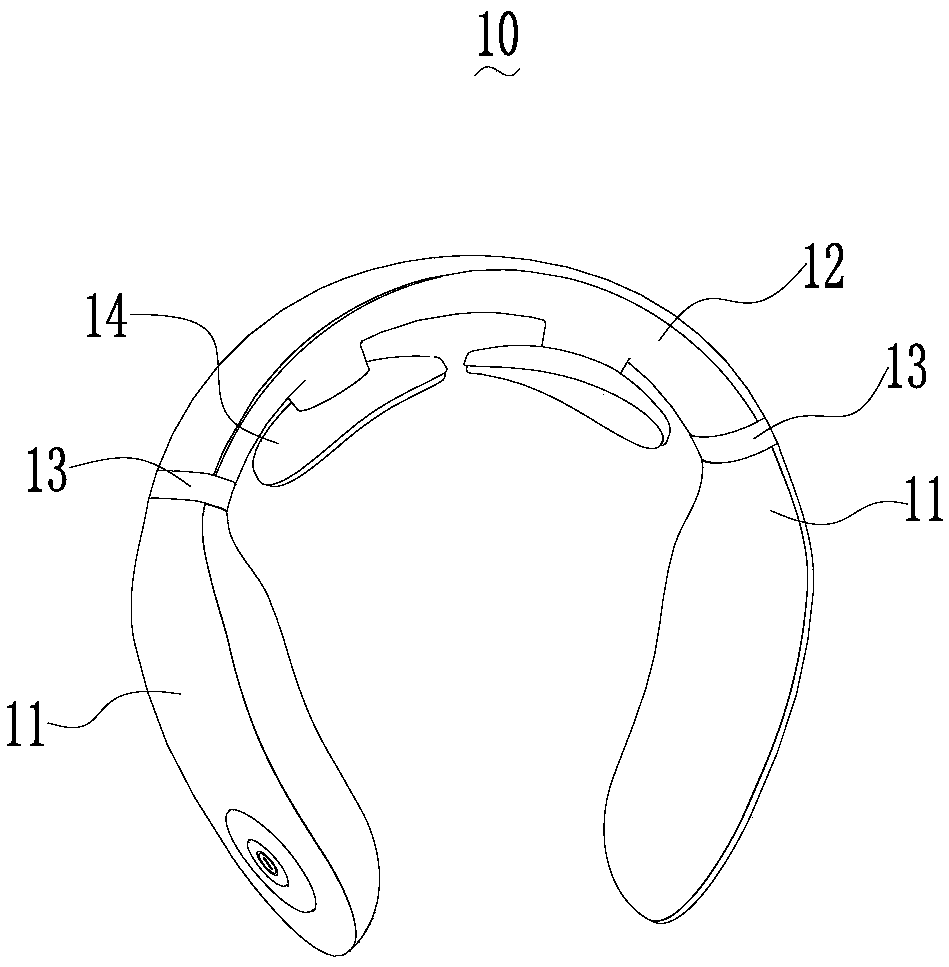

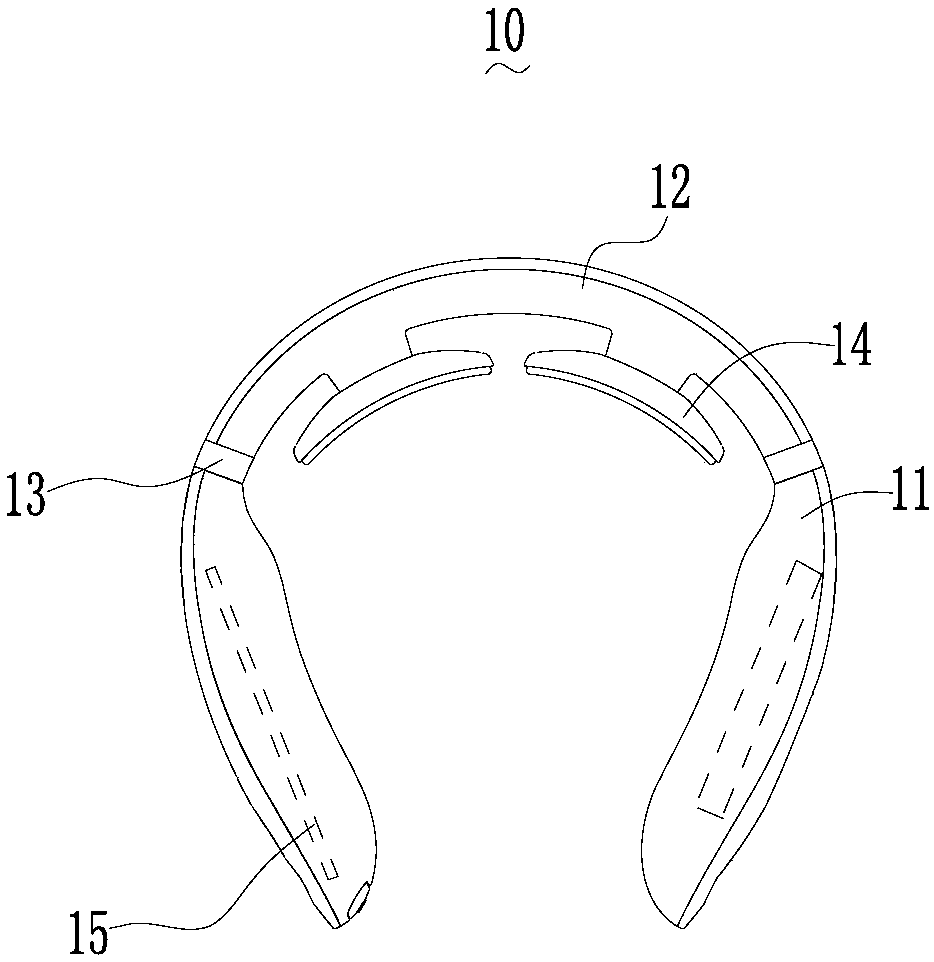

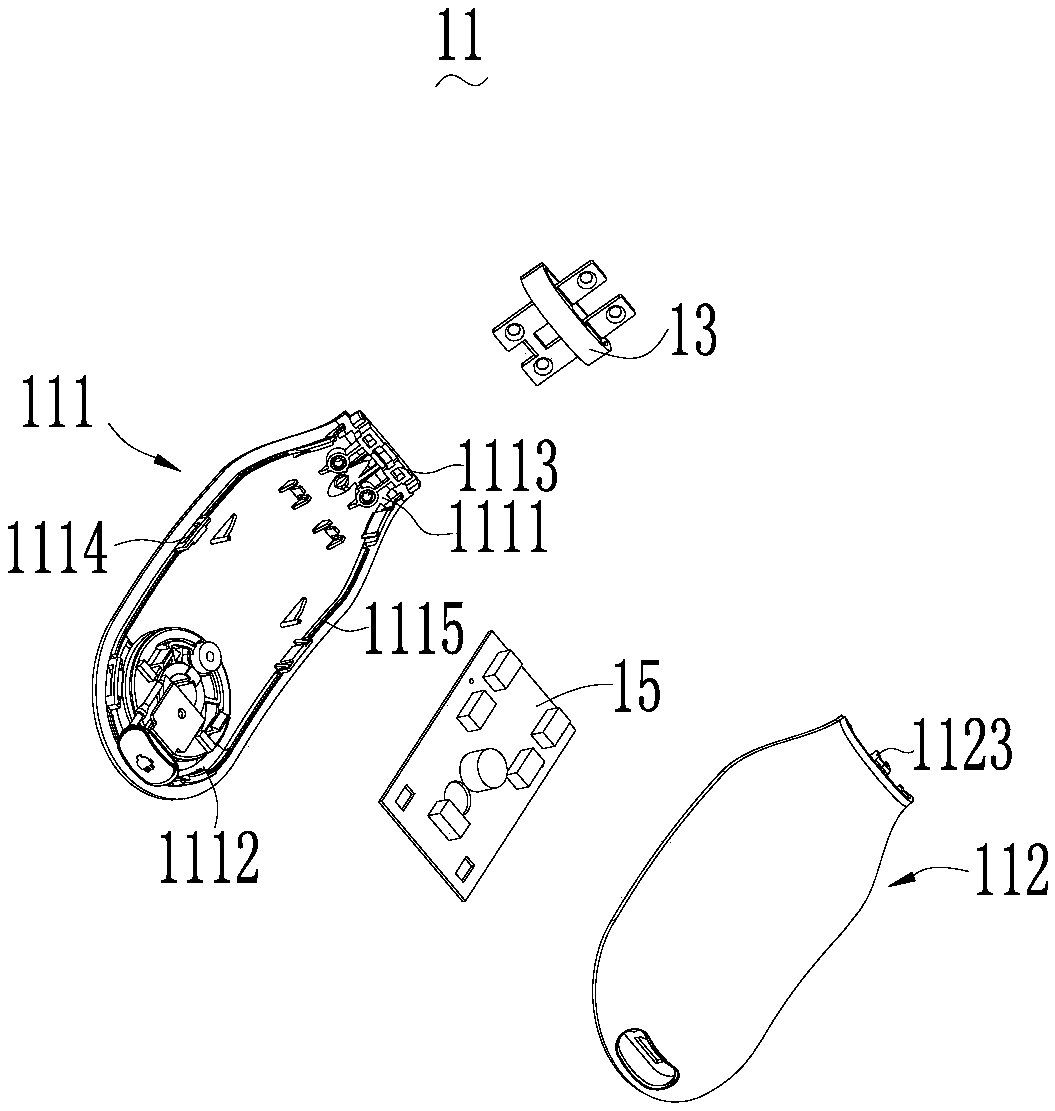

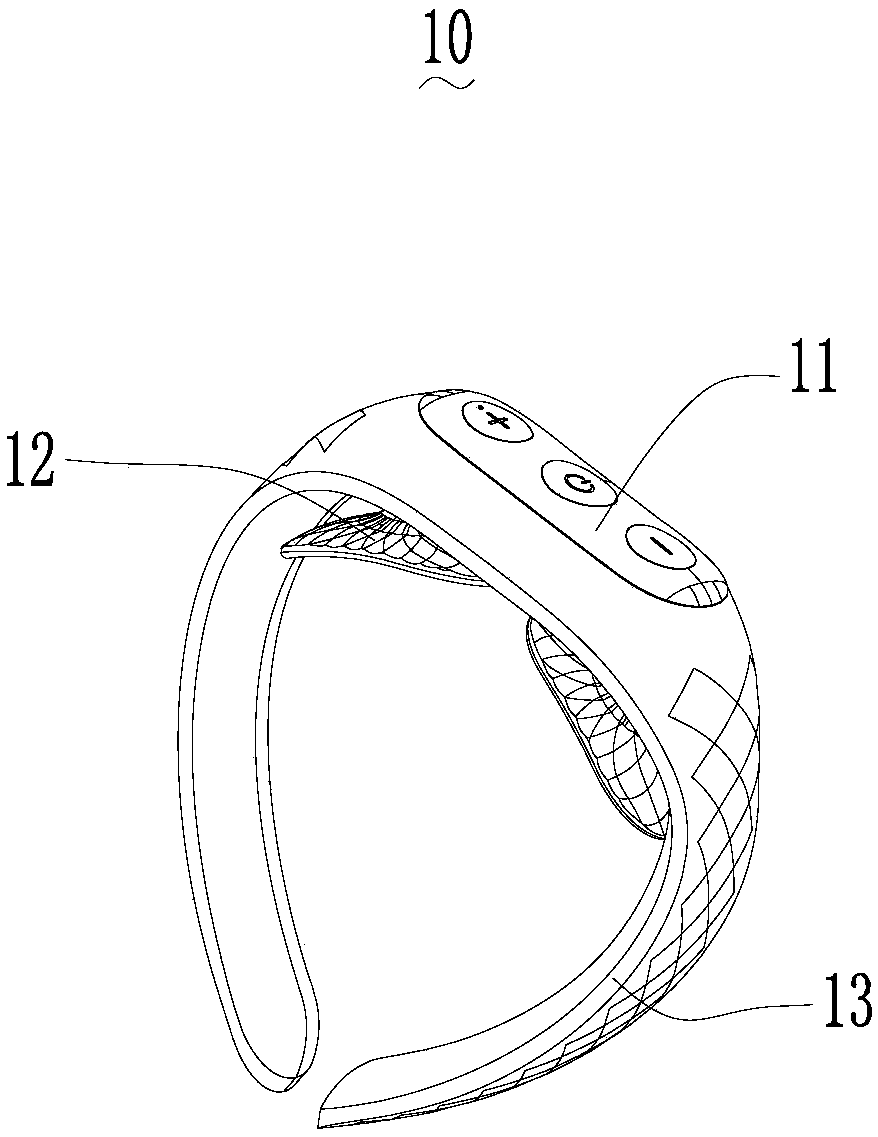

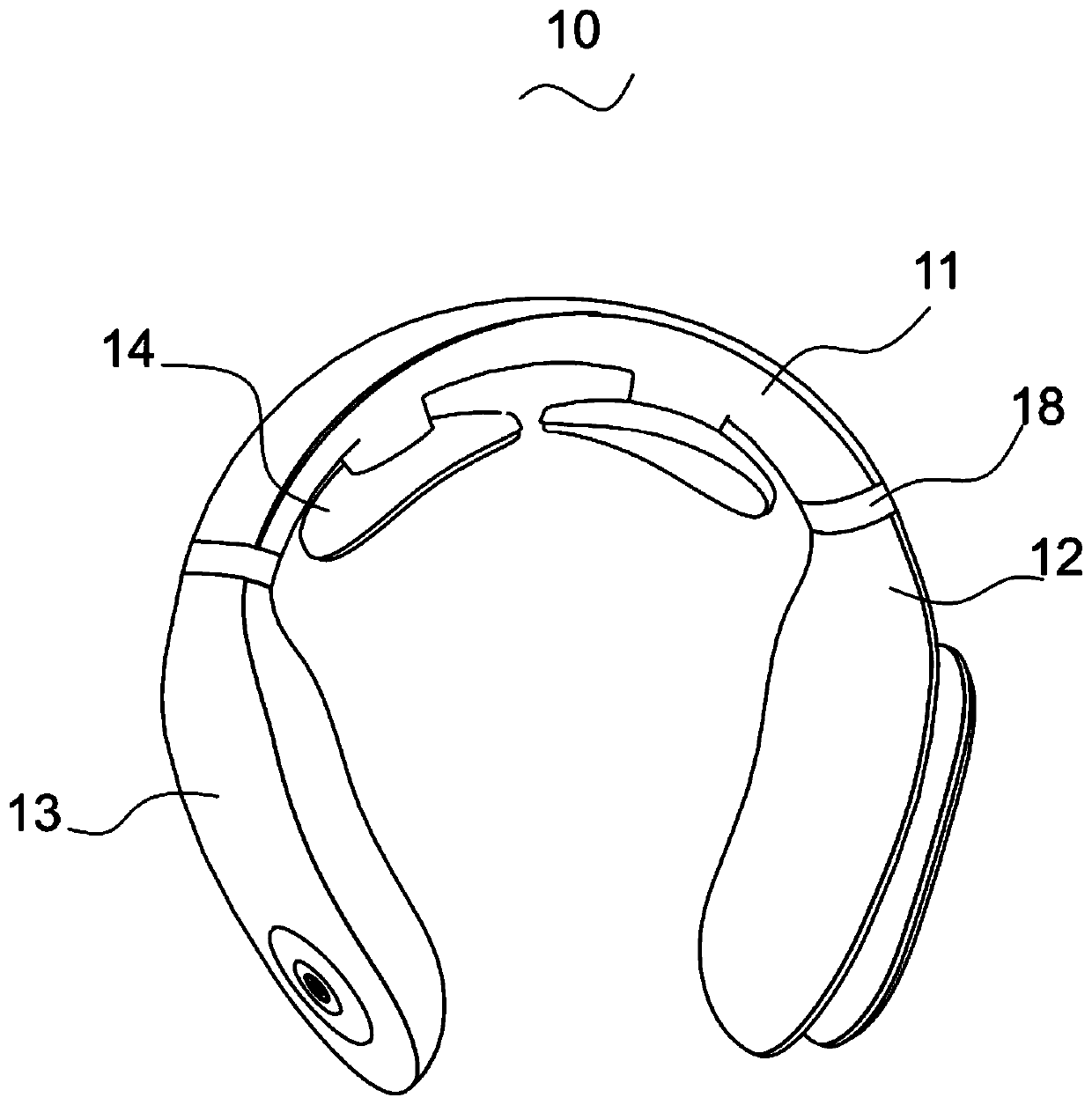

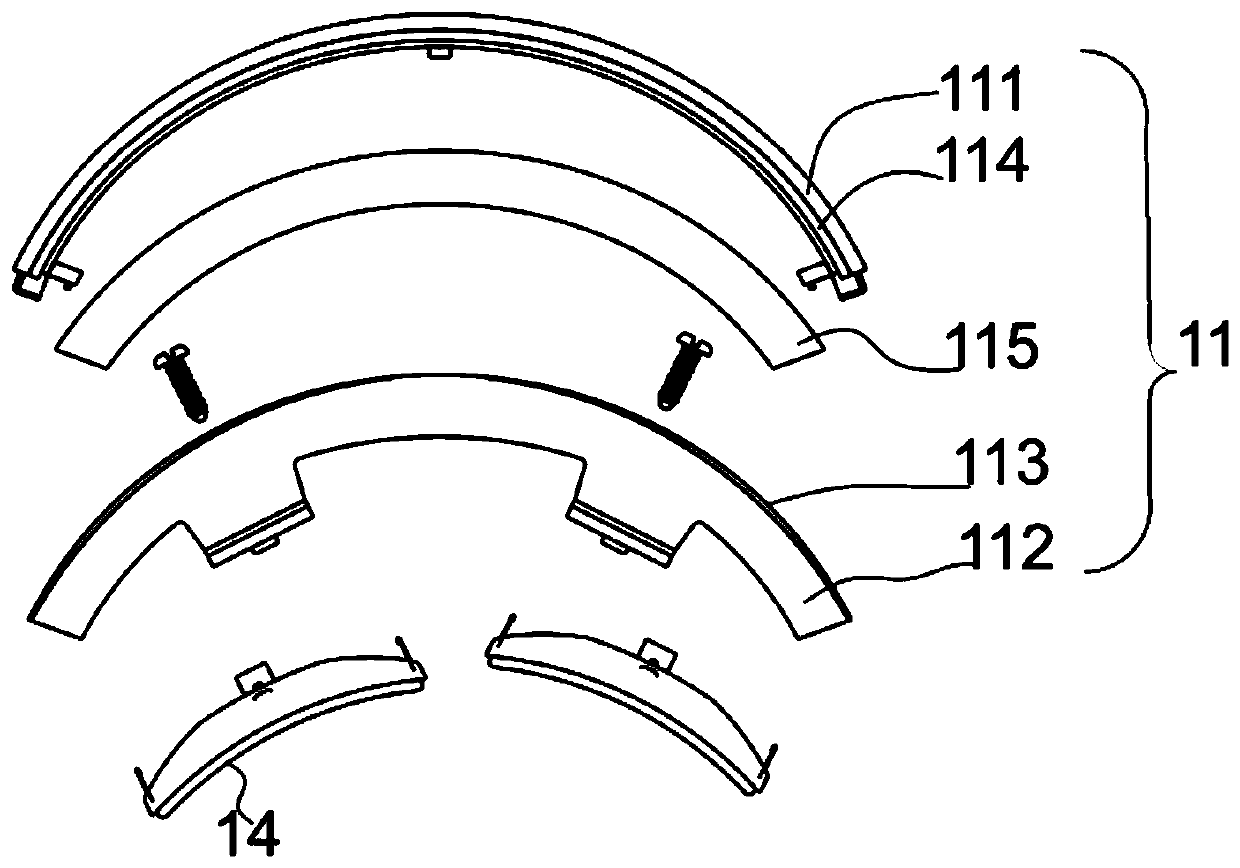

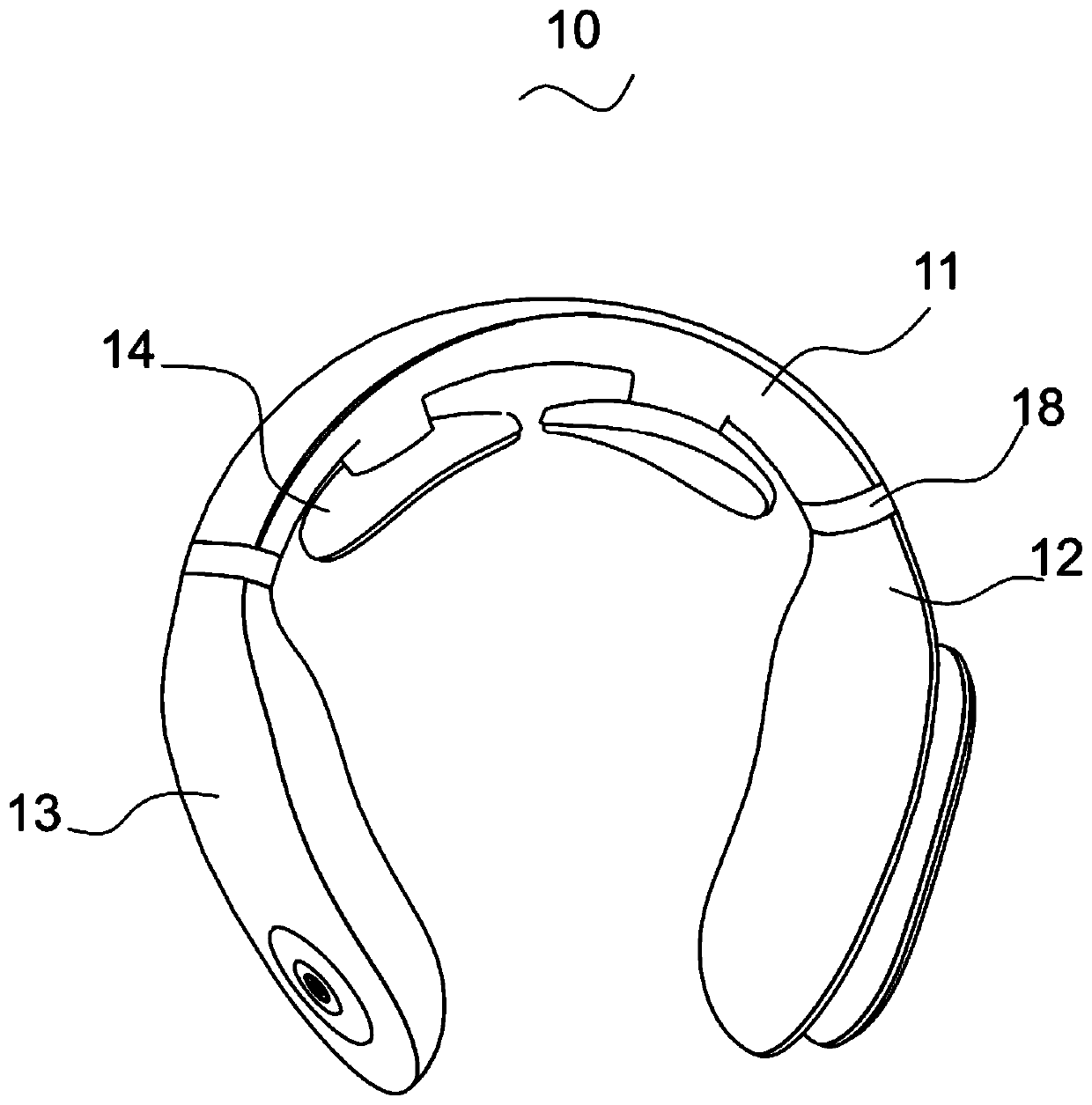

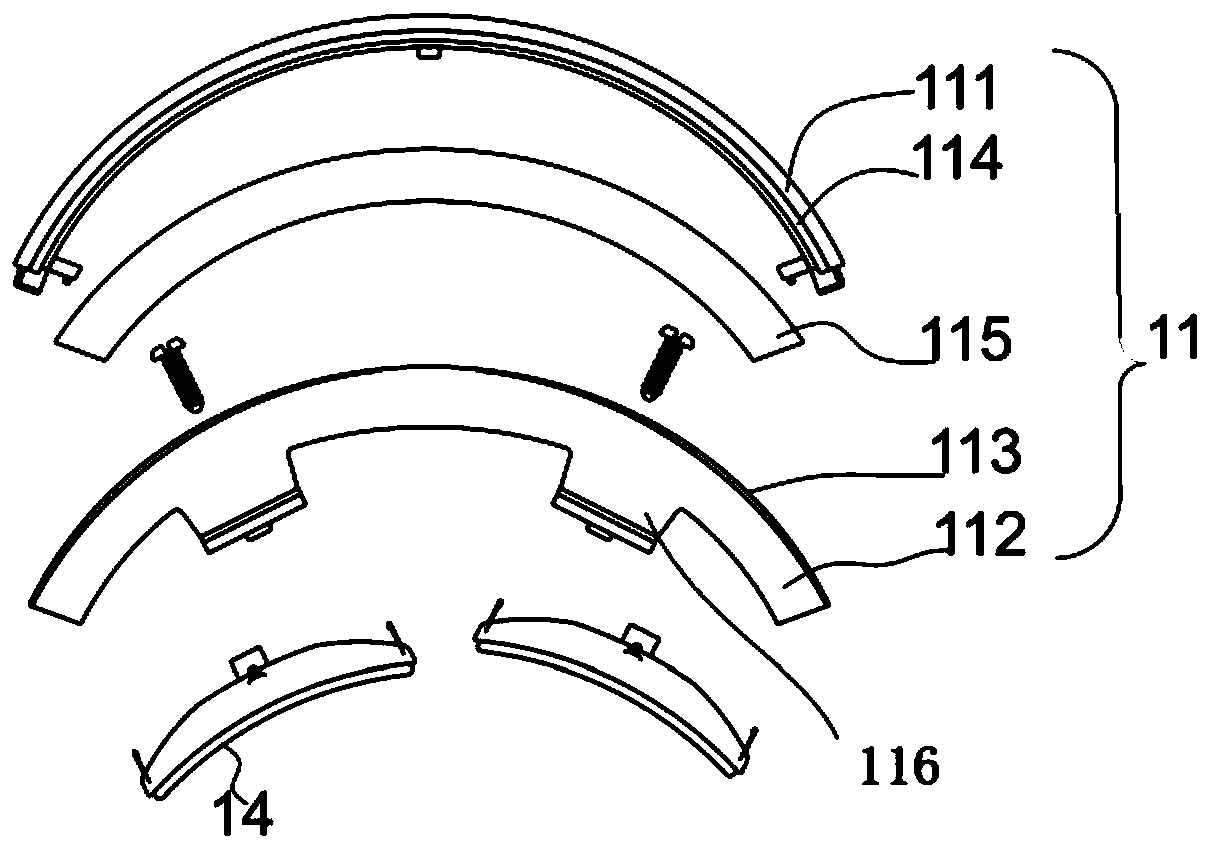

Neck massager

ActiveCN109621191AAdapt to thicknessEasy to disassembleElectrotherapyChiropractic devicesEngineering

The invention discloses a neck massager. The neck massager comprises a handle, an elastic arm, a connector, an electrode assembly and an electric pulse generation device electrically connected with the electrode assembly. The handle is connected to the elastic arm through the connector and comprises a first outer shell and a first inner shell buckled to the first outer shell, the first outer shellcomprises a connection end and a free end opposite to the connection end, and the connection end is connected with the connector; the first inner shell is clamped to the connector, and the free end swings with the connector as the fulcrum under the effect of external force to drive the first inner shell to be separated from the connector. The neck massager is worn through deformation of the elastic arm and well adapts to the thickness of the neck.

