Mini-LED backlight component and manufacturing method thereof

A mini-led and backlight technology, applied in the field of Mini-LED backlight and its production, can solve problems such as poor splicing, and achieve the effect of improving the problem of dark lines between light panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

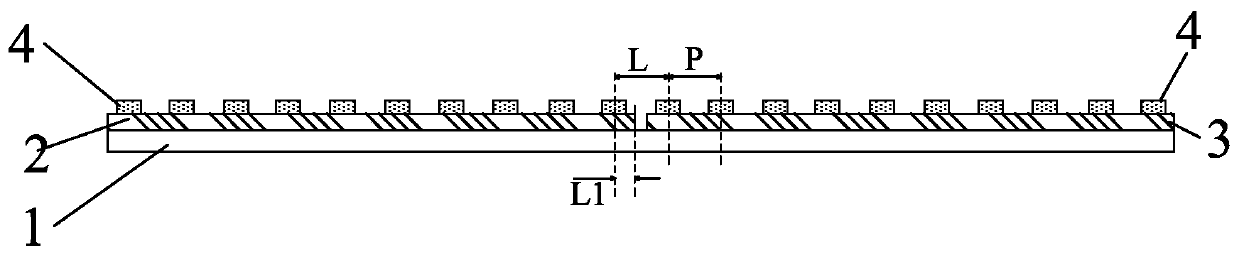

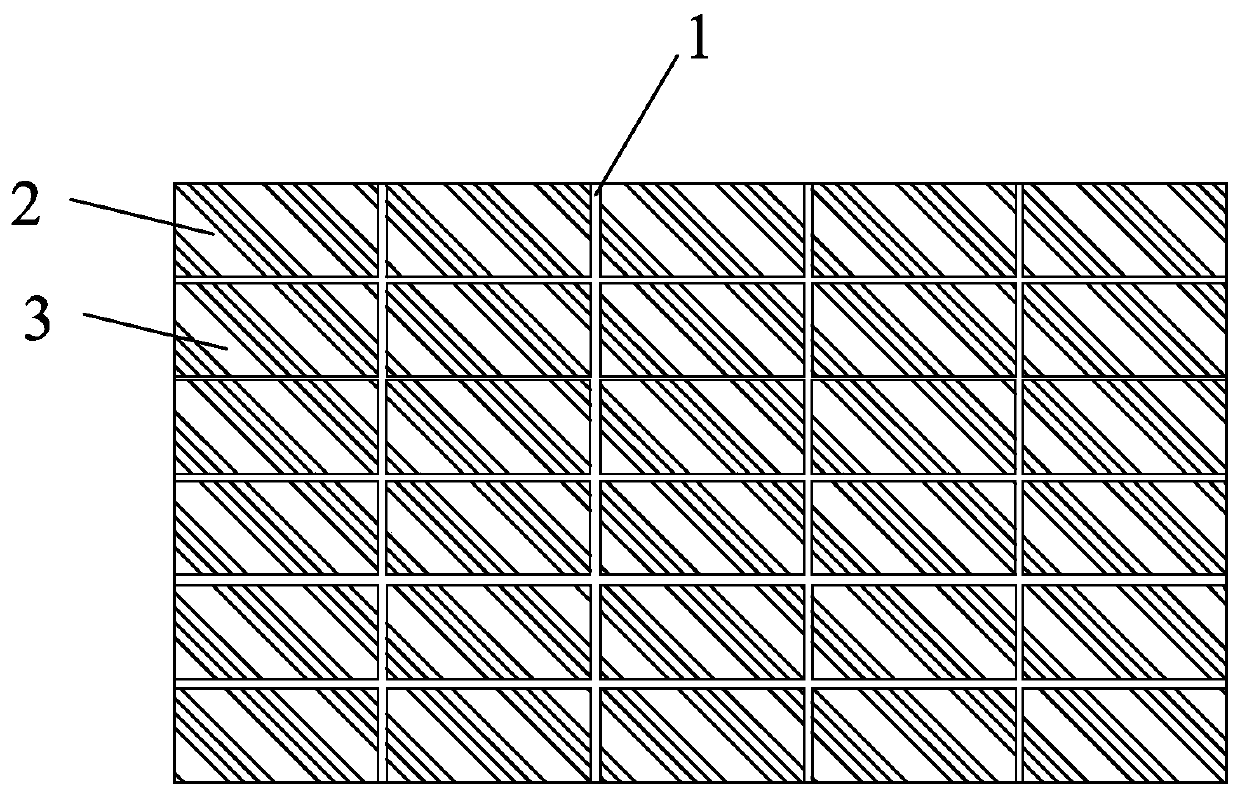

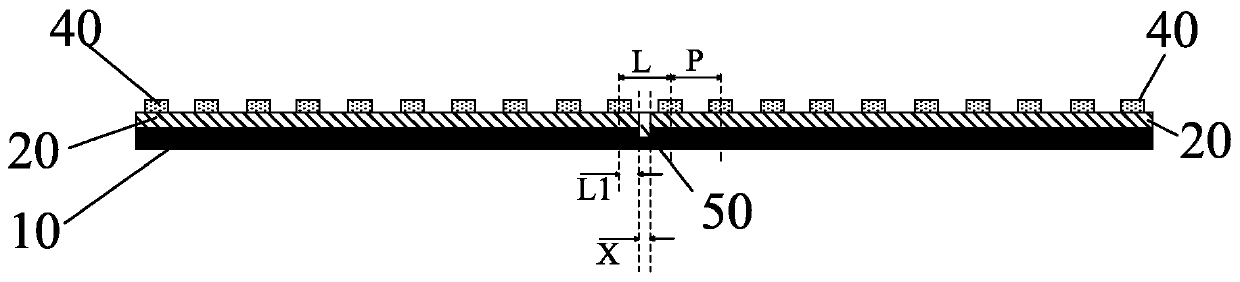

[0032] see figure 2 , which is a side view of a preferred embodiment of the Mini-LED backlight of the present invention, the Mini-LED backlight mainly includes: a backplane 10 and a plurality of rectangular lamp panels 20 provided with Mini-LEDs 40 arranged in an array, so The lamp panels 20 are arranged in an array and spliced on the back panel 10; there are joints between adjacent lamp panels 20, and the back panel 10 is provided with grooves corresponding to the joints, and the joints And the groove is filled with cured white glue 50.

[0033] In the present invention, a groove is designed on the back plate 10, and the non-groove part is used to fix the lamp panel 20; white glue 50 is filled in the groove, and the height of the white glue 50 should be higher than the groove, and the reflectivity of the white glue 50 is More than 90%, which is similar to the reflectivity of the current reflective sheet. White glue can use PA6T, PA9T, PCT, EMC or SMC materials. In this ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com