Back-cutting rewinding equipment

A roll equipment and back-cutting technology, applied in the field of back-cutting and rewinding equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

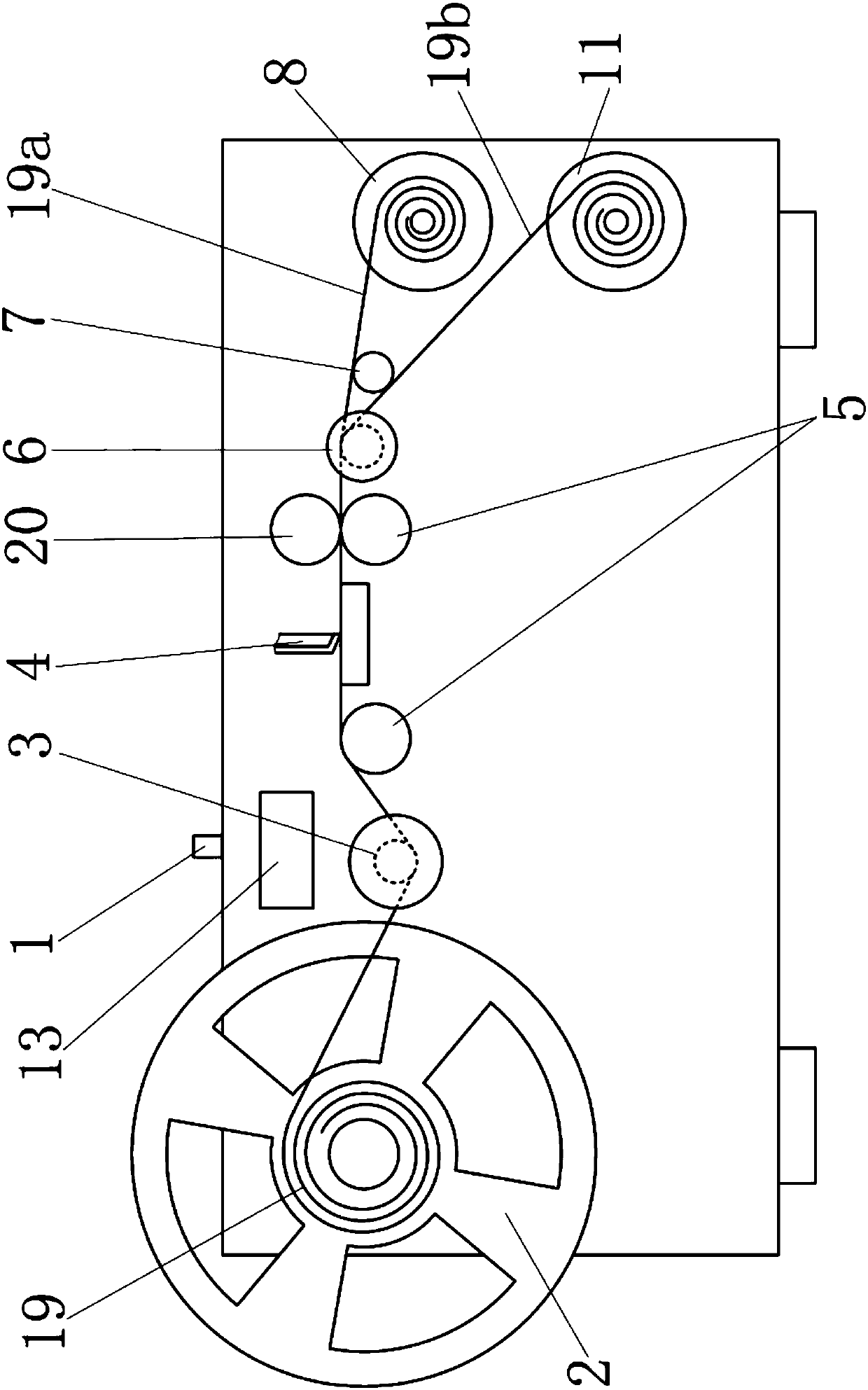

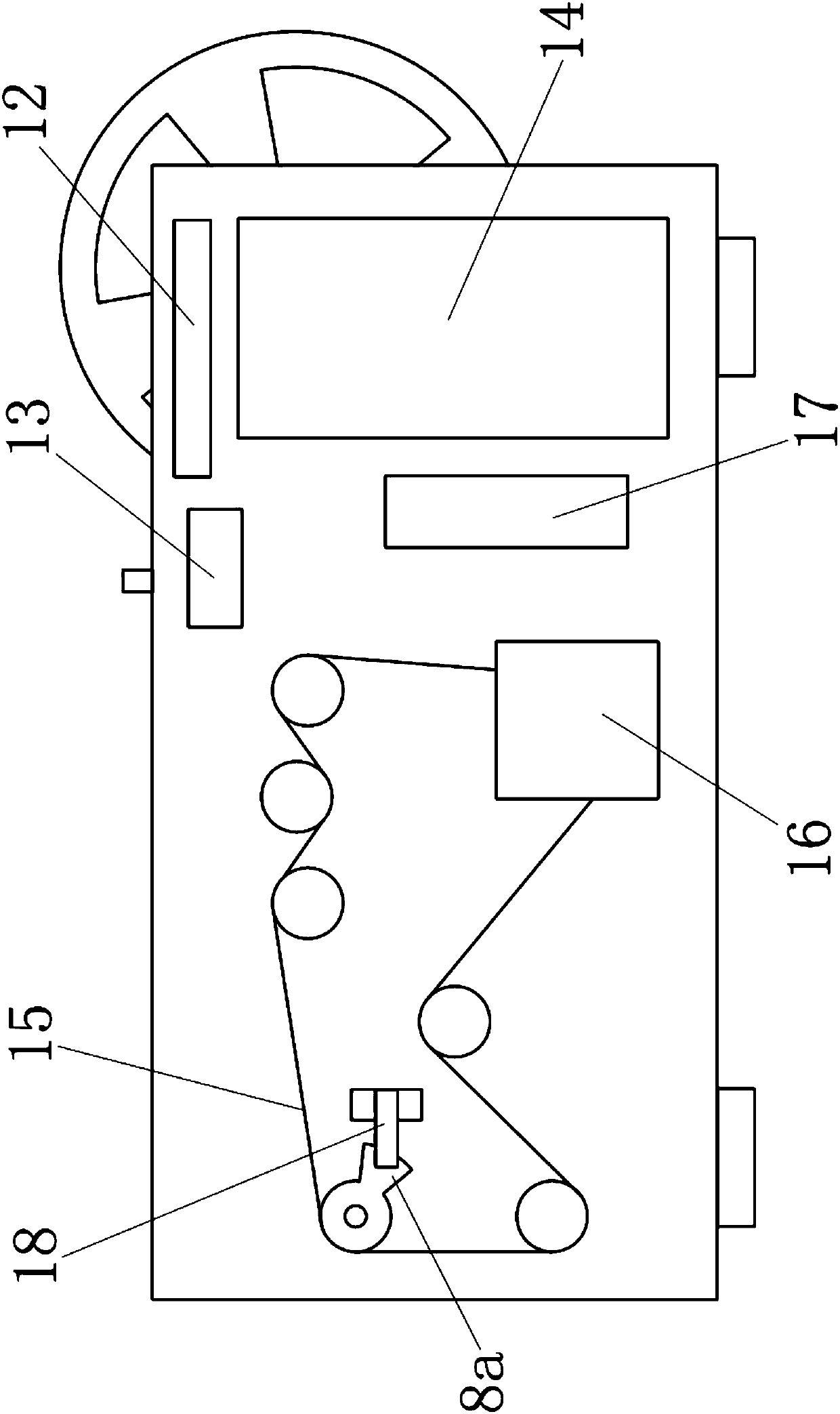

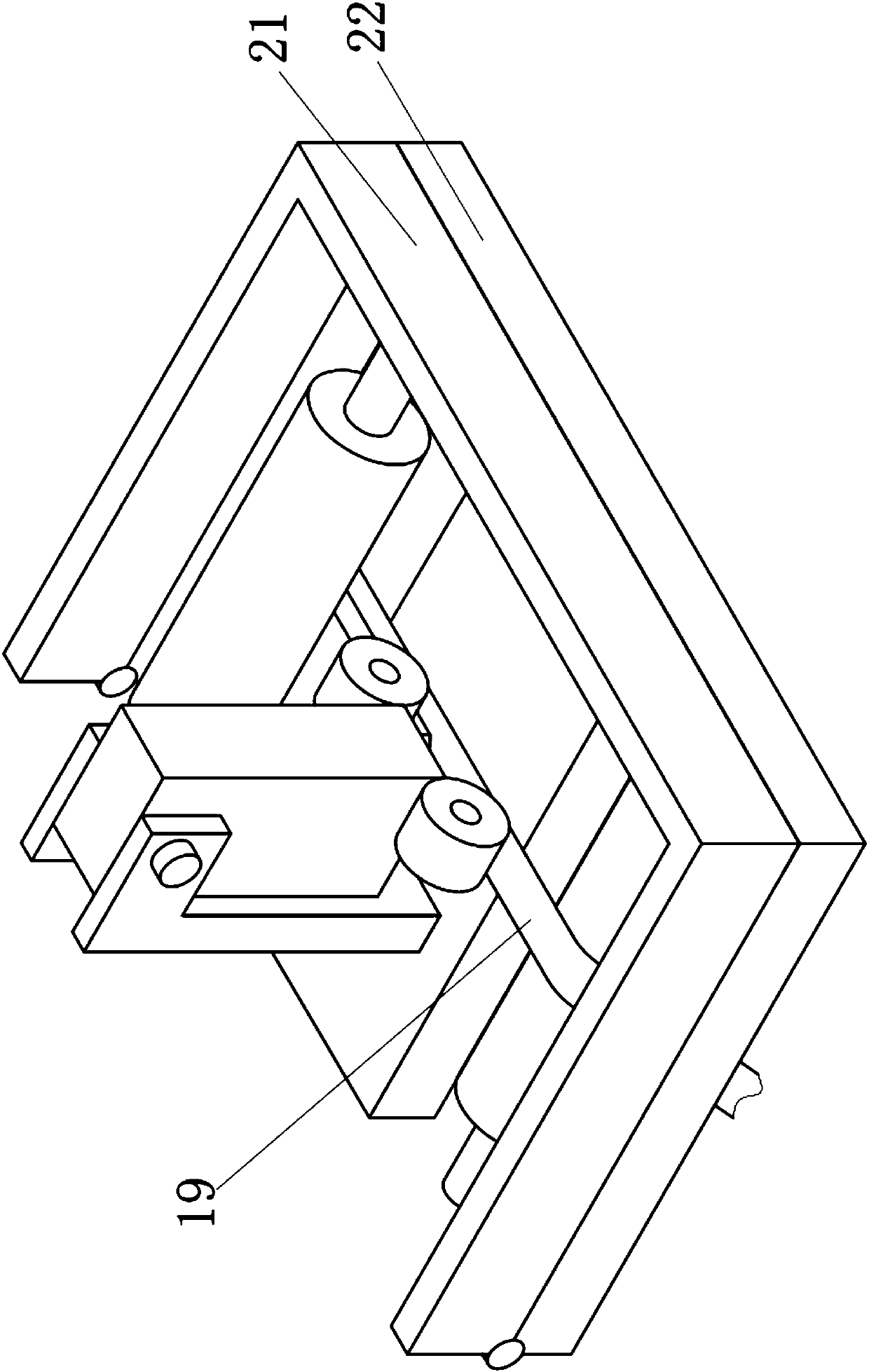

[0035] In order to achieve the purpose of the present invention, a back cutting and rewinding equipment is used for cutting and rewinding raw material paper. The raw material paper is a paper roll in which backing paper, gummed paper, and transparent film are laminated sequentially along the thickness direction. Including: the cutting knife 4 cuts the backing paper along the central symmetrical line of the length direction without touching the adhesive paper; the finished product reel 8 collects the cut backing paper 19a and the adhesive paper; the waste reel 11 collects the backing paper 19a and the adhesive paper The separated transparent film 19b; the finished product winding shaft 8 is made of a shaft core 8d and a baffle plate at an axle end, and the baffle plate is equipped with a ring cone surface 8b that facilitates guiding the backing paper 19a and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com