A greasy repairing device and a greasy repairing method for surface defects of plates

A technology for putting putty and boards, applied in the direction of irregularity removal devices, wood processing appliances, manufacturing tools, etc., can solve the problems that cannot be putty coated and repaired

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

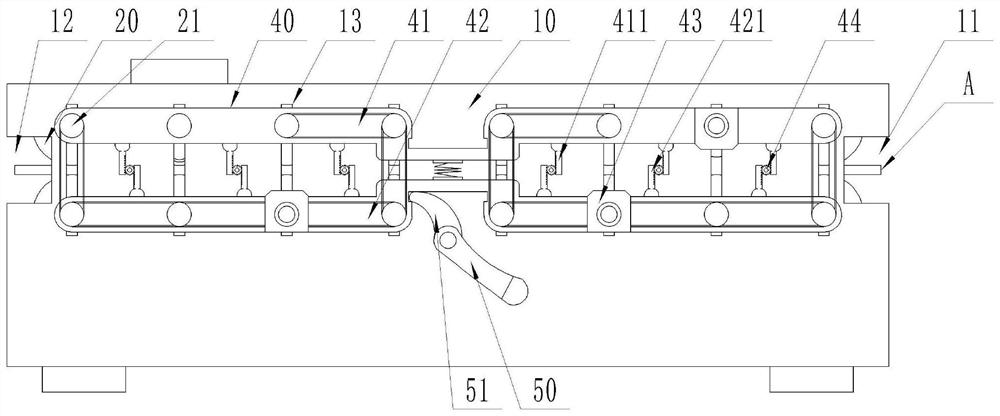

[0073] A greasy repair device for sheet surface defects, wherein, such as figure 1 , 2 Said, including: the casing 10 , the pressing roller 20 , and the greasing mechanism 30 .

[0074] The front and rear ends of the casing 10 respectively have an inlet 11 and an outlet 12 .

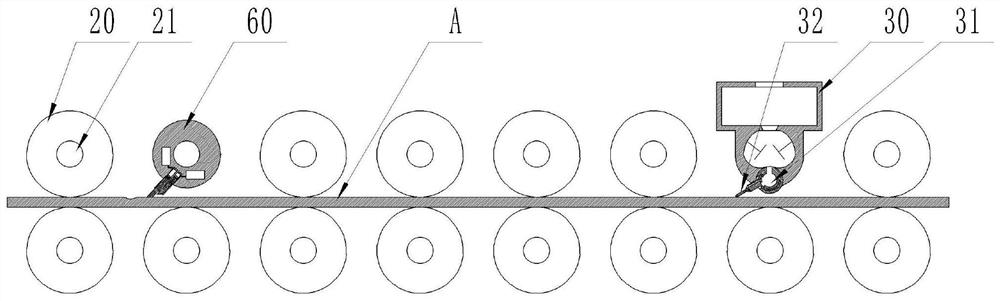

[0075] The pressing rollers 20 are arranged in the casing 10, and a plurality of pressing rollers 20 are distributed on the upper and lower ends of the casing 10. There is a certain gap between the pressing rollers 20, and the size of the gap is adapted to the thickness of the sheet. The pressing rollers 20 have a rotating shaft. 21 , the rotating shaft 21 is movably connected to the housing 10 .

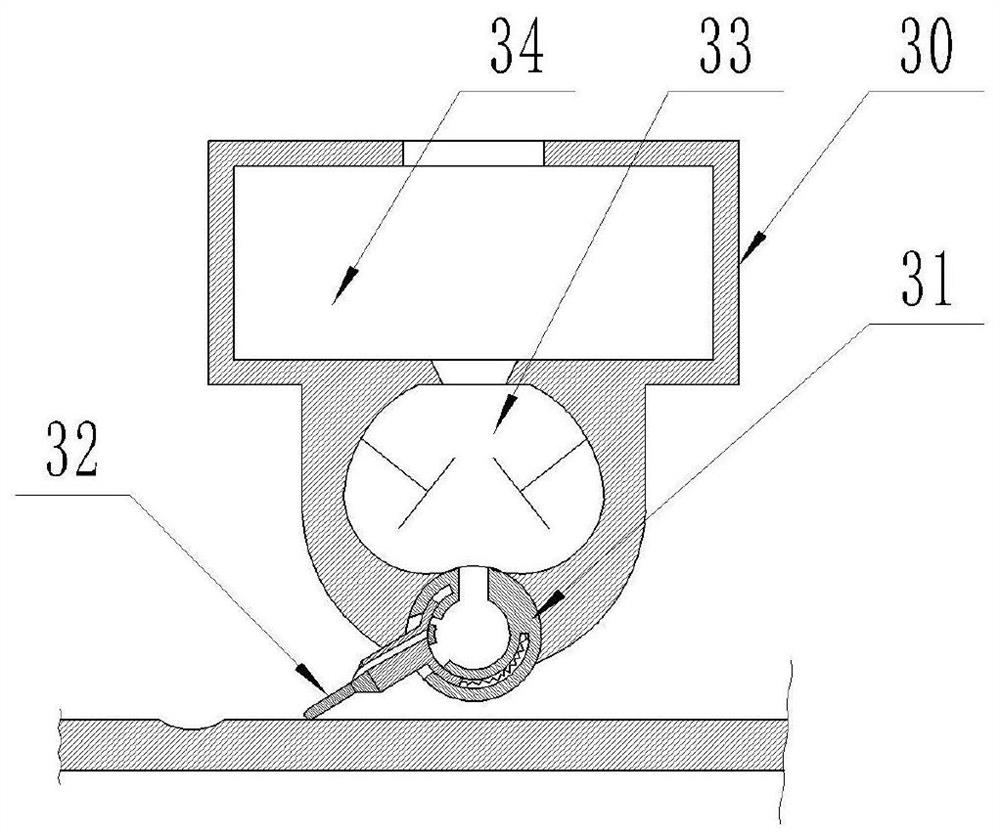

[0076] like Figure 3-6 As shown, the greasing mechanism 30 is arranged in the casing 10, and the greasing mechanism 30 is located at the upper end of the pressing roller 20 at the lower end of the casing 10. The greasing mechanism 30 has a detection component 31, and the detection component 31 has: a greas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com