Non-rotational part axis crack detection device and method based on ray detection

A non-rotating body and crack detection technology, which is applied in the direction of material analysis using radiation, can solve the problems of non-rotating body shaft flaw detection, operator injury, complexity, etc., achieve continuous real-time crack detection and radiation protection, and solve real-time continuous detection The problem and the effect of the problem of radiation protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

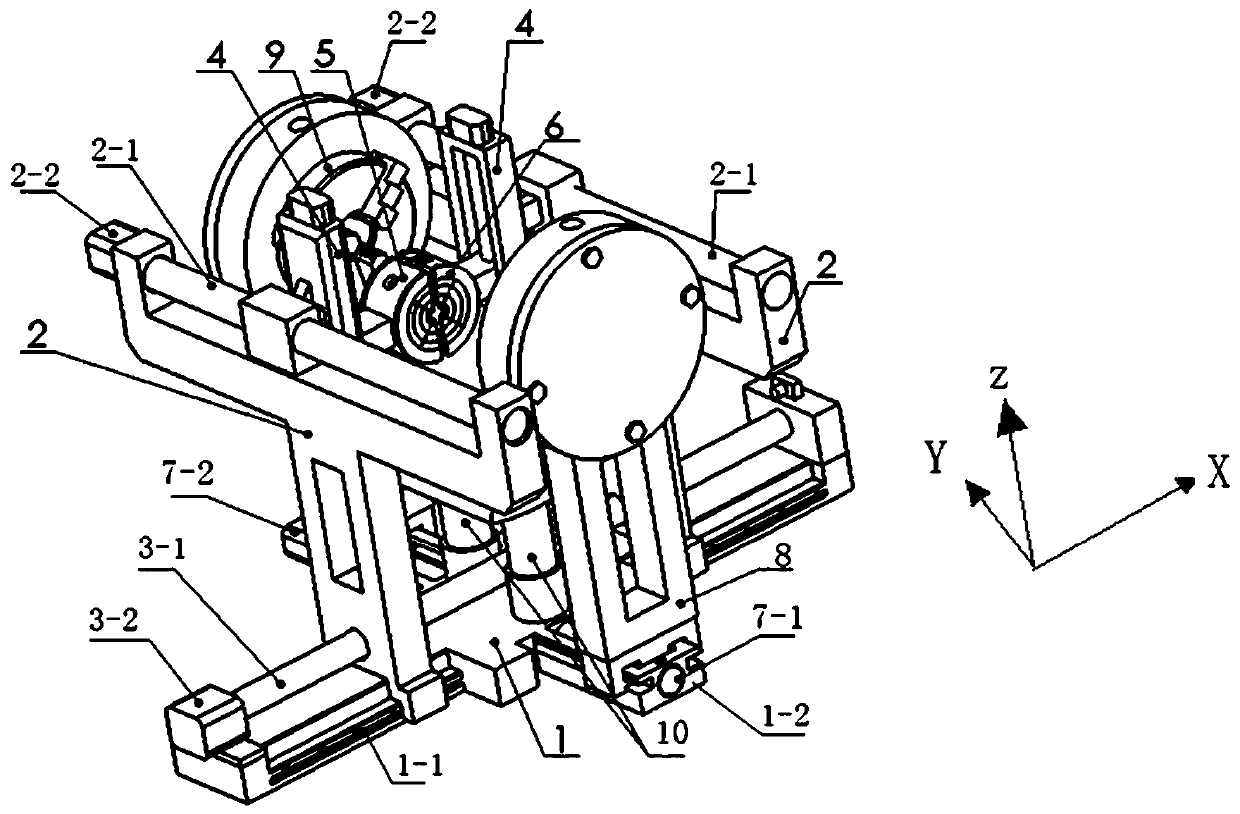

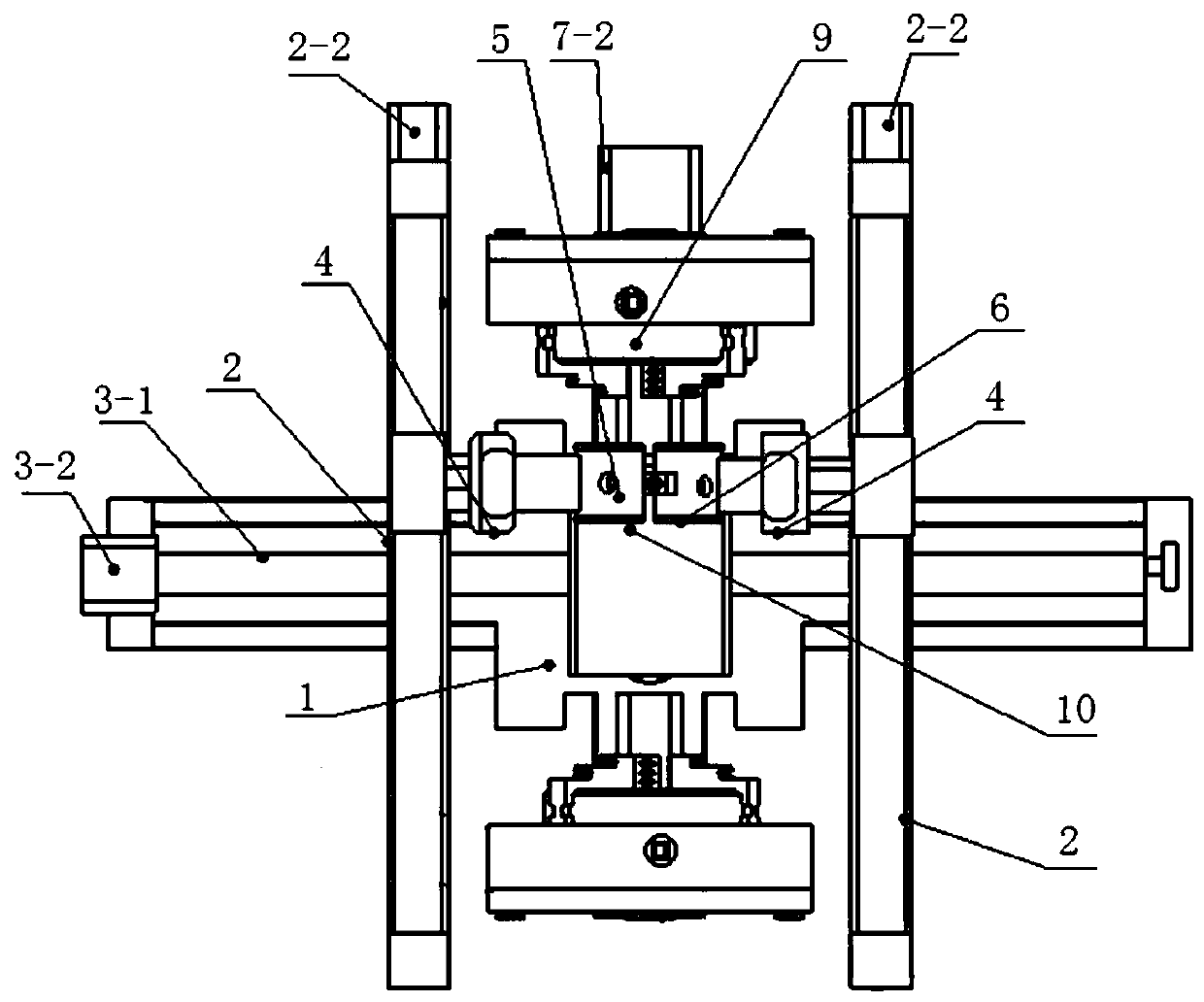

[0050]The technical solution of a non-rotating body shaft crack detection device based on radiation detection according to the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

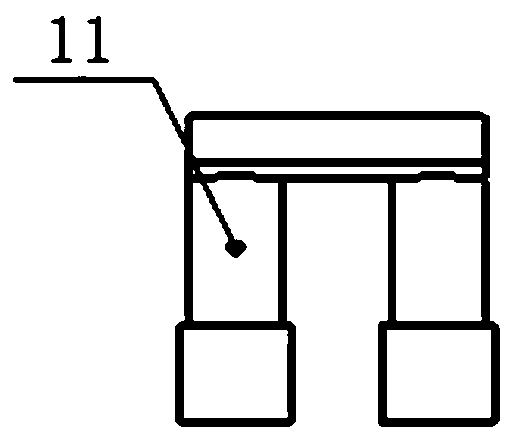

[0051] A non-rotating body shaft crack detection device based on ray detection in the present invention includes: a bidirectional ball screw 2, a driving motor 3, a first support frame group 4, a second support frame group 5, a lifting mechanism 10, a one-way ball screw Rod 7, ball screw slide table 8, three-jaw chuck 9, annular ray mounting frame 10, shutter 11 and limit switch 12;

[0052] The bottom of the first support frame group 4 is placed in the groove of the cross-shaped slide rail base 1 and is connected with the cross-shaped slide rail base 1 by sliding fit. The rod 2 is connected to the first motor 3 through the base of the cross-shaped slide rail, and the upper part of the first support frame group 4 is fixedly ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap