Power battery cover plate and manufacturing method thereof

A technology of power battery and manufacturing method, which is applied to battery cover/end cover, battery pack components, battery box/jacket, etc., can solve problems such as complex assembly gaps and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical means adopted by the present invention to achieve the intended invention purpose are further described below in conjunction with the drawings and preferred embodiments of the present invention.

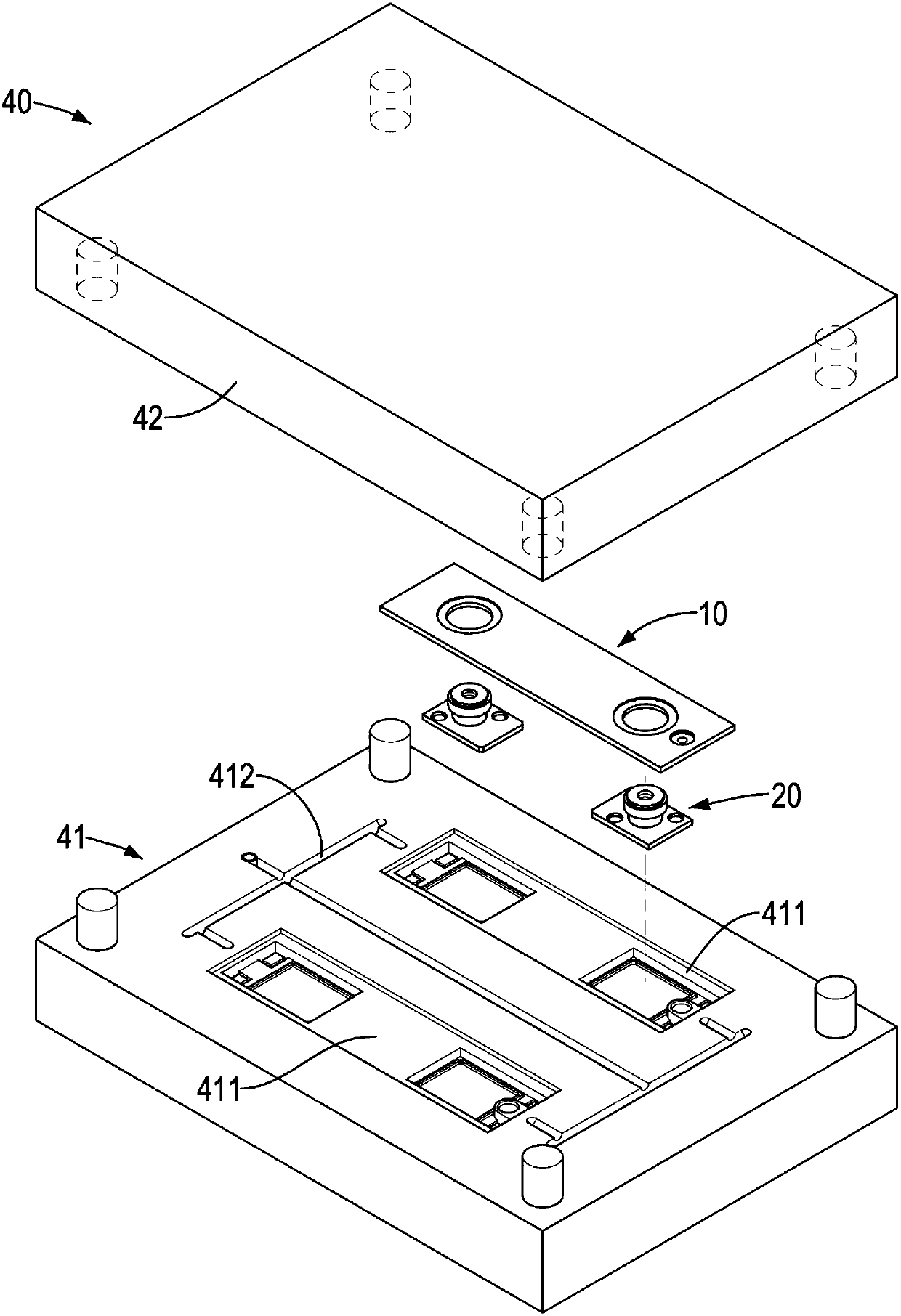

[0033] The present invention provides a method for manufacturing a power battery cover, and the preferred embodiments of the present invention are as follows Figure 1 to Figure 4 shown, including the following steps:

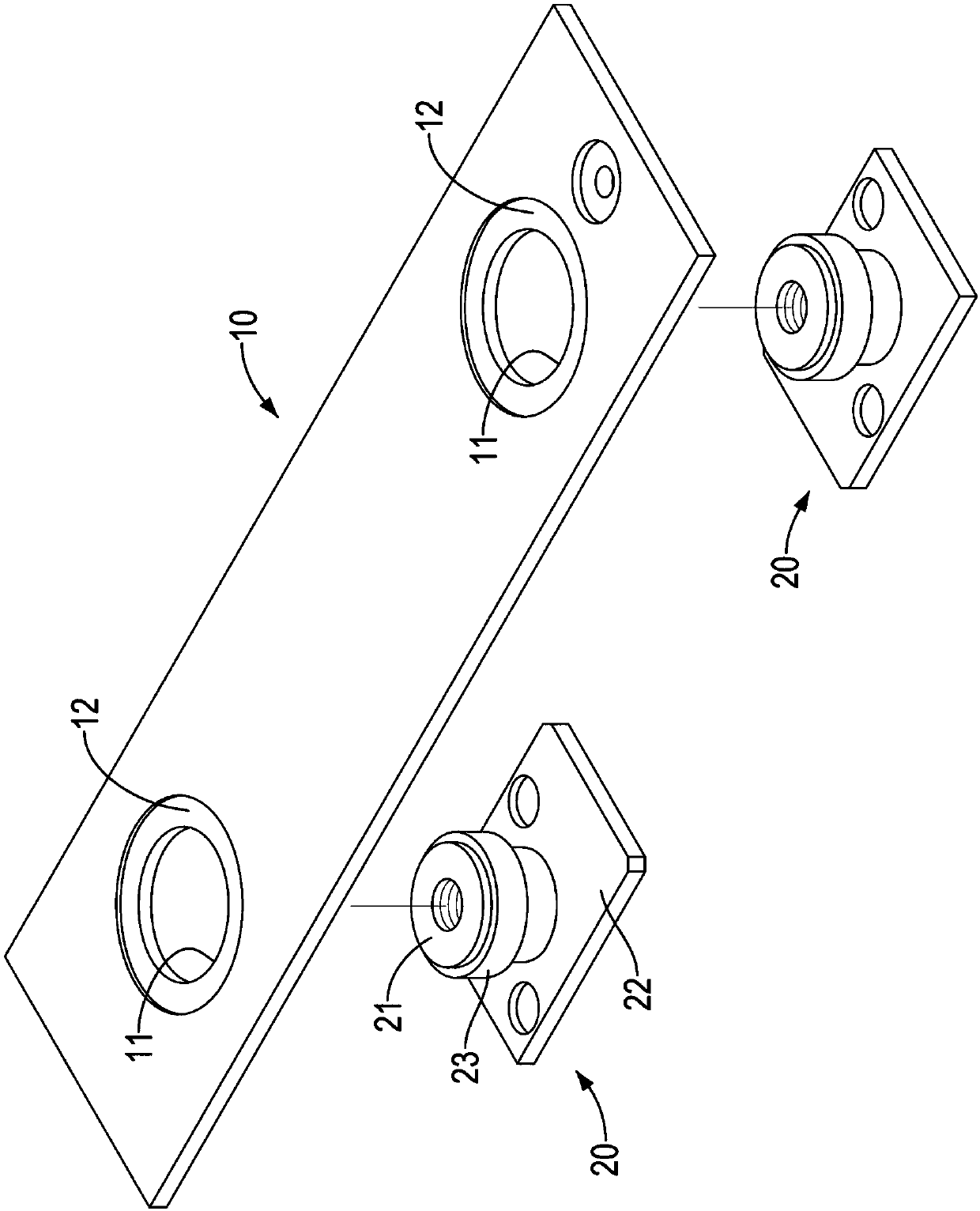

[0034] A. Preparation materials: such as figure 2 As shown, a substrate 10 and two electrode columns 20 are prepared, the substrate 10 has a top surface and a bottom surface, and two through holes 11 and two grooves 12 are arranged at intervals, wherein each groove 12 is recessed on the top of the substrate 10 surface, and respectively surround the outer periphery of the two through holes 11, and each groove 12 has the same center of circle as the corresponding through hole 11; the two electrode columns 20 are respectively a positive electrode co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com