Owner:GUANGDONG SKG INTELLIGENT TECH CO LTD

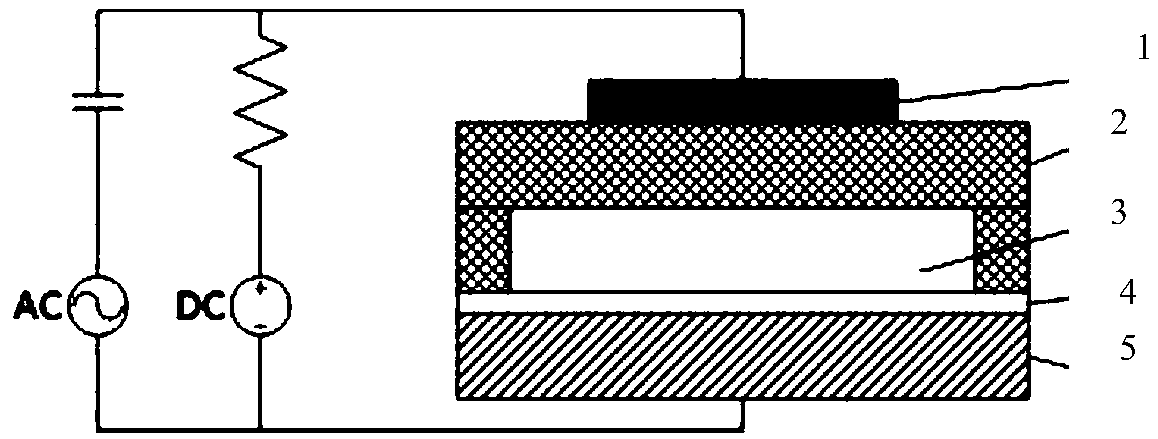

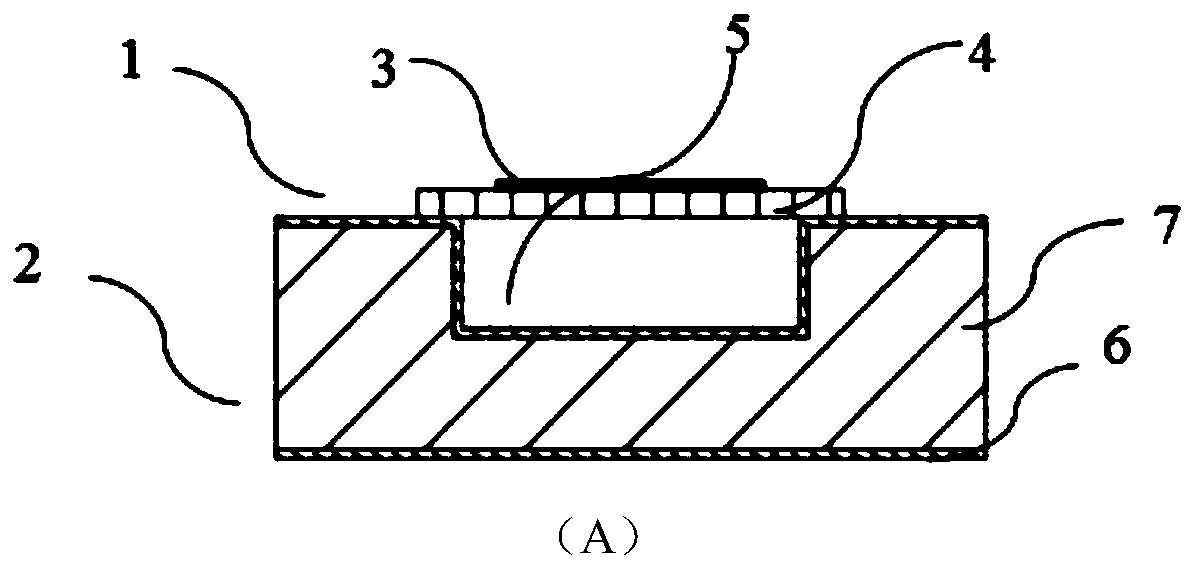

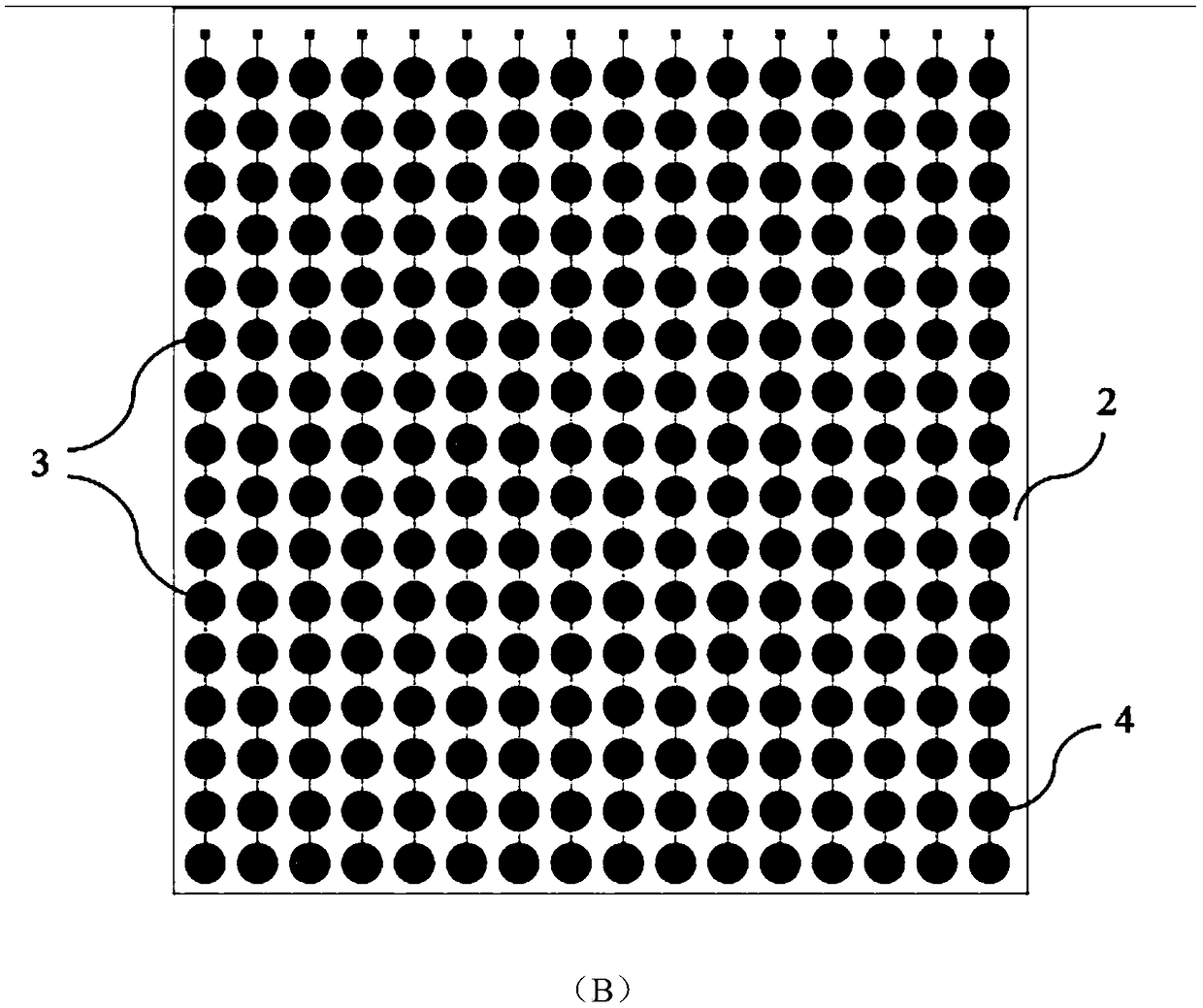

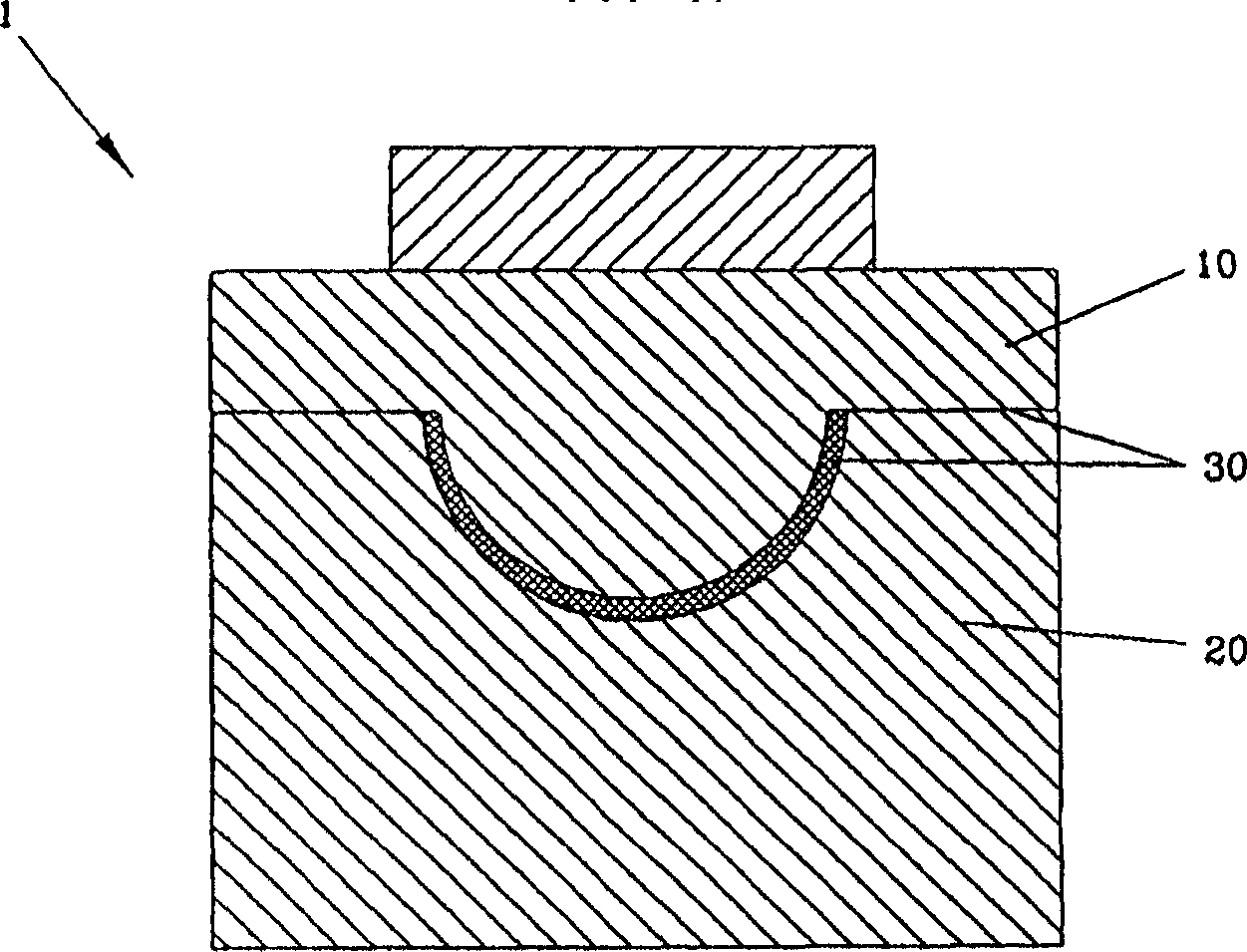

Air-coupled capacitive micromachining ultrasonic transducer, preparation method and application

ActiveCN108704827AHigh electromechanical coupling efficiencyLow acoustic impedanceAfter-treatment detailsVacuum evaporation coatingSilicon nitrideAluminium

The invention relates to an air-coupled capacitive micromachining ultrasonic transducer, a preparation method and application. A transducer array comprises 16 array elements; each array element is formed by multiple sensing units; each sensing unit is structurally formed by an upper electrode 1, a vibrating diaphragm 2, a cavity 3 and a base 5 sequentially from top to bottom; and each base is usedas a lower electrode. The working frequency of the designed transducer is 100kHz to 2MHz. The transducer array is manufactured based on an SOI bonding process; each vibrating diaphragm is made of monocrystalline silicon; each upper electrode is gold or aluminum; an insulating layer 4 is silicon dioxide or silicon nitride; and the array elements of the transducer are divided through etching the low-resistance-silicon bases to form grooves, so that the array with the multiple array elements is formed. According to the air-coupled ultrasonic transducer, an ultrasonic wave in a metal plate or a composite plate is excited through an air coupling manner and is used for nondestructively detecting internal defects of the plate. The transducer is matched with a phased array system, and pulse drivesignals of the array elements are delay-controlled, so that the phase-controlled deflection and the focusing of an acoustic beam are adjusted, and the freedom degree of detecting is increased.

Owner:TIANJIN UNIV

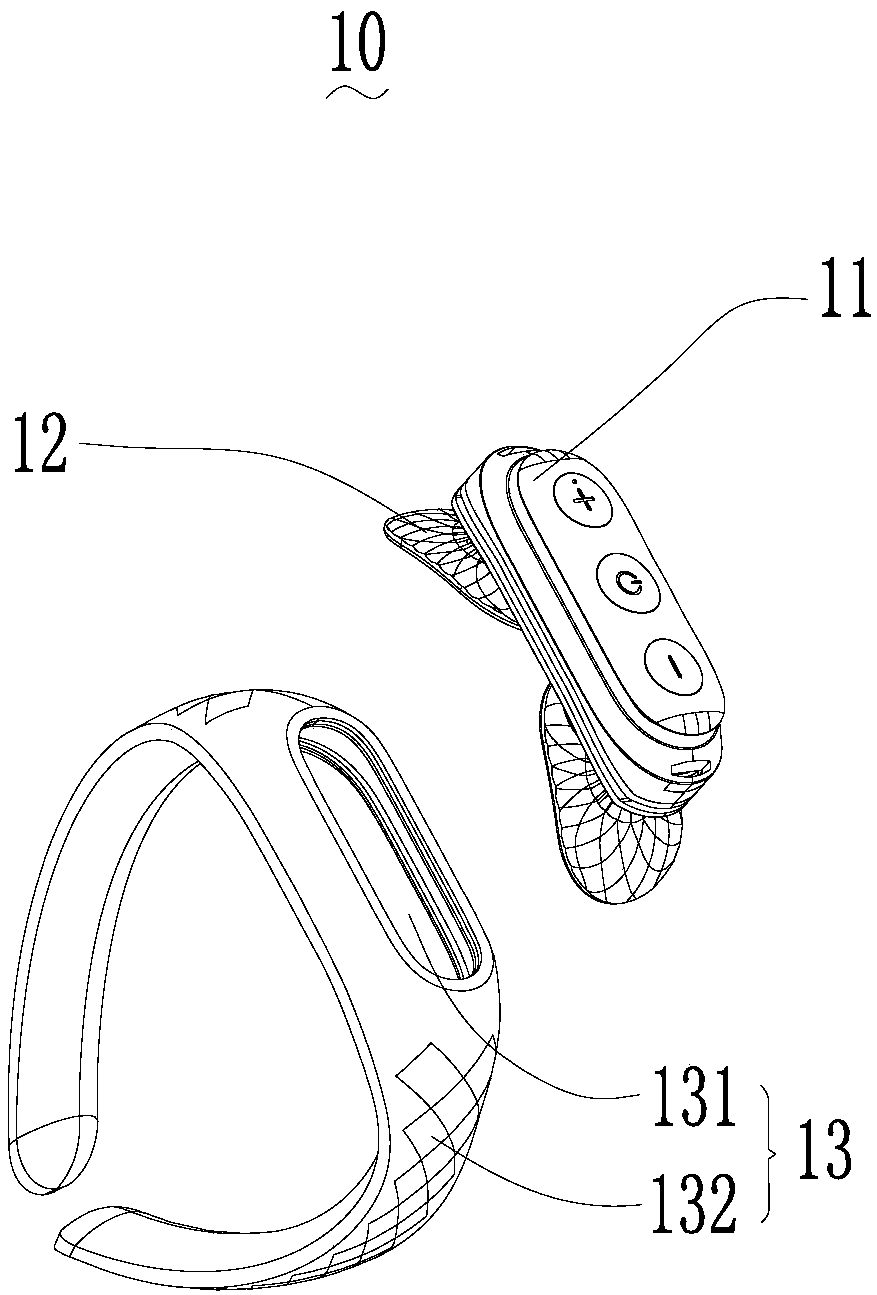

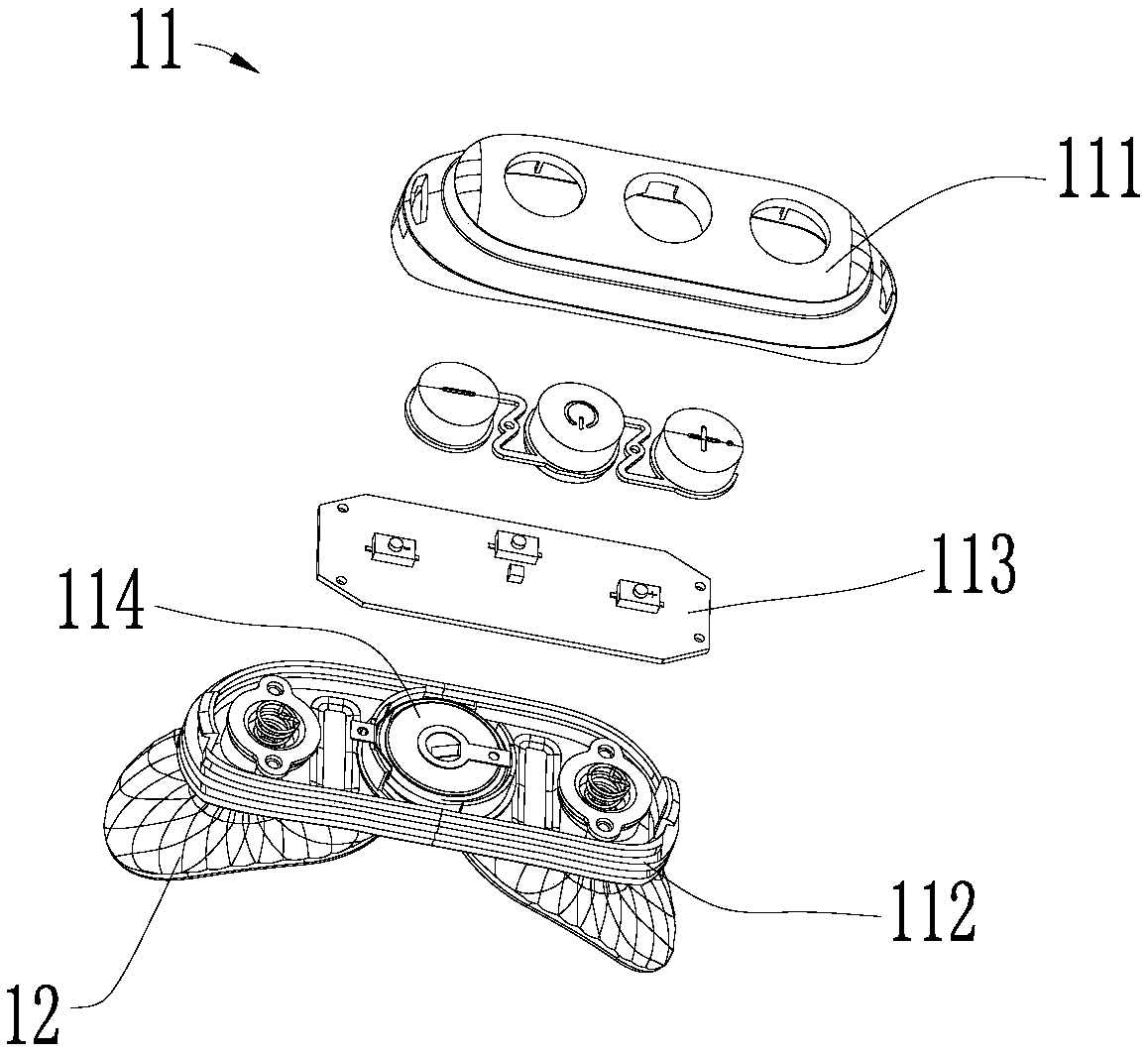

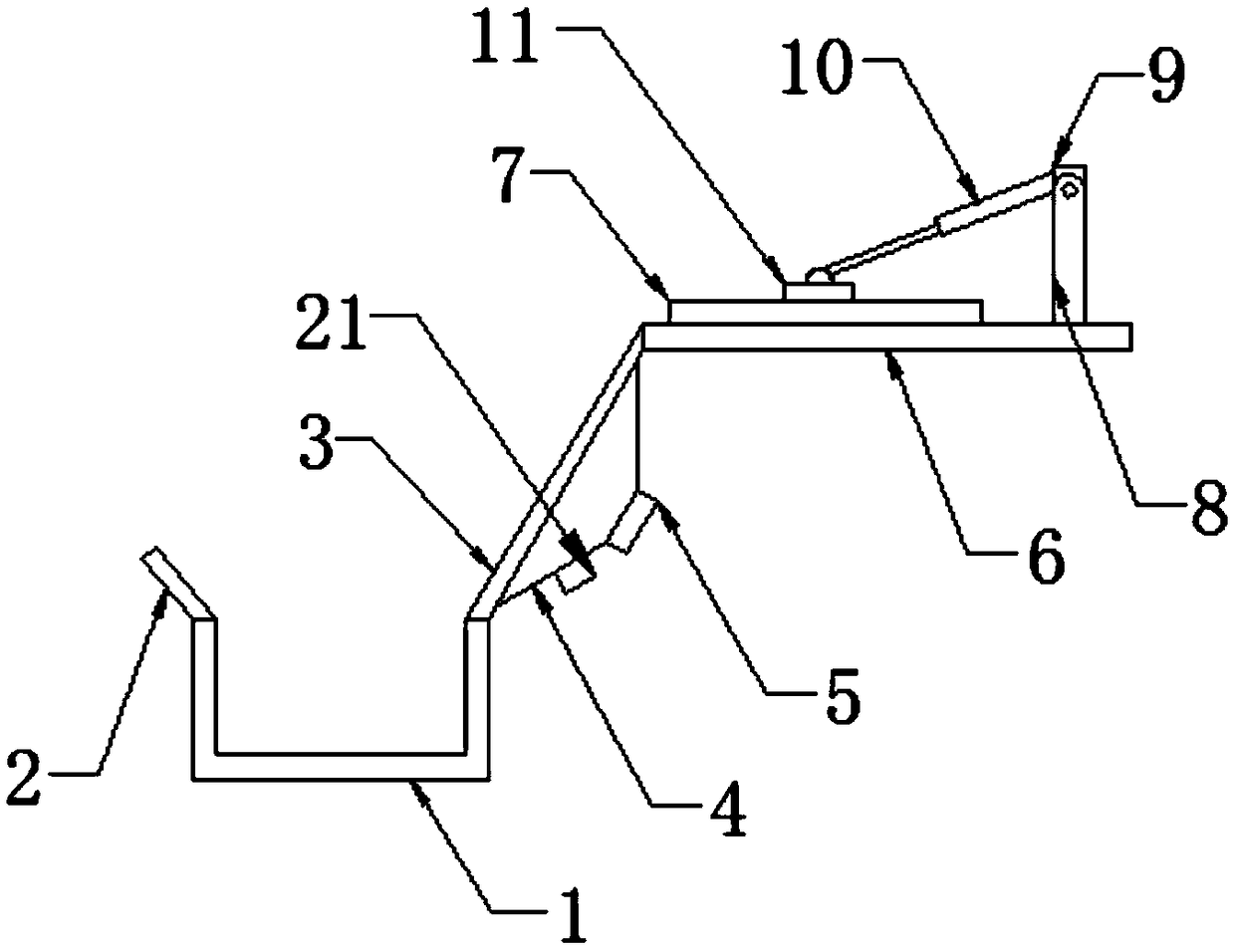

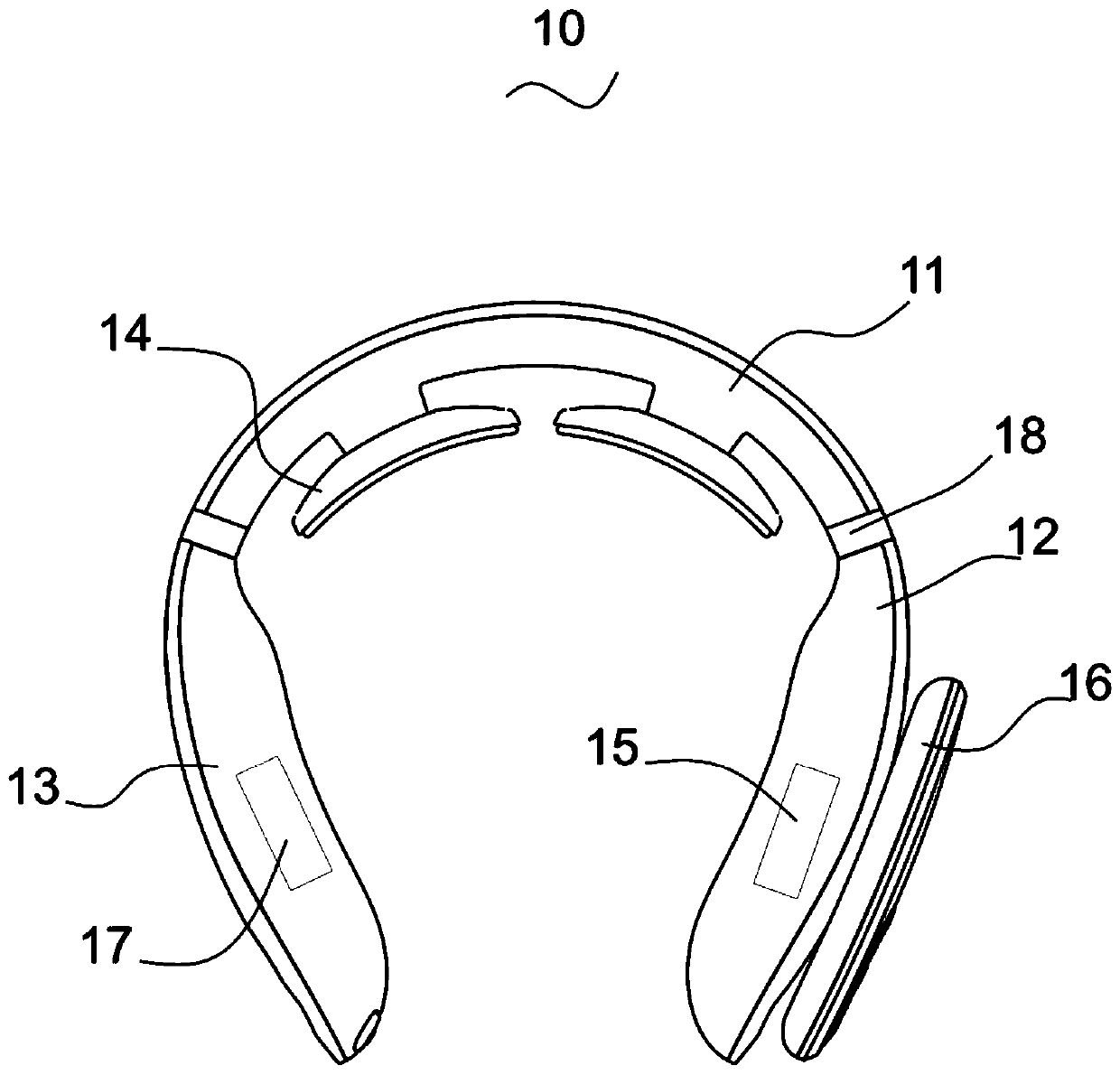

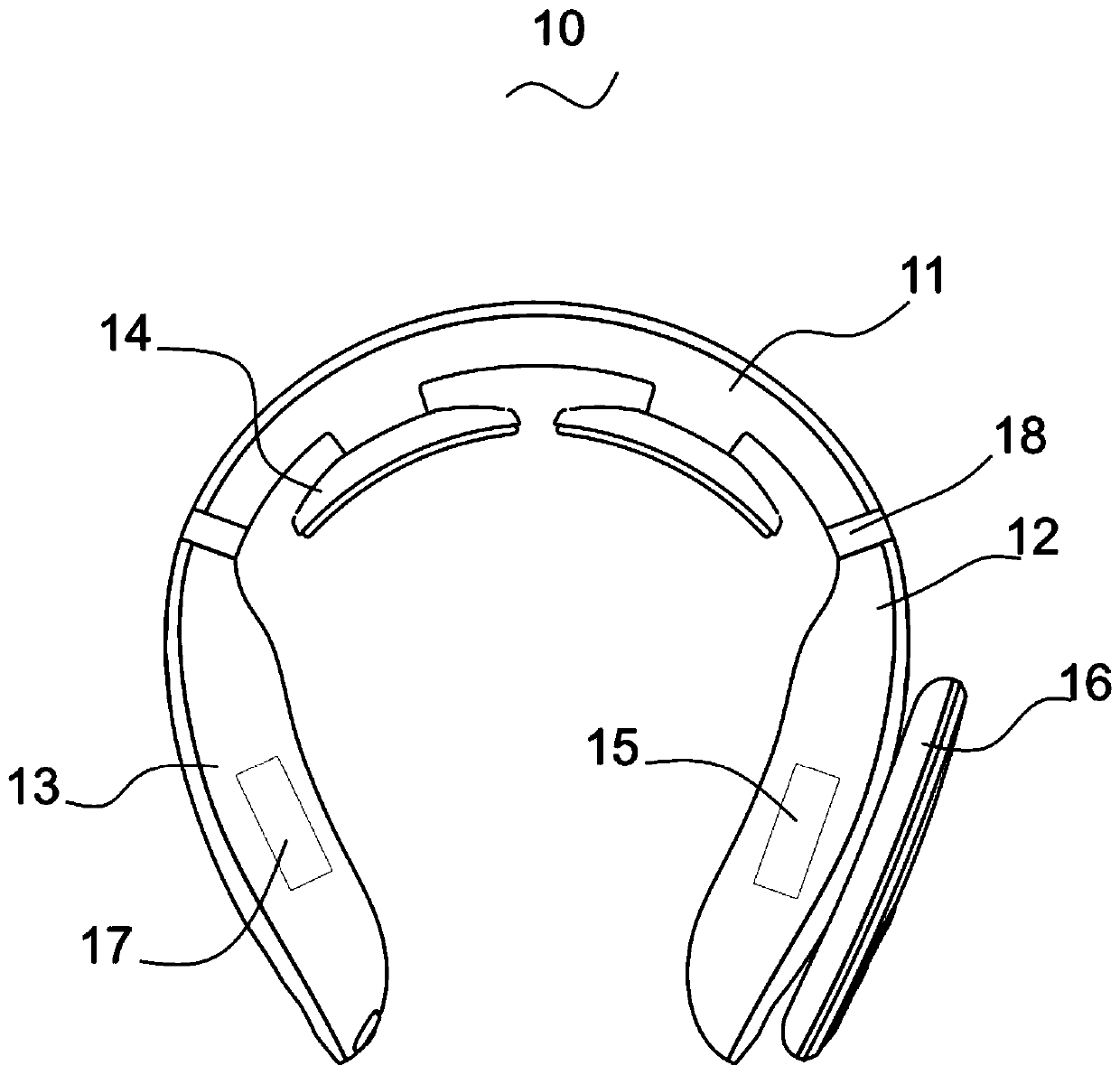

Portable neck massage instrument

PendingCN109603001AAdapt to wearAdapt to thicknessExternal electrodesArtificial respirationMassageEngineering

The invention discloses a portable neck massage instrument, which comprises a main body of a rigid anti-deformation structure, a massage component fixed on the main body, and a flexible neckband for accommodating the main body. The central part of the flexible neckband is provided with an accommodating groove for accommodating the main body. The flexible neckband extends along the two ends of theaccommodating groove to form two neckband arms, respectively. The two neckband arms have an initial state and a clamping state relative to the initial state, when the being in the clamping state, thetwo neckband arms swing with the main body as a fulcrum while self elastic deformation occurs to adapt to the contour of the human neck. The two neckband arms provide the clamping force to clamp the human neck. The portable neck massage instrument can better adapt to the thickness of different human necks and achieve comfortable wear.

