Three-dimensional Radius Compensation Method of Probe Measuring Ball for Contact Scanning Measurement of Blade Section

A radius compensation, contact technology, applied in measuring devices, instruments, etc., can solve problems such as cosine error, and achieve the effect of improving the accuracy of radius compensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with specific drawings and embodiments.

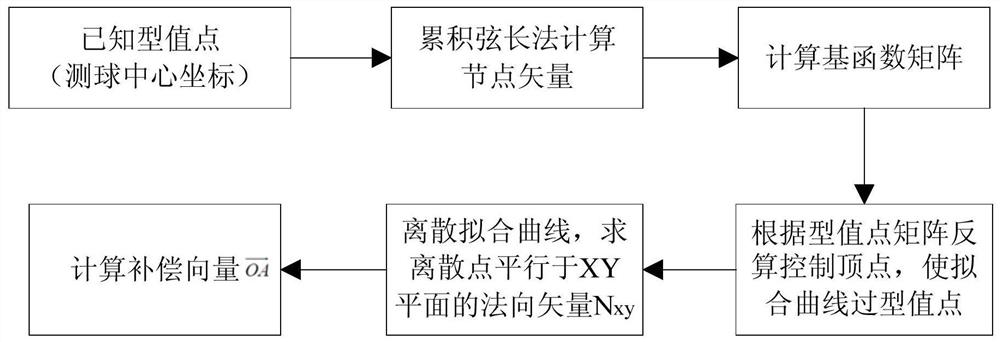

[0039] The present invention proposes a method for compensating the three-dimensional radius of a probe measuring ball for contact scanning measurement of a blade cross section, comprising the following steps:

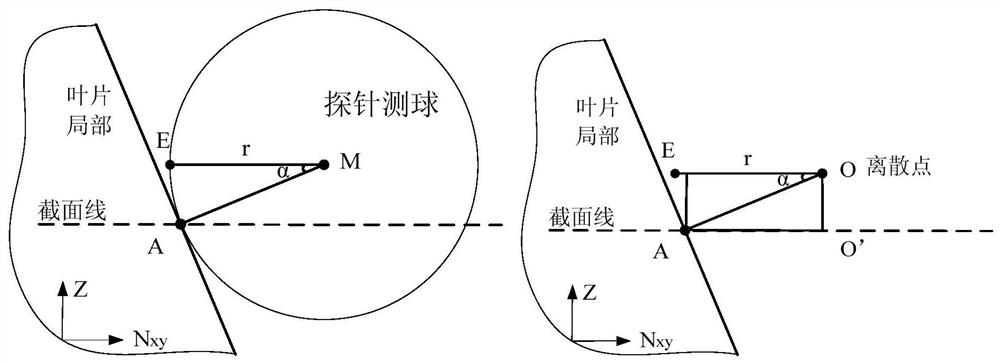

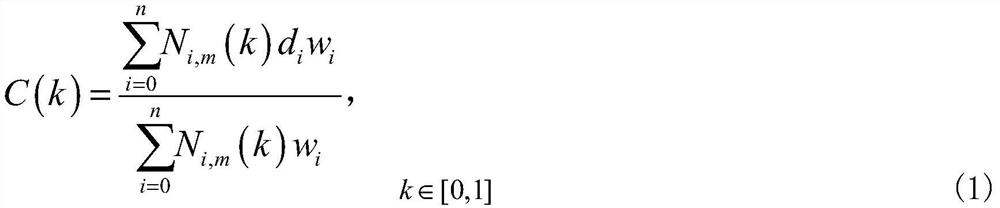

[0040] Step S101, using the coordinate system XYZ based on the coordinate system of the blade to be measured, and using the center point M of each measuring ball measured in three coordinates as the type of NURBS (Non-Uniform Rational B-Splines) curve Value point P, use the cumulative chord length method to calculate the node vector K of the NURBS curve, and calculate the basis function matrix N of the NURBS curve i,m ; According to the type value point matrix, the control vertex matrix D is back-calculated, so that the fitted NURBS curve passes through the type value points;

[0041] specifically,

[0042] Take the coordinate system of the blade to b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com