Apparatus and method for molding spacer fabric or thicken material

A molding device and molding technology are applied in applications, household appliances, household components, etc., and can solve problems such as material thinning and molding processing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

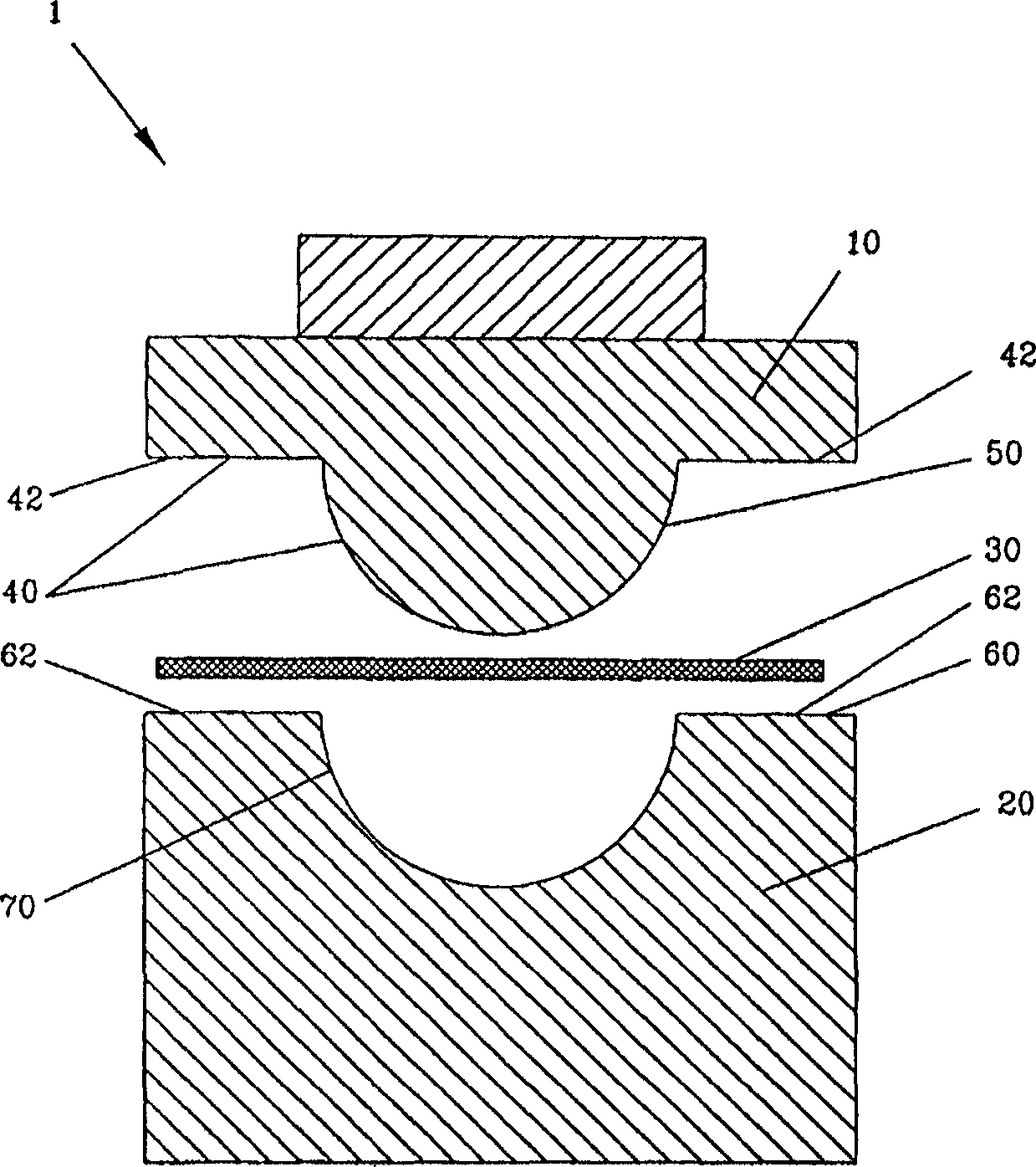

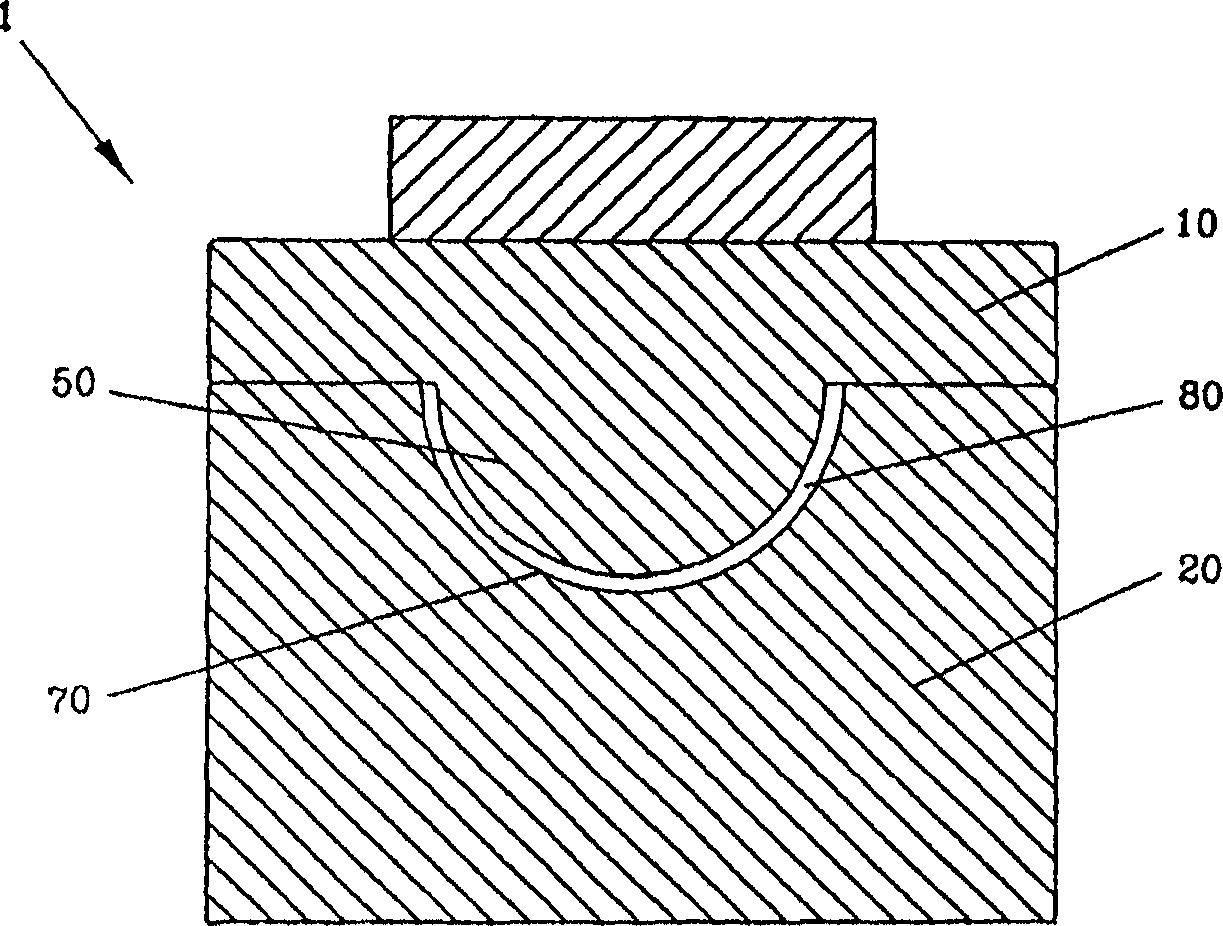

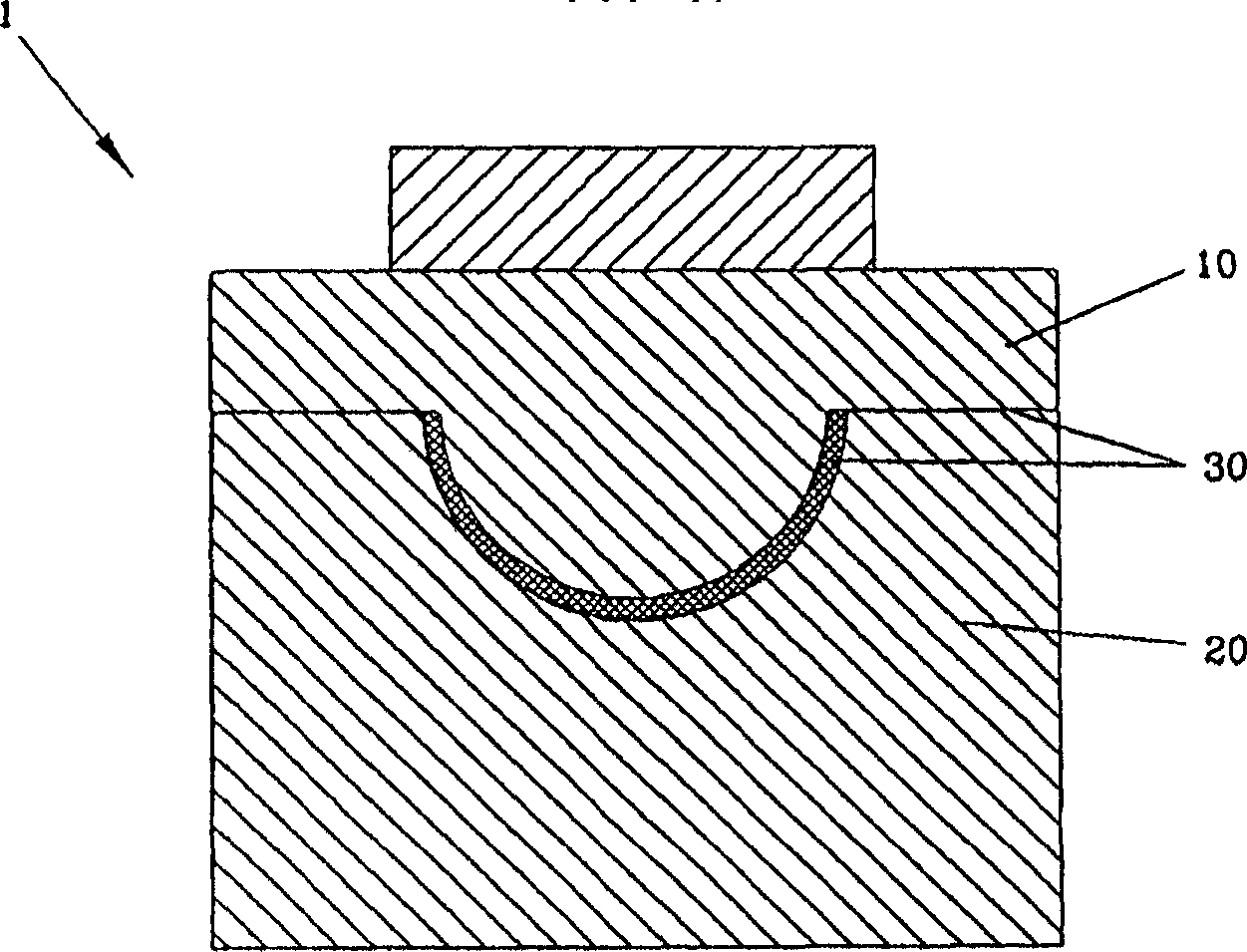

[0019] Referring to the accompanying drawings, especially figure 1 , shows an exemplary embodiment of a device for molding thickened material, which device is generally indicated by reference numeral 1 . The device 1 preferably has at least two mold parts: a first mold 10 and a second mold 20 . Preferably, the two molds are complementary to each other.

[0020] Preferably, the first mold 10 and the second mold 20 cooperate to mold or form the thickened material 30 positioned therebetween into the three-dimensional shape required, such as a molded bra pad. Preferably, the thickening material 30 can be any of a variety of materials or a combination of these materials (ie, batting, foam, etc.), and can be fabricated in a variety of forms, such as apparel or upholstery. three-dimensional shape

[0021] The first mold 10 preferably has at least one first contact surface 40 with at least one dome-shaped raised portion 50 . The first contact surface 40 preferably also has a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com