Owner:GUANGDONG SKG INTELLIGENT TECH CO LTD

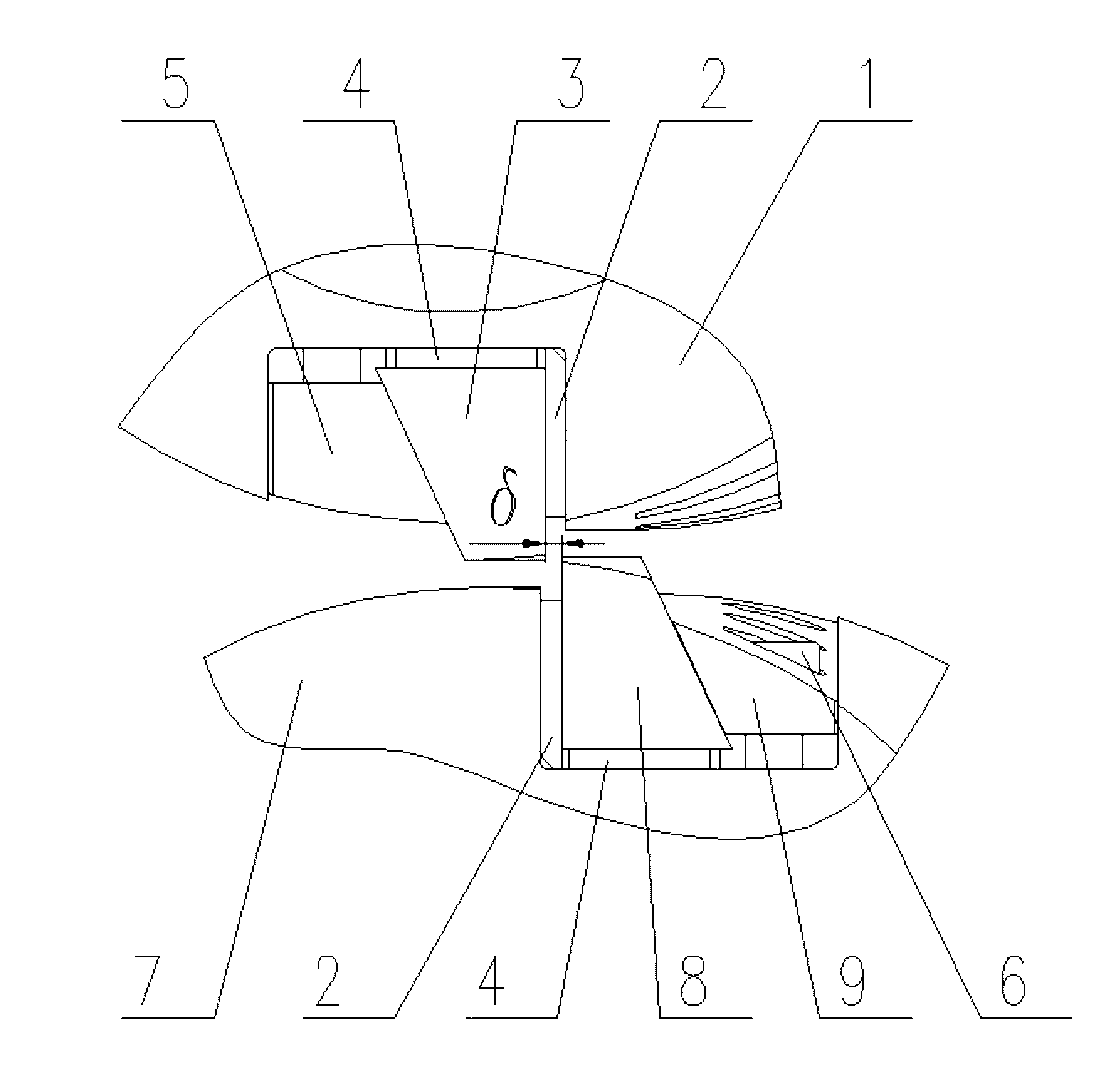

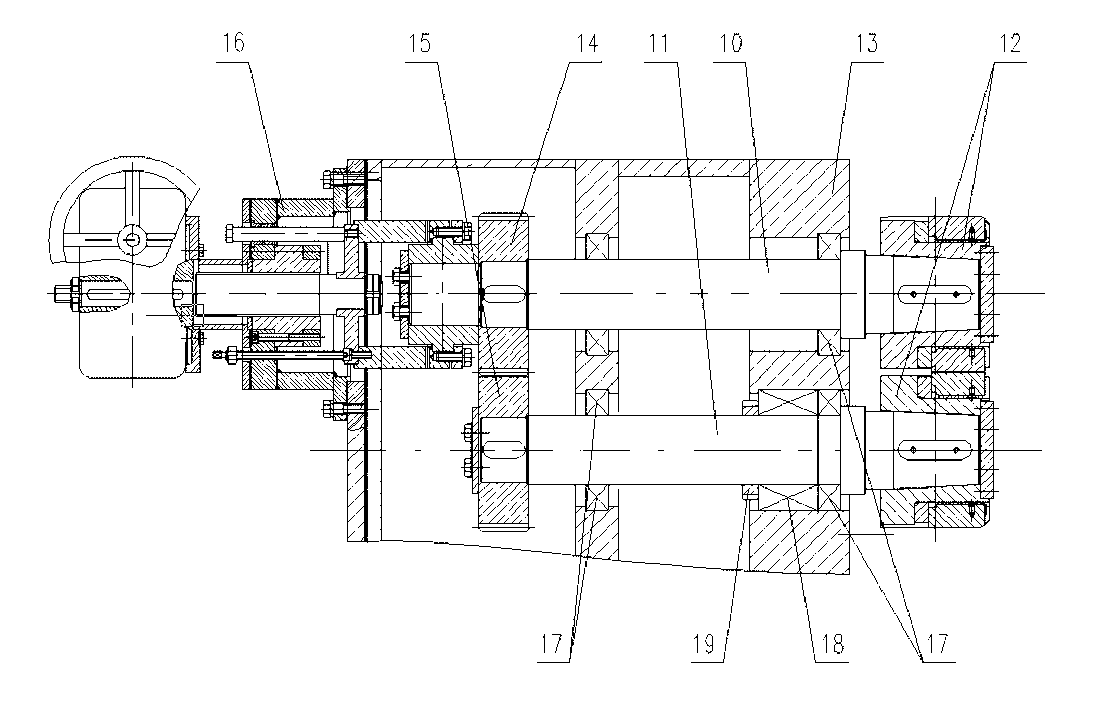

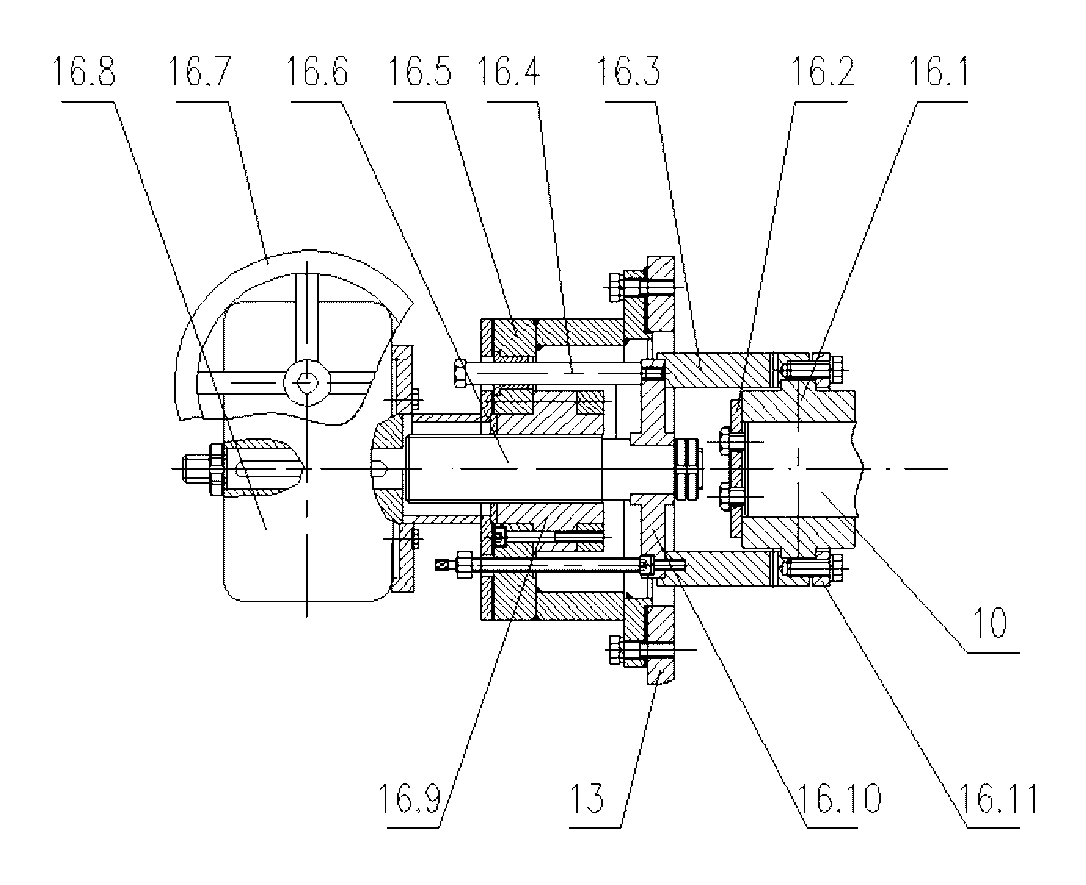

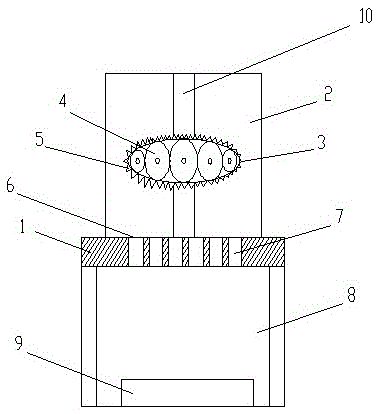

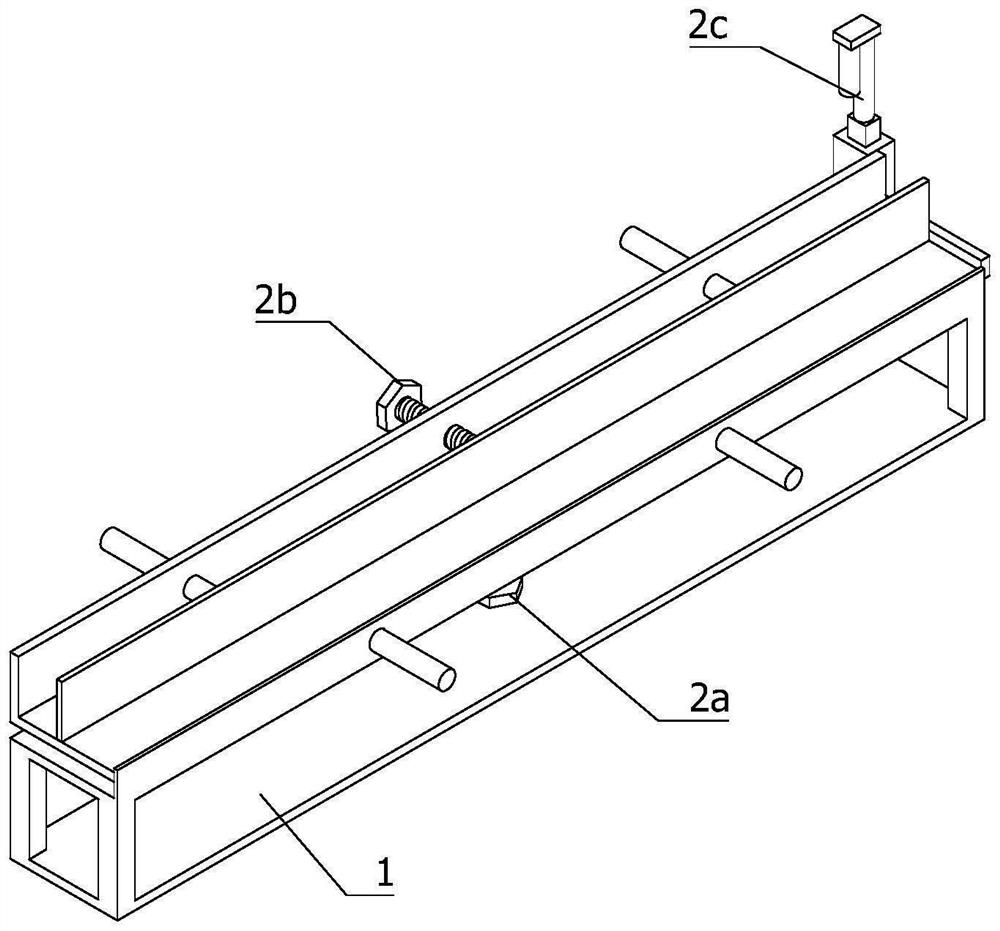

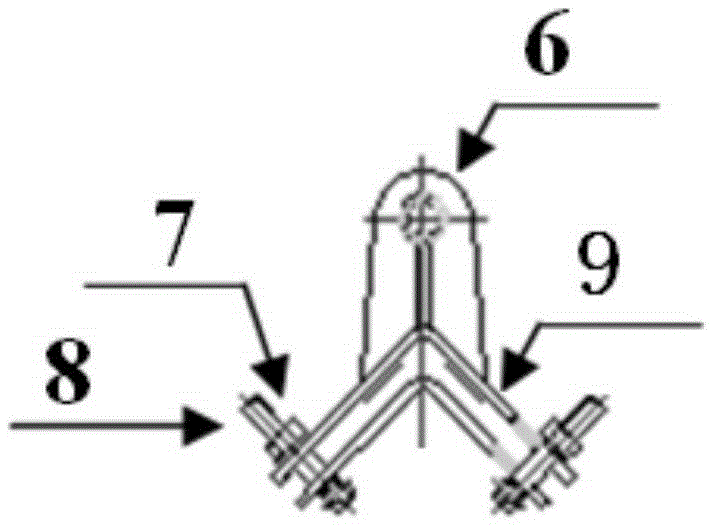

Axial micro adjusting method for side clearance of meshed cutter head of side crusher

ActiveCN102699410AAdapt to thicknessAdaptationShearing machinesShearing machine accessoriesAxial displacementDrive shaft

The invention discloses an axial micro adjusting method for the side clearance of a meshed cutter head of a side crusher. The side crusher comprises a first driving shaft, a second driving shaft, the meshed cutter head, a machine frame, a first synchronizing gear, a second synchronizing gear, a supporting bearing, a positioning bearing and a fixing nut, wherein the meshed cutter head comprises an upper cutter head, a side pad, an upper blade, a lower pad, an upper pressing plate, a bolt, a lower cutter head, a lower blade and a lower pressing plate; and a set of axial adjusting device is connected to the tail end of the first driving shaft and comprises a shaft hub, a pressing plate, a shaft hub sleeve, a guide screw rod, a frame body, a worm, a hand wheel, a worm gear case, a worm sleeve, a connecting plate and a fixing sleeve. The axial displacement amount of the first driving shaft is determined by a rotating range allowed by the hand wheel, and the final side clearance theta between the blade of the upper blade and the blade of the lower blade is given in the rotating range and is less than or equal to the allowed axial clearance, so that axial micro adjustment on the side clearance of the meshed cutter head of a side crusher is realized. The side crusher has the characteristics of simple structure and convenience in mounting.

Owner:CHINA NON-FERROUS METALS PROCESSING TECH CO LTD

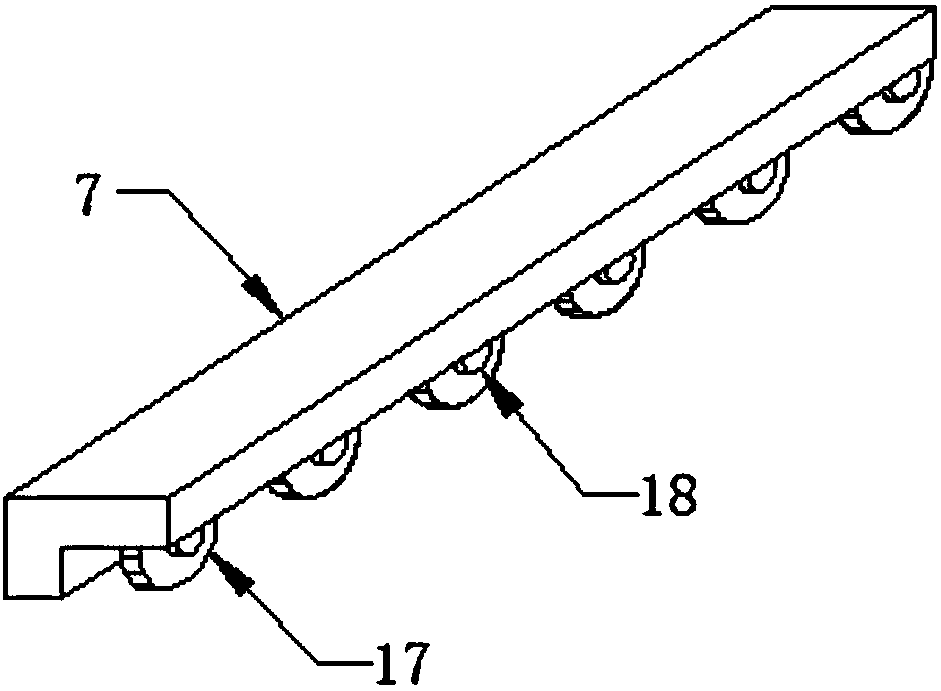

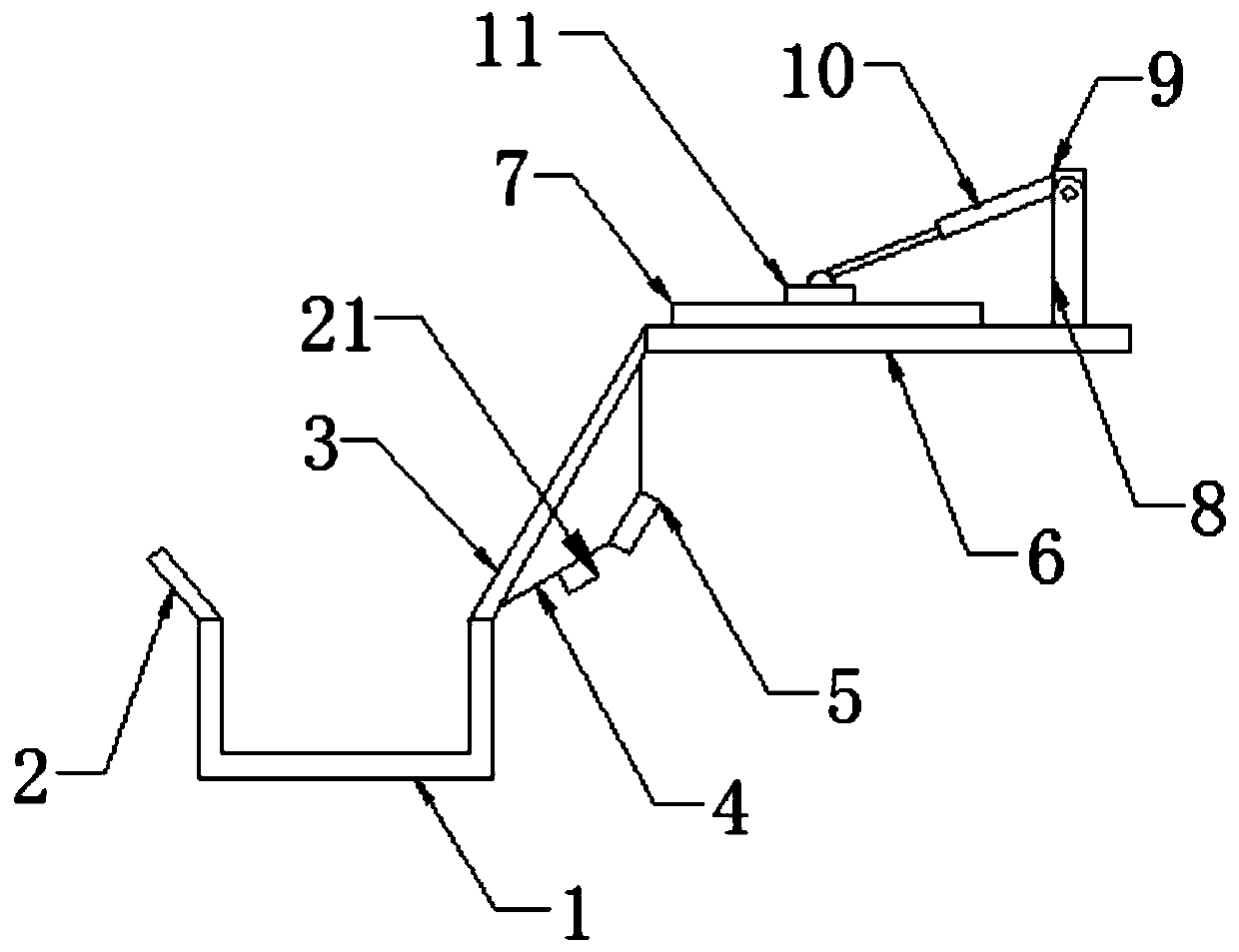

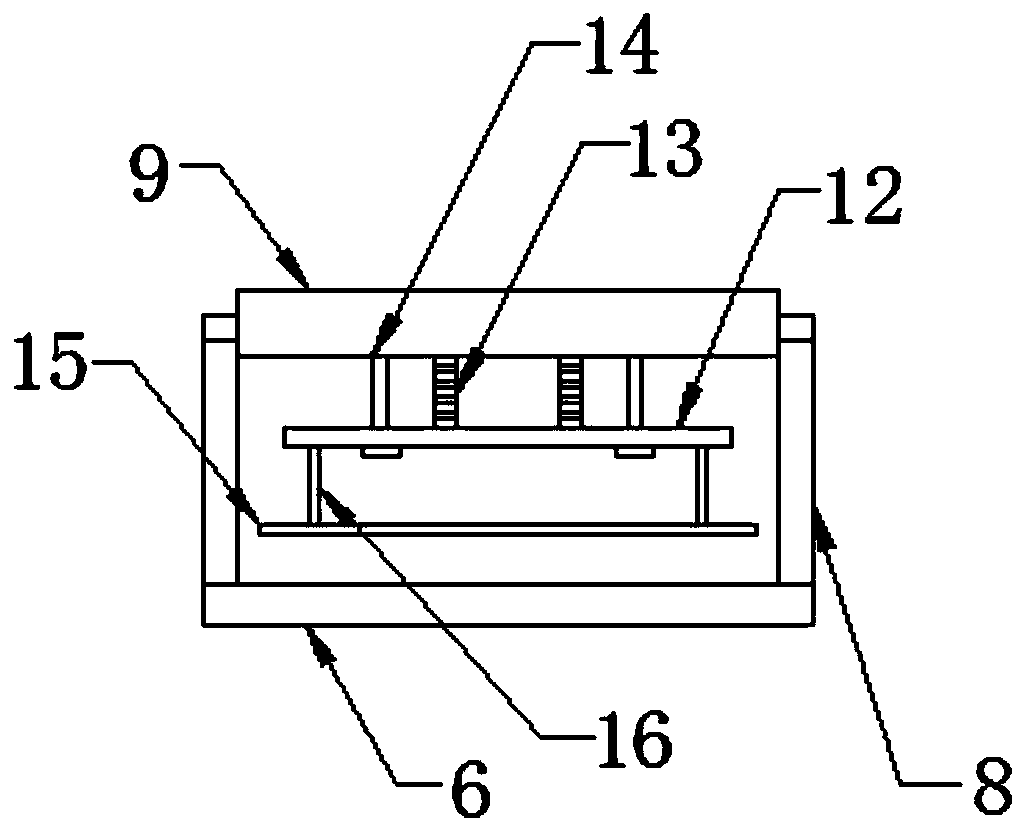

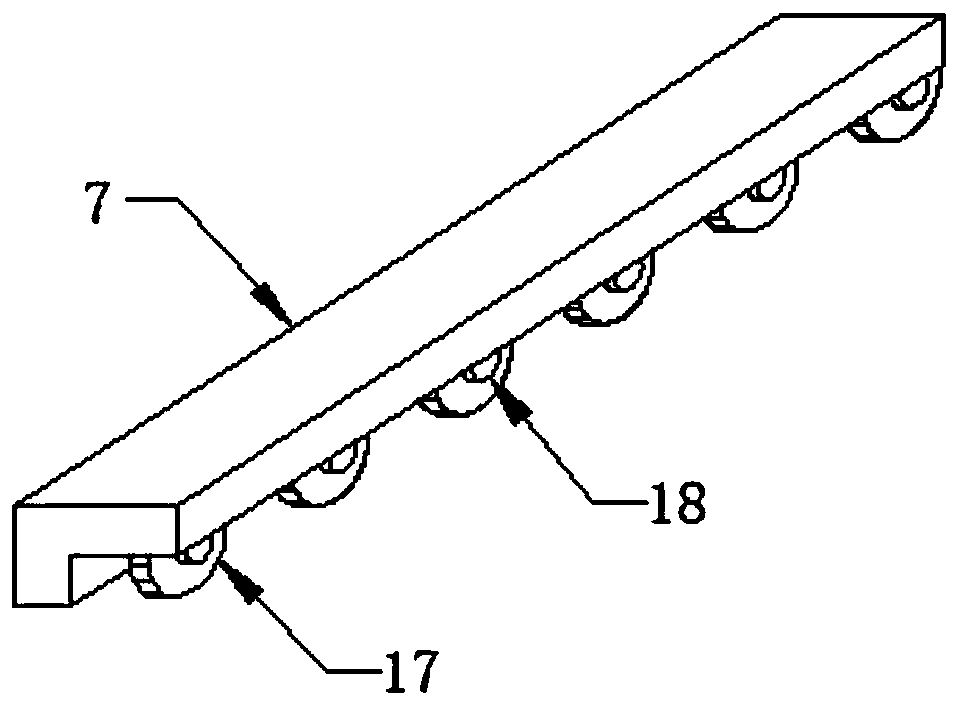

Cloth pressing device for warp knitting machine

ActiveCN108611751AQuickly eliminate static electricityAvoid sticking to each otherWarp knittingPulp and paper industryStatic electricity

The invention discloses a cloth pressing device for a warp knitting machine. The device comprises a storage groove, an inclined plate and a panel. A guiding plate is arranged at one side of the top end of the storage groove, the inclined plate is fixedly arranged at the other side of the top end of the storage groove, a blowing mechanism is arranged at one side of the inclined plate, the panel isfixedly arranged at one end of the inclined plate, the two sides of the top end of the panel are each fixedly provided with an L-shaped pressing strip, the two corners of the top end of the panel areeach fixedly provided with a supporting column, the tops of the two supporting columns are fixedly connected with the two ends of a transverse plate respectively, and a stretchable rod is installed inthe middle of one side of the transverse plate. Due to the design of the guiding plate and the storage groove, cloth can be stored, due to cooperative use of the inclined plate and the blowing mechanism, static electricity on the cloth can be rapidly removed, cloth adhesion is avoided, and meanwhile the cloth is spread out by means of gravity; a plurality of wheels are arranged at one sides of the two L-shaped pressing strips, the two sides of the cloth can be flattened, and uniform and flat transportation of the cloth is ensured.

