Double side plate type beam-end anti-torque joint with unilateral bolt connection

A single-side bolt and double-side plate technology, which is applied to buildings and building structures, etc., can solve the problems of complex stress state in the node area, difficulty in approaching the two ends of the channel stiffeners, and affecting the bearing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further described below in conjunction with accompanying drawing:

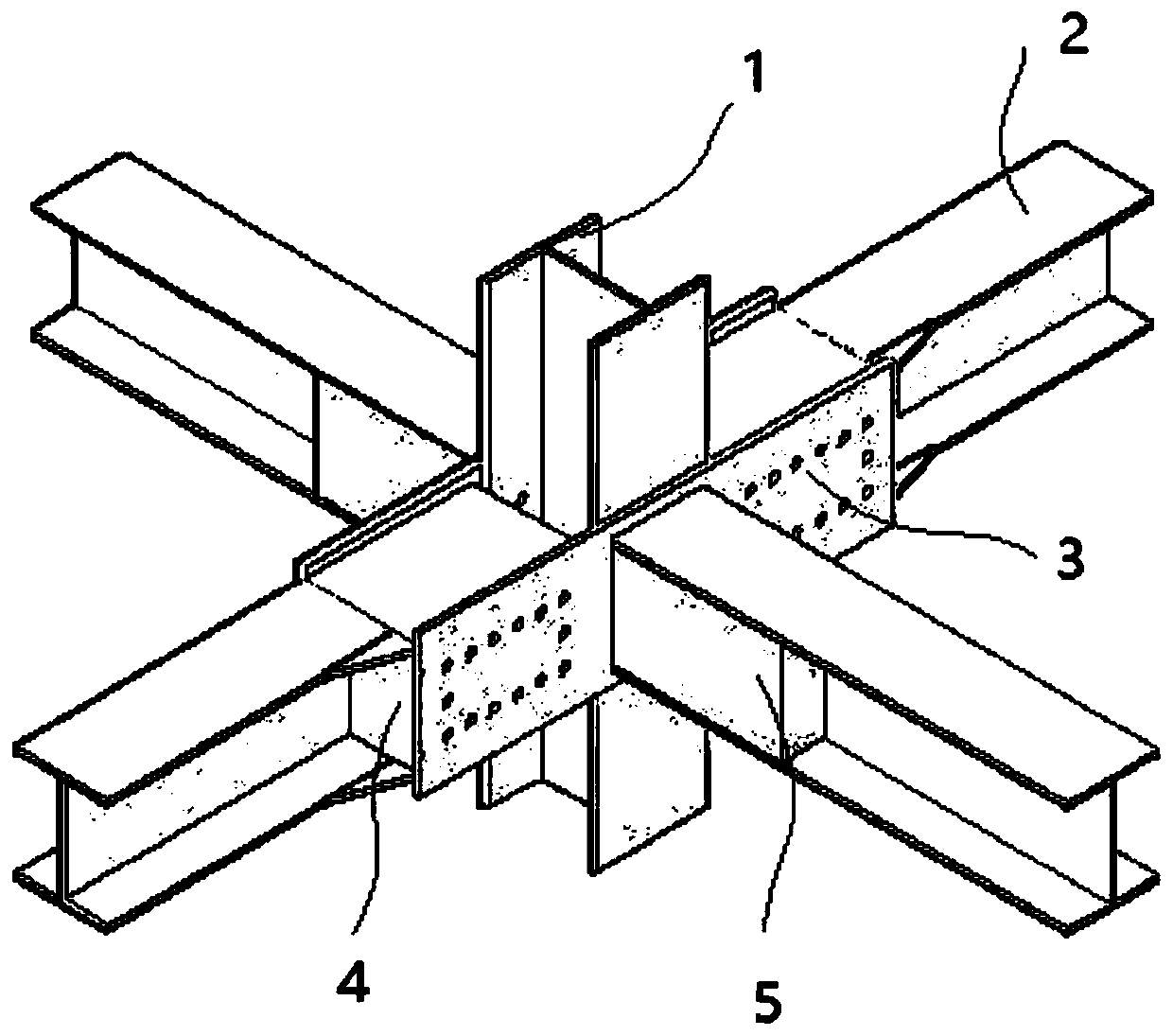

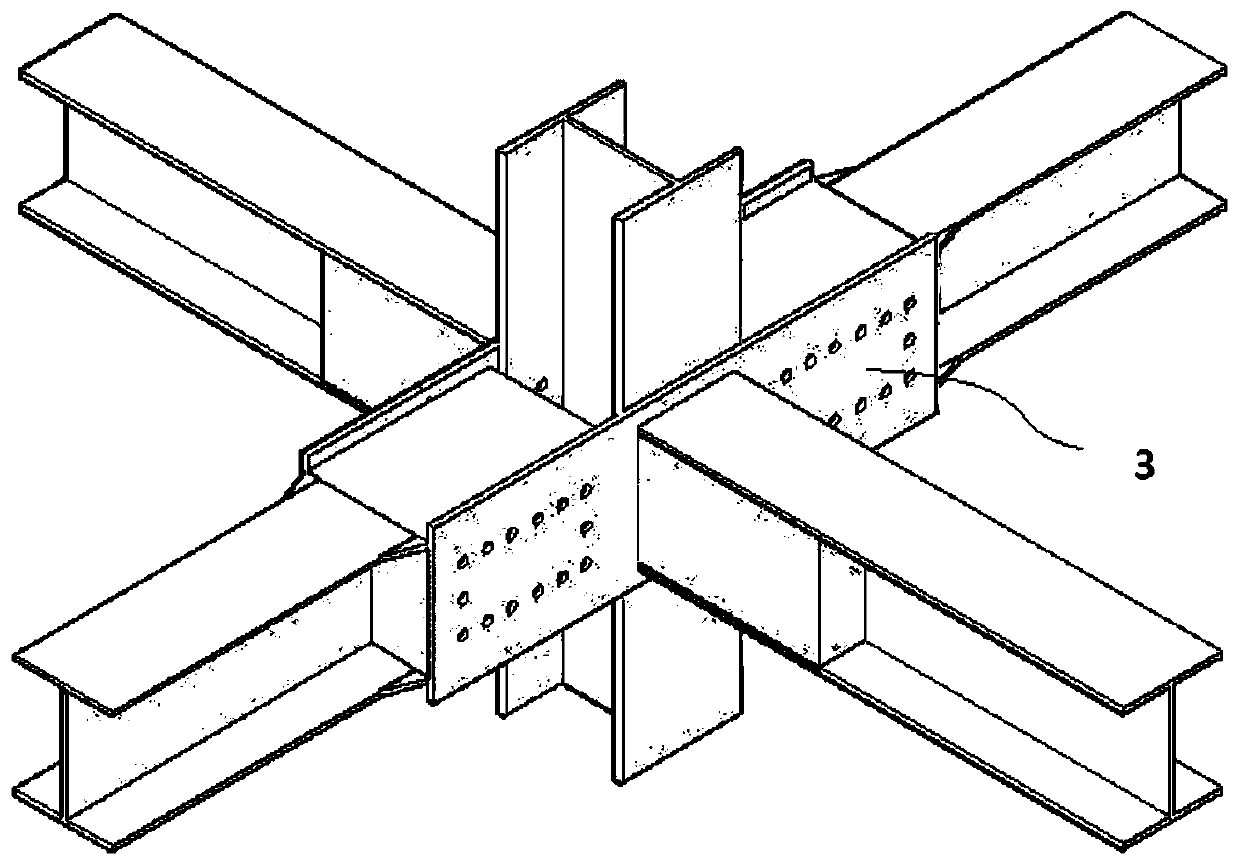

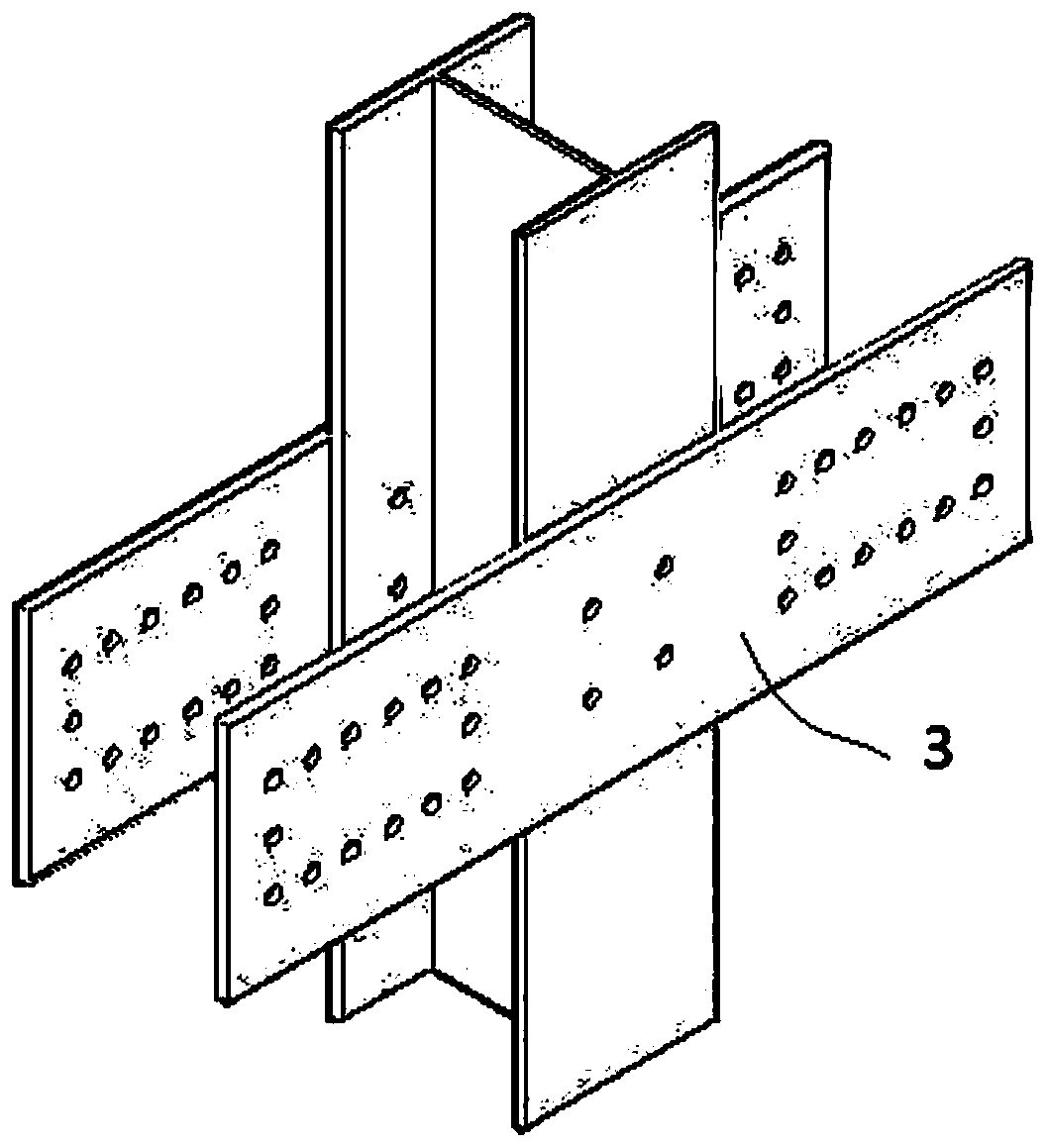

[0028] see Figure 1 to Figure 10 , the beam-end torsional joints connected by double-sided plate type single-sided bolts, including H-shaped steel column 1, side plate 3 and H-shaped steel beam 2; the two side plates 3 are respectively fixed on the flanges on both sides of H-shaped steel column 1, and The two side plates 3 are parallel to each other, and the axis of the side plate 3 is perpendicular to the axis of the H-shaped steel column 1; the positions of the H-shaped steel column 1 on the outer surfaces of the two side plates 3 are vertically fixed with H-shaped steel beams; H-shaped steel beams perpendicular to the web of the H-shaped steel column 1 are fixedly arranged on both sides of the web of the H-shaped steel column 1 between the plates 3 .

[0029] The flange of the H-shaped steel beam 2 located between the two side plates 3 is wider than the outer flange between...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap