Method, device and equipment for installing camera shooting assembly

A technology for camera components and installation locations, which is applied in the computer field and can solve problems such as frequent back and forth operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

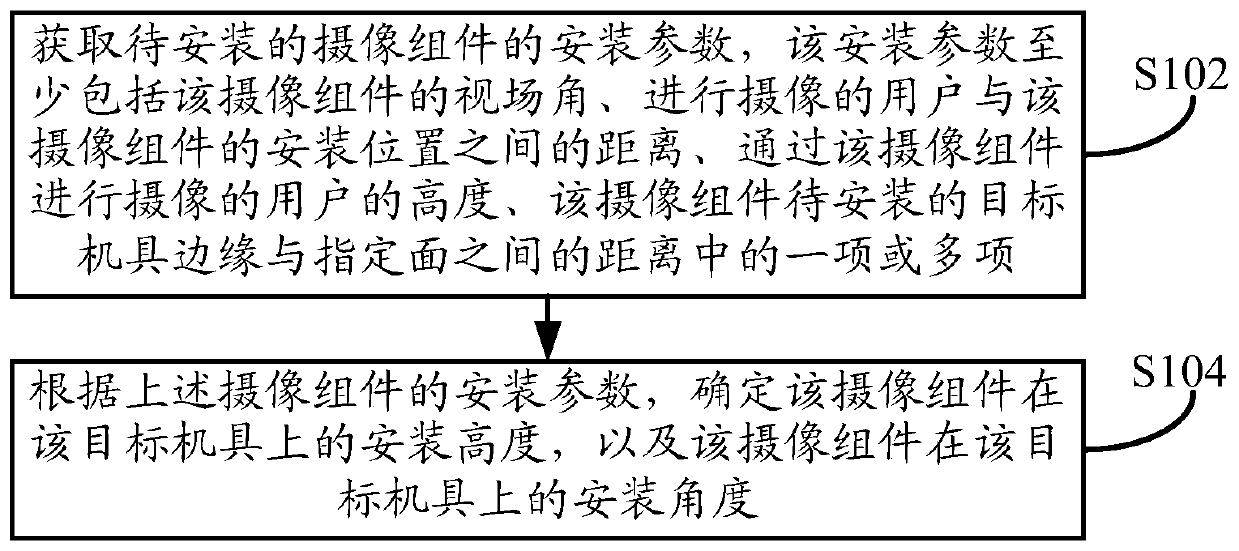

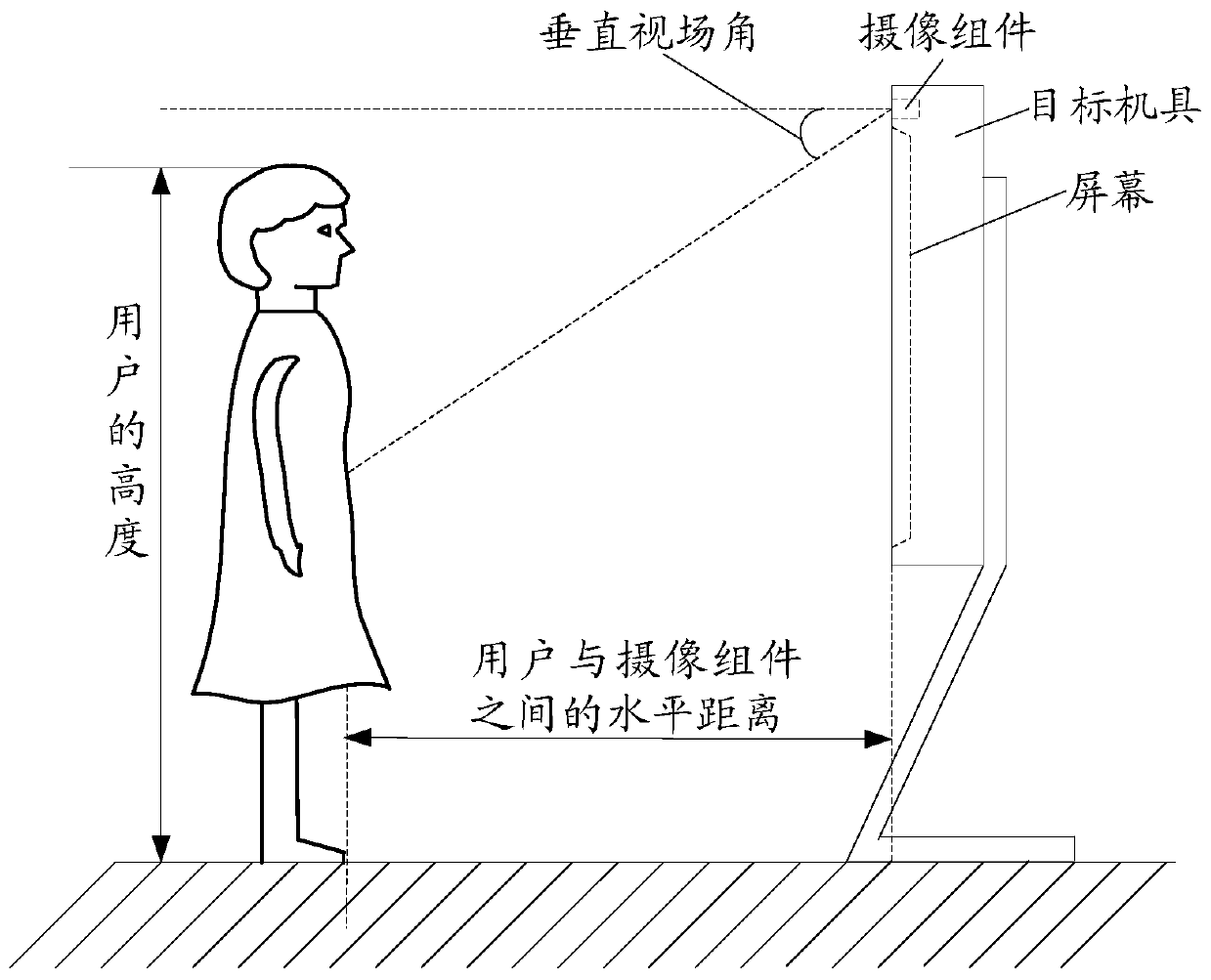

[0074] Such as figure 1 As shown, the embodiment of this specification provides a method for installing a camera component. The execution body of the method may be an electronic device, such as a terminal device or a server, where the terminal device may be a mobile phone or a tablet Mobile terminal equipment such as a computer may also be equipment such as a personal computer. The server may be an independent server, or a server cluster composed of multiple servers. The method specifically may include the following steps:

[0075] In step S102, the installation parameters of the camera assembly to be installed are obtained, the installation parameters include at least the field of view angle of the camera assembly, the distance between the user who takes the image and the installation location of the camera assembly, and the distance between the camera assembly and the installation position of the camera assembly. One or more of the height of the user, the distance between ...

Embodiment 2

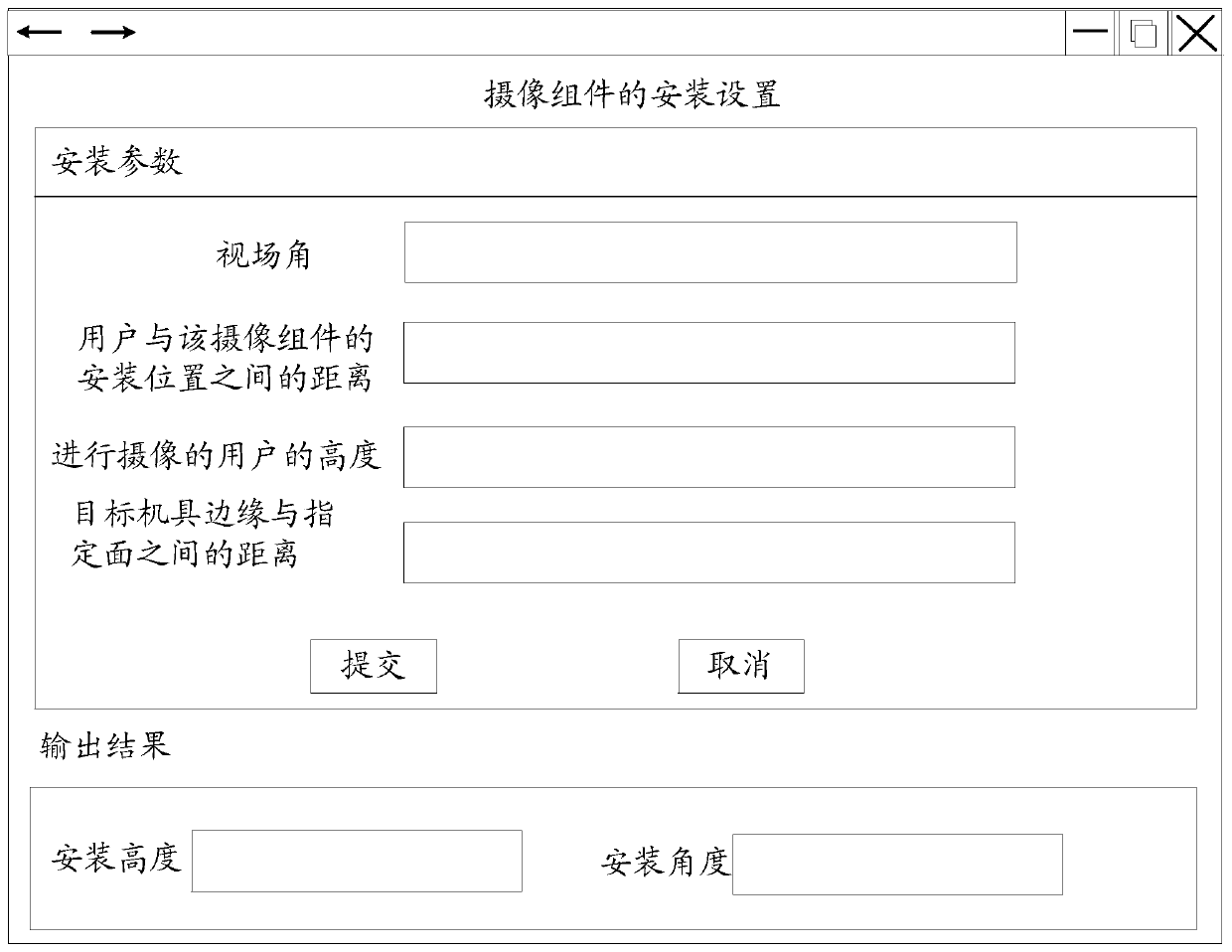

[0090] Such as Figure 4 As shown, the embodiment of this specification provides a method for installing a camera component. The execution body of the method may be an electronic device, such as a terminal device or a server, where the terminal device may be a mobile phone or a tablet Mobile terminal equipment such as a computer may also be equipment such as a personal computer. The server may be an independent server, or a server cluster composed of multiple servers. The method specifically may include the following steps:

[0091] In step S402, the installation parameters of the camera assembly to be installed are obtained, the installation parameters at least include the angle of view of the camera assembly, the distance between the user who takes the image and the installation location of the camera assembly, One or more of the height of the user, the distance between the edge of the target implement to which the camera component is to be installed and the specified surf...

Embodiment 3

[0103] Such as Figure 5 As shown, the embodiment of this specification provides a method for installing a camera component. The execution body of the method may be an electronic device, such as a terminal device or a server, where the terminal device may be a mobile phone or a tablet Mobile terminal equipment such as a computer may also be equipment such as a personal computer. The server may be an independent server, or a server cluster composed of multiple servers. The method specifically may include the following steps:

[0104]In step S502, the installation parameters of the camera assembly to be installed are acquired, the installation parameters include at least the field of view angle of the camera assembly, the distance between the user who takes the image and the installation location of the camera assembly, One or more of the height of the user, the distance between the edge of the target implement to which the camera component is to be installed and the specified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com