Owner:浙江华煌针织科技股份有限公司

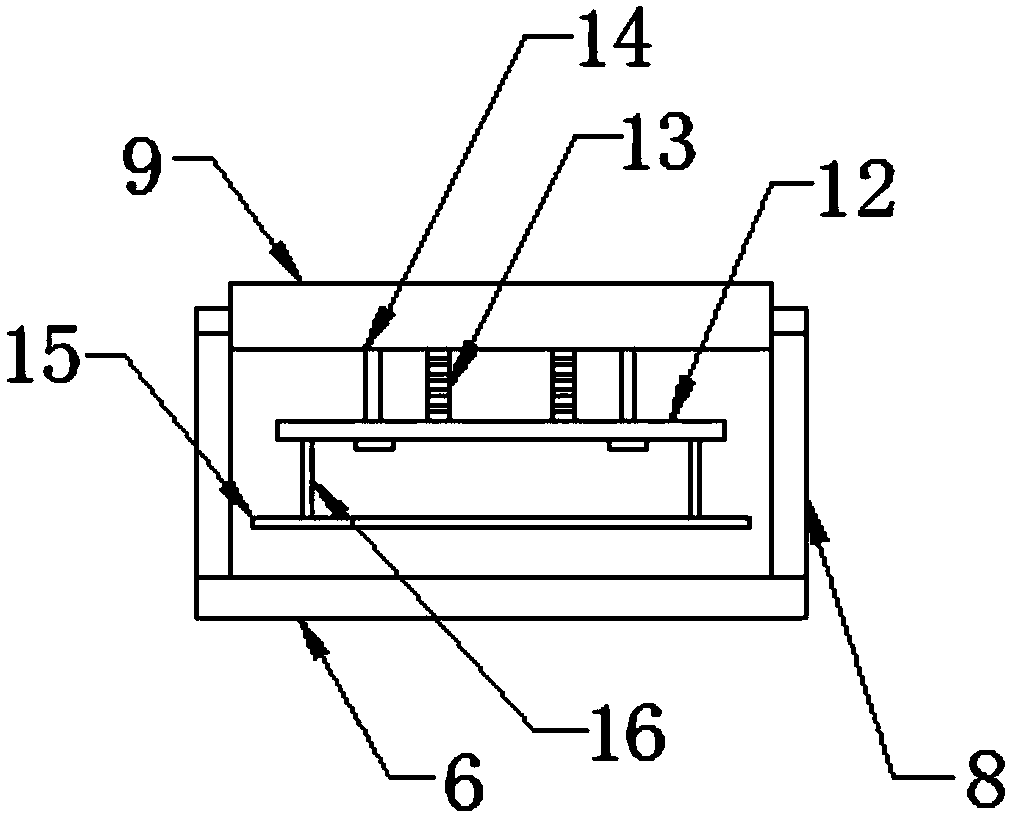

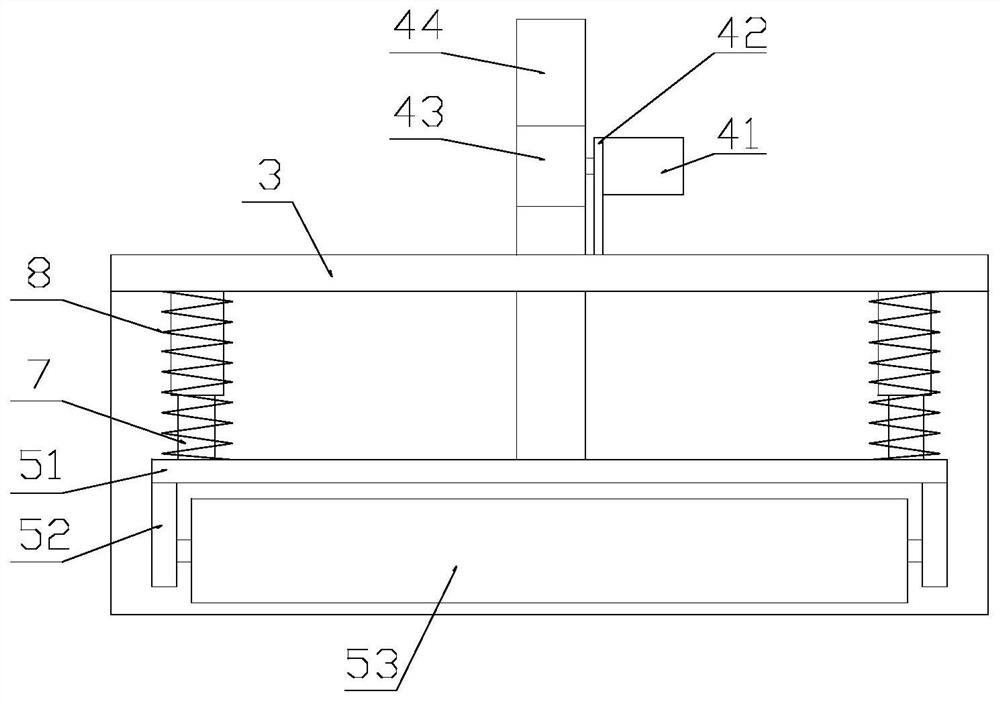

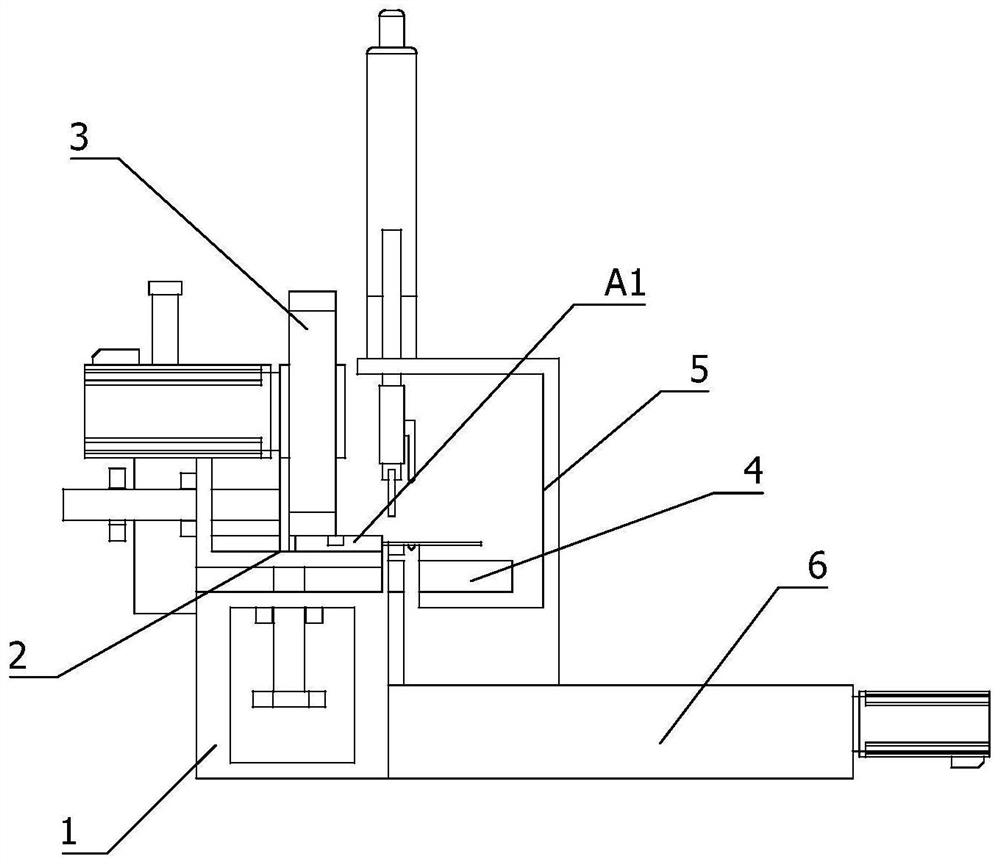

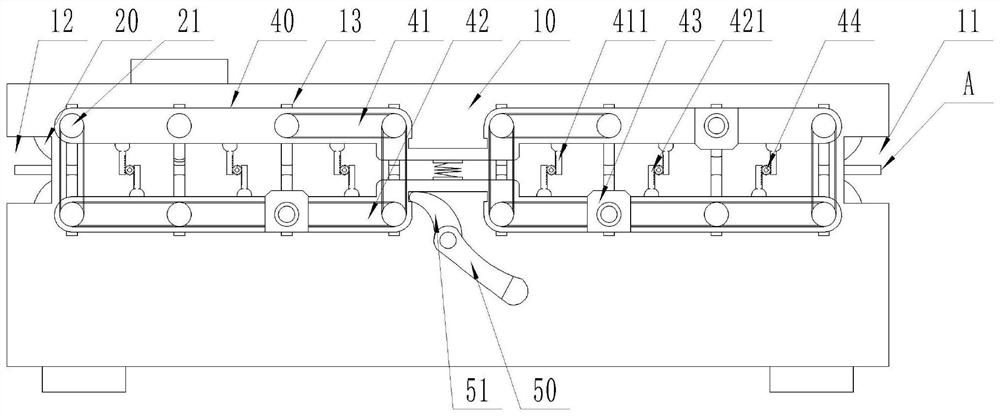

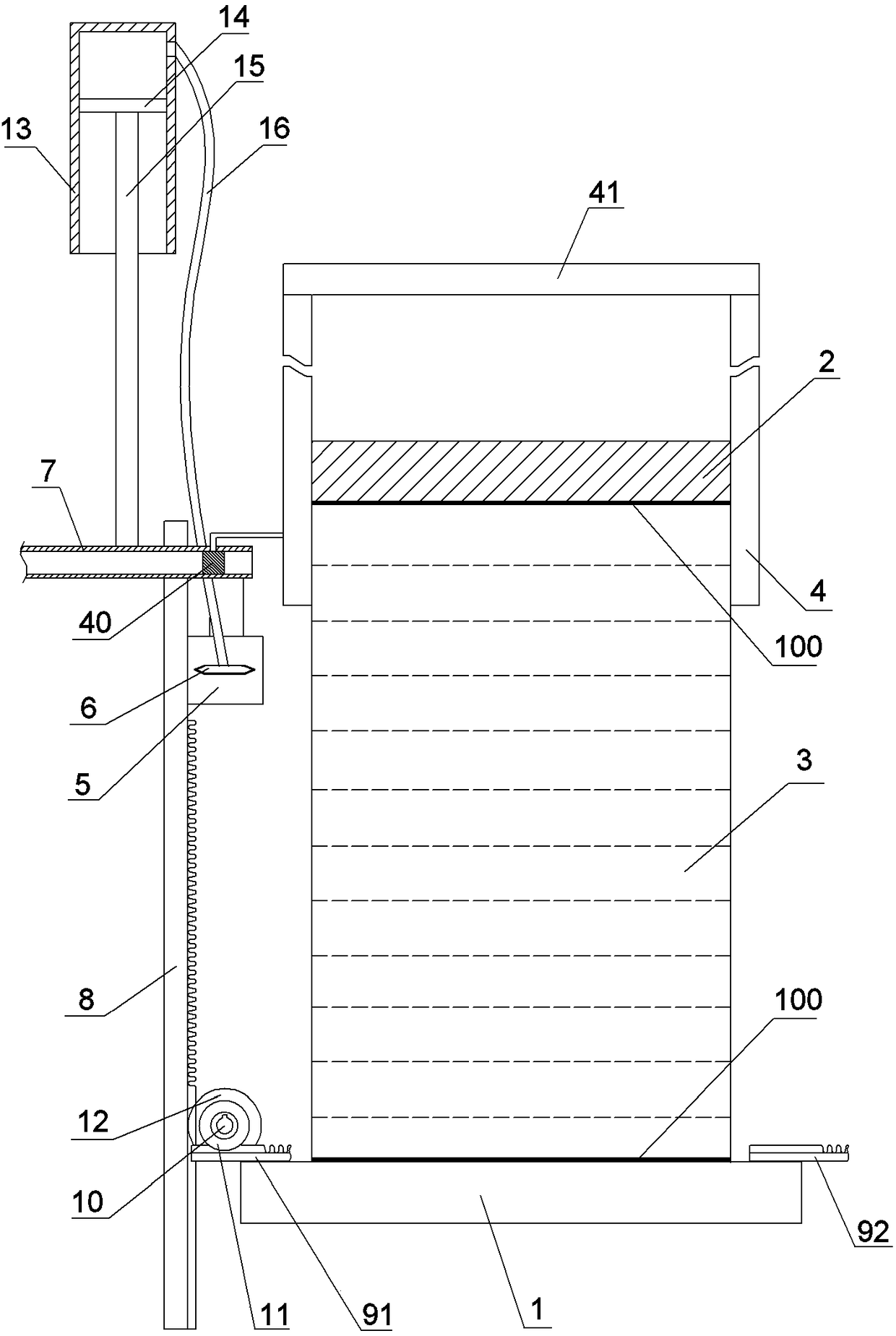

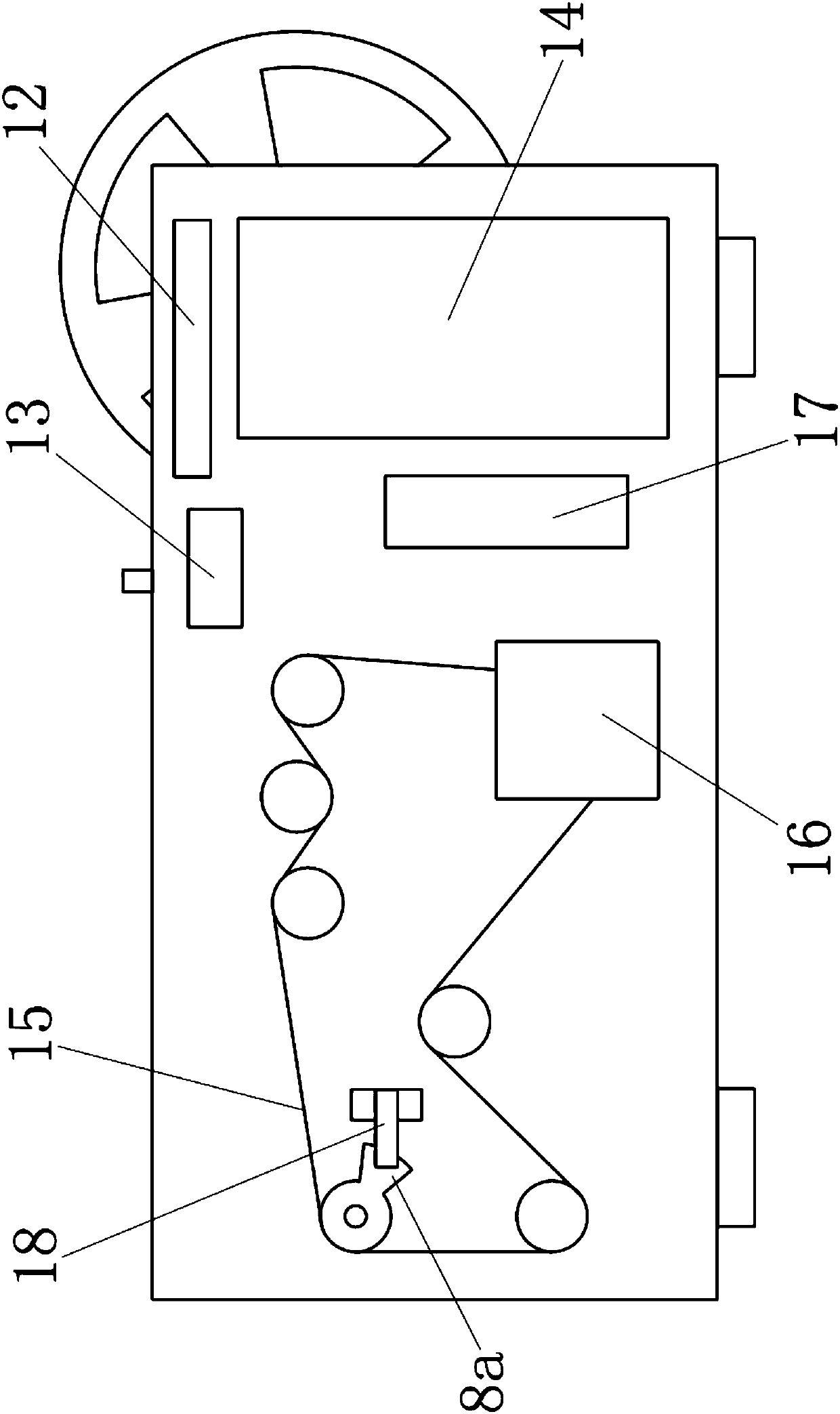

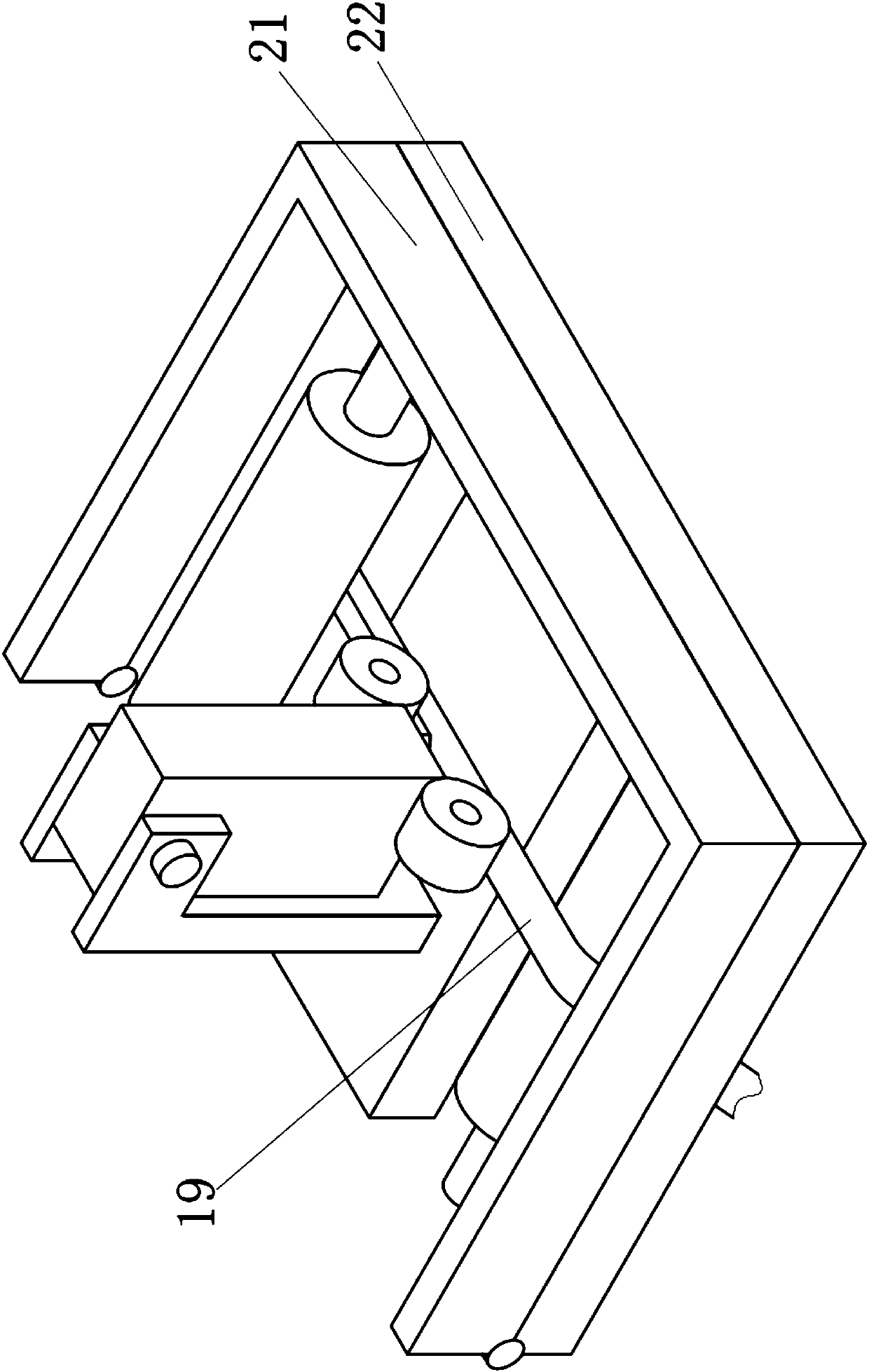

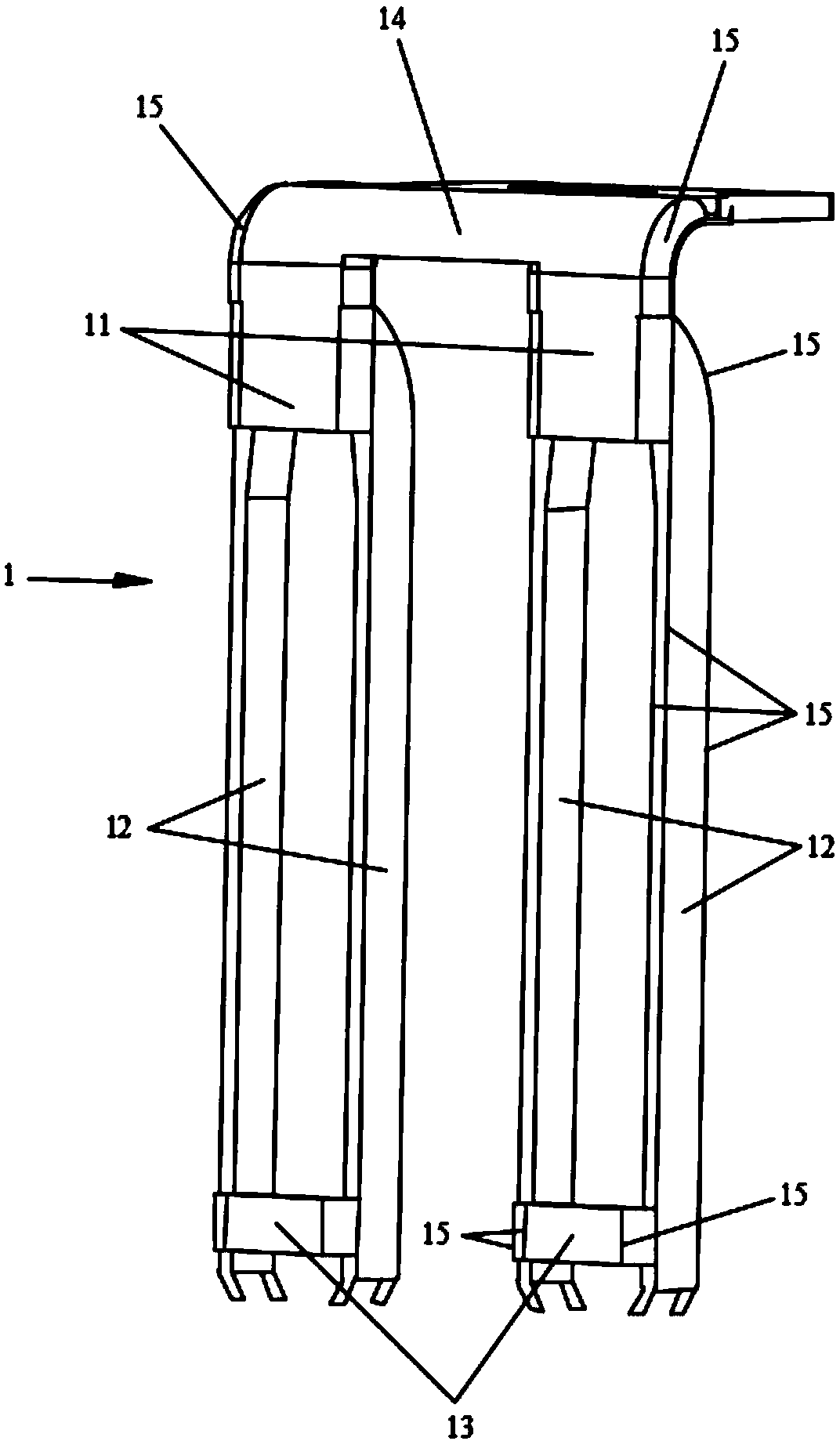

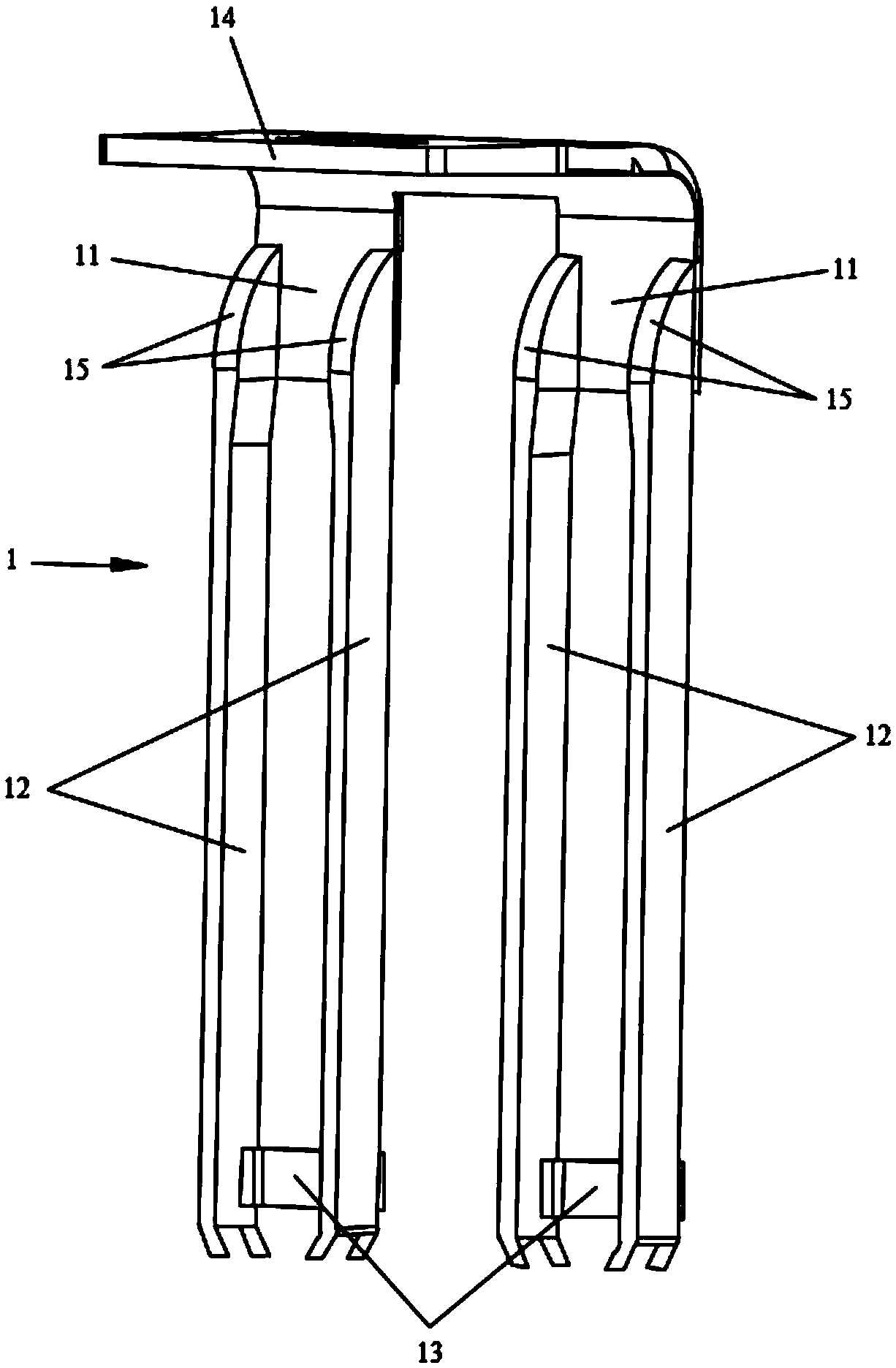

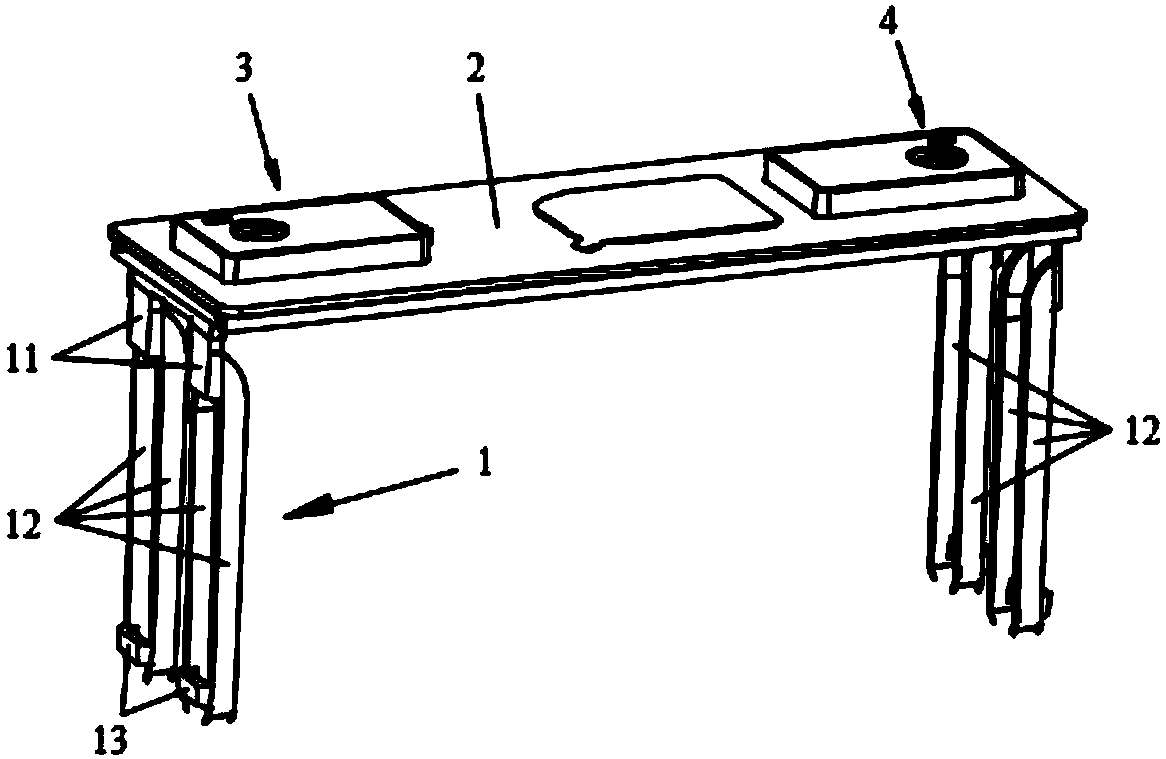

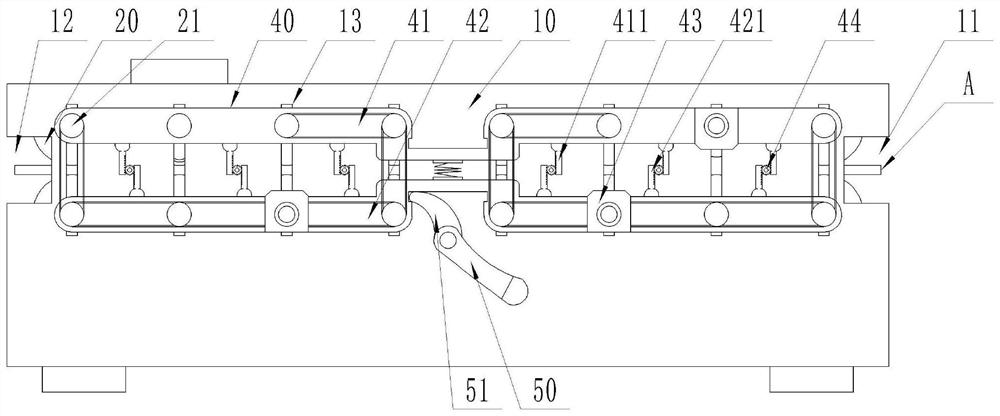

Cloth pressing device of sewing machine and working method of cloth pressing device

InactiveCN112680888AAdapt to thicknessReduce tensionWork-feeding meansPressersElectric machineryControl switch

The invention discloses a cloth pressing device of a sewing machine. The cloth pressing device comprises a workbench, a sewing machine body, tensioning seats, lifting mechanisms, pressing wheel mechanisms, a tensioning mechanism and a control switch set, wherein the sewing machine body is fixed above the workbench; the tensioning seats are symmetrically arranged on the two sides of the workbench with the sewing machine as the center; the tensioning seats are slidably connected with the workbench; the lifting mechanisms are arranged in the longitudinal centers of the tensioning seats; pressing wheel mechanisms are connected to the lower portions of the lifting mechanisms; the tensioning mechanism is arranged in the workbench; the control switch set is arranged on the front side of the workbench; and the sewing machine body, the lifting mechanisms and a second motor of the tensioning mechanism are electrically connected with the control switch set. The cloth pressing device of the sewing machine is simple and reasonable in structure, capable of automatically adapting to tensioning according to the width and thickness of cloth, high in automation degree, capable of reducing the workload of workers and capable of improving the production efficiency.

Owner:徐州力达缝纫设备制造有限公司

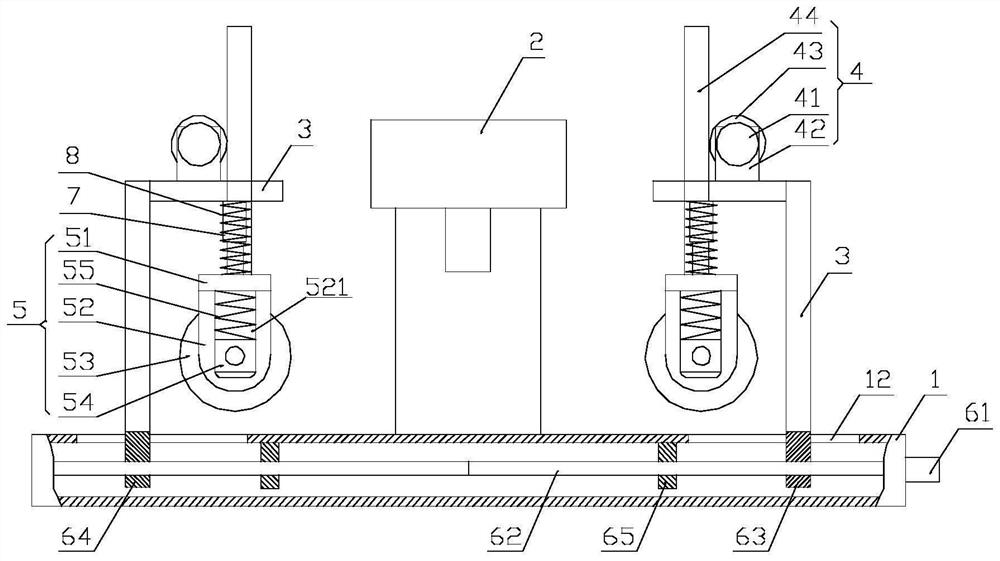

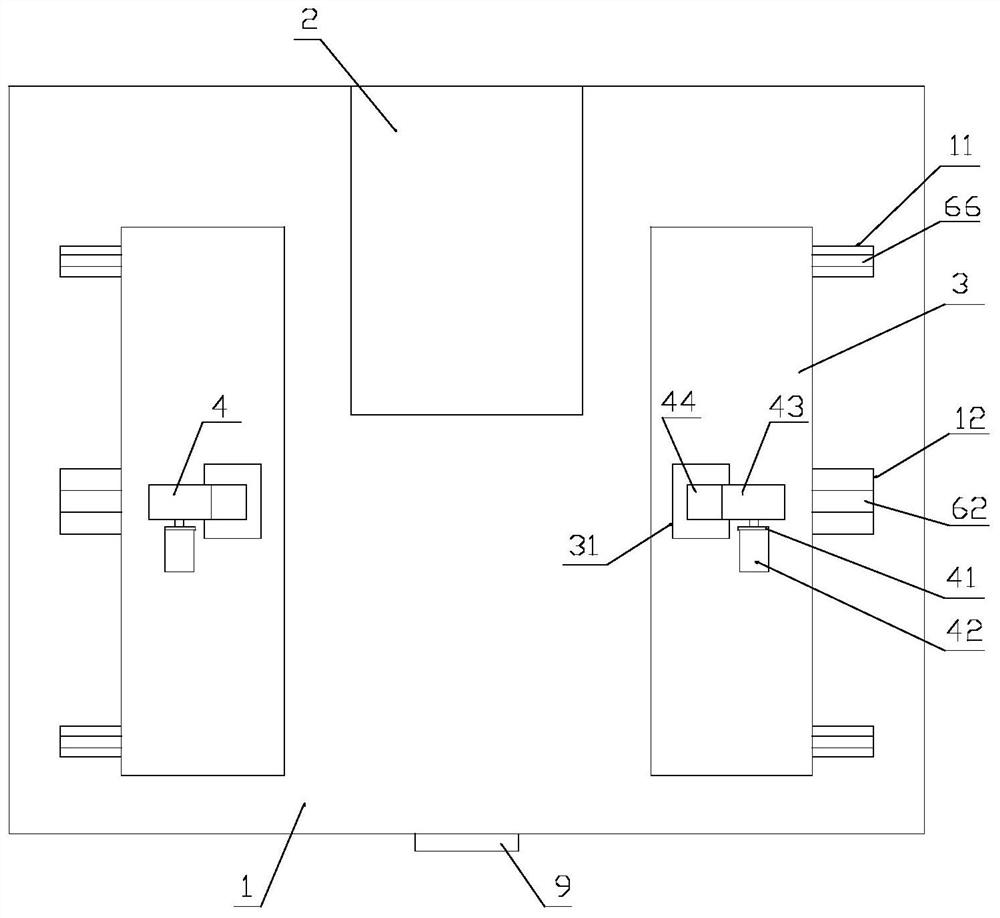

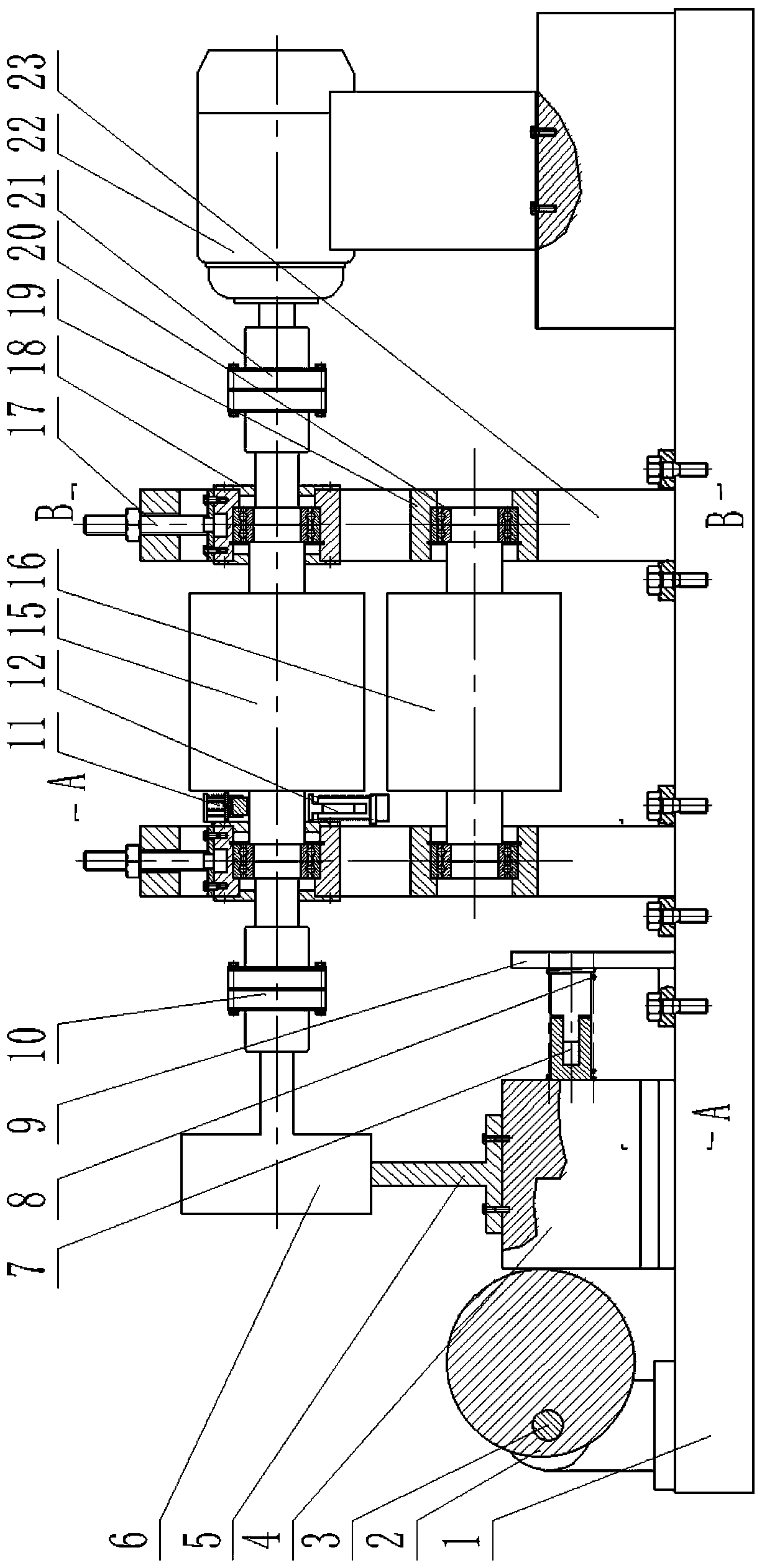

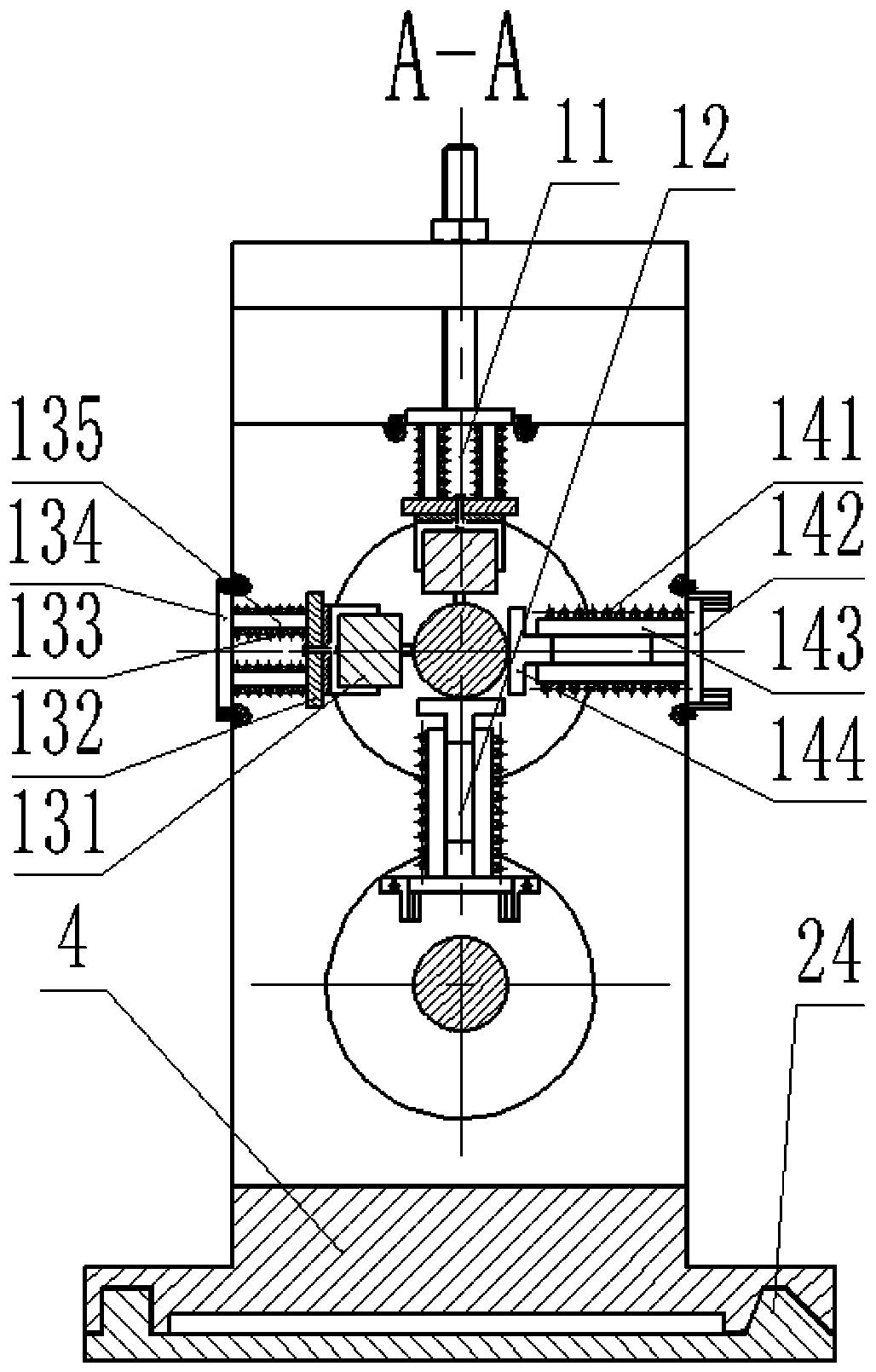

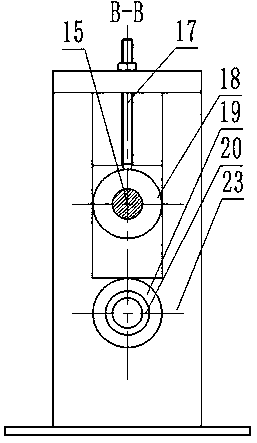

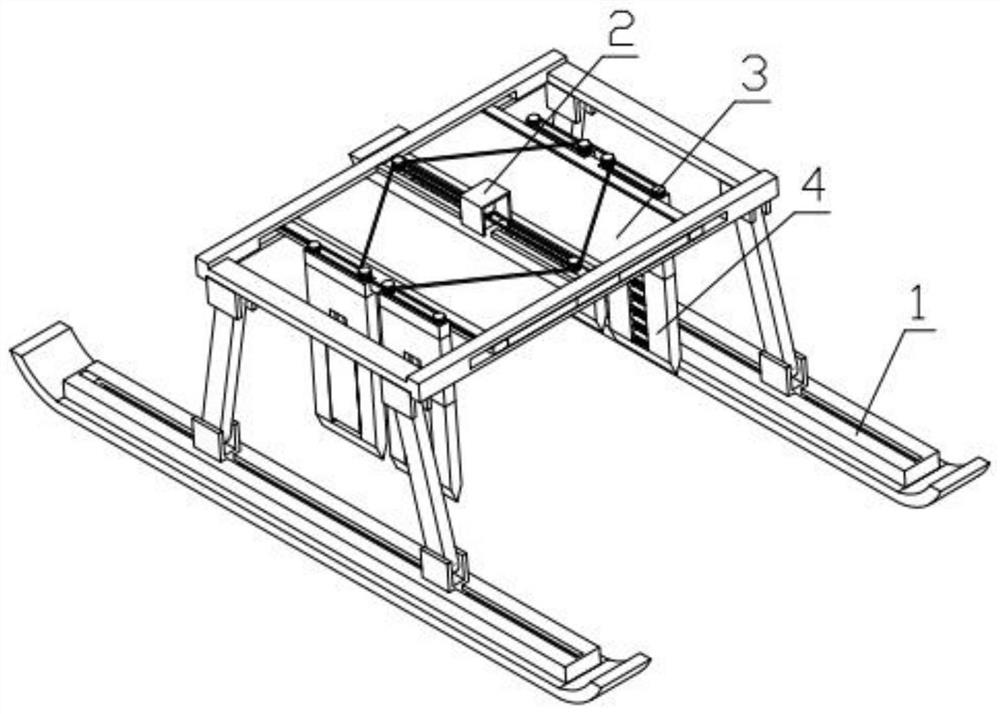

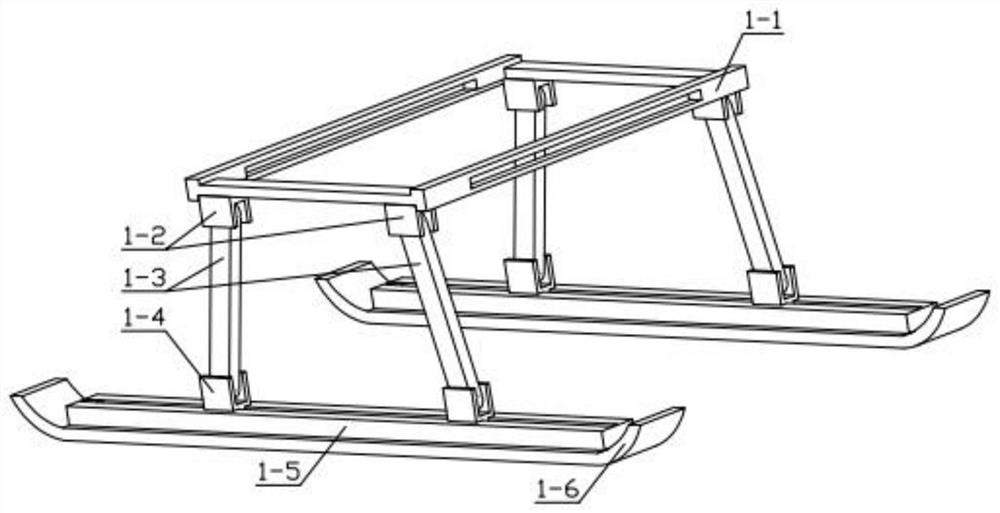

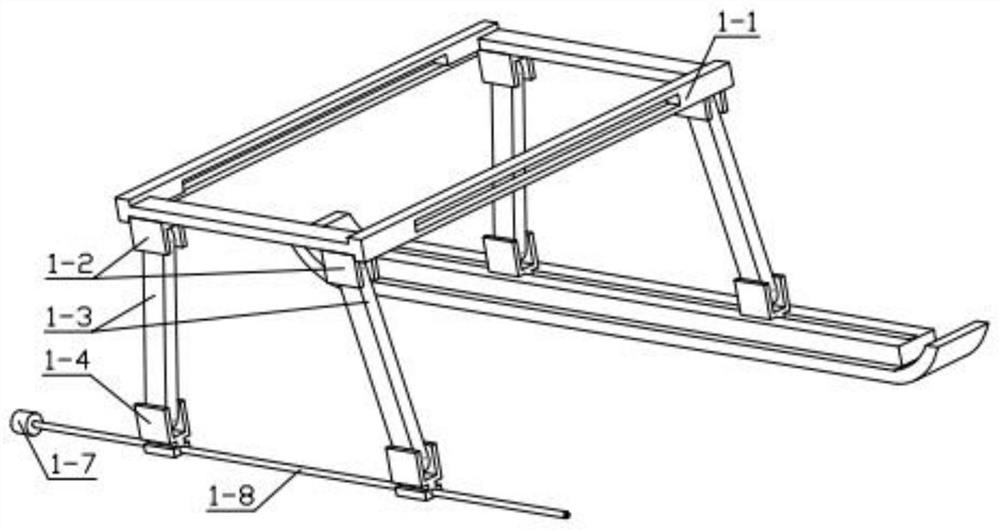

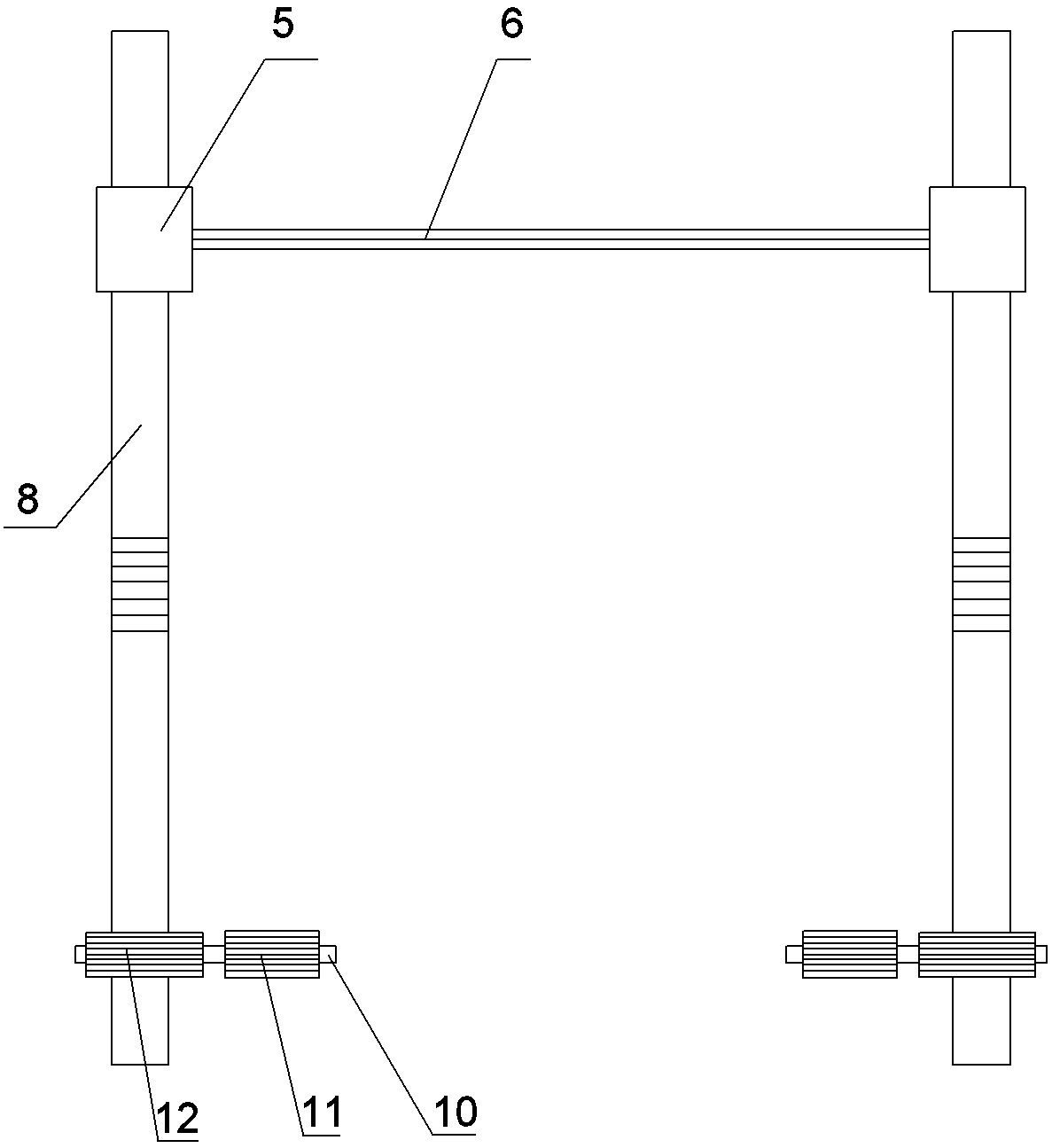

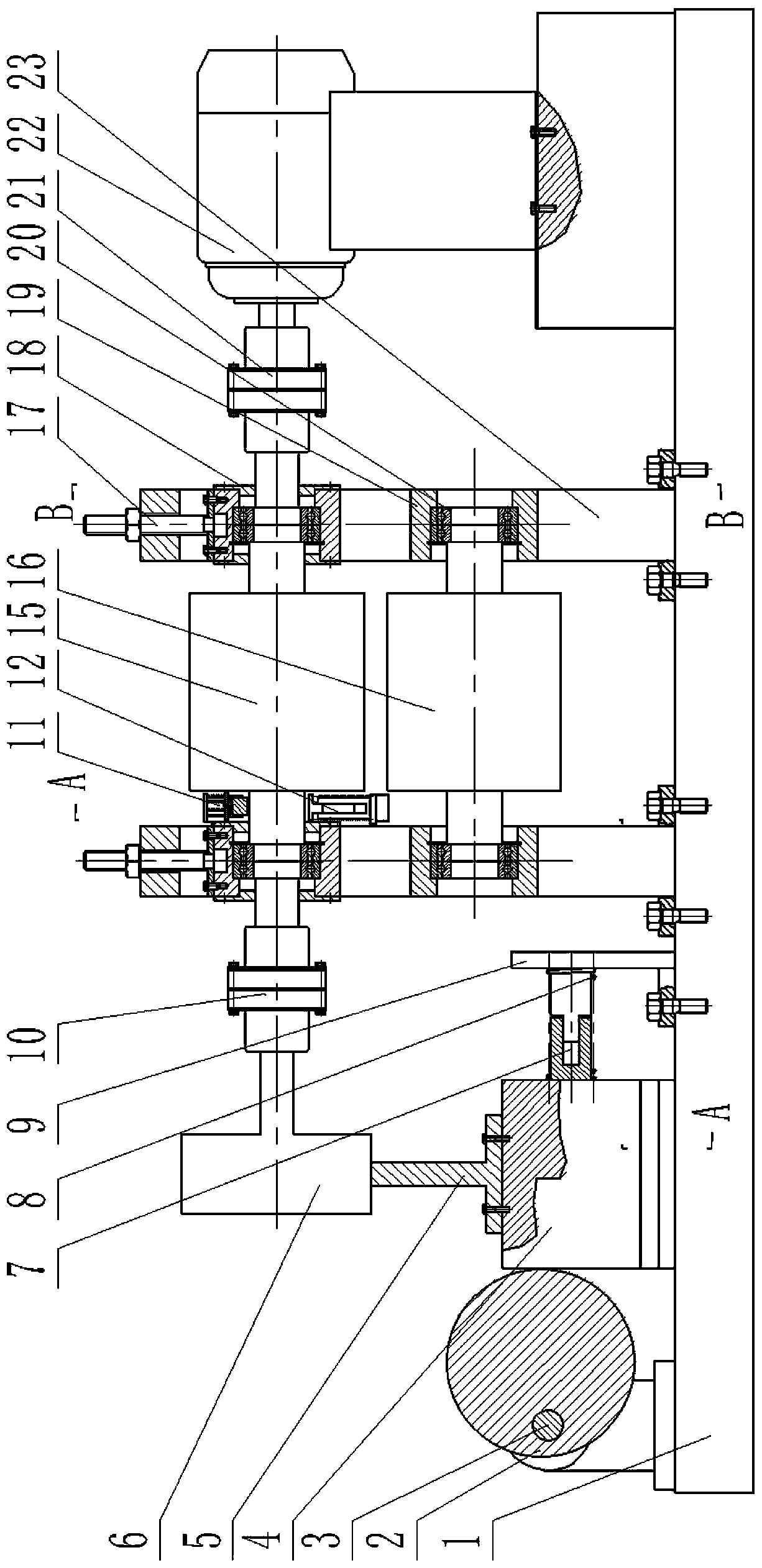

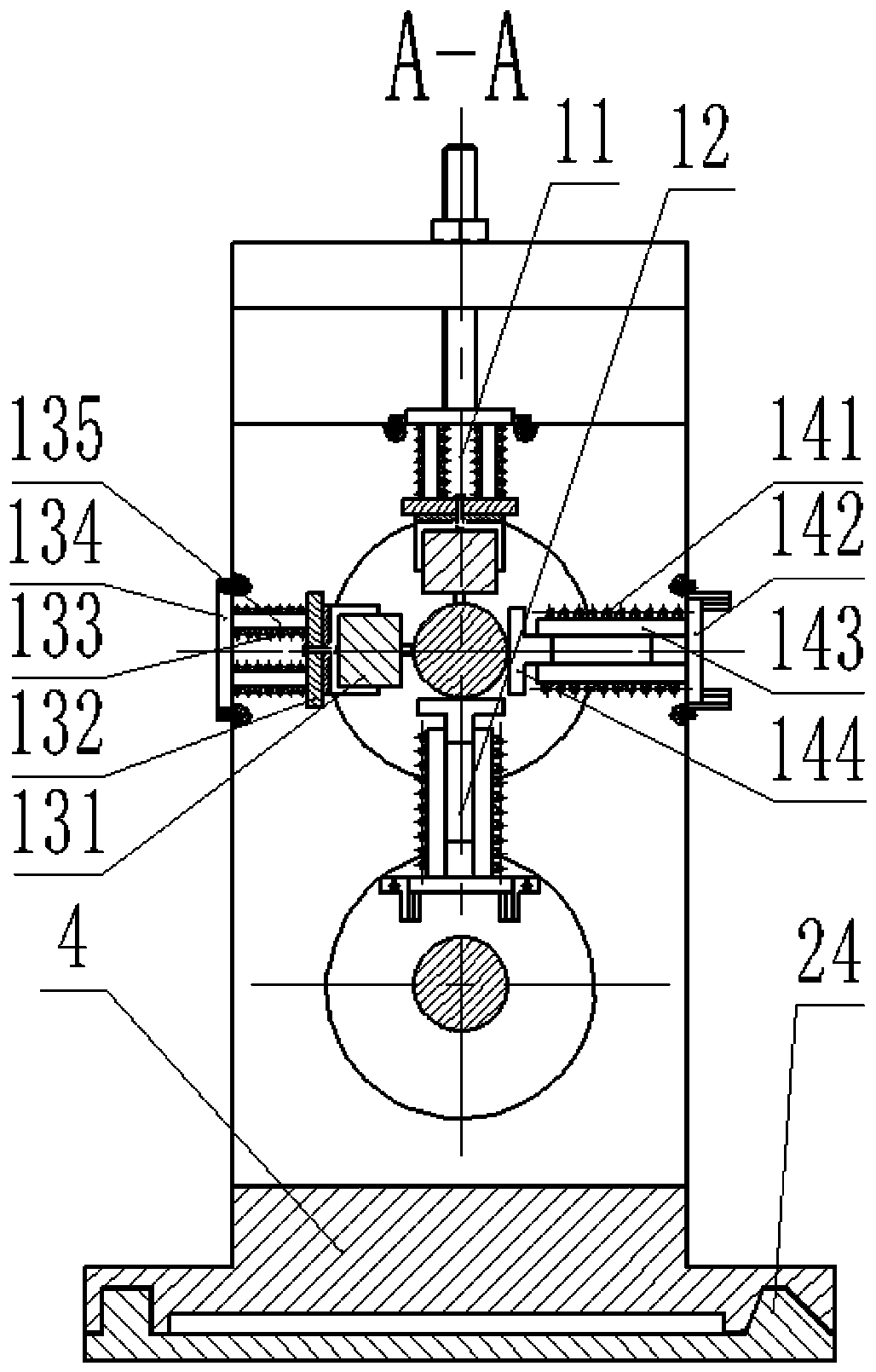

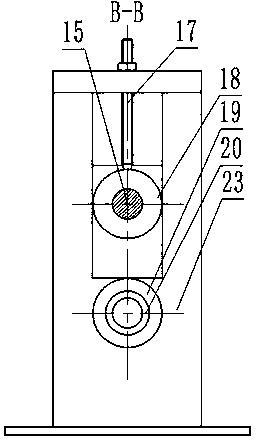

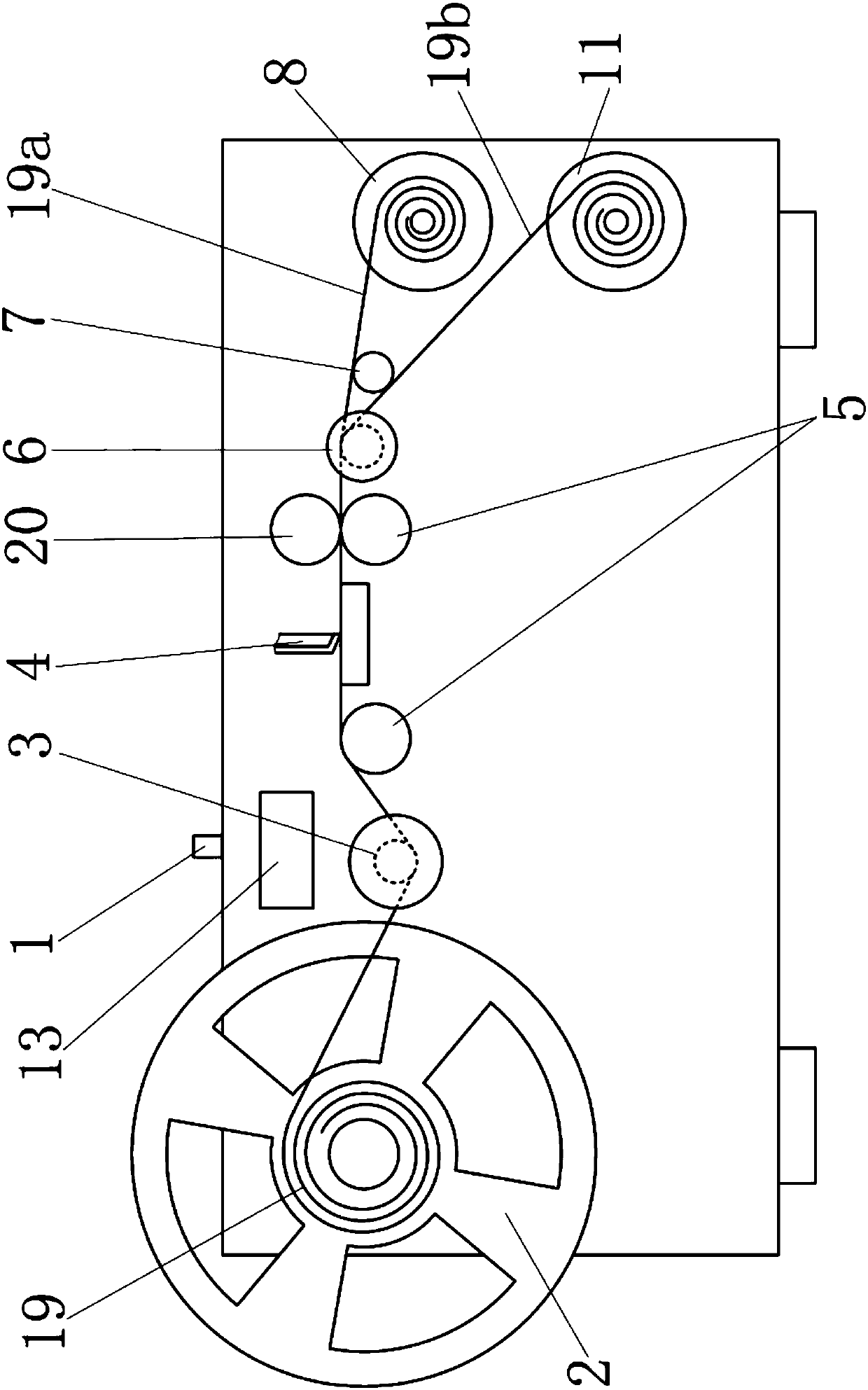

Asynchronous rolling external vibration simulation experiment platform

ActiveCN110523783AAdapt to thicknessIncrease flexibilityMeasuring devicesTensioning/braking arrangementsEddy currentEngineering

The invention discloses an asynchronous rolling external vibration simulation experiment platform which at least comprises an external vibration generation device. The external vibration generation device comprises an upper roller assembly, a lower roller assembly, a horizontal power-assisted mechanism, a vertical power-assisted mechanism, a horizontal drawer type telescopic mechanism, a verticaldrawer type telescopic mechanism, an eddy current vibrator, an eccentric assembly and a spring feedback mechanism. The eccentric assembly directly acts on the eccentric support and enables the eccentric support to vibrate axially, and indirectly acts on the eddy current vibrator fixed to the eccentric support to achieve axial vibration or superposition of axial vibration and torsional vibration, and the spring feedback mechanism and the eccentric assembly correspondingly and reversely act on the eccentric support to provide feedback energy. The asynchronous rolling external vibration simulation experiment platform is beneficial to revealing the influence of rolling vibration on the rolling forming quality of a rolled piece, clarifies the influence rule of external vibration and the rollingforming quality of the rolled piece, provides effective experiment data for the research, and provides a more accurate simulation experiment platform for rolling vibration.

Owner:HENAN POLYTECHNIC UNIV

hanging neck massager

Owner:GUANGDONG SKG INTELLIGENT TECH CO LTD

Lifting and rapid cutting device for thin-plate steel belt

The invention discloses a lifting and rapid cutting device for a thin-plate steel belt. The lifting and rapid cutting device comprises a working table. A lifting fixing frame is arranged at the upper end of the working table, a cutting device body is installed on the lifting fixing frame and internally provided with a plurality of engaged gear pieces, a crawler-type cutting strip is arranged at the outer end of the cutting device body, the inner side end of the crawler-type cutting strip is connected with the gear pieces in a buckled manner, and sawteeth are arranged at the outer side end of the crawler-type cutting strip; and a chip discharging port is formed in the center of the table top of the upper end of the working table, a plurality of chip discharging holes are formed in the chip discharging port, a material storing box is arranged at the lower end of the chip discharging port, and a dust sucking device is arranged in the material storing box. By means of the lifting and rapid cutting device in the manner, the height of a cutting machine can be adjusted so that the thin-plate steel belt can be rapidly cut; as the engaged gear pieces drive the crawler-type cutting strip to cut, the cutting range can be expanded, and the cutting requirement of a thin plate with the larger width can be met; and vertical adjustment can be achieved during cutting, and therefore the lifting and rapid cutting device is suitable for various board thicknesses.

Owner:WUXI LIANCHUANG SHEET

Easy-to-wear neck massager

PendingCN110681047AImprove fitAvoid pins and needlesElectrotherapyArtificial respirationHuman bodyStructural engineering

The invention discloses an easy-to-wear neck massager. The easy-to-wear neck massager comprises an elastic arm, a first handle, a second handle, at least two electrode assemblies and an electric appliance element, wherein the first handle and the second handle are fixedly connected to two sides of the elastic arm, and adopt rigid housings; the electric appliance element is arranged in one of the two handles to increase the balancing weight of the handle; and the first handle, the second handle and the two electrode assemblies surround under a state of being free from stress to form a circularregion S for accommodating the neck of the human body, and are arranged on the periphery of the circular region S. According to the easy-to-wear neck massager disclosed by the invention, the first handle, the second handle and the two electrode assemblies are set to be located on the periphery of the circular region S under the state of being free from stress, so that wearing in a manner of four-point clamping is realized.

Owner:GUANGDONG SKG INTELLIGENT TECH CO LTD

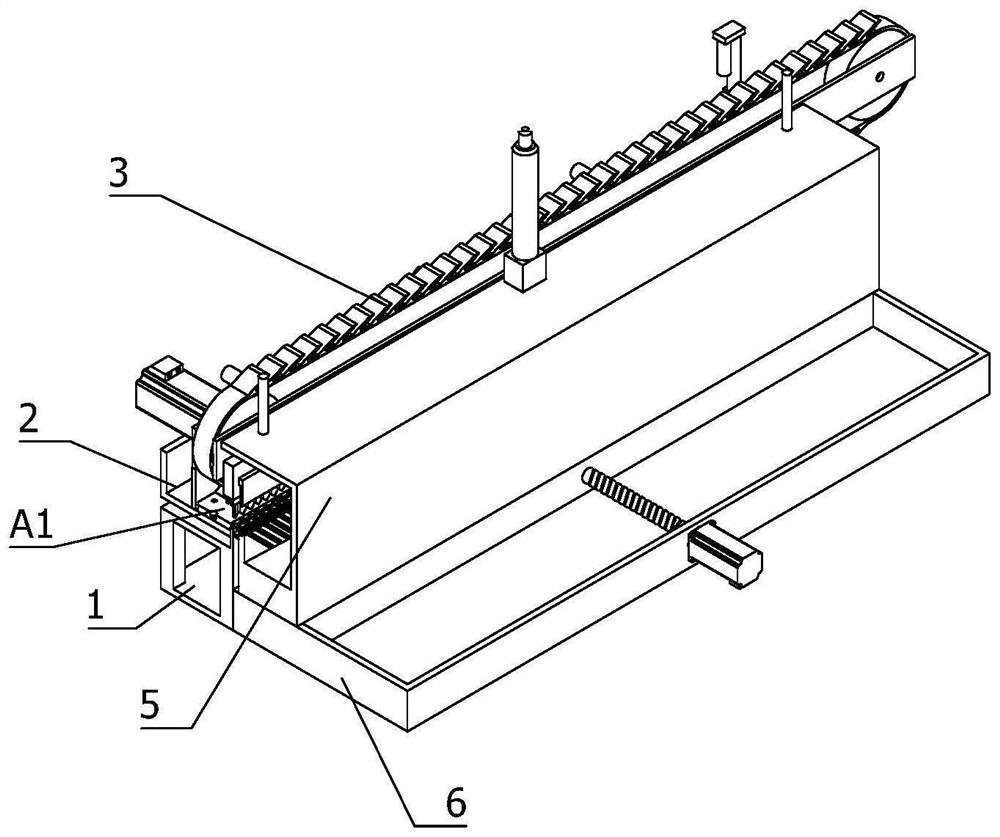

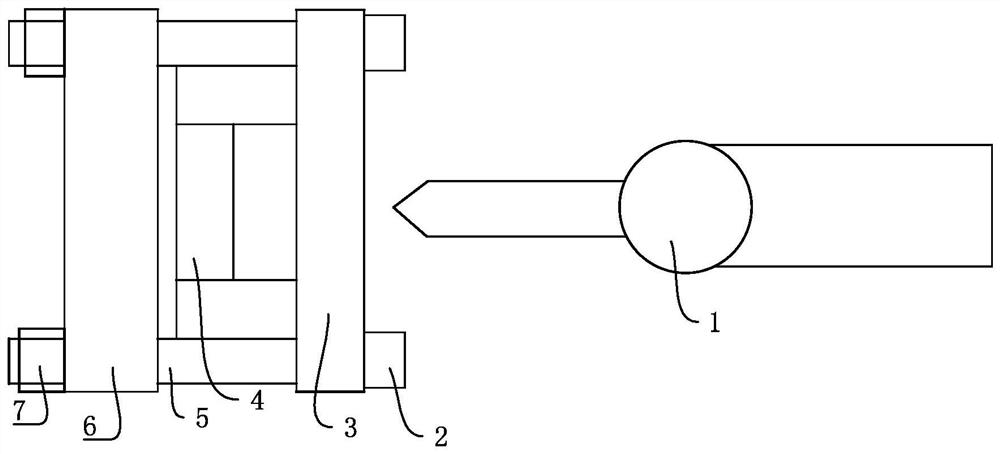

A pin-cutting device for high-power field effect transistors

ActiveCN114029424BSave human effortIncrease productivitySemiconductor/solid-state device manufacturingBall screwEngineering

The invention relates to the technical field of field effect transistor production, in particular to a pin cutting device for high-power field effect transistors, comprising a bracket, a transistor limiting arrangement device, a conveying device, a guide column, a pin carding and cutting device and a ball screw The sliding table; the transistor limit arrangement device is fixedly installed on the bracket; the conveying device is fixedly installed on the transistor limit arrangement device; the ball screw sliding table is arranged beside the bracket; The cutting device is fixedly connected with the working end of the ball screw slide table; the guide column is provided with several symmetrically arranged on the side of the bracket, one end of the guide column is fixedly connected with the bracket, and the end of the guide column away from the bracket slides and extends through the pin combing and cutting device. The present application can effectively save manpower and at the same time improve production efficiency.

Owner:先之科半导体科技(东莞)有限公司

Collagen pet gel and preparation method thereof

InactiveCN105684931AImprove digestibilityPromote absorptionAnimal feeding stuffTaming and training devicesFiberAdditive ingredient

Owner:JIANGXI HUAHENG PET FOODS CO LTD

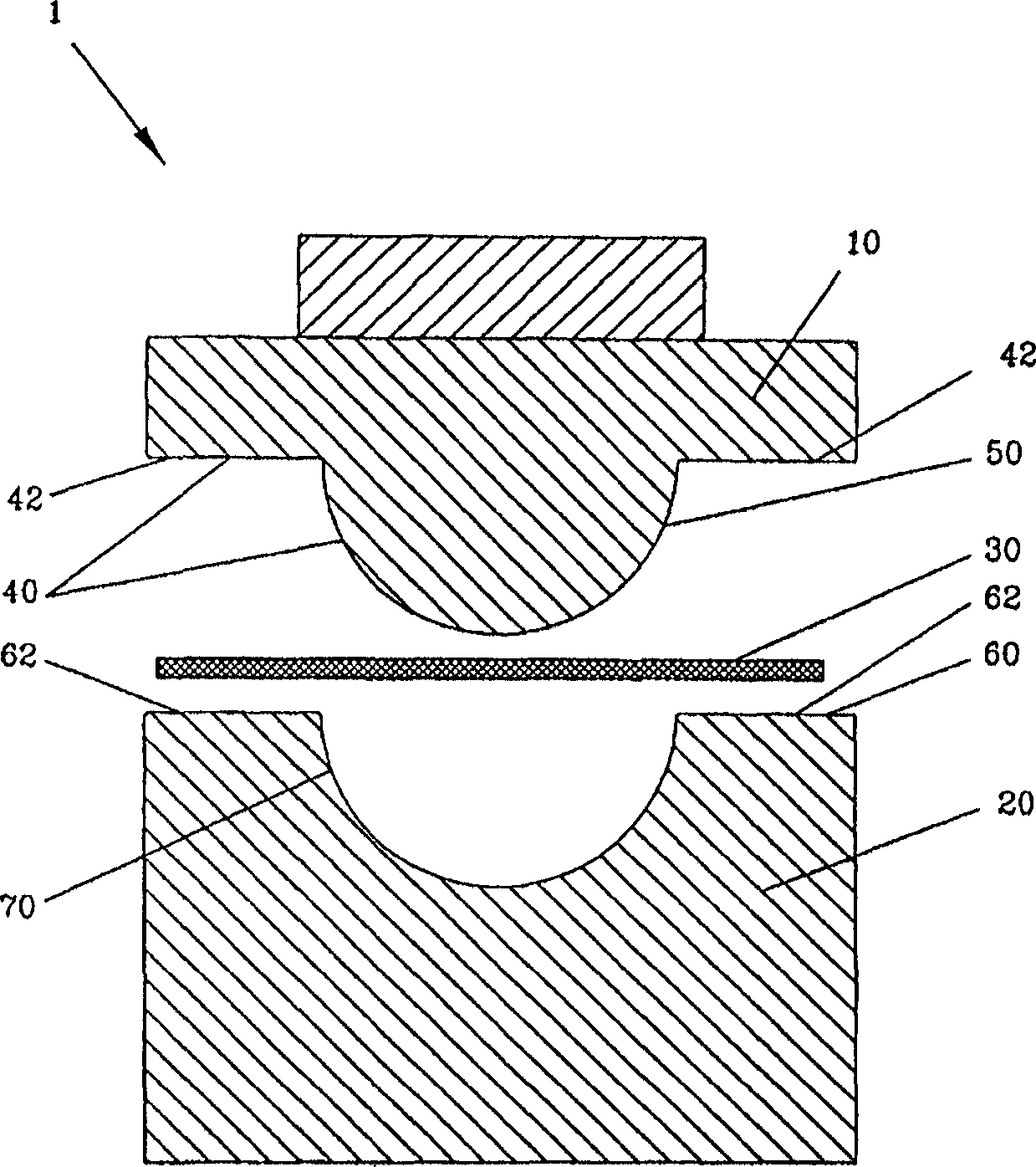

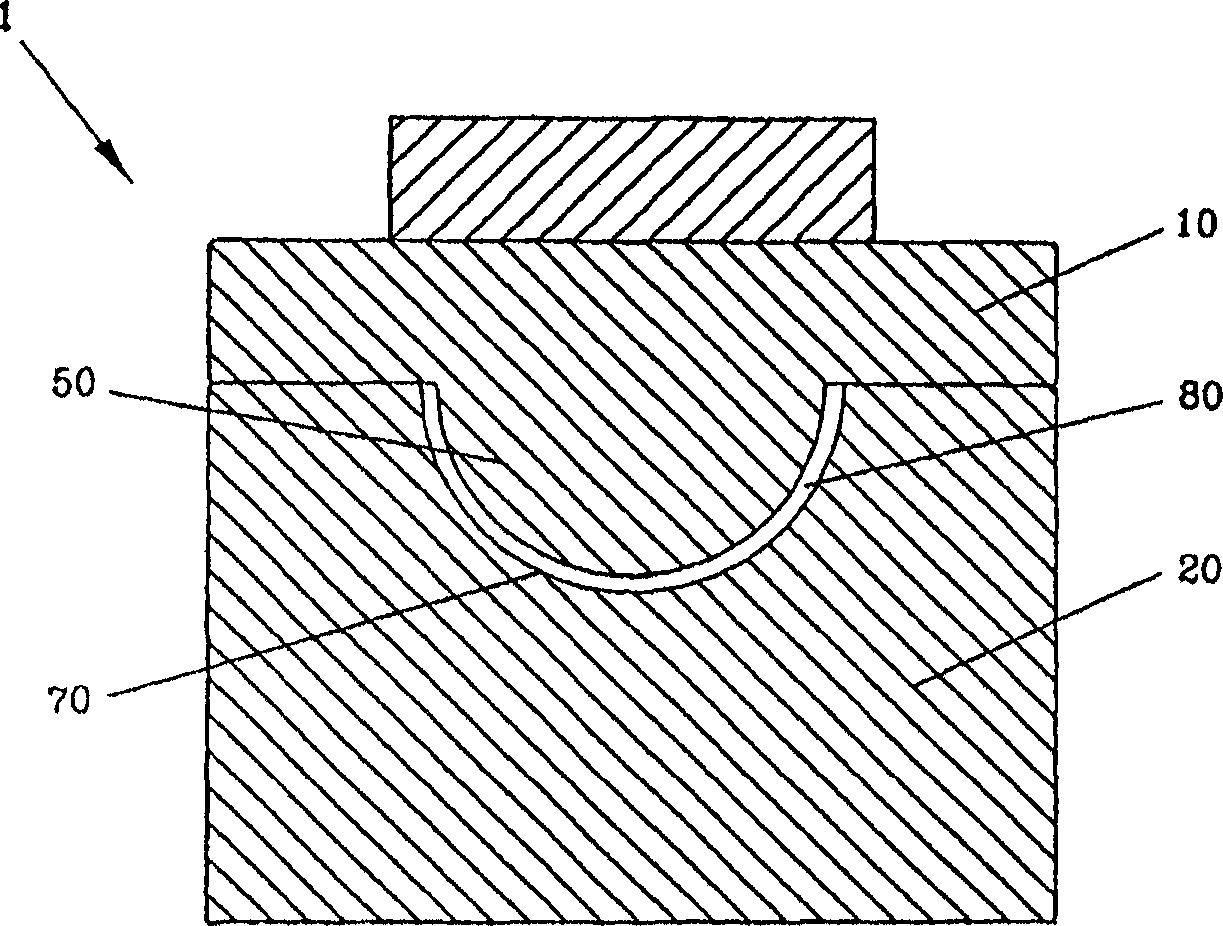

Novel direct opening type injection molding machine synchronous hooping device

PendingCN111993650ARealize opening and closing movementConsistent movementStructural engineeringMachine

The invention discloses a novel direct opening type injection molding machine synchronous hooping device. The problems that in the prior art, a hooping device in an injection molding machine cannot besynchronous, consequently, a die is damaged and noise is generated are solved. The novel direct opening type injection molding machine synchronous hooping device comprises a movable die plate, a pullrod, a hooping device and a synchronous device. Due to the fact that sliding grooves are formed in the inner side of a pull rod hole, two semi-hooping nuts can only move in the opening direction of the sliding grooves due to sliding blocks, meanwhile, a synchronous rotary disc is arranged so that the two semi-hooping nuts can be driven to move synchronously, various kinds of damage and noise generated when synchronization is not conducted are prevented, the two semi-hooping nuts are arranged in the pull rod hole, the length of a pull rod can be shortened, and therefore the length of the wholemachine is shortened; and when the two semi-hooping nuts are used for hooping the pull rod, the two semi-hooping nuts are fixed to the pull rod under the cooperation of protrusions and grooves, and the hooping effect of the two semi-hooping nuts is better.

Owner:HAITIAN PLASTICS MACHINERY GRP

Ice collecting and taking device

InactiveCN112502105AEasy to moveAvoid leaningWater cleaningAtmospheric sciencesMechanical engineering

Owner:哈尔滨市阿城区兴盛腻子粉厂

Putty coating repair device and method for plate surface defects

The invention discloses a putty coating repair device for plate surface defects, and relates to the technical field of plate processing equipment. The greasing repair device comprises a shell, compression rollers and a putty coating mechanism, the putty coating mechanism is provided with a detection assembly, and the detection assembly is provided with a putty supply cavity, a slideway, probes, sliding plates, spraying openings, partition plates and elastic pieces. When the plate defects are detected, all the probes on the detection assembly are jacked up synchronously, so that all the probesabut against the horizontal plane of a plate at the same time, if the probes touch the defect positions of the plate in the plate moving process, the probes on the defects fall into the defect positions under the pulling force of the elastic pieces, and accordingly, the positions of the sliding plates connected to the probes are changed; and under the condition that the positions of the other sliding plates are not changed, the spraying opening in the sliding plate with the changed position is separated from the partition plates on the other sliding plates with the unchanged positions to be blocked so that the spraying opening can guide putty in the putty supply cavity into the defect positions of the plate, and putty coating repair is carried out on the defective plate part needing to becoated with the putty.

Owner:张家港市盛港绿色防火建材有限公司

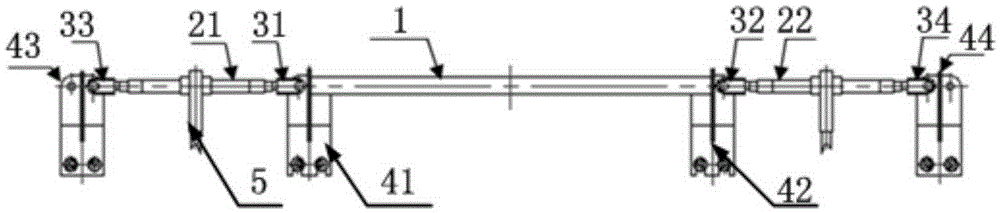

Portable device for replacing iron tower main material clad steel for power transmission line

The invention discloses a portable device for replacing iron tower main material clad steel for a power transmission line. The device comprises a holding pole, a first connecting screw, a second connecting screw, a third connecting screw, a fourth connecting screw, a first lead screw, a second lead screw, a first clamping part, a second clamping part, a third clamping part and a fourth clamping part, wherein the first clamping part, the second clamping part, the third clamping part and the fourth clamping part are fixedly clamped with a main steel angle for fixing the replaced clad steel. The first connecting screw and the second connecting screw are connected with the two ends of the holding pole respectively, one end of the first lead screw is sleeved with the first connecting screw, one end of the second lead screw is sleeved with the second connecting screw, the other end of the first lead screw and the other end of the second lead screw are sleeved with the third connecting screw and the fourth connecting screw respectively, and the first clamping part, the second clamping part, the third clamping part and the fourth clamping part are connected with the first connecting screw, the second connecting screw, the third connecting screw and the fourth connecting screw respectively. The iron tower main material clad steel can be replaced fast and easily through the portable device.

Owner:STATE GRID CORP OF CHINA +1

Device for sponge sheet machining

InactiveCN108527465APrevent slidingPrevent lateral shiftMetal working apparatusEngineeringMechanical engineering

The invention belongs to the field of sponge machining, and particularly discloses a device for sponge sheet machining. The device comprises a rack, and a cutting mechanism is slidably connected to the rack, wherein the cutting mechanism comprises sliding seats and a hollow cutter, and multiple exhaust inlets are formed in the cutter; a piston cavity is fixed to the rack, a piston is slidably connected in the piston cavity, a piston rod is fixedly connected to the piston, the piston rod is fixedly connected with the sliding seats, and the piston cavity communicates with the hollow cutter through a hose; a supporting plate is slidably arranged on the portion, below the cutting mechanism, of the rack, a limiting plate is detachably connected to the supporting plate, the limiting plate is located above the cutting mechanism, the upper surface of the supporting plate and the lower surface of the limiting plate are each provided with an anti-skid layer, and baffles are vertically and slidably connected to the side walls of the limiting plate separately; and each sliding seat is provided with a clamping part, clamping matching parts which are matched with the clamping parts are fixedly connected to the baffles, and a transmission mechanism is connected between the supporting plate and the cutting mechanism. By means of the device for sponge sheet machining, the sponge slicing efficiency can be improved.

Owner:重庆致昌塑胶制品有限公司

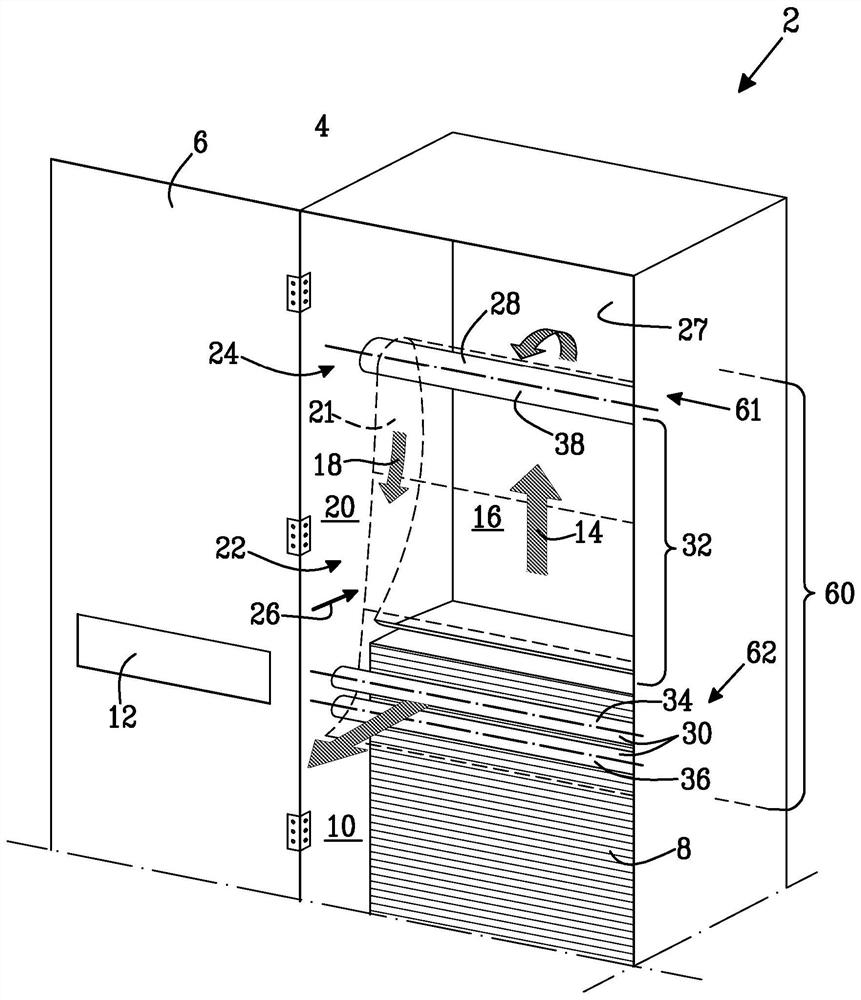

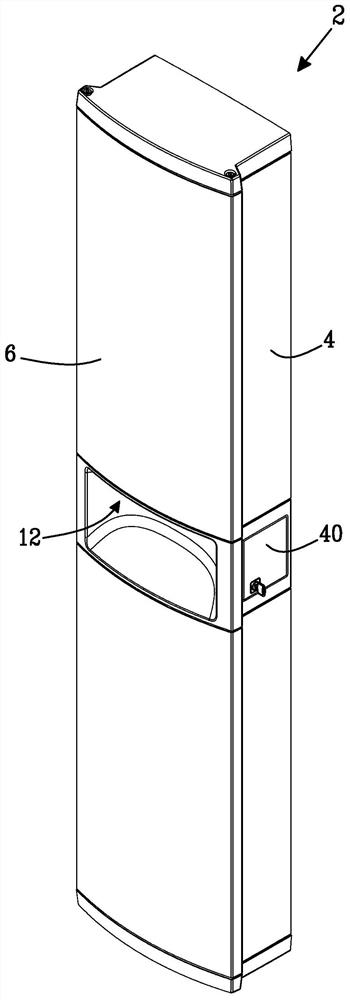

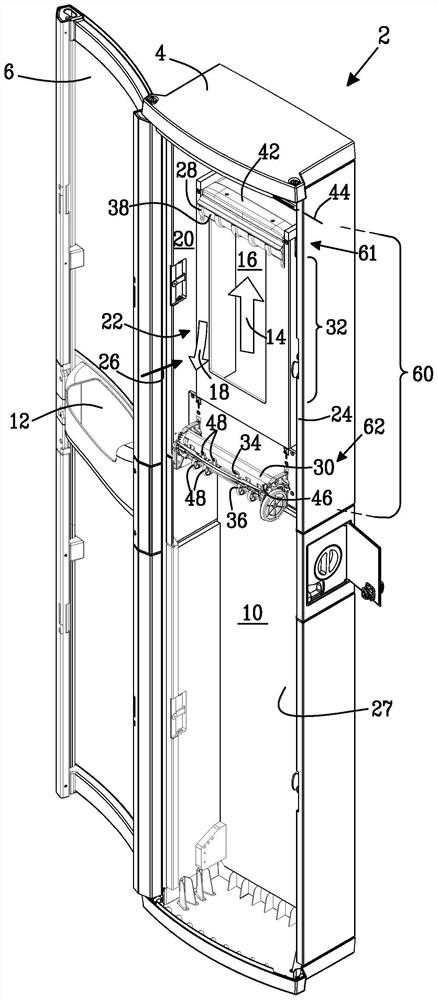

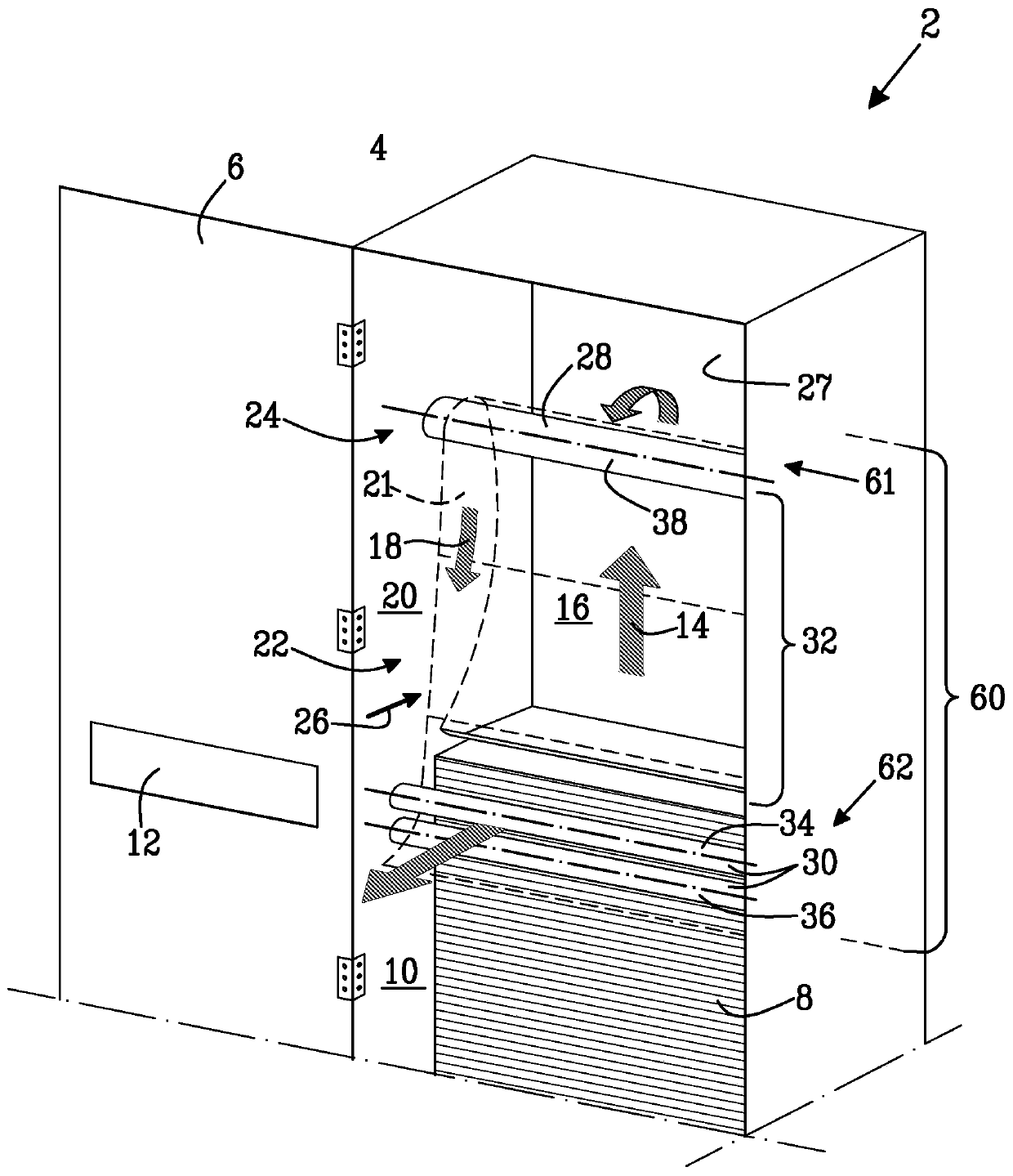

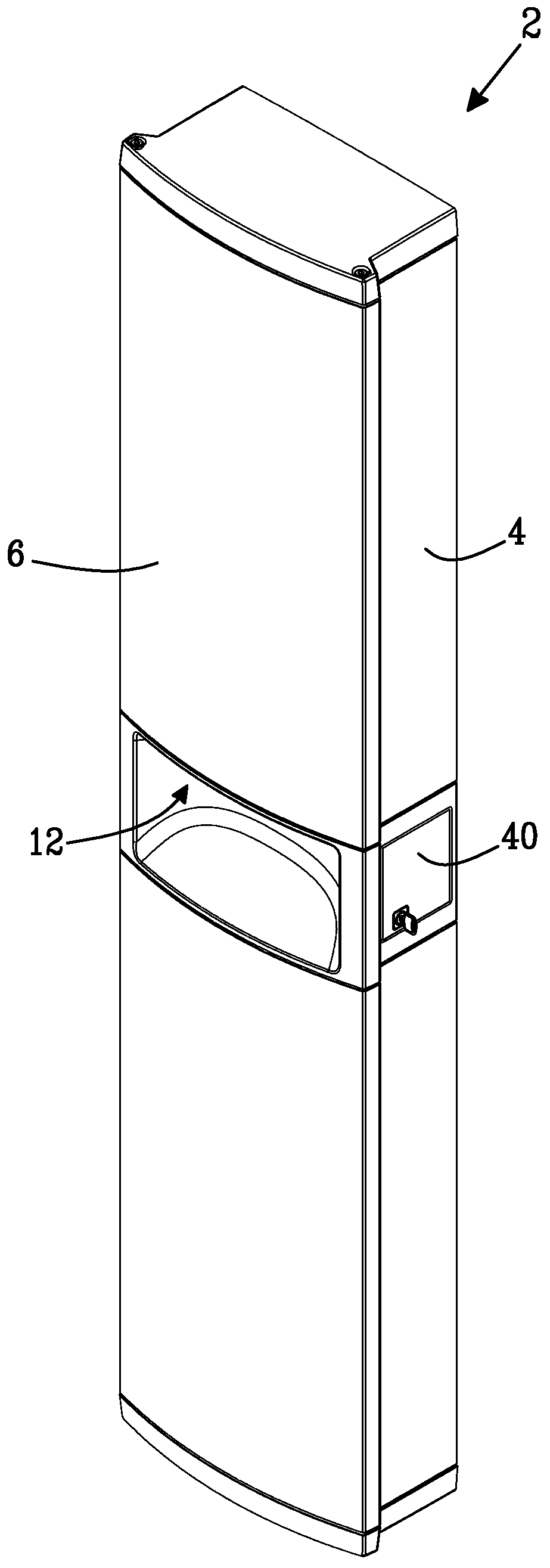

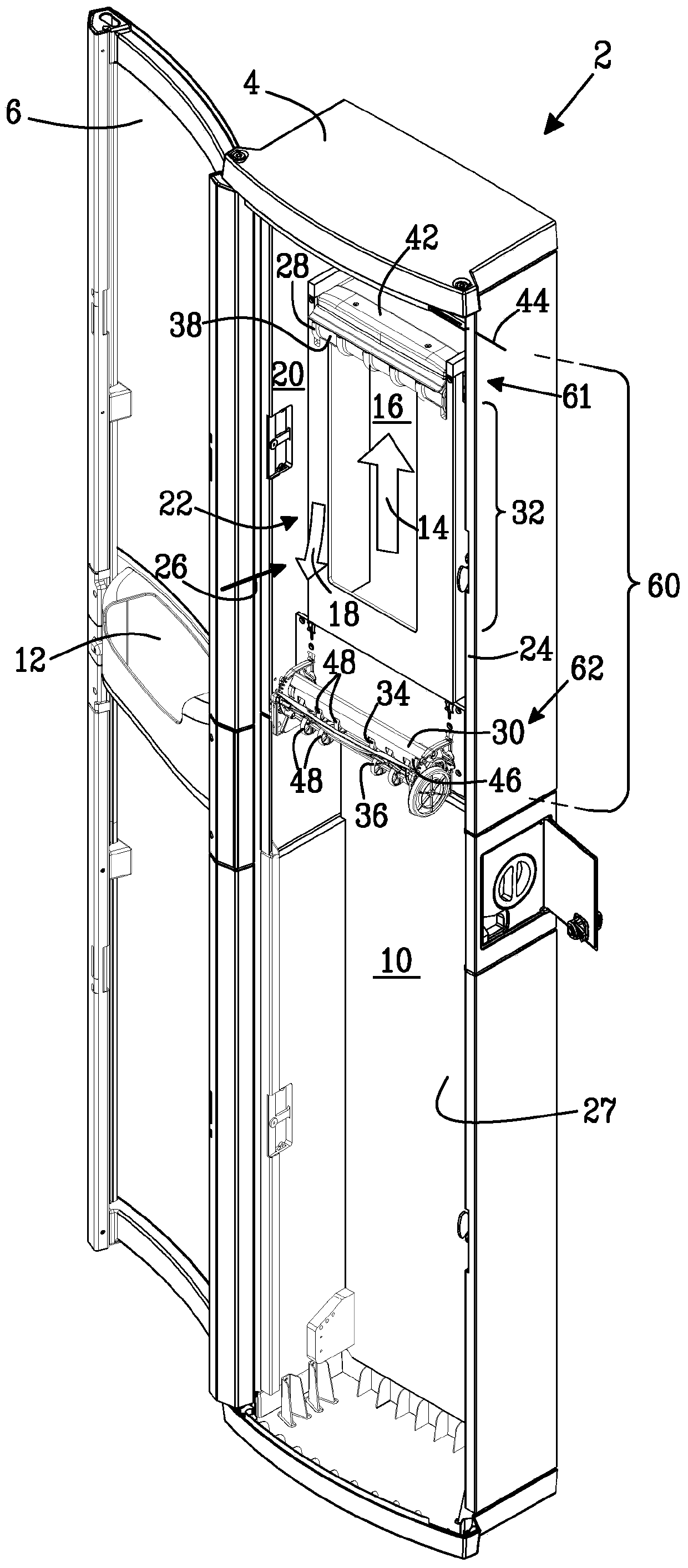

dispenser

ActiveCN106413494BIncreasing the thicknessAdapt to thicknessDomestic applicationsStructural engineeringMechanical engineering

Owner:ESSITY HYGIENE & HEALTH AB

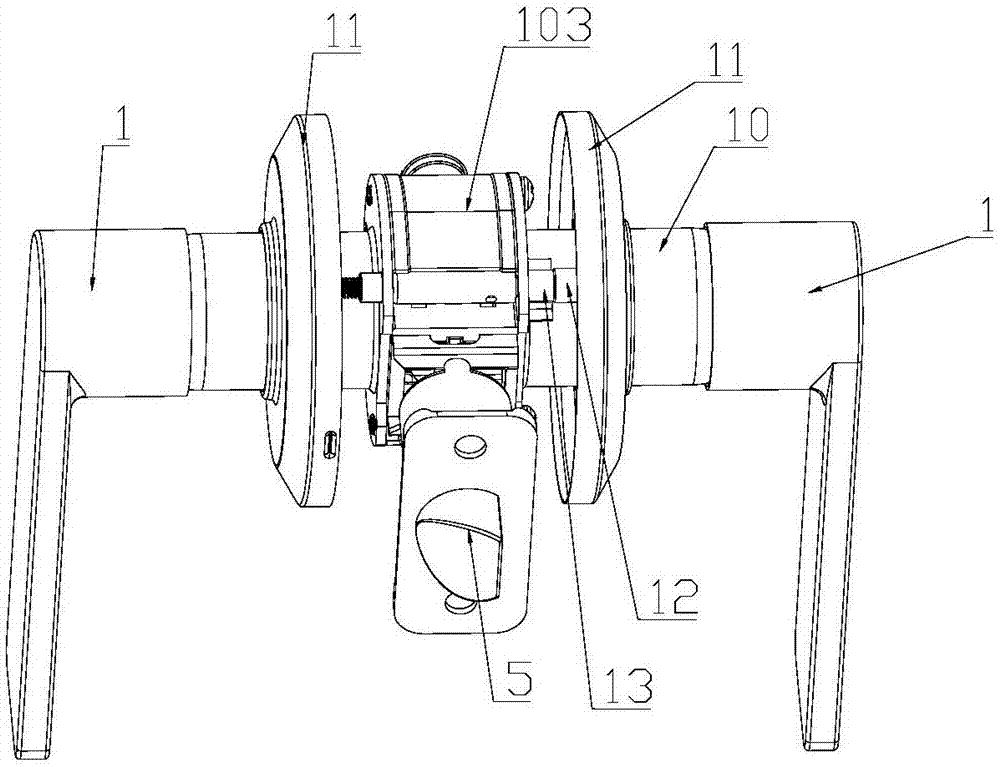

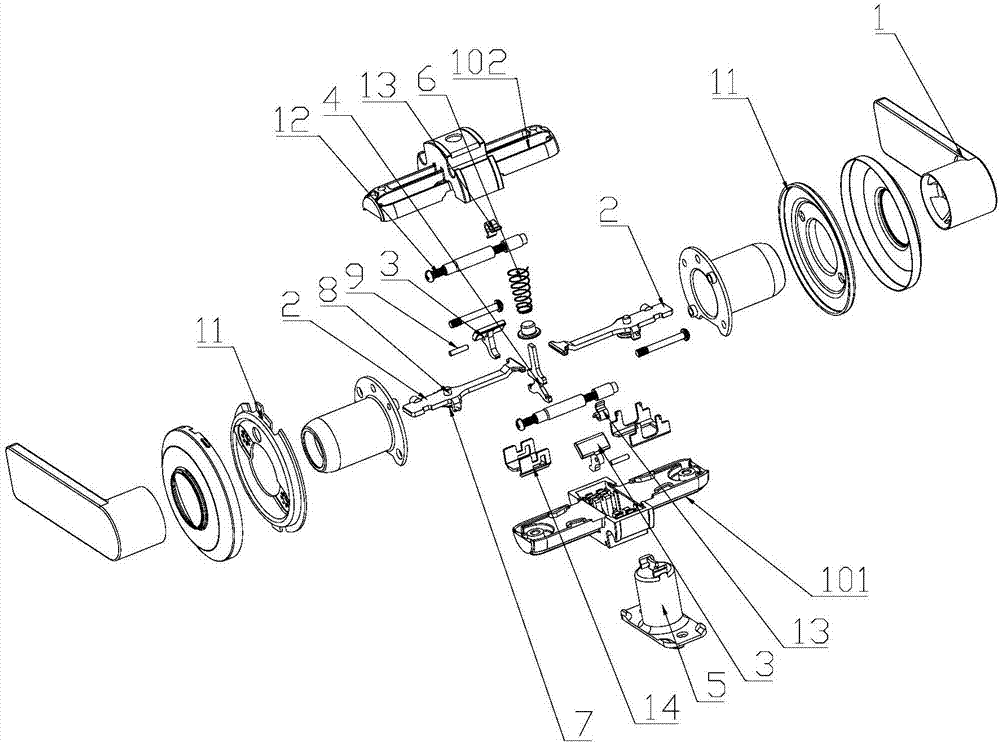

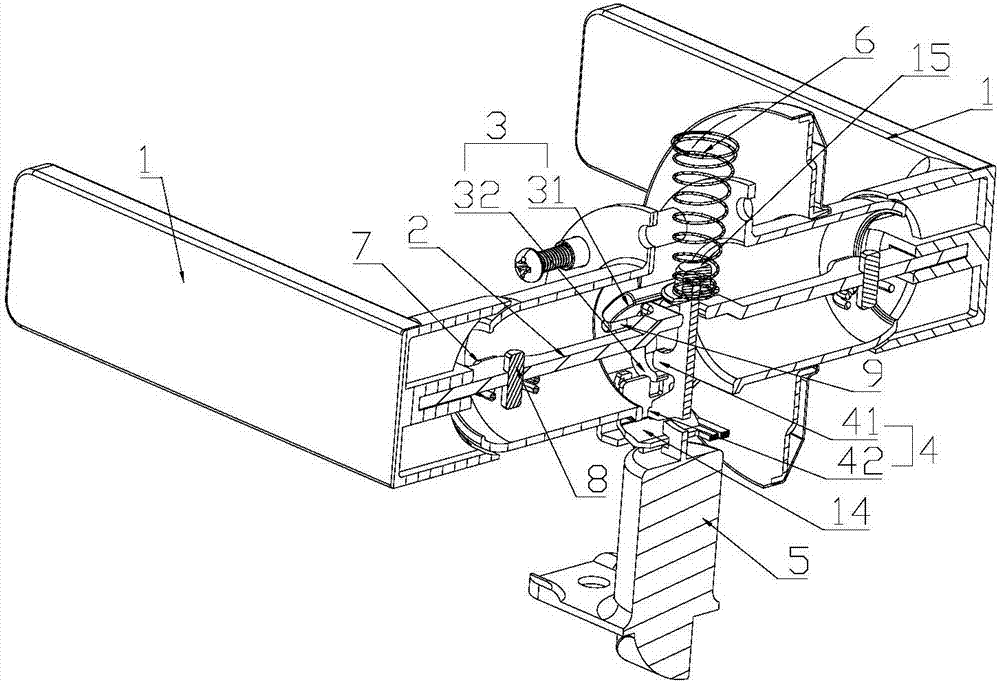

Handle lock

InactiveCN107269121ASimple structureFew partsConstruction fastening devicesLock casingsSoftware engineering

The invention provides a handle lock which comprises handles, stirring rods, reverse rotating blocks, a sliding block, a lock tongue and a reset device enabling the lock tongue to reset. The stirring rods, the reverse rotating blocks and the sliding block are located in a shell. The stirring rods and the reverse rotating blocks are hinged to the shell. Each reverse rotating block comprises a rotating portion and a touch portion. Each rotating portion and the corresponding touch portion are located on the two sides of a hinged shaft of the corresponding reverse rotating block correspondingly. One end of each stirring rod is connected with the corresponding handle, and the other end of each stirring rod and the corresponding rotating portion are arranged adjacently. One end of the sliding block is connected with the lock tongue, and the other end of the sliding block and the touch portions are arranged adjacently. The stirring rods rotate to touch the rotating portions of the reverse rotating blocks to rotate, and therefore the touch portions of the reverse rotating blocks touch the sliding block, and the sliding block is jacked up. The handle lock is simple in structure and is provided with few parts.

Owner:CMECH (GUANGZHOU) INDUSTRIAL LTD

Distributor

ActiveCN110742539AIncreasing the thicknessAdapt to thicknessDomestic applicationsDistributorIndustrial engineering

Owner:ESSITY HYGIENE & HEALTH AB

An In Vitro Vibration Simulation Experiment Platform for Asynchronous Rolling

ActiveCN110523783BAdapt to thicknessIncrease flexibilityMeasuring devicesTensioning/braking arrangementsTorsional vibrationAxial vibration

The invention discloses an asynchronous rolling external vibration simulation experiment platform which at least comprises an external vibration generation device. The external vibration generation device comprises an upper roller assembly, a lower roller assembly, a horizontal power-assisted mechanism, a vertical power-assisted mechanism, a horizontal drawer type telescopic mechanism, a verticaldrawer type telescopic mechanism, an eddy current vibrator, an eccentric assembly and a spring feedback mechanism. The eccentric assembly directly acts on the eccentric support and enables the eccentric support to vibrate axially, and indirectly acts on the eddy current vibrator fixed to the eccentric support to achieve axial vibration or superposition of axial vibration and torsional vibration, and the spring feedback mechanism and the eccentric assembly correspondingly and reversely act on the eccentric support to provide feedback energy. The asynchronous rolling external vibration simulation experiment platform is beneficial to revealing the influence of rolling vibration on the rolling forming quality of a rolled piece, clarifies the influence rule of external vibration and the rollingforming quality of the rolled piece, provides effective experiment data for the research, and provides a more accurate simulation experiment platform for rolling vibration.

Owner:HENAN POLYTECHNIC UNIV

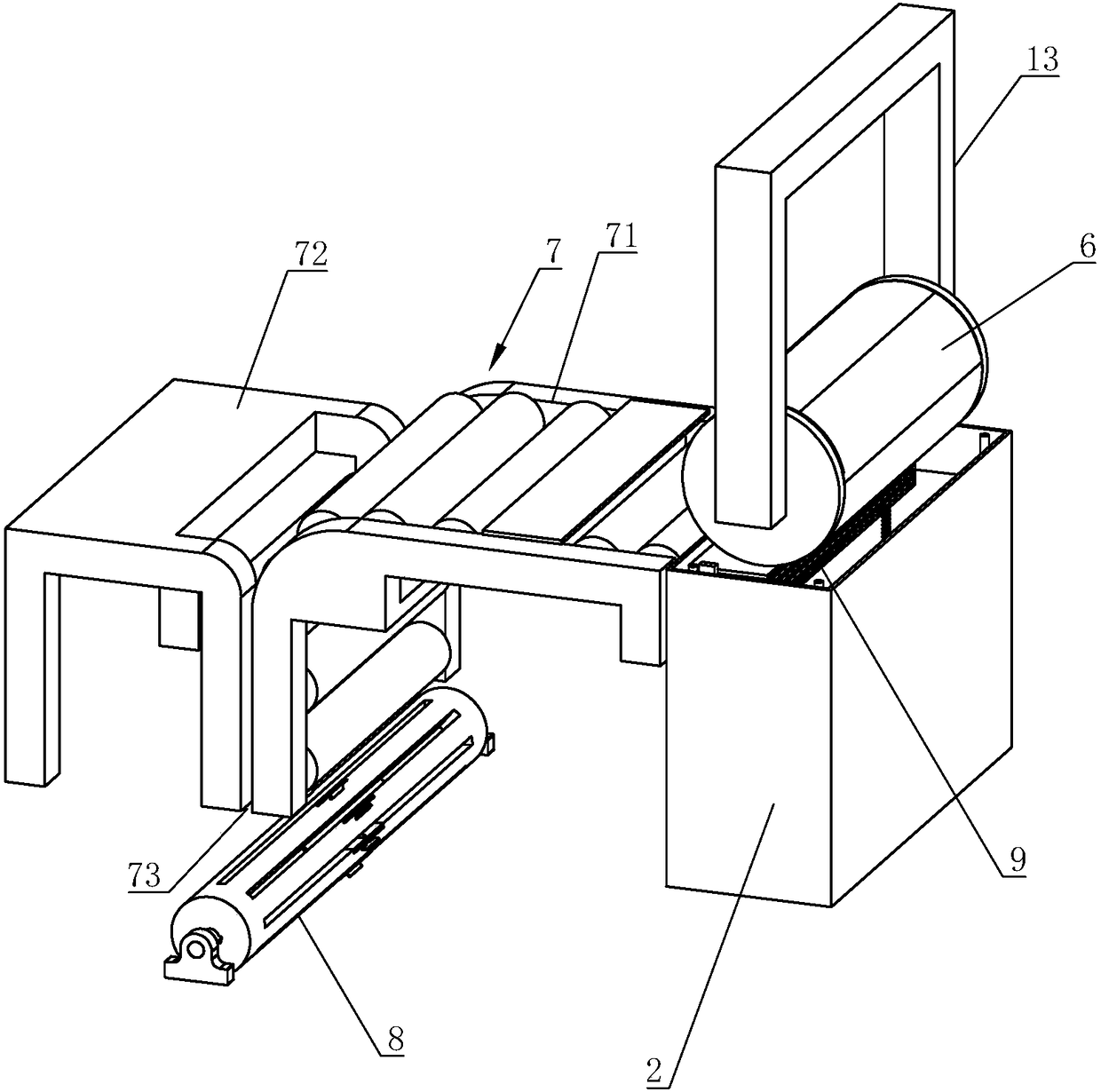

Back-cutting rewinding equipment

PendingCN107720384AGuaranteed flatnessBoot windingArticle deliveryWebs handlingPulp and paper industryBack cutting

The invention discloses back-cutting rewinding equipment which comprises a nicking tool, a finished product winding shaft and a waste winding shaft, wherein the nicking tool is used for cutting off back paper along the central symmetric line in the length direction without touching adhesive paper, the finished product winding shaft is used for collecting cut-off back paper and the adhesive paper,and the waste winding shaft is used for collecting transparent films separated from the back paper and the adhesive paper. The finished product winding shaft is composed of a shaft core and a baffle plate at one shaft end, the baffle plate is provided with an annular tapered surface capable of conveniently guiding the back paper and the adhesive paper to enter the finished product winding shaft, and one sides of the back paper and the adhesive paper abut against the baffle plate for rewinding; a blind hole is formed in the center of the baffle plate, the shaft core is inserted into the blind hole to be matched with the blind hole, and the depth of the blind hole is half of the value obtained by subtracting the width of the back paper or the adhesive paper from the axial length of the shaftcore; and the shaft core is provided with an openable limiting rod capable of applying elastic pressure to the shaft core, when the limiting rod is in a closed state, the shaft core and the baffle plate are limited and fixed, and a separating path is provided for the shaft core when the limiting rod is opened and closed. By adopting the back-cutting rewinding equipment, separation and collectionof coiled materials with different layers can be facilitated, and meanwhile, specific coiled materials are cut off, so that the efficiency and the quality of cutting and collecting are guaranteed.

Owner:YIHE PRECISION IND SUZHOU

A cloth pressing device for a warp knitting machine

ActiveCN108611751BQuickly eliminate static electricityAvoid sticking to each otherWarp knittingStructural engineeringIndustrial engineering

The invention discloses a cloth pressing device for a warp knitting machine. The device comprises a storage groove, an inclined plate and a panel. A guiding plate is arranged at one side of the top end of the storage groove, the inclined plate is fixedly arranged at the other side of the top end of the storage groove, a blowing mechanism is arranged at one side of the inclined plate, the panel isfixedly arranged at one end of the inclined plate, the two sides of the top end of the panel are each fixedly provided with an L-shaped pressing strip, the two corners of the top end of the panel areeach fixedly provided with a supporting column, the tops of the two supporting columns are fixedly connected with the two ends of a transverse plate respectively, and a stretchable rod is installed inthe middle of one side of the transverse plate. Due to the design of the guiding plate and the storage groove, cloth can be stored, due to cooperative use of the inclined plate and the blowing mechanism, static electricity on the cloth can be rapidly removed, cloth adhesion is avoided, and meanwhile the cloth is spread out by means of gravity; a plurality of wheels are arranged at one sides of the two L-shaped pressing strips, the two sides of the cloth can be flattened, and uniform and flat transportation of the cloth is ensured.

Owner:浙江华煌针织科技股份有限公司

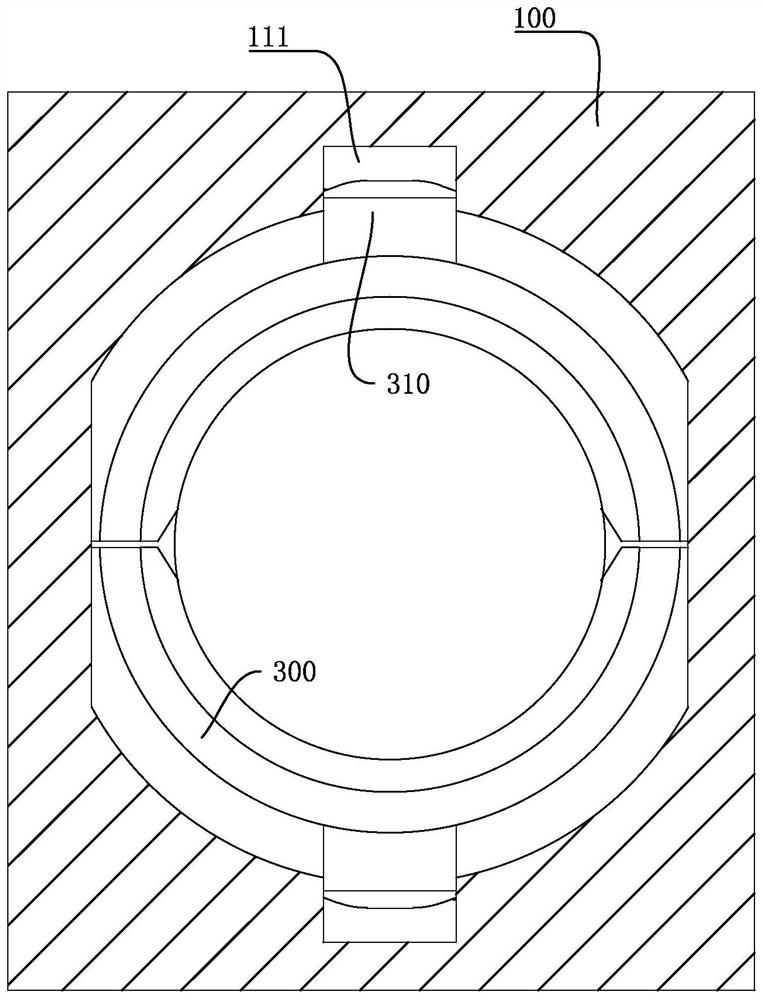

Current collector structure, battery structure and preparation method of current collector structure

PendingCN109119582ASimple structureAdapt to thicknessElectrode carriers/collectorsSecondary cellsCurrent collectorElectrical and Electronics engineering

The invention discloses a current collector structure, a battery structure and a preparation method of the current collector structure, belonging to the technical field of batteries. The current collector structure comprises a current collector body and current collector legs, wherein one end of the current collector body is connected with a cover plate and the other end is connected with the plurality of current collector legs, and the current collector body and the current collector legs are staggered, so that the current collector body and the current collector legs can be arranged in different thicknesses; the thickness range of the collector body is 1.7 mm-1.9 mm, and the thickness range of the collecting legs is 0.9 mm-1.1 mm, thus the thickness of the current collector body is larger, the relatively large current can be borne, and the thickness of the current collector legs is smaller, so that welding with wires is facilitated. The battery structure provided by the invention comprises a cover plate and the abovementioned current collector structure, wherein the cover plate structure comprises a cover plate, and the current collector legs are respectively welded with wires. The invention has the advantages of simple structure, adapting the thickness to the requirements of various parts, convenient welding with the wires, and being capable of bearing relatively large current.

Owner:SHENZHEN KEDALI IND CO LTD

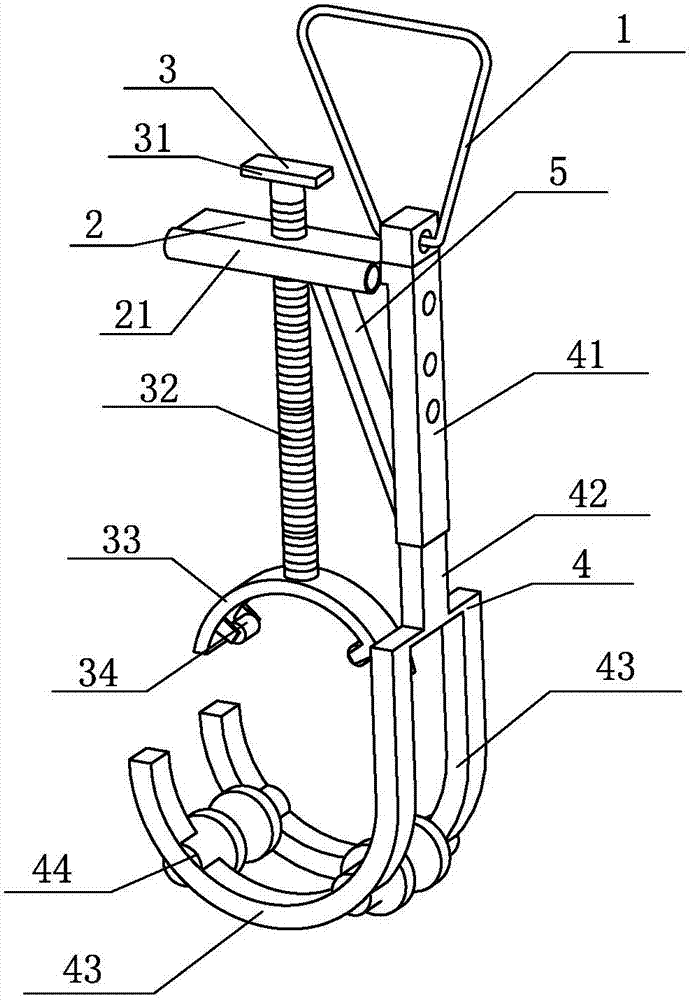

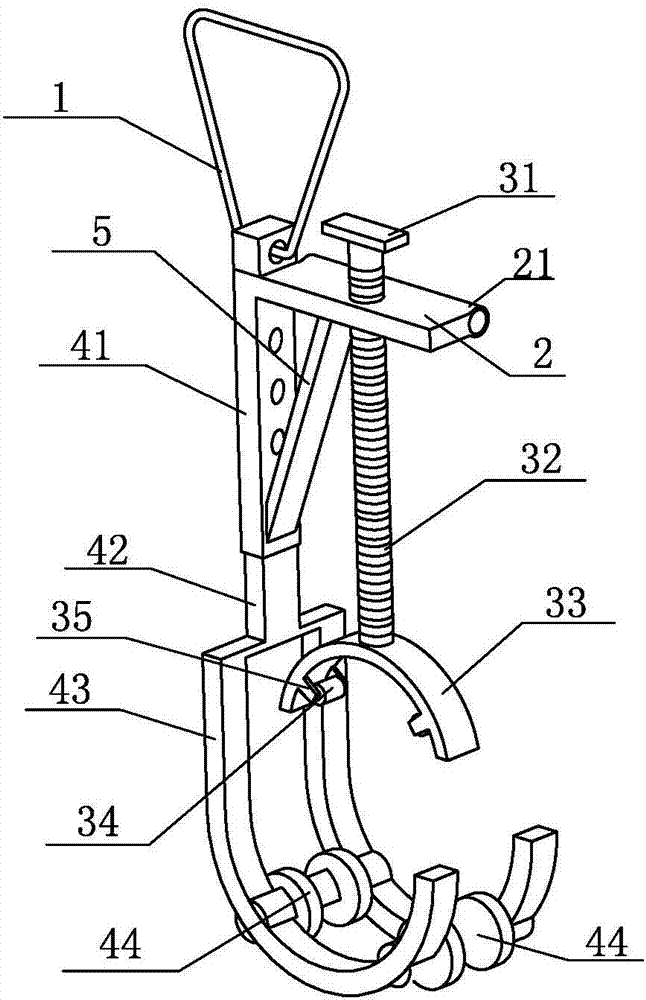

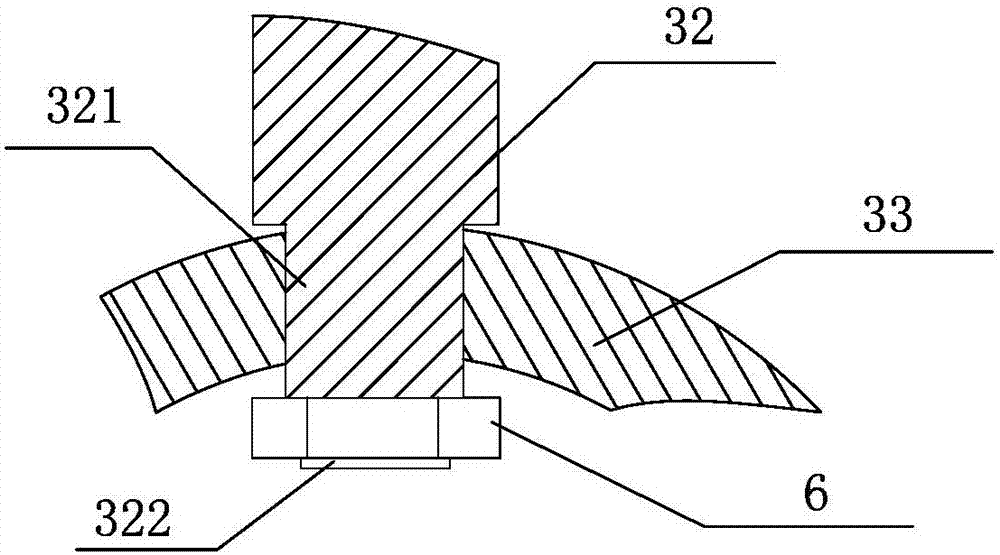

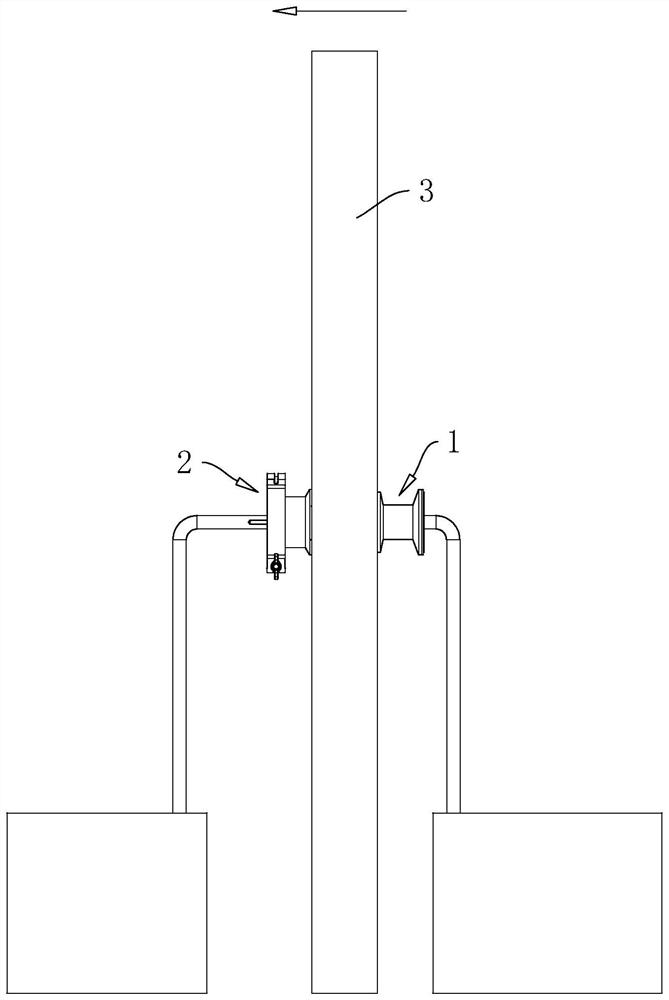

Manual traction aid for cable pay-off

InactiveCN105762700BAdapt to thicknessRotation made easyApparatus for overhead lines/cablesApparatus for laying cablesManual tractionEngineering

The invention provides a cable laying manual traction auxiliary tool comprising a handle, a support transverse plate, an upper compacting device, and a lower support device. The handle is hinged to one end portion of the support transverse plate. A threaded through hole is disposed on the center of the support transverse plate. A threaded rod in the upper compacting device is sleeved by the threaded through hole. An inverted-T-shaped connection rod in the lower support device is disposed on one end of the support transverse plate and is located under the handle. The cable laying manual traction auxiliary tool is simple in structure and easy to carry. The upper compacting device and the lower support device may not only clamp a cable firmly in a used process, but also fundamentally eliminate a torsion problem in a manual cable laying process.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

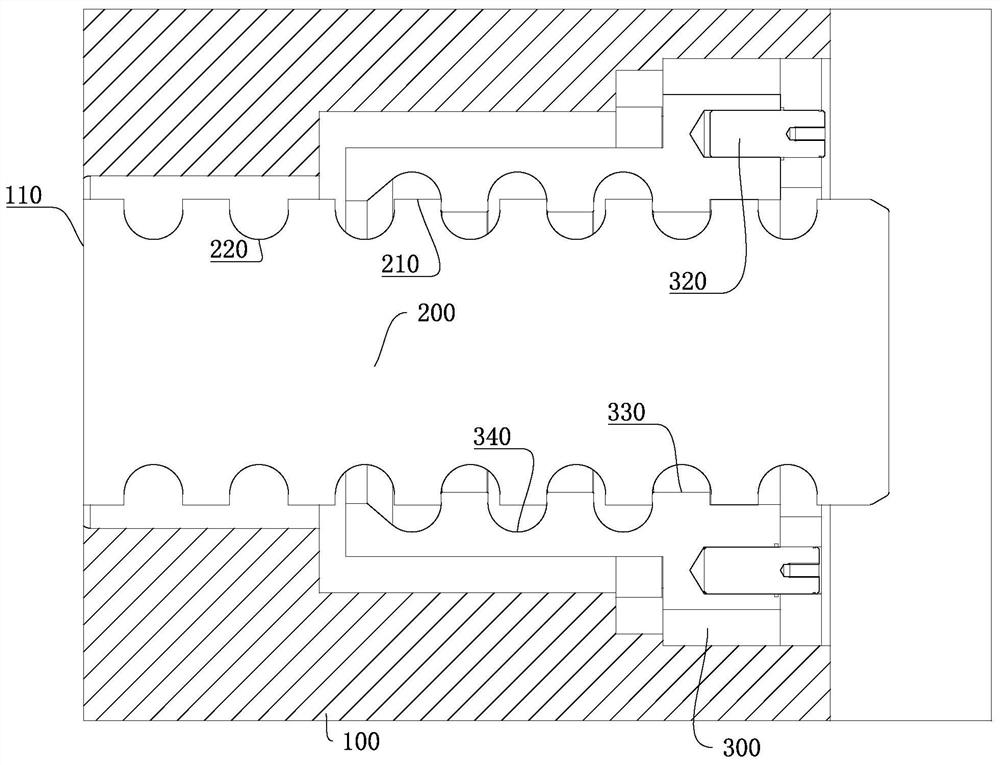

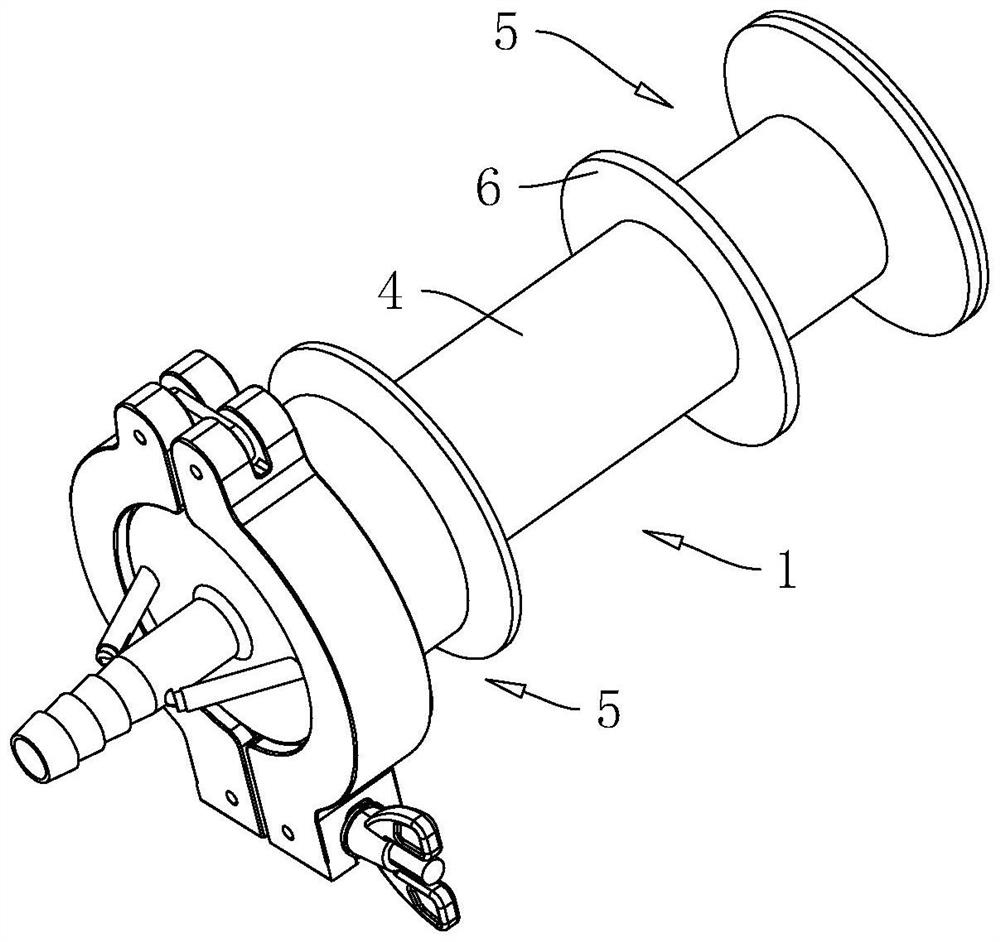

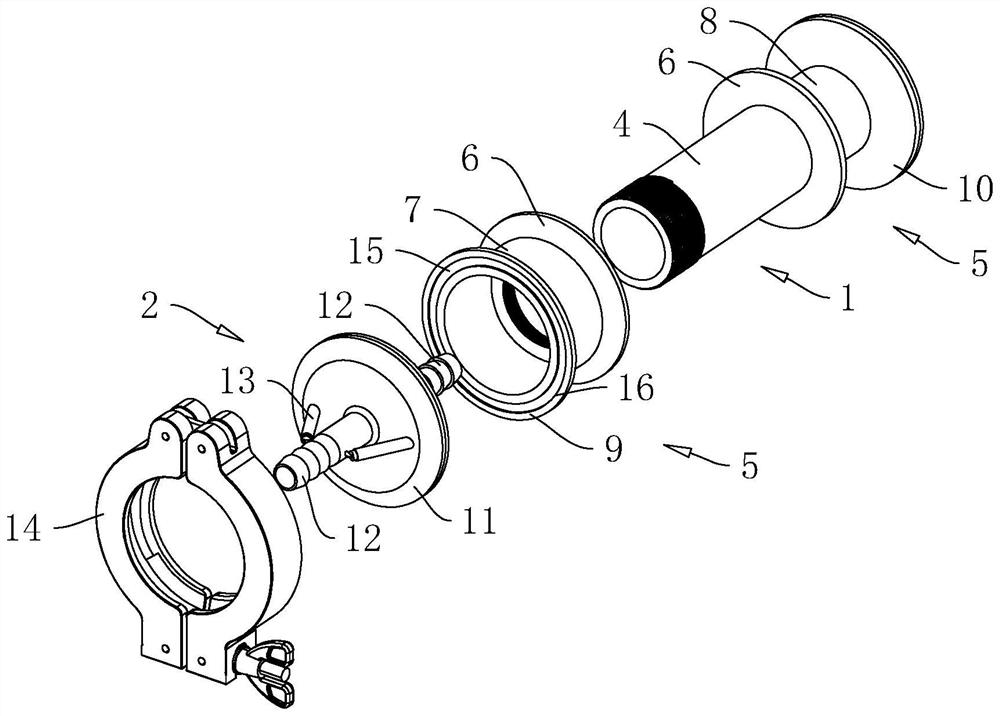

Clean area cross-grade low-pollution communication device

PendingCN114249102AImprove delivery efficiencyLow pollution rateControl devices for conveyorsEnvironmental engineeringMechanical engineering

The invention relates to the field of laboratory equipment, in particular to a clean area cross-level low-pollution communicating device which comprises a communicating pipe and a conveying communicating piece, the conveying pipe is used for penetrating through a wall, and the conveying communicating piece is connected with the communicating pipe in a sealed mode. The method has the effect of reducing the pollution probability of the reagent.

Owner:ZHEJIANG VACIN BIO PHARMA LTD

A greasy repairing device and a greasy repairing method for surface defects of plates

The invention discloses a greasy repairing device for surface defects of plates, relates to the technical field of plate processing equipment, and comprises: a shell, a pressure roller, and a greasy mechanism. The greasing mechanism has a detection component, and the detection component has: a greasing chamber, a slideway, a probe, a slide plate, a spray port, a partition, and an elastic member. When detecting plate defects, firstly lift up all the probes on the detection assembly synchronously so that all probes touch the horizontal surface of the plate at the same time. For example, when the probes touch the defect of the plate during the plate movement, the defect The probe on the top will fall into the defect under the tension of the elastic member, then the position of the slide plate connected to the probe will change. If the positions of other slide plates remain unchanged, the position of the spray port on the slide plate that has changed position will not leave the position. Therefore, the spray port will be able to introduce the putty in the greasy chamber to the defect of the board, and carry out putty coating and repair on the defective parts of the board that need to be greasy.

Owner:张家港市盛港绿色防火建材有限公司

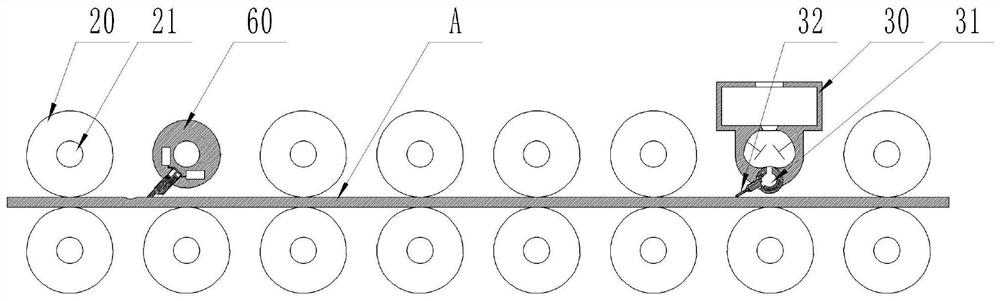

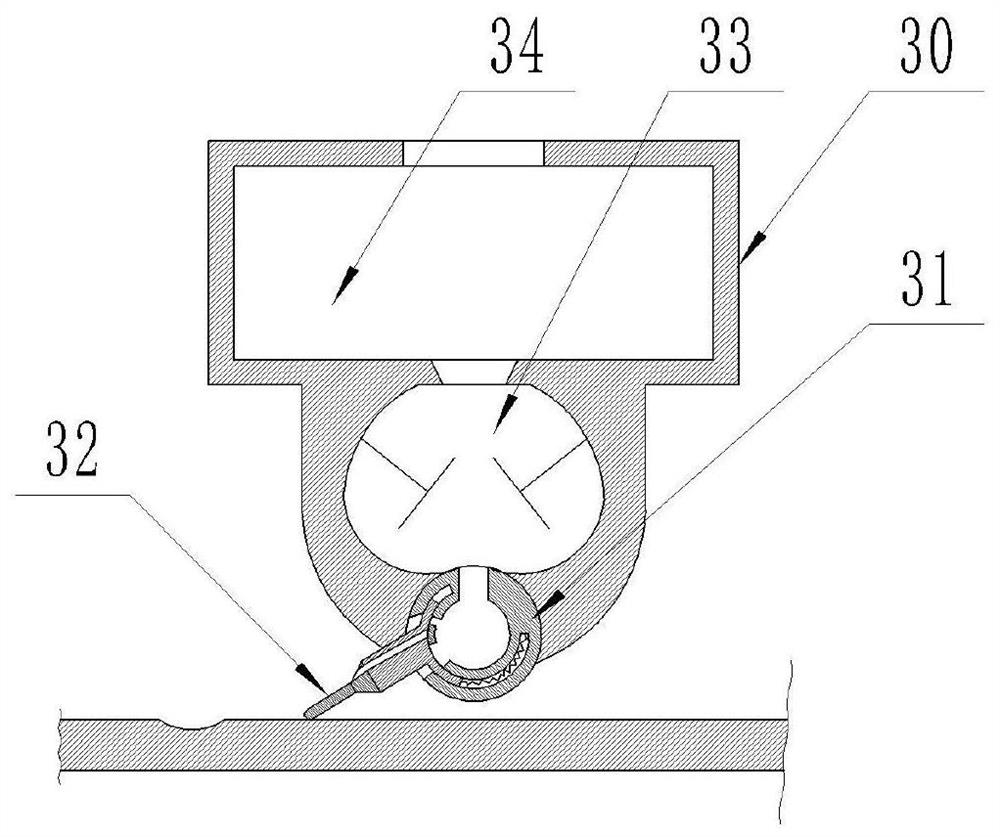

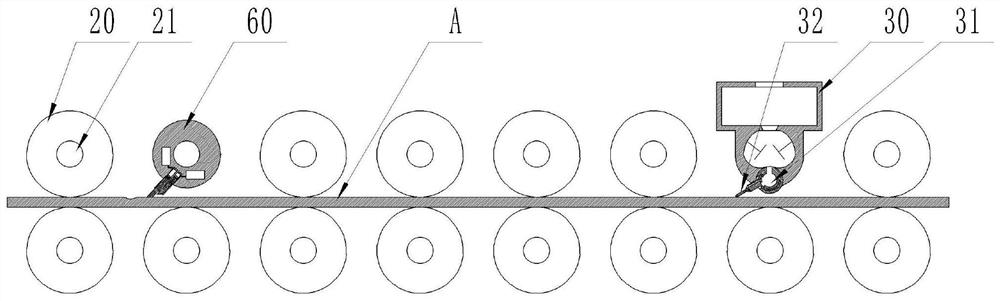

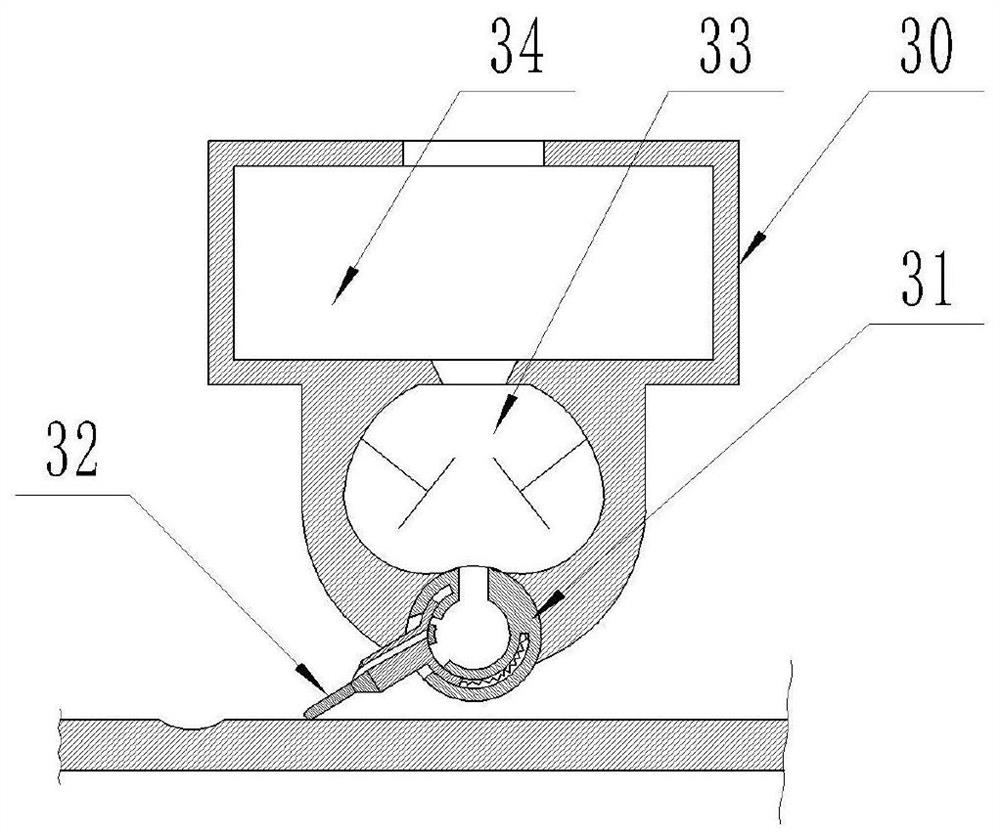

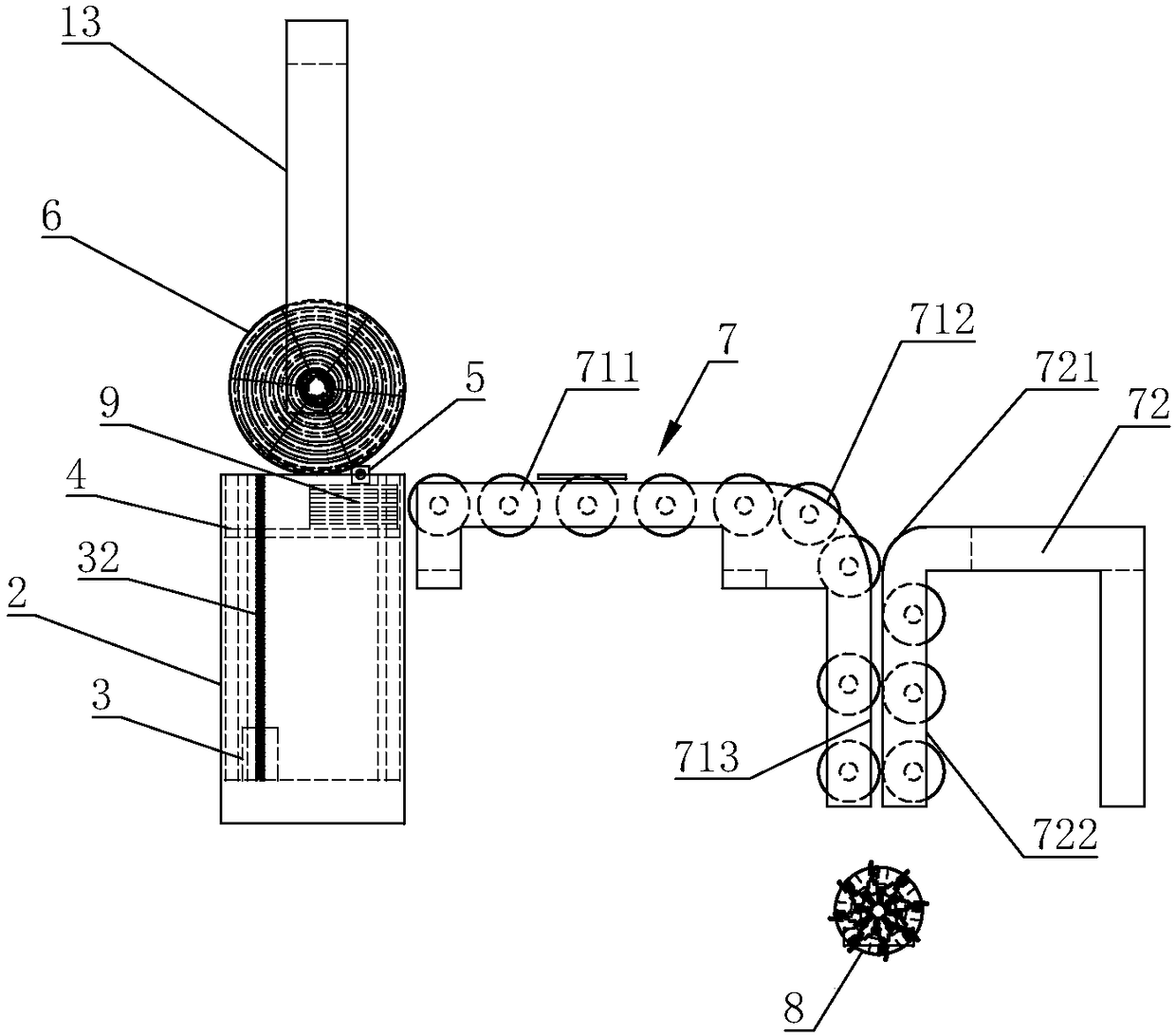

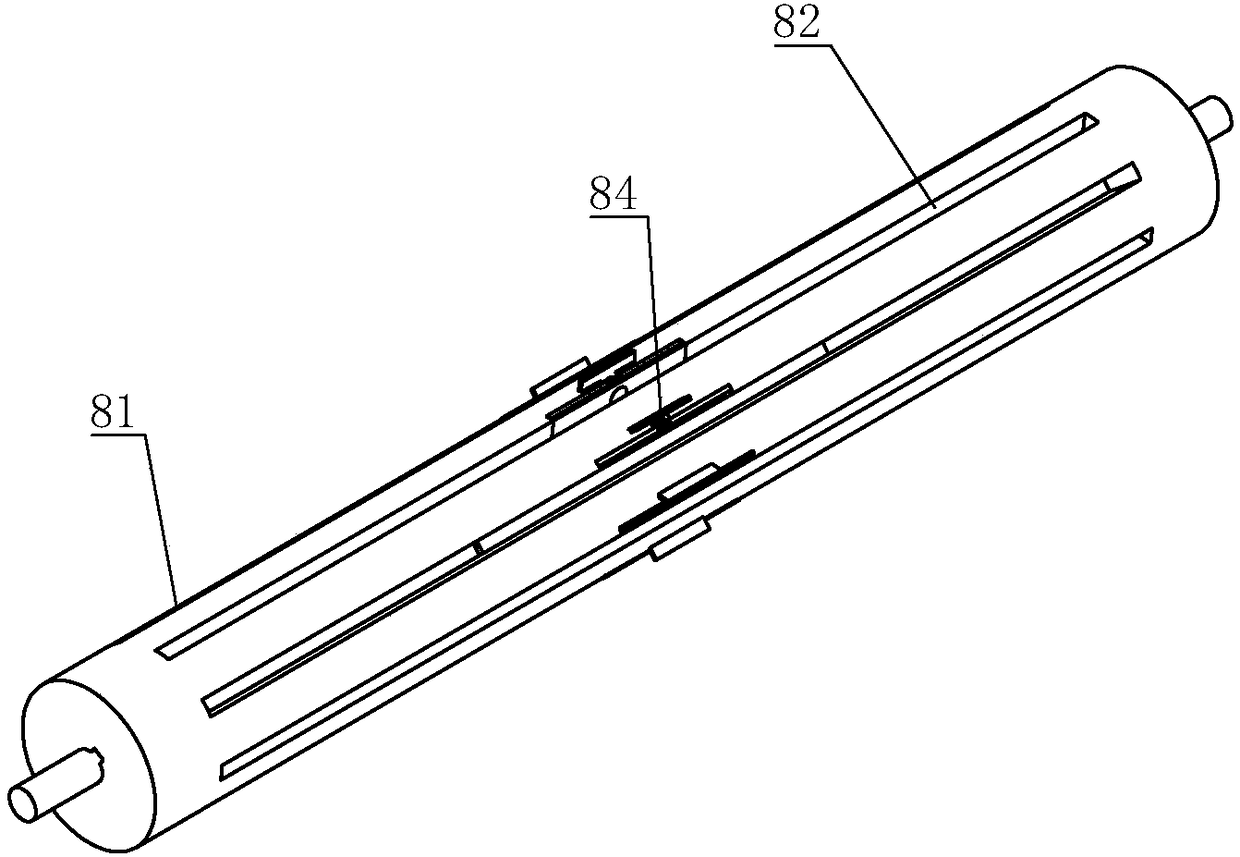

Radiator fin separating, taking and conveying equipment

ActiveCN108423416AImprove work efficiencyReduce labor burdenConveyorsConveyor partsRotating drumHeat spreader

The invention discloses radiator fin separating, taking and conveying equipment. The radiator fin separating, taking and conveying equipment comprises a controller, a bin and a conveying device arranged at the rear end of the bin, wherein a lead screw driven to rotate by a servo motor is vertically arranged in the bin, a lifting supporting plate is connected to the lead screw in a threaded manner,and a fin separating roller and a detection sensor used for detecting radiator fins are arranged at the top end of the bin. A radiator fin scattering clamp is arranged below the conveying device. Theradiator fin scattering clamp comprises a rotating drum, multiple clamping grooves are axially formed in the outer peripheral surface of the rotating drum at intervals, a clamping mechanism is arranged in each clamping groove, the rotating drum is driven to rotate by a third power device, and the detection sensor, a controller of the servo motor, a first power device, a second power device and the third power device are electrically connected with the controller. According to the radiator fin separating, taking and conveying equipment, the stacked radiator fins can be automatically separated,taken and conveyed, and the working efficiency is improved.

Owner:WEIFANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com