Axial micro adjusting method for side clearance of meshed cutter head of side crusher

A technology of micro-adjustment and edge breaking machine, which is applied in the mechanical field to achieve good results, convenient installation and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The invention relates to an axial micro-adjustment method for the side clearance of an engaging cutter head of an edge crusher.

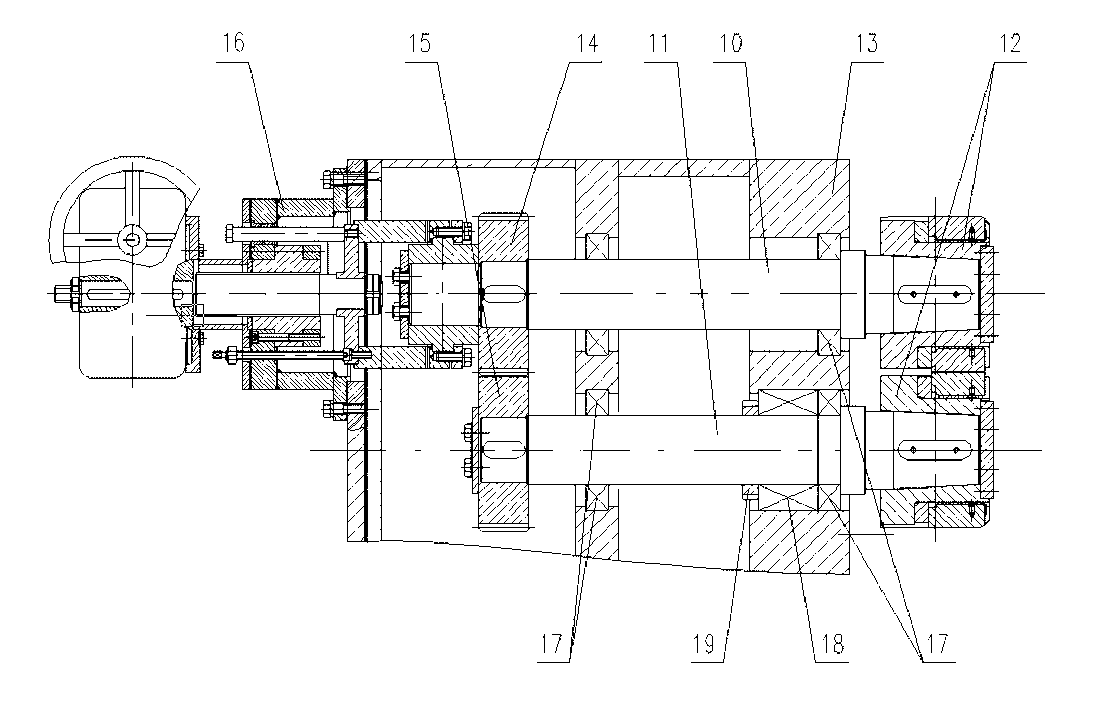

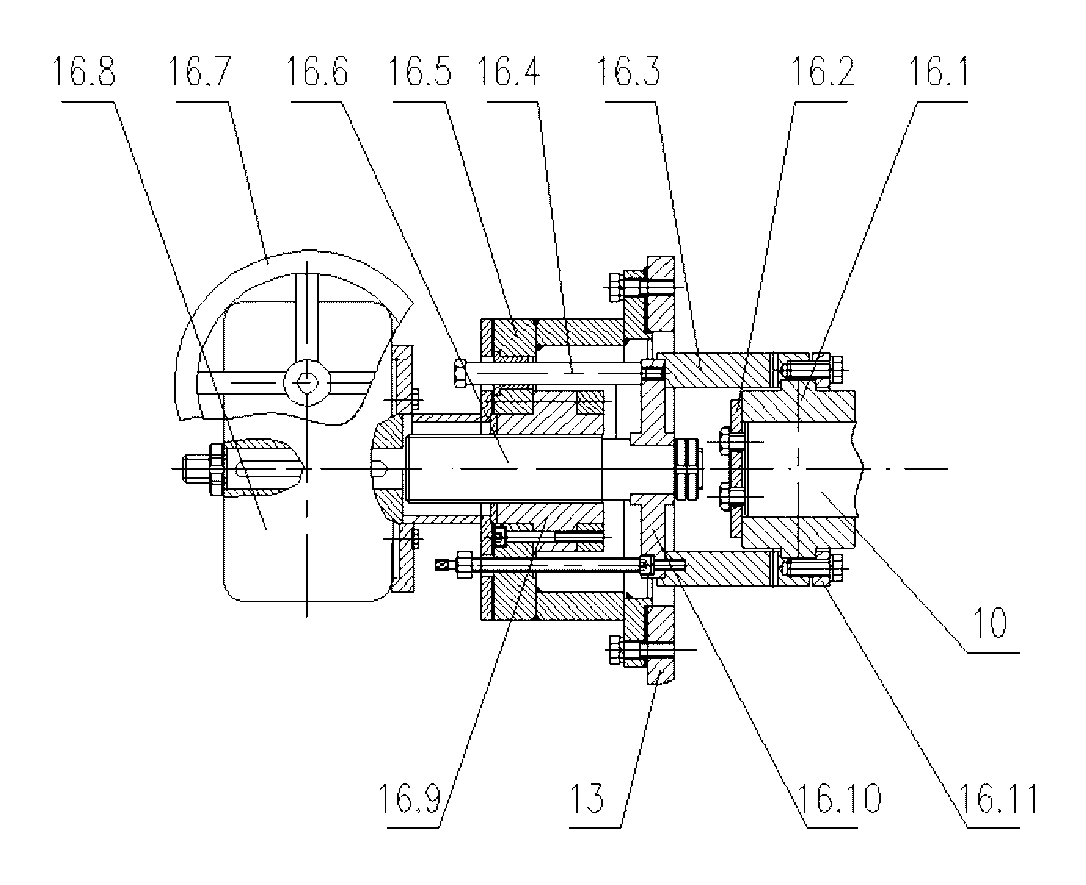

[0033] combine figure 2 First, the edge crusher includes a first transmission shaft 10, a second transmission shaft 11, an engaging cutter head 12, a frame 13, a first synchronous gear 14, a second synchronous gear 15, a support bearing 17, a positioning bearing 18 and a fixed nut 19.

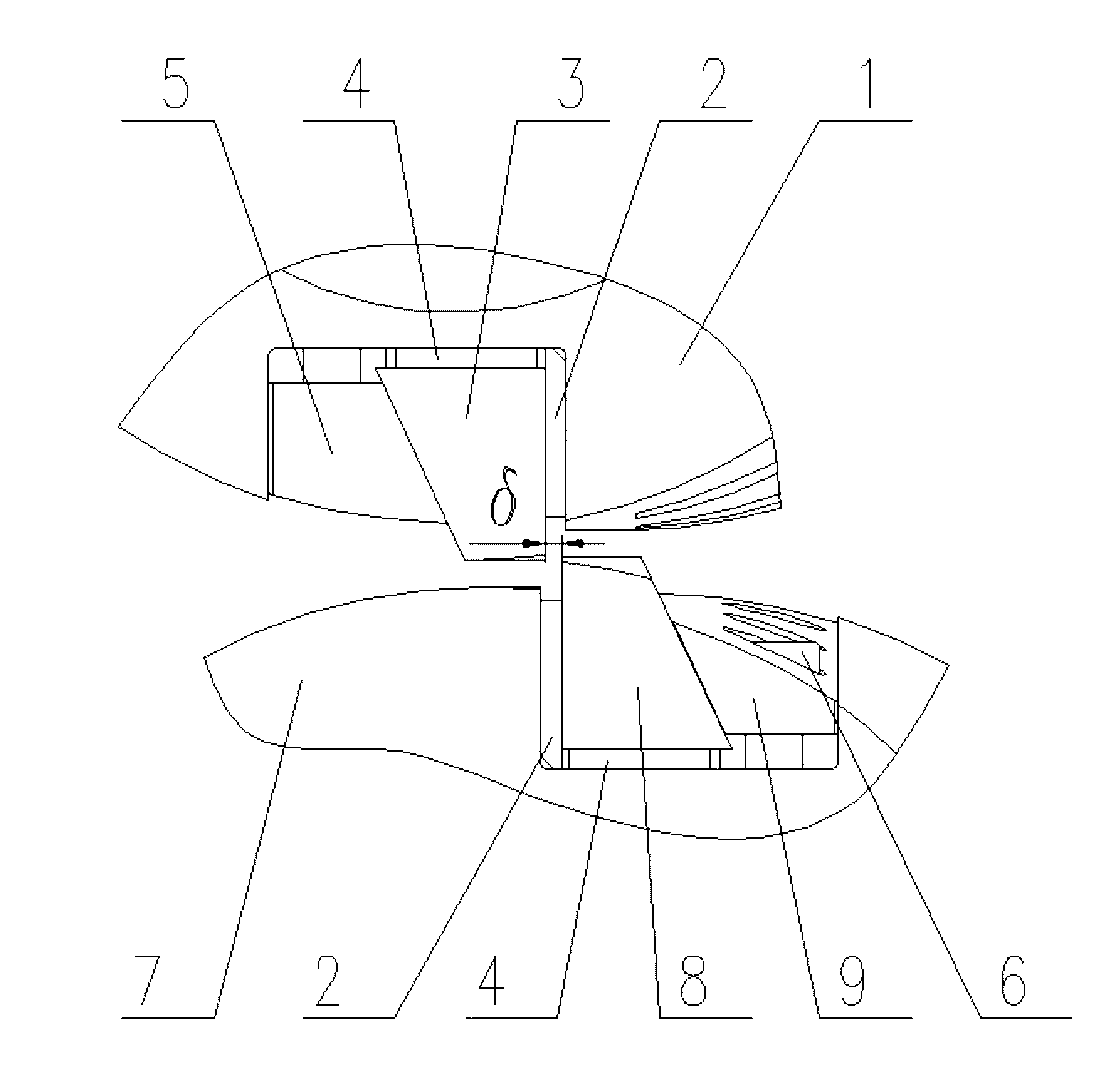

[0034] combine figure 1 , the meshing cutter head 12 includes an upper cutter head 1, a side gasket 2, an upper blade 3, a lower gasket 4, an upper pressure plate 5, a bolt 6, a lower cutter head 7, a lower blade 8 and a lower pressure plate 9. The upper cutterhead 1 and the lower cutterhead 7 in the disc 12 have the same structure, the upper blade 3 and the lower blade 8 in the engaging cutterhead 12 have the same structure and have blades, and the upper pressing plate 5 and the lower pressing plate 9 in the engaging cutterhead 12 The structure is